Why Heat Exchanger Coils Are Critical for Every Refrigeration System

Heat exchanger coils are the heart of any cooling system, transferring thermal energy between different fluids to create the temperatures your facility needs.

Key Functions:

- Transfer heat between refrigerant and air or water

- Enable phase changes from liquid to gas and back

- Control temperatures in evaporators and condensers

- Maximize efficiency through increased surface area

Common Types:

- Finned-tube coils (most popular for HVAC)

- Microchannel coils (compact, 40% less refrigerant)

- Plate-fin coils (lightweight, easy to clean)

- Shell-and-tube coils (high pressure applications)

Whether you're running a funeral home's mortuary cooler or a hospital's HVAC system, these coils determine how well your equipment performs. Poor coil selection leads to higher energy bills, frequent breakdowns, and temperature control problems.

As American Mortuary Coolers with years of experience supplying reliable refrigeration systems nationwide, I've seen how the right heat exchanger coils make the difference between equipment that lasts decades and systems that fail when you need them most.

Quick heat exchanger coils definitions:

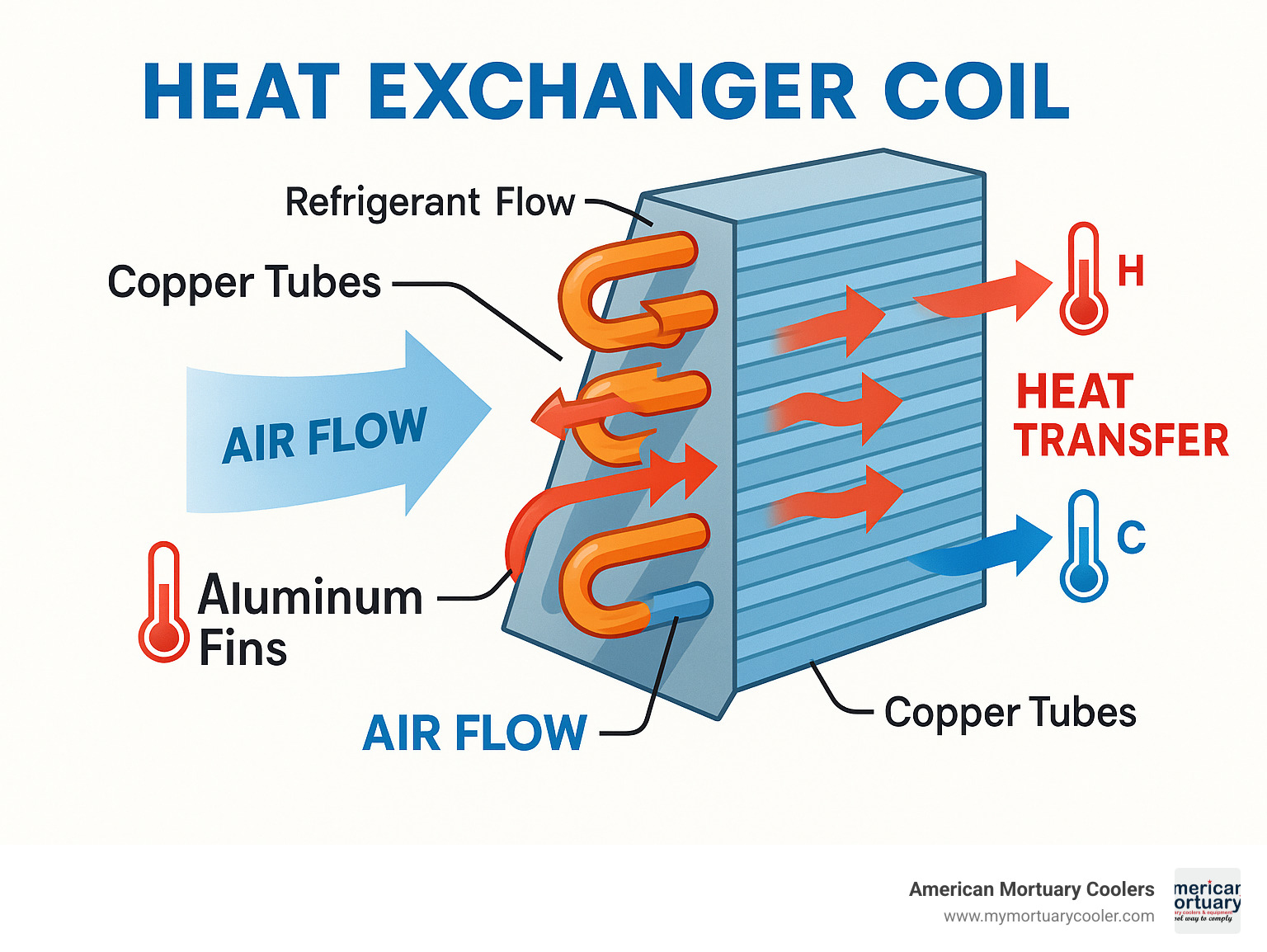

Heat Exchanger Coils 101: How They Work

Heat exchanger coils work by using thermal conduction and convection to move heat efficiently. Thermal conduction passes heat through solid materials - from hot refrigerant inside copper tubes, through the metal, and into aluminum fins. Convection occurs when air flowing over those fins picks up the heat and carries it away.

Counter-flow designs are most efficient because refrigerant and air move in opposite directions, maintaining maximum temperature difference. Cross-flow arrangements are more common since they're easier to build and service.

The real magic happens during phase change - when liquid refrigerant evaporates, it absorbs enormous amounts of heat energy. When that gas condenses back to liquid, it releases all that energy.

Anatomy of a Coil

Tubes carry refrigerant and are typically copper between 3/8" and 5/8" diameter for excellent heat conduction and corrosion resistance.

Fins multiply surface area by 10-20 times compared to bare tubes while creating beneficial turbulence in airflow.

Headers and manifolds ensure even refrigerant distribution. Poor design creates hot spots and kills efficiency.

Casing protects components and guides airflow. Our mortuary coolers use heavy-duty casings that handle frequent cleaning and disinfection.

Heat Transfer Fundamentals

Surface area rules everything - more surface area equals more heat transfer. Scientific research on convergence angles shows even small fin design improvements boost performance significantly.

Temperature difference drives heat transfer - bigger temperature gaps move heat faster. Turbulence from smart fin design breaks up slow-moving air layers, dramatically improving heat transfer rates.

Major Types and Typical Applications

The heat exchanger coils market is valued at $17.5 billion and growing 5% annually, serving HVAC systems, industrial processes, commercial refrigeration, and specialty applications like mortuary coolers.

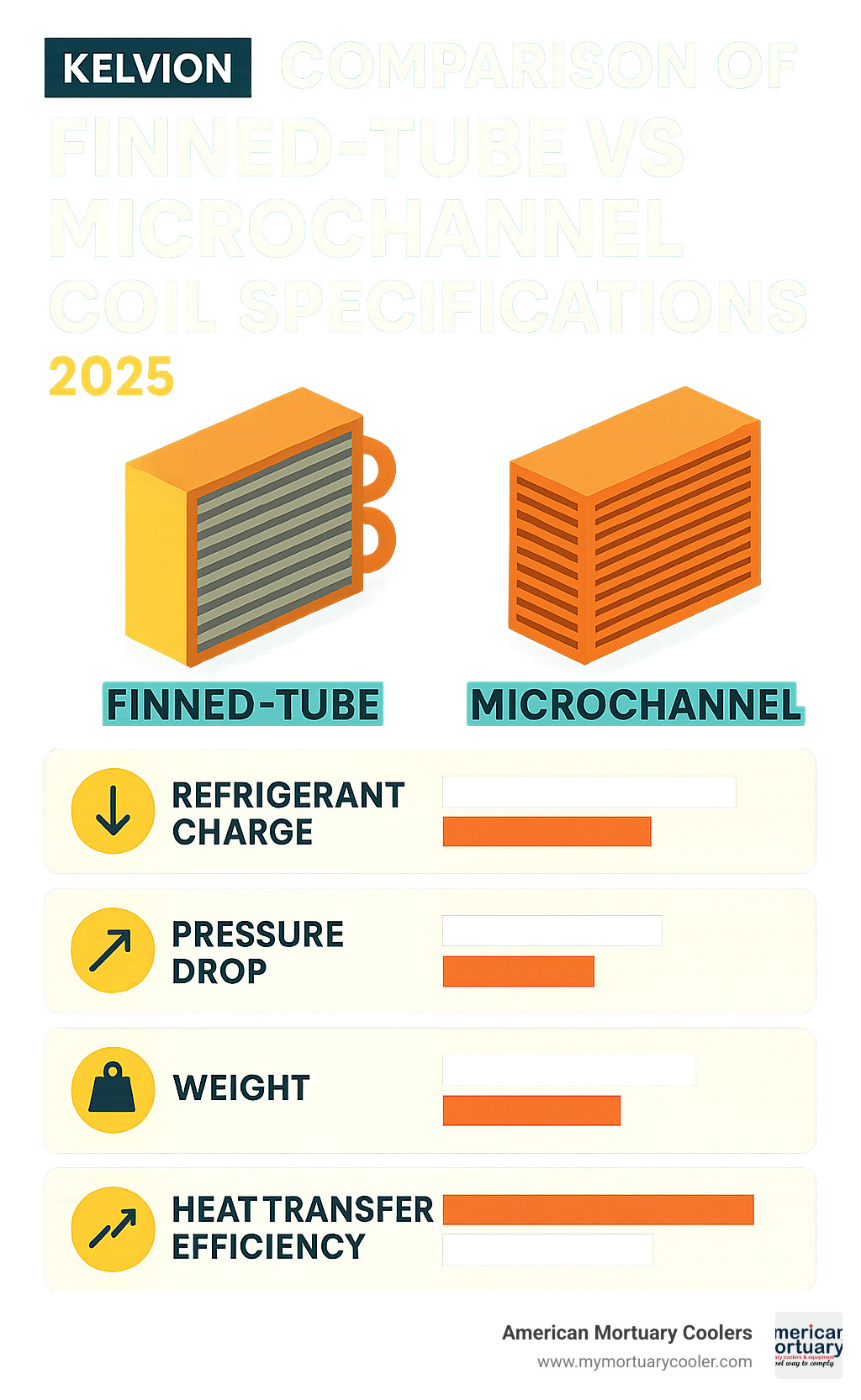

Finned-Tube Heat Exchanger Coils

Finned-tube designs dominate HVAC applications. Copper tubes carry refrigerant while aluminum fins create massive surface area for heat transfer. Tube diameters range from 3/8" to 5/8", with fin densities of 8-14 fins per inch. For mortuary coolers, we use 10-12 fins per inch to balance performance with cleanability.

Plate-Fin Coils

Plate-fin heat exchanger coils are 5 times lighter than shell-and-tube designs and offer complete disassembly for thorough cleaning - crucial for food processing and pharmaceutical applications. Corrugated surfaces create beneficial turbulence but are limited to 300 PSIG and 400°F.

Shell-and-Tube & Shell-and-Coil

Shell-and-tube designs handle high pressures above 30 bar and temperatures over 260°C. More info about thermo-pack shells shows these can save 10-15% on energy costs through cross-counterflow subcooling.

Microchannel Heat Exchanger Coils

Microchannel coils use channels below 1mm diameter to achieve amazing heat transfer while using 40% less refrigerant. Scientific research on microchannel sinks confirms the high surface area-to-volume ratio creates significantly better performance. Modern designs also provide 20% less air pressure loss.

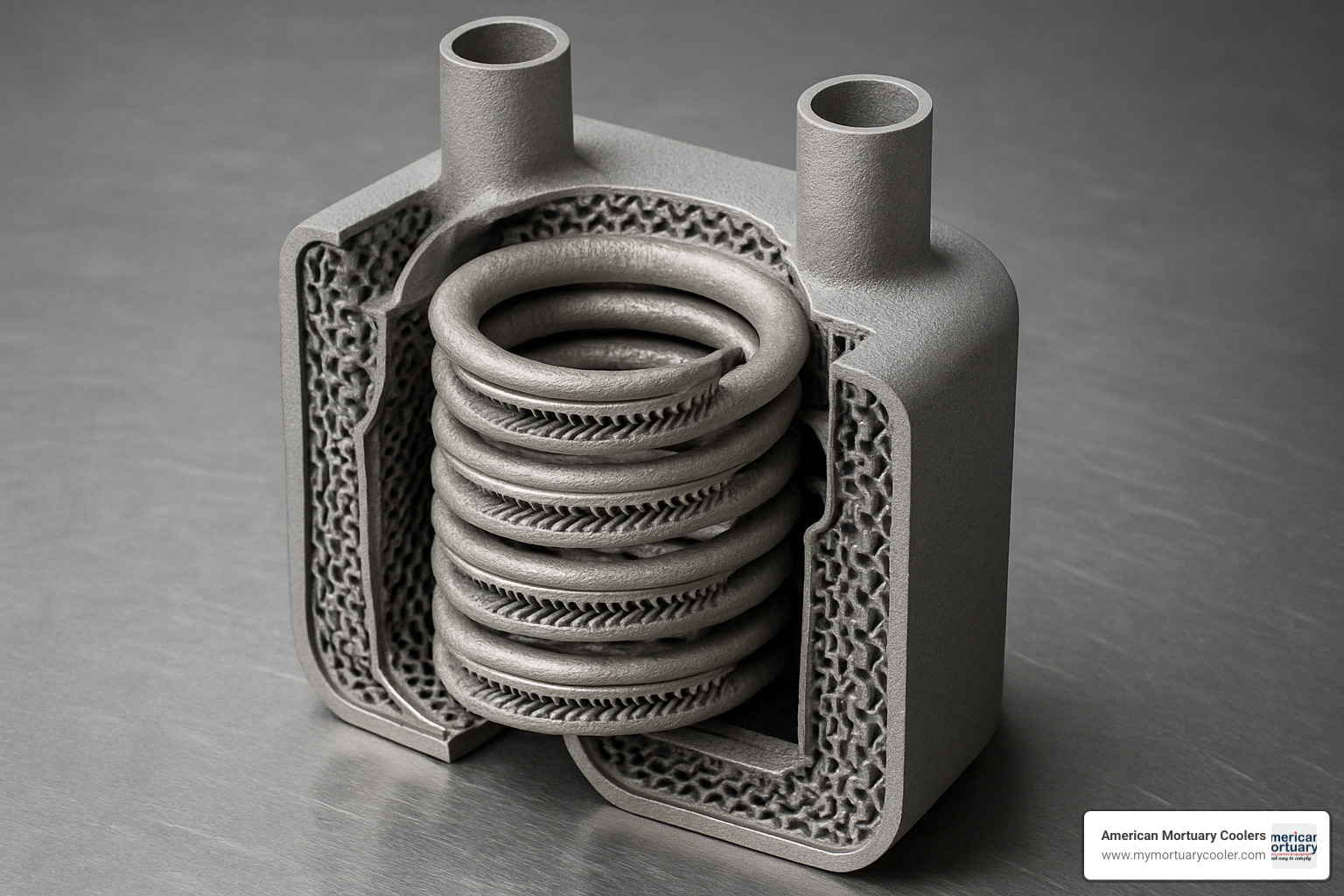

Specialty & Custom Coils

Helical and spiral coils pack long heat transfer lengths into tight spaces. Marine applications use titanium or cupro-nickel for seawater resistance. Cryogenic applications need special materials for extreme temperatures. At American Mortuary Coolers, we design custom coils for unique funeral home requirements.

Design & Material Factors That Drive Performance

Heat exchanger coil performance depends on balancing tube diameter, fin spacing, circuiting, and corrosion protection. Smaller tubes provide more surface area but higher pressure drops. Closer fin spacing improves heat transfer but makes cleaning harder.

Materials Matter

Copper conducts heat excellently and resists corrosion while remaining cost-effective and serviceable. Aluminum fins are lightweight and economical but need corrosion protection in harsh environments. Stainless steel costs more but handles frequent chemical cleaning without degrading - valuable for mortuary applications.

Protective coatings like Heresite provide exceptional chemical resistance while AmeriCoat blocks corrosion without reducing thermal conductivity.

Configuration & Sizing

Row count affects capacity and pressure drop - more rows mean more heat transfer but higher fan power requirements. Face velocity around 400-600 FPM balances performance with quiet operation for funeral homes.

Software selection tool helps optimize configurations without manual calculations.

