Understanding Reefer Lorries: The Backbone of Cold Chain Transport

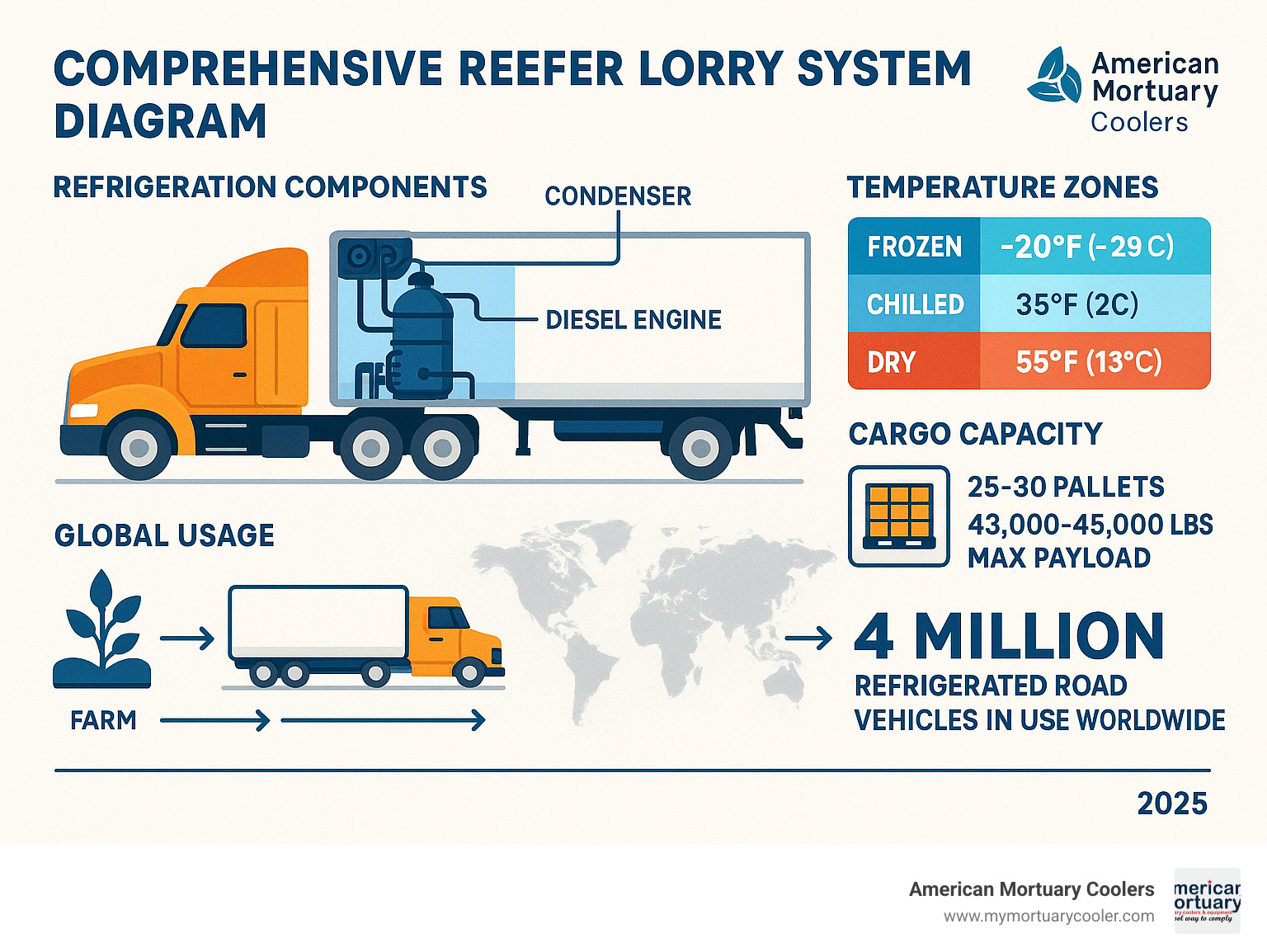

A reefer lorry is a refrigerated truck or trailer designed to transport perishable goods at controlled temperatