Understanding Commercial Cold Storage Solutions

When it comes to preserving temperature-sensitive items, nothing beats the reliability of walk in refrigeration units. These spacious, insulated enclosures are the workhorses of commercial cold storage, keeping everything from fresh produce to deceased loved ones at precisely the right temperature.

Think of walk in refrigeration units as the refrigeration world's answer to the tiny house movement – except instead of downsizing, you're upgrading to something that gives you room to breathe (and store). They come in several flavors to match your specific needs:

Walk-in Coolers keep things chilled between 35°F and 45°F – perfect for fresh food, flowers, and beverages. They're the energy-efficiency champions of the walk-in world, helping keep your utility bills in check while preserving your products.

Walk-in Freezers take things to the next level with temperatures from -10°F to 0°F. They're built tougher with beefier R-32 insulation and heated door components to prevent freeze-ups. Your frozen goods will thank you.

Combination Units offer the best of both worlds with separate temperature-controlled compartments. It's like having a duplex for your perishables – cold neighbors living harmoniously side by side.

Specialized Units cater to unique industry needs, whether you're storing the deceased, temperature-sensitive medications, or crafting the perfect lager. These units prove that one size definitely doesn't fit all.

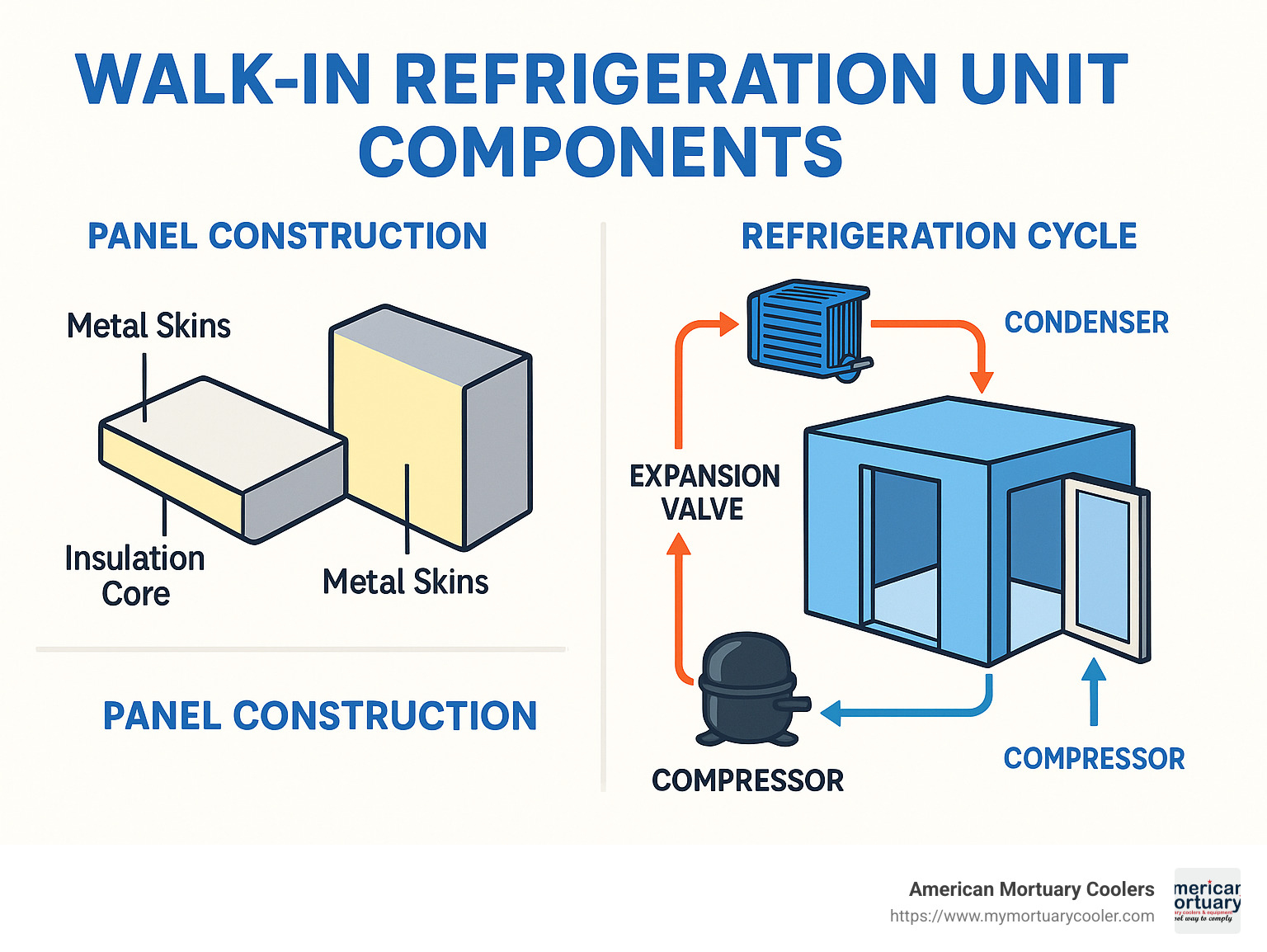

The beauty of walk in refrigeration units lies in their modular design. They're built from insulated panels that snap together like sophisticated building blocks to form walls, ceilings, and sometimes floors. Add in a properly sized refrigeration system, and you've got yourself a temperature-controlled room that stands ready to serve 24/7.

Investing in the right walk-in unit means finding that sweet spot between upfront costs and long-term energy savings while ensuring your specific storage needs are met with room to grow.

Here at American Mortuary Coolers, we've made it our business to understand the unique cold storage requirements of funeral homes and mortuary facilities. We craft custom walk in refrigeration units that not only preserve dignity through proper temperature control but also comply with all industry regulations. Based in Tennessee, we deliver our durable, custom solutions directly to funeral professionals across the continental United States.

If you're researching specific solutions, you might find these resources helpful:

Walk In Refrigeration Units 101

Walk in refrigeration units are much more than just big refrigerators. They're specially designed insulated rooms with powerful cooling systems that maintain precise temperatures for preserving everything from food to flowers to the deceased. Unlike your home fridge or even commercial reach-ins, these units are spacious enough for people to walk inside, making them perfect for businesses that need to store large quantities of temperature-sensitive items.

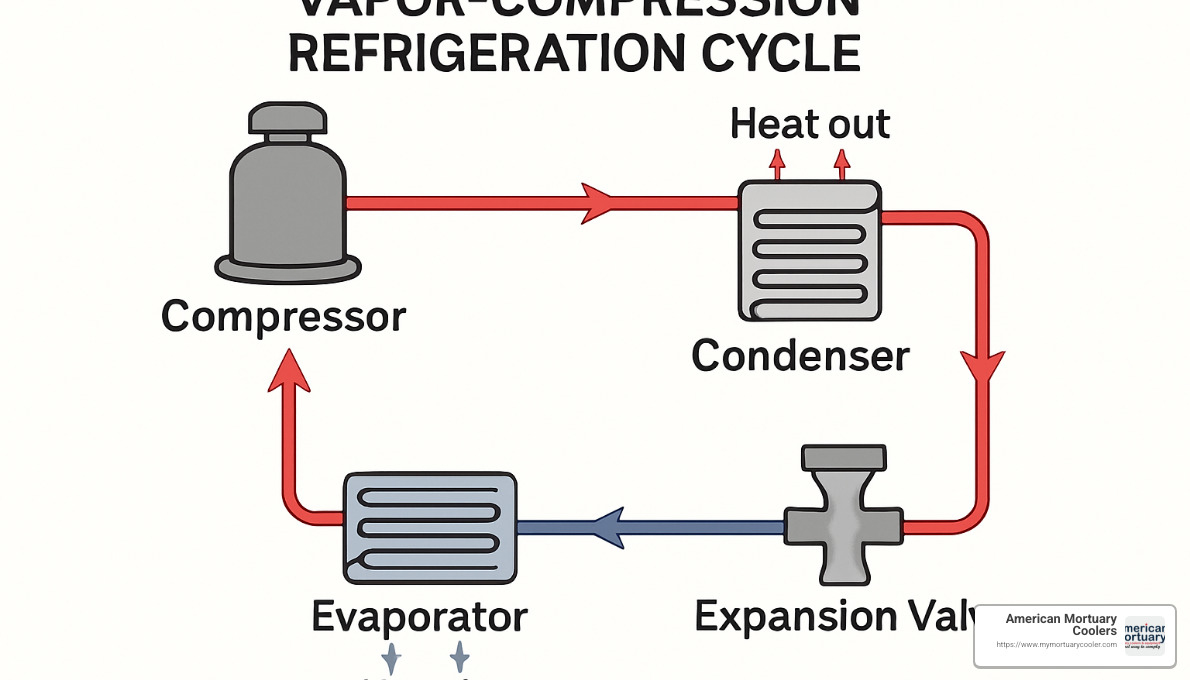

At the heart of every walk-in is the vapor-compression refrigeration cycle – the same basic principle that keeps your home refrigerator cold, just on a much larger scale. This clever system works through four main components that work together like a well-rehearsed band:

- Compressor: The hardworking heart of the system that pressurizes refrigerant gas, raising its temperature

- Condenser: Acts like a radiator, releasing captured heat to the outside world

- Expansion Valve: Creates a pressure drop that dramatically cools the refrigerant

- Evaporator: Absorbs heat from inside the walk-in, cooling the interior air

Different businesses need different temperatures, which is why walk in refrigeration units come in several varieties. Coolers keep things chilled but not frozen (typically 35°F-45°F), while freezers maintain below-freezing temperatures (usually -10°F to 0°F). For businesses needing both, combination units offer separate compartments with different temperature zones. We at American Mortuary Coolers specialize in units that maintain the ideal 35°F-38°F range that properly preserves the deceased with dignity.

How Does a Walk-In Work?

Think of a walk in refrigeration unit as running a continuous relay race to keep things cold. The process starts with the compressor – the workhorse that pressurizes refrigerant gas, making it hot and high-pressure (like air in a bicycle pump warming up when you compress it).

This heated gas then travels to the condenser, typically mounted outside or on top of the unit. Here, the refrigerant releases its heat to the surrounding air (you can feel this warm air if you've ever stood near an outdoor AC unit). As it cools, the refrigerant condenses into a liquid, much like water droplets forming on a cold glass on a humid day.

Next, this liquid refrigerant passes through an expansion valve – a kind of controlled bottleneck that causes a sudden drop in pressure. This pressure drop creates a dramatic cooling effect (similar to how aerosol cans get cold when sprayed).

"The magic happens in the evaporator," explains one of our refrigeration specialists at American Mortuary Coolers. "This is where the now-cold refrigerant absorbs heat from inside the walk-in, cooling the interior. As it warms up, it evaporates back into a gas and heads back to the compressor to start the journey all over again."

A thermostat monitors the temperature inside, cycling the compressor on and off as needed to maintain your precise settings – whether you're storing restaurant ingredients or providing appropriate care for the deceased.

Key Benefits Over Reach-Ins

When it comes to serious cold storage, walk in refrigeration units offer tremendous advantages over multiple smaller reach-in units.

Bulk storage capacity is perhaps the most obvious benefit – a well-designed walk-in maximizes your available space far more efficiently than several standalone units. This is particularly important in businesses where square footage comes at a premium.

Labor savings might be less obvious but equally important. Your staff can step inside to organize, rotate, and access inventory much more efficiently. Instead of opening multiple doors and hunting through different units, everything is accessible in one organized space – saving valuable time during busy periods.

Temperature stability is crucial for sensitive items. The larger air mass inside a walk-in maintains more consistent temperatures when doors are opened. In mortuary settings, this stability is particularly important for preserving dignity and preventing deterioration.

Despite their larger size, well-designed walk in refrigeration units can actually be more energy efficient per cubic foot than multiple smaller units. Fewer door openings and better insulation contribute to this efficiency, helping keep your utility bills in check.

Customization is another major advantage. At American Mortuary Coolers, we can configure walk-ins to your exact space requirements and storage needs, unlike pre-manufactured reach-ins that come in limited sizes. Whether you need special racking for caskets or extra-wide doors, we can design it.

For businesses handling perishable items, food safety is paramount. Better organization and temperature stability contribute to improved compliance with health regulations, reducing the risk of spoilage and waste.

Finally, there's longevity. Quality walk-in units typically provide 15-20 years of reliable service or more, compared to just 7-10 years for most reach-ins. This makes them not just a purchase, but a long-term investment in your business's future.

Selecting Your Walk-In: Types, Sizes, Components & Materials

Choosing the right walk in refrigeration unit feels a bit like picking a new car—lots of options, each with its own set of features, and you want to make sure you get exactly what you need. Let's break down these choices into manageable pieces so you can find your perfect cold storage solution.

Cooler, Freezer or Combo?

First things first—what temperature do you need to maintain?

Walk-in Coolers keep things chilly but not frozen (35°F to 45°F). They're perfect for fresh produce, dairy products, flowers, and in our world of mortuary services, short-term body preservation. They're the energy-efficient option with less insulation (typically R-25) and lower operating costs. Many of our funeral home clients prefer these for their reliability and economy.

Walk-in Freezers take things to the next level of cold (-10°F to 0°F). These units require thicker insulation (R-32) and come with heated door components to prevent sticking—because nobody wants to tug on a frozen door! They use more energy but provide the deep freeze needed for long-term preservation.

Combination Units offer the best of both worlds—separate compartments with individual temperature controls. They're space-savers compared to having two separate units, and they provide convenient access between temperature zones. For facilities with diverse needs, these combo units are often the perfect solution.

One of our clients, Dale J. Schrock, shared his experience: "I am very pleased with my freezer. It has given us no problems at all. It holds temperature perfectly and looks great from the outside." That's exactly what we love to hear!

Panel Materials & Insulation

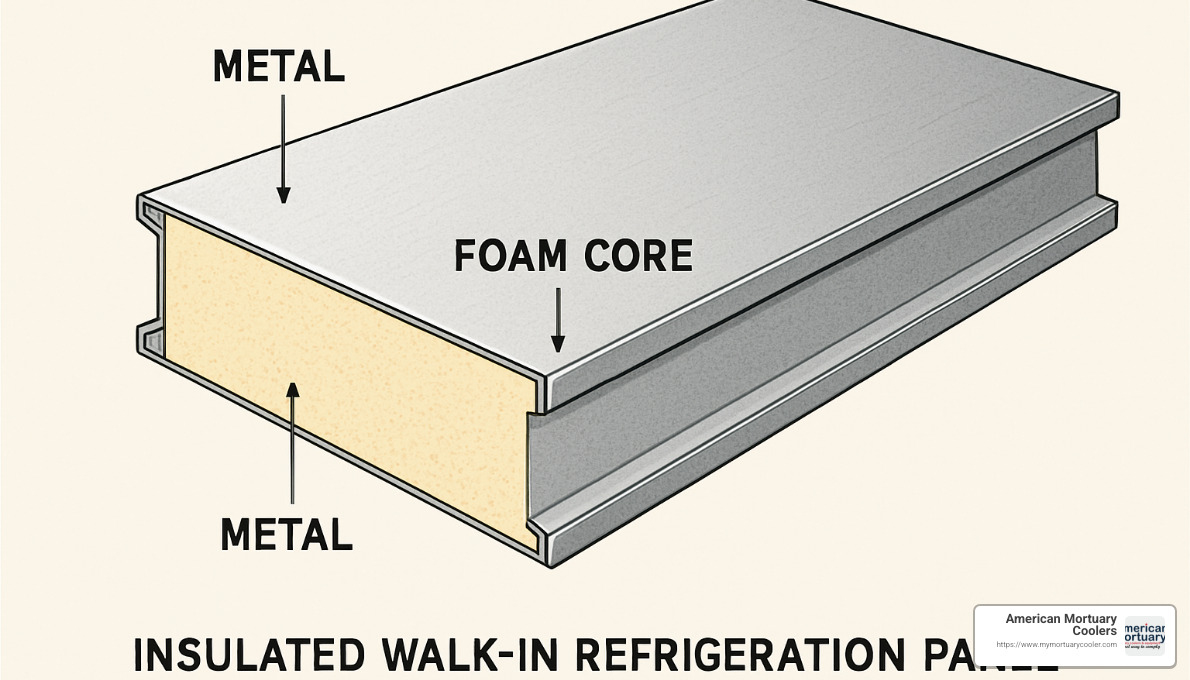

The "skin" and "bones" of your walk in refrigeration unit determine its durability and efficiency.

For exterior and interior panels, you've got several options. Aluminum is lightweight and won't corrode, making it great for indoor use. Galvanized steel offers more strength with good corrosion resistance—it's our workhorse option. For premium applications, stainless steel can't be beat for durability and cleanability, which is why we often recommend it for mortuary interiors where sanitation is paramount.

If your unit will live outdoors, consider fiberglass. It laughs at temperatures above 175°F, doesn't rust in coastal air, and has excellent thermal properties with a conductivity of just 0.04 BTU—far better than metal options for energy efficiency.

Inside those panels, the insulation does the heavy lifting. Polyurethane foam is the industry standard, typically foamed-in-place between panel skins for an airtight seal. For high-humidity environments, Extruded Polystyrene (XPS) offers superior moisture resistance. Budget-conscious buyers might consider Expanded Polystyrene (EPS), which provides good insulation at a lower cost.

Key Components Inside the Box

The heart and lungs of your walk in refrigeration unit are the components that keep it breathing cold air.

Your evaporator unit comes in various mounting styles. Top-mounts are common but reduce interior height. Side-mounts preserve headroom but take up wall space. For maximum interior space, "penthouse" systems place the evaporator on the roof. Each has its place, depending on your specific needs.

The condensing unit can either be self-contained (attached directly to the walk-in) or remote (located elsewhere, like outside or in a mechanical room). Self-contained units are simpler to install but add heat to their surroundings. Remote units improve efficiency by rejecting heat elsewhere—a smart choice for tight spaces or hot environments.

Doors might seem simple, but they're critical components. Heavy-duty, triple-hinged designs ensure years of trouble-free operation. Magnetic gaskets create that satisfying "thunk" of a perfect seal. Safety releases are non-negotiable—they ensure nobody gets trapped inside. Many clients add strip curtains to reduce cold air loss during frequent entries.

Don't forget the supporting players: pressure relief vents (essential for freezers), energy-efficient LED lighting, digital thermometers, and alarms to monitor temperatures. For easy access, ramps make moving carts or trolleys a breeze.

Choosing walk in refrigeration units for capacity

Sizing your walk in refrigeration unit correctly saves money and headaches down the road.

Start by calculating your cubic footage needs. Estimate the total volume of products you'll store, then add 15-20% for air circulation—proper airflow is essential for even cooling. Don't forget to account for shelving and organization systems, and always plan for growth. Nothing's more frustrating than outgrowing your unit too quickly.

Panel thickness (typically 4") eats into your usable space. For a quick estimate, subtract 8" from exterior dimensions to get your interior working area. If you're using a top-mount evaporator, factor in that space too.

When planning your shelving layout, ensure aisles are at least 36" wide for comfortable movement. If you'll use carts, make sure they can turn corners without becoming a three-point-turn challenge. Position shelving to maximize space while maintaining good airflow—blocking air circulation is a recipe for temperature inconsistencies.

For our mortuary clients, we typically express capacity in terms of body capacity. At American Mortuary Coolers, we offer standard units sized for 4-5, 8-10, 16-20, and 24-30 bodies. Of course, we're always happy to create custom configurations for unique facility needs—it's what we do best.

More info about walk-in prices

Learn more about thermal conductivity

Performance Factors: Energy Efficiency, Installation & Maintenance

When it comes to walk in refrigeration units, energy efficiency isn't just about being eco-friendly – it directly impacts your bottom line. Since these units run 24/7, even small efficiency improvements can lead to significant savings over time.

Self-Contained vs Remote Systems

Choosing between self-contained and remote refrigeration systems is a bit like deciding between an all-in-one appliance or a component system – each has its place depending on your needs.

Self-contained systems mount directly on your walk-in (usually on top), arriving pre-charged with refrigerant and ready to go. They're the simpler choice for installation and typically cost less upfront. Think of them as the "plug-and-play" option. The main drawback? They release heat right into the surrounding area, which isn't ideal if your unit sits in an already air-conditioned space – you'll essentially be paying to cool the same area twice!

"I initially considered a self-contained unit for our small funeral home," shares one of our customers. "But our installation space was already tight and poorly ventilated. Going remote was definitely the right call for us."

Remote systems place the condensing unit away from the walk-in, often outdoors. While they require professional installation with copper line sets and field charging, they offer compelling advantages. They keep heat and noise outside your workspace, run more efficiently (especially in warm environments), and typically cost less to operate long-term. For larger walk in refrigeration units, remote systems almost always make more financial sense over time.

| Feature | Self-Contained | Remote |

|---|---|---|

| Installation Complexity | Lower | Higher |

| Initial Cost | Lower | Higher |

| Operating Efficiency | Good | Better |

| Heat Load on Building | Higher | None |

| Noise Level in Workspace | Higher | Lower |

| Maintenance Accessibility | Variable | Better |

| Relocation Ease | Easier | More Complex |

Indoor vs Outdoor Placement

Your walk in refrigeration unit can live indoors or outdoors, but each location comes with its own set of considerations.

Indoor installations enjoy natural protection from weather elements, allowing for standard aluminum or galvanized steel panels. They generally experience more consistent ambient conditions, which improves efficiency and extends equipment life. The trade-off? You'll need adequate ventilation for heat dissipation and might need to sacrifice valuable indoor space.

Many funeral homes prefer indoor placement for their mortuary coolers, as it provides easier access and greater privacy. As one director put it, "Having our cooler right next to our preparation room saves time and maintains dignity during transfers."

Outdoor installations free up precious indoor space but require weather-resistant construction to handle everything Mother Nature throws their way. Fiberglass exterior panels excel here – they can withstand temperatures above 175°F without warping and won't rust or corrode even in coastal environments. Proper foundation is crucial too; you'll need a concrete pad designed to support the unit's weight, plus a roof rated for your local snow load (up to 100 lbs per square foot in some regions).

At American Mortuary Coolers, we primarily recommend indoor installations for mortuary applications, but we can provide robust outdoor solutions when space constraints demand it. More info about indoor walk-ins

Maintaining walk in refrigeration units

Think of maintenance as preventive medicine for your walk in refrigeration unit. A little regular attention saves a lot of money and headaches down the road.

For mortuary coolers, proper cleaning is especially important. Regular sanitizing of interior surfaces not only maintains proper conditions but also shows respect for the deceased and their families. We recommend wiping down door gaskets monthly to prevent mold and ensure proper sealing – a simple task that prevents costly air leaks.

The refrigeration system itself needs regular check-ups too. Quarterly cleaning of condenser coils prevents efficiency-robbing dust buildup, while annual professional inspections can catch small issues before they become big problems. Don't forget about those drain lines – a clogged drain can lead to water damage and unpleasant odors.

"I've seen walk-ins last 5 years and I've seen them last 25 years," notes our service manager. "The difference almost always comes down to maintenance. A well-maintained unit not only lasts longer but costs less to operate every single day."

We recommend setting up a maintenance calendar with these key intervals:

- Monthly: Check temperatures, clean interior surfaces, inspect gaskets

- Quarterly: Clean condenser coils, check electrical connections

- Annually: Professional service inspection, refrigerant level check

- Every 5 years: Evaluate for possible component upgrades

This consistent attention ensures your walk in refrigeration unit maintains proper temperatures year after year, providing the reliable performance that's absolutely essential in the funeral industry.

Budget, Customization & Industry Applications

Investing in a walk in refrigeration unit is a significant decision that requires thoughtful budget planning. Let's explore the financial considerations, customization options, and how these units serve various industries to help you make a choice that's both practical and cost-effective.

Upfront vs Lifetime Costs

When planning your budget for a walk in refrigeration unit, you'll need to consider both the initial investment and what it'll cost you down the road.

The upfront costs typically range from $5,000 for basic models to $30,000+ for larger, feature-rich units. Installation adds another $2,000-$10,000 depending on complexity. Don't forget about site preparation costs like pouring a concrete pad or upgrading your electrical system.

But that's only part of the story. The ongoing costs are equally important to consider:

Your monthly energy bills will likely run between $100-$600+, depending on unit size, efficiency, and usage patterns. Regular maintenance, while necessary, adds to your operational expenses. And of course, there's always the possibility of repairs or component replacements as the unit ages.

"Think of your walk-in as an investment rather than an expense," our team often advises clients. "Higher quality upfront usually means lower costs over time."

At American Mortuary Coolers, we understand budget constraints can be challenging, which is why we offer 100% financing options with competitive rates and flexible terms. Our industry-leading warranty package includes a remarkable 20-year panel warranty and 5-year coverage on entrance doors and compressors, giving you peace of mind about your investment.

Popular Add-Ons & Accessories

Your walk in refrigeration unit can be customized with accessories that improve functionality, efficiency, and convenience.

Storage solutions transform your walk-in from an empty box into an organized system. Wire shelving offers excellent air circulation, while solid shelving provides more stable support for heavier items. For our mortuary clients, specialized body trays and roll-in racks make a world of difference in daily operations.

Door improvements might seem minor, but they make a huge impact. Strip curtains dramatically reduce cold air loss when doors are opened. Window kits let you see inside without opening the door. Kick plates protect the bottom of your doors from damage caused by carts and foot traffic.

The technology side is where things get interesting. Monitoring systems have come a long way, with digital thermometers, remote monitoring capabilities, and automatic alerts if temperatures drift or doors are left ajar. These features aren't just convenient—they can prevent thousands of dollars in product loss.

"One of our funeral home clients told me their temperature monitoring system paid for itself the first time it alerted them to a compressor issue before any damage occurred," shares one of our specialists.

For comfort and efficiency, LED lighting packages provide better visibility while using less energy than traditional bulbs. Motion sensors can automatically turn lights on and off, saving energy and adding convenience.

Real-World Success Stories

There's nothing like hearing from people who've already invested in walk in refrigeration units to understand their real-world impact.

Dale J. Schrock, a restaurant owner who purchased one of our units, didn't mince words: "I am very pleased with my Polar King freezer. It has given us no problems at all. It holds temperature perfectly and looks great from the outside. Thanks so much for all of your help."

In the floral industry, where product freshness directly impacts profitability, Sue Schnaitman found that her walk-in transformed her operation: "We have been so happy with our new walk-in. The glass display doors that we have has helped make product rotation very simple. Even the health department complemented the walk-in. Thanks again for a job well done."

For those in the catering business, mobility can be crucial. Dennis Langhoff shared his experience: "I have no doubt that investing in our trailer has been beneficial to our Catering Business and would highly recommend 'Polar King' as a reputable company that builds a great refrigerated Catering Trailer."

In our specialty area of funeral service, we've helped countless funeral homes across the country. One director in Tennessee told us something we hear often: "The modular design made installation simple, and the stainless steel interior has made cleaning and maintenance straightforward. The unit maintains perfect temperature and has been completely reliable since day one."

These aren't just testimonials—they're confirmation that investing in quality pays dividends in reliability, efficiency, and peace of mind.

FAQs & Conclusion

Let's address some of the most common questions we hear about walk in refrigeration units, especially from our funeral home clients who are considering this important investment.

What size walk-in do I need?

Sizing your walk-in correctly is crucial for efficiency and functionality. For restaurant owners, we recommend calculating based on your menu variety and how often you receive deliveries. Floral shops should consider their peak seasonal volumes (Valentine's Day and Mother's Day can require double the normal capacity!).

For our mortuary clients, we typically frame the conversation around maximum capacity needs. Most funeral homes choose from our standard configurations that accommodate 4-5, 8-10, 16-20, or 24-30 bodies, depending on their service volume.

When calculating your space requirements, remember to add 20-30% extra space for proper air circulation and potential growth. Don't forget to account for aisle space for staff movement and remember that the actual interior dimensions will be smaller than the exterior footprint due to the panel thickness.

"Many first-time buyers overlook the importance of future growth," our lead designer often reminds clients. "It's much more cost-effective to purchase a slightly larger unit initially than to replace it in a few years."

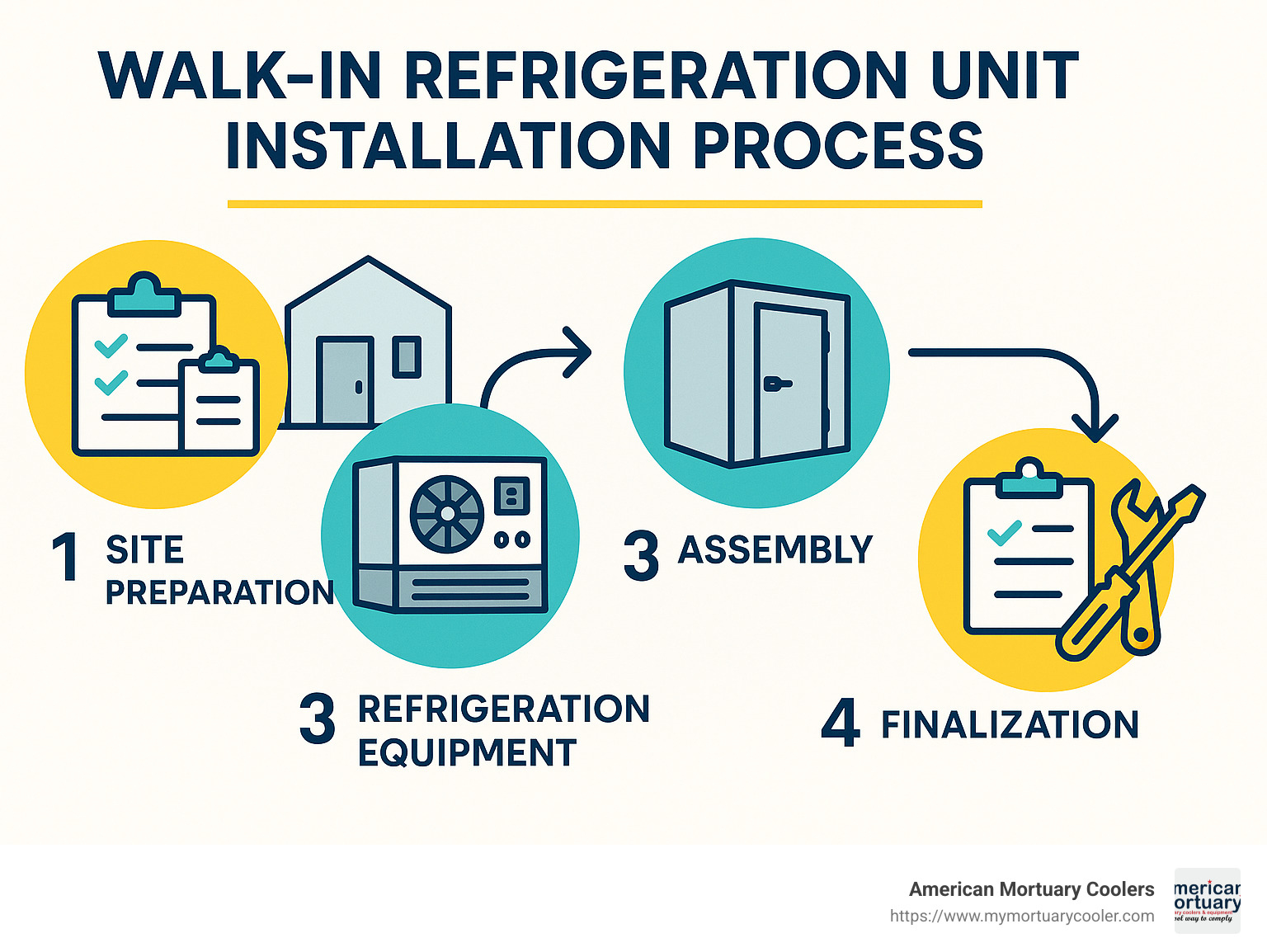

How long does installation take?

Installation time varies based on several factors, but we pride ourselves on efficiency without sacrificing quality.

Our quick-ship modular units can be delivered and installed in as little as two weeks, which has been a lifesaver for funeral homes facing unexpected equipment failures. Custom units naturally take longer – typically 4-8 weeks for manufacturing plus installation time.

The actual on-site installation process is relatively quick:

- Small, pre-assembled units can often be installed in a single day

- Medium-sized units with self-contained refrigeration usually take 2-3 days

- Larger units with remote refrigeration systems typically require 3-5 days

At American Mortuary Coolers, we provide comprehensive installation instructions with every unit, and our network of certified technicians covers all regions we serve. We'll never leave you guessing about how to get your new equipment up and running.

How do I keep energy costs low?

Energy efficiency is a major concern for our clients, and rightfully so – your walk in refrigeration unit will run 24/7/365.

The most impactful efficiency strategy is proper sizing. An oversized unit wastes energy continuously, while an undersized unit strains to maintain temperature. Beyond that, good door management makes a tremendous difference – installing strip curtains and training staff to minimize door opening time can reduce energy consumption by up to 15%.

Regular maintenance is equally important. Clean condenser coils, proper refrigerant levels, and well-functioning gaskets all contribute to optimal efficiency. One funeral director in Georgia told us: "After upgrading to EC motors and LED lighting in our walk-in, we saw a 22% reduction in our monthly energy costs."

For new installations, consider investing in panels with higher R-values (we recommend R-32 for freezers), energy-efficient EC fan motors, and smart control systems that optimize refrigeration cycles. The upfront cost difference is typically recovered within 2-3 years through lower utility bills.

Certifications & Compliance

Quality walk in refrigeration units should meet several important standards to ensure safety, efficiency, and compliance:

UL Listing ensures electrical components meet rigorous safety standards, while NSF Certification verifies that units meet food safety and sanitation requirements. Energy Star certification identifies particularly energy-efficient models, and EPA compliance ensures refrigerants meet current environmental regulations.

For mortuary applications specifically, units must comply with health department regulations regarding body storage, which vary somewhat by state. Our team stays current on these requirements and ensures all our units meet or exceed the necessary standards in your location.

"When the health inspector visited after our installation," one Kentucky funeral director shared, "he commented that our new American Mortuary Cooler was the nicest, most compliant unit he'd seen in the county."

Conclusion

Walk in refrigeration units represent a significant investment for any business, but when properly selected, installed, and maintained, they provide reliable temperature control and storage efficiency for many years.

At American Mortuary Coolers, we've dedicated ourselves to designing and manufacturing custom walk-in refrigeration solutions specifically for the funeral industry. Our units are built with the unique requirements of mortuary facilities in mind – featuring durable construction, precise temperature control, and easy-to-clean interiors that simplify your daily operations.

From our headquarters in Tennessee, we provide direct delivery to the contiguous 48 states, with regional support across the country. Whether you're opening a new facility in Johnson City TN, upgrading equipment in Atlanta GA, or expanding operations in Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, or Pittsburgh PA, we have the expertise to design, deliver, and support the perfect walk-in refrigeration system for your needs.

Our commitment doesn't end with delivery – we stand behind our products with industry-leading warranties and responsive support whenever you need it.

The ultimate guide to choosing a walk-in mortuary cooler