Quality Manufacturing

Mechanical expansion creates perfect tube-to-fin contact. Helium leak testing catches microscopic leaks before installation. ISO 9001 certification ensures consistent manufacturing quality.

Selection, Maintenance & Troubleshooting Guide

Choosing and maintaining heat exchanger coils properly prevents expensive failures and ensures reliable operation.

Choosing the Right Coil

Heat load calculations must include safety margins - we add 10-20% for mortuary coolers where precise temperature control is critical. Fluid compatibility with refrigerants is essential. Space constraints often drive custom solutions. More info about walk-in coolers discusses timing considerations.

Preventing Fouling & Failure

Scaling from hard water minerals acts like insulation. Biofilm creates slimy layers that reduce efficiency. Corrosion starts small but eventually destroys coils. Freezing can burst tubes instantly without proper glycol protection.

Good filtration and water treatment prevent most problems. Regular glycol concentration monitoring prevents freeze damage.

Maintenance Best Practices

Quarterly inspections with annual deep cleaning work for most mortuary applications. Chemical cleaning removes deposits water alone can't touch. Beginner Freeze Coil Mistakes and How to Avoid Them covers common defrost problems.

Troubleshooting Common Issues

Refrigerant leaks often indicate coil deterioration. Frozen evaporator coils usually mean defrost system problems. High pressure drop typically indicates fouling or airflow restrictions. Defrost timer settings must match actual frost patterns.

Innovations, Standards & Sustainability Trends

Heat exchanger coil technology is advancing rapidly with new materials and manufacturing methods that improve performance while protecting the environment.

Microgroove copper tubes increase internal surface area by 2-3 times. Additive manufacturing creates geometries impossible with traditional methods. Hybrid heat exchangers combine different mechanisms for optimal performance.

ASME codes govern pressure vessel design while TEMA standards specify shell-and-tube construction. The PED directive regulates European markets.

Green Building Design

Low GWP refrigerants reduce environmental impact. Heat recovery ventilation transfers heat between air streams. LEED points reward efficient HVAC systems. Waste heat reuse captures otherwise rejected energy.

Future Outlook

The market grows 5% annually driven by efficiency demands. AI-driven predictive maintenance will predict problems before failure. IoT sensors provide real-time performance monitoring. Compact designs continue improving through advanced manufacturing.

Frequently Asked Questions about Heat Exchanger Coils

What causes coil fouling and how do I prevent it?

Heat exchanger coil fouling happens when materials build up on heat transfer surfaces. Scaling from hard water minerals, biofilm from bacteria, and particulate fouling from airborne contaminants all reduce performance.

Prevention includes water treatment systems, regular cleaning schedules, and good air filtration. For mortuary coolers, we recommend quarterly cleaning with EPA-approved disinfectants.

How often should coils be cleaned or replaced?

Cleaning frequency depends on environment - dusty areas need monthly attention while clean locations can go 3-4 months. Replace when repair costs approach 50% of replacement cost or when multiple leaks indicate overall deterioration. With proper maintenance, coils can last 15-20 years.

What's the difference between standard and custom coils?

Standard coils cost less and ship quickly but may not perfectly fit your needs. Custom coils are designed for your exact application, providing optimal performance and perfect fit. For mortuary applications where precision matters, custom solutions usually provide better long-term value despite higher initial cost.

Conclusion

Heat exchanger coils are the quiet workhorses making modern refrigeration possible. From tiny microchannel coils to massive industrial units, these devices work continuously to move heat exactly where needed.

At American Mortuary Coolers, we've learned that the right coil makes the difference between reliable equipment and costly failures. Today's technology offers exciting improvements - microchannel coils use 40% less refrigerant, protective coatings survive frequent cleaning, and smart sensors predict problems before they occur.

We've shipped custom systems across the continental United States, each relying on carefully selected heat exchanger coils. Quality matters - the best design won't help if poorly manufactured or incorrectly installed.

Whether planning a new funeral home or upgrading existing facilities, heat exchanger coils are an investment in peace of mind. Quality coils and proper installation save thousands in energy costs and emergency repairs over the years.

For more information about mortuary refrigeration solutions and how the right heat exchanger coils can improve your facility's performance, visit our comprehensive resource center. Our team is ready to help you find the perfect cooling solution that will keep working long after you've forgotten it's there.