What Is a Reach-In Refrigerator and Why Your Business Needs One

A reach in refridgerator is a commercial upright refrigeration unit with front-opening doors that provides quick access to stored items without entering the storage space. These units are essential for businesses that need frequent access to refrigerated products while maintaining optimal food safety temperatures.

Key Facts About Reach-In Refrigerators:

- Temperature Range: FDA recommends 38°F to 41°F (3.3°C to 5°C)

- Capacity: Typically 18-72 cubic feet

- Applications: Restaurants, medical facilities, bars, convenience stores

- Market Position: #1 selling commercial refrigeration cabinet

- Energy Standards: Must comply with EISA requirements

Reach-in refrigerators have been the chef's companion in commercial kitchens worldwide for over 40 years, offering reliable cold storage that keeps ingredients fresh and accessible. The FDA requires commercial refrigeration to maintain temperatures between 38°F and 41°F to ensure optimal food preservation and prevent spoilage.

These versatile units serve multiple industries beyond foodservice. Medical facilities use them for pharmaceutical storage, bars rely on them for beverage cooling, and specialty businesses depend on their consistent temperature control. With storage capacities that far exceed residential units and built-in safety features like door alarms and self-closing hinges, reach-in refrigerators are designed for heavy commercial use.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping businesses select the right reach in refridgerator solutions for their specific needs. My background includes working with funeral homes, medical facilities, and commercial operations to provide reliable, American-made refrigeration equipment that meets strict industry standards.

Key reach in refridgerator vocabulary:

Why This Guide Matters

Understanding reach in refridgerator technology is crucial for several reasons. First, proper food safety compliance prevents costly health violations and protects your customers. The FDA's strict temperature requirements aren't suggestions—they're legal mandates that can make or break your business.

Energy savings represent another compelling reason to choose the right unit. Commercial refrigeration can account for up to 40% of a restaurant's energy costs, so selecting an efficient model pays dividends for years. ENERGY STAR certified units can reduce operating costs by 15-20% compared to standard models.

Return on investment becomes clear when you consider that a quality reach in refridgerator typically lasts 10-15 years with proper maintenance. The initial investment of $1,100-$5,000 spreads across thousands of service days, making the daily cost remarkably low for such critical equipment.

What Is a Reach-In Refrigerator?

Think of a reach in refridgerator as the workhorse of commercial kitchens—it's an upright cabinet with doors that open from the front, letting you grab what you need without stepping inside. Unlike those massive walk-in coolers where you literally walk into the storage space, or those low-profile undercounter units hiding beneath prep tables, reach-ins strike the perfect balance between storage capacity and easy access.

These units are built tough for commercial use, with heavy-duty components that can handle the constant opening and closing that happens in busy kitchens. The "reach-in" name comes from exactly what you'd expect—you reach in through the front door to grab your ingredients, supplies, or products.

Most reach in refridgerator units range from 18 cubic feet (perfect for small cafes) up to 72 cubic feet (ideal for large restaurants). To put that in perspective, your home refrigerator probably holds around 20 cubic feet, so even our smallest commercial units pack serious storage power while delivering the reliability that busy businesses demand.

The FDA requires these units to maintain temperatures between 38°F and 41°F—a narrow window that keeps food fresh without freezing it. Scientific research on optimal food holding temps confirms this temperature range significantly extends shelf life and prevents dangerous bacterial growth.

How a Reach-In Differs from Other Commercial Units

Walk-in coolers are great for bulk storage, but every time you open those big doors, cold air rushes out and warm air rushes in. With a reach in refridgerator, you're only opening a smaller door for a few seconds, which means better temperature stability and lower energy costs.

Prep tables combine refrigerated storage with workspace, but they sacrifice storage capacity for convenience. Merchandisers focus on showing off products through glass doors and fancy lighting, making them perfect for displaying beverages or grab-and-go items.

Core Components of a Reach-In Refrigerator

Every quality reach in refridgerator starts with solid cabinet insulation. We're talking about four inches of dense polyurethane foam that keeps the cold in and the heat out. This thick insulation doesn't just save energy—it prevents that annoying condensation that can make cheaper units sweat all over your floor.

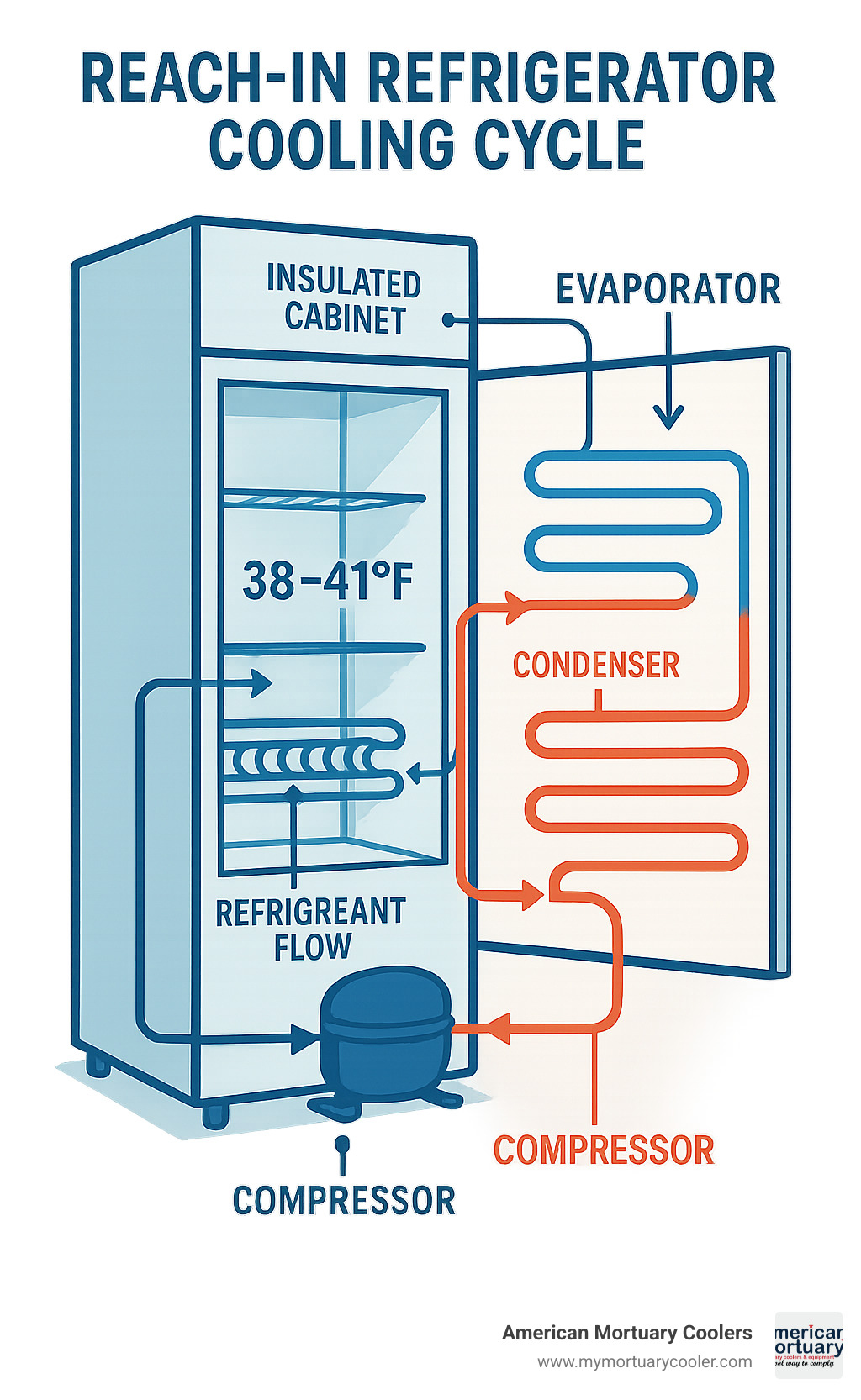

The compressor is the heart of the whole system. Modern units typically use either reciprocating or scroll compressors, with scroll types running quieter and more efficiently. Inside the cabinet, evaporator coils do the actual cooling work by removing heat from your stored items.

Thermostatic controls keep everything at the right temperature through digital displays and smart microprocessor systems. Advanced models can log temperature data, send alerts to your phone, and even connect to remote monitoring systems—pretty handy when you're not on-site but need to know your refrigeration is working properly.

Major Types & Configurations

When you're shopping for a reach in refridgerator, you'll find several configurations designed to match different business needs. The most important decision you'll face is choosing between solid doors and glass doors. Solid doors are like the reliable pickup truck of refrigeration—they're energy-efficient workhorses that get the job done without frills. Glass doors, on the other hand, are more like a showcase vehicle that lets everyone see what's inside.

Single-section units work perfectly for smaller operations, offering 18-25 cubic feet of storage behind one door. Double-section models step things up with two doors and 35-50 cubic feet of space—ideal for most restaurants and cafes. If you're running a large operation, triple-section units can provide 70+ cubic feet of storage.

Pass-through models offer doors on both sides, creating a convenient workflow where staff can load from the back and grab items from the front. The compressor placement affects your daily operations more than you'd expect. Top-mount compressors keep the machinery up high, away from flour dust and kitchen debris. Bottom-mount units keep the heat closer to the floor, which can help your air conditioning system work more efficiently.

| Feature | Solid Door | Glass Door |

|---|---|---|

| Energy Efficiency | Higher | Lower |

| Initial Cost | Lower | Higher |

| Product Visibility | None | Excellent |

| Maintenance | Less | More |

| Best For | Back-of-house | Front-of-house |

Solid-Door Reach-In Refrigerators

Solid doors are the energy-saving champions of the refrigeration world. Without glass panels creating thermal bridges, these units maintain more consistent temperatures while using less electricity. The cost savings start right at purchase. Solid-door units typically cost 15-20% less than their glass-door cousins because they don't need fancy lighting systems or expensive glass panels.

Light protection actually helps preserve food quality. Dairy products, certain vegetables, and many other foods maintain better nutritional value and appearance when stored in complete darkness. Maintenance stays simple with solid doors. You won't spend time cleaning glass panels or replacing interior lighting.

Glass-Door Reach-In Refrigerators

Glass doors transform your refrigerator into a display case that works around the clock. Staff can instantly see what's available without opening doors, which actually saves energy during busy periods. The sales impact can be remarkable. Convenience stores consistently report 20-30% higher beverage sales when customers can see their options through glass doors.

Modern LED lighting makes products look their best while consuming minimal energy. These lighting systems last 50,000+ hours and produce almost no heat. Maintenance requirements are higher than solid doors, but most operators find the increased sales easily justify the extra maintenance time.

Compressor Placement & Performance

Top-mount compressors make perfect sense in dusty environments like bakeries or pizza shops. When flour and other particles are floating around at floor level, keeping your compressor up high means cleaner coils and better performance.

Bottom-mount compressors excel in hot kitchens because they keep the heat-generating components closer to the floor. This placement can actually help your air conditioning system work more efficiently, since hot air naturally rises anyway.

The key is matching your compressor placement to your specific situation. Consider your kitchen's dust levels, heat load, and how easy you want maintenance to be when making this choice.

Sizing & Selection Guide

Choosing the right reach in refridgerator size feels overwhelming at first, but a few simple rules make the process much easier. The foodservice industry has developed a helpful guideline: 5 cubic feet of refrigerated storage per kitchen staff member. So if you have 4 cooks on your team, you'd need around 20 cubic feet of reach-in capacity.

Of course, this is just a starting point. A pizza shop that makes fresh dough daily needs more space than a cafe that serves mostly sandwiches. Your menu complexity and prep style matter more than generic formulas.

Footprint widths range from compact 24-inch single-door units to massive 81-inch triple-door models. The most popular sizes are 27", 30", 35", 54", and 78" to fit different kitchen layouts. Measure your available space carefully—these units are heavy and not easy to move once installed.

Don't forget about height clearances. Most units stand 70-84 inches tall, and you'll need extra room for the doors to swing open. The counter-depth versus standard-depth decision impacts both looks and storage. Counter-depth units create a sleek, built-in appearance by aligning with your 24-inch base cabinets. But you'll sacrifice some internal volume for that clean look.

For operations needing massive storage capacity, consider walk-in alternatives which provide significantly more space for bulk storage.

Calculating the Right Size for Your Operation

Skip the generic formulas and analyze your actual menu instead. Grab a pen and list every refrigerated ingredient you use. Estimate how much you store during your busiest periods. Don't forget that packaging takes up space—a gallon of milk needs more room than just one gallon of liquid volume.

Peak inventory periods drive your sizing decision, not average daily needs. Most restaurants stock up before weekends, holidays, or special events. Size your reach in refridgerator for these peak times, or you'll find yourself scrambling for storage space when you need it most.

Future growth planning saves money and headaches down the road. If you're thinking about expanding your menu or increasing volume, size up by 20-30% initially. The price difference between a 35 cubic foot and 50 cubic foot unit is often less than adding a second unit later.

Industry-Specific Applications

Restaurants represent the biggest market for reach-in units. The quick-access design suits busy kitchen environments perfectly. Cooks can grab ingredients without losing focus on their current tasks, and the front-opening doors don't block traffic flow like walk-in coolers can.

Healthcare facilities need pharmaceutical-grade temperature control for medications and lab specimens. These applications often require more precise monitoring than food storage, sometimes including chart recorders or alarm systems.

Bakeries face unique challenges with dough storage, frosting holding, and finished product display. Consistent temperatures prevent yeast activation in stored dough and keep delicate decorative elements stable.

Bars and beverage operations rely heavily on reach-in refrigeration for beer storage, wine holding, and cocktail ingredient organization. Glass-door models work beautifully for bottle display and help bartenders quickly identify what's available.

Key Features, Performance & Compliance

When you're investing in a reach in refridgerator, understanding the key features separates a good purchase from a great one. Modern commercial units pack impressive technology into seemingly simple cabinets, and knowing what to look for ensures you get equipment that works reliably for years.

Digital thermostats have revolutionized temperature control in commercial refrigeration. These microprocessor-controlled systems maintain temperatures within ±1°F of your setpoint—far superior to the old mechanical thermostats that could swing 3-5 degrees. Many include helpful features like temperature alarms and data logging that make compliance documentation much easier.

The auto-defrost system works behind the scenes to prevent ice buildup that steals your storage space and makes the compressor work harder. Door alarms might seem like a small feature, but they're lifesavers during busy periods. When doors stay open longer than 60-90 seconds, the alarm reminds staff to close them properly.

The shelving system in quality units supports up to 250 pounds per shelf and adjusts in half-inch increments. NSF-certified wire shelving promotes proper air circulation while making cleanup easier. Self-closing hinges ensure doors seal properly even when staff gets distracted during rush periods.

NSF and UL listings aren't just alphabet soup—they're your assurance that the unit meets strict standards. NSF certification confirms the unit meets rigorous food safety requirements, while UL listing ensures all electrical components meet safety standards. Most health departments require these certifications.

ENERGY STAR certification identifies models that exceed federal efficiency standards by at least 15%. While these units cost more upfront, the energy savings typically pay back the difference within two years.

Temperature Management Best Practices

Getting the most from your reach in refridgerator requires attention to temperature management details that many operators overlook. Calibration ensures your thermometer readings match reality throughout the unit's lifespan. We recommend professional calibration annually or whenever readings seem off.

Data loggers provide continuous temperature monitoring that creates permanent records for health department inspections. These devices typically record temperatures every 15 minutes and store weeks or months of data.

The FDA's 38-41°F requirement isn't arbitrary—it represents the sweet spot where food stays safe without freezing damage. Temperatures below 38°F can cause cellular damage in fresh produce, while temperatures above 41°F allow dangerous bacterial growth.

Food Safety & Regulatory Standards

Regulatory compliance isn't optional in commercial foodservice—it's the foundation that keeps your business operating legally and safely. HACCP systems identify refrigeration as a critical control point requiring continuous monitoring and documentation. Your reach in refridgerator must maintain proper temperatures consistently, and you need records proving it.

Local health codes vary by jurisdiction but typically reference FDA guidelines as the baseline. Some areas require specific temperature monitoring equipment or particular documentation procedures. Check with your local health department about specific requirements before purchasing equipment.

For operations requiring more specialized temperature control and monitoring systems, our experience with morgue refrigeration safety provides insights into advanced compliance requirements that may apply to healthcare and laboratory applications.

Maintenance, Energy Efficiency, Brands & Costs

Cleaning schedules prevent most performance problems and extend equipment life. Daily tasks include wiping down surfaces and checking door seals. Weekly cleaning should include interior sanitizing and exterior cleaning. Monthly maintenance involves condenser coil cleaning and temperature calibration checks.

Gasket inspection prevents energy loss and temperature fluctuations. Damaged door gaskets allow warm air infiltration, forcing the compressor to work harder. Replace gaskets when they show cracks, tears, or permanent deformation.

Condenser coil brushing removes dust and debris that reduces efficiency. Dirty coils can increase energy consumption by 25-30% and shorten compressor life. Clean coils monthly in normal environments, weekly in dusty conditions.

Service contracts provide professional maintenance and priority repair service. Most manufacturers recommend annual professional service including refrigerant level checks, electrical component testing, and calibration verification.

Energy consumption varies significantly by model size and efficiency rating. Typical reach in refridgerator units consume 2,000-4,000 kWh annually, costing $200-$400 in electricity at average commercial rates.

Leading brands include True Manufacturing (the market leader with over 40 years experience), Atosa (value-oriented commercial equipment), HABCO (featuring removable Cassette® refrigeration systems), SABA (mid-range reliability), and Koolmore (budget-friendly options).

Price ranges span from $1,100 for basic single-door units to over $5,000 for large triple-door models with advanced features. Glass-door units typically cost 15-20% more than comparable solid-door models.

Warranty coverage typically includes 3-5 years on parts and labor, with longer coverage on major components like compressors. Some manufacturers offer extended warranties for additional cost.

Solid vs Glass Door Cost Breakdown

Initial price differences favor solid-door units by $200-$800 depending on size. This cost difference reflects the simpler construction and fewer components in solid-door models.

Operating costs vary significantly between door types. Solid-door units typically consume 15-25% less energy due to better insulation and no interior lighting requirements.

Payback periods for the energy savings of solid doors typically range from 2-4 years depending on usage patterns and local energy costs. High-volume operations with frequent door openings see faster payback periods.

Common Mistakes to Avoid

Oversizing wastes energy and floor space while undersizing creates operational problems. Accurately assess your actual storage needs rather than guessing or over-estimating requirements.

Poor airflow clearance around condensing units causes overheating and premature failure. Maintain manufacturer-specified clearances even if it requires rearranging other equipment.

Ignoring warranty terms can void coverage and leave you responsible for expensive repairs. Read warranty conditions carefully and follow recommended maintenance schedules to maintain coverage.

Frequently Asked Questions about Reach-In Refrigerators

Let me answer the most common questions I hear from business owners about reach in refridgerator units. These questions come up repeatedly, and getting the answers right can save you money and headaches down the road.

What temperature should a commercial reach-in hold?

Your commercial reach in refridgerator should maintain temperatures between 38°F and 41°F according to FDA guidelines. This isn't just a suggestion—it's the law for food safety compliance.

The sweet spot is typically 39-40°F for your setpoint. This gives you a safety cushion when staff open doors frequently or when the unit cycles through defrost periods. Going below 38°F risks freezing damage to produce and dairy products. Above 41°F puts you in the danger zone where bacteria multiply rapidly.

Does top-mount or bottom-mount save more energy?

Bottom-mount compressors typically win the energy efficiency battle in most kitchens. They keep the waste heat down low, which means your air conditioning system doesn't have to work as hard to cool your kitchen.

However, top-mount units can be more efficient in dusty environments like bakeries or pizza shops. When flour and debris settle at floor level, bottom-mount condensers get dirty faster, which hurts efficiency. A clean top-mount condenser often outperforms a dirty bottom-mount unit.

The energy difference usually amounts to 5-10% either way, depending on your specific environment. More important than placement is keeping those condenser coils clean—regardless of where they're located.

How often should I clean the condenser coils?

Clean your condenser coils monthly in normal environments, weekly if you're dealing with flour, dust, or other airborne particles.

Dirty coils are energy vampires—they can increase your electricity consumption by 25-30% while shortening your compressor's life dramatically. Use a soft brush or compressed air to gently remove debris. Work carefully around those delicate fins—they bend easily and damaged fins reduce airflow.

Your reach in refridgerator is working hard 24/7 to keep your products safe. A little regular maintenance keeps it running efficiently for years to come.

Conclusion

Choosing the right reach in refridgerator isn't just about buying equipment—it's about investing in the foundation of your business success. Whether you're keeping ingredients fresh in a busy restaurant or maintaining critical supplies in a medical facility, the right refrigeration makes everything else possible.

Throughout this guide, we've walked through the essentials together. Proper sizing means planning for your busiest days, not your average ones. Temperature control between 38-41°F isn't just a suggestion—it's your shield against costly health violations and spoiled inventory. Energy efficiency might seem like a small detail, but it quietly saves you hundreds of dollars every year.

The choice between solid and glass doors, top-mount versus bottom-mount compressors, and single versus multi-section units all come down to understanding your specific needs. A busy kitchen benefits from quick-access solid doors, while a convenience store thrives with glass-door visibility that boosts impulse sales.

Maintenance planning protects your investment from day one. Simple monthly tasks like cleaning condenser coils and checking door seals prevent the expensive problems that catch businesses off guard. A quality reach in refridgerator should serve you faithfully for 10-15 years with proper care.

At American Mortuary Coolers, we've spent years understanding what makes refrigeration systems work reliably under pressure. From our Tennessee headquarters, we've delivered custom cold-storage solutions across all 48 contiguous states. Our experience with specialized applications—from funeral homes to medical facilities—gives us insight into what really matters when temperatures can't fail.

We know that behind every reach in refridgerator purchase is a business owner who needs equipment that simply works, day after day. That's why we focus on durable, American-made solutions that handle real-world demands without breaking down when you need them most.

Ready to explore your options? Whether you need a single compact unit for a small operation or a complete cold-storage system for a large facility, we're here to help you make the right choice for your specific situation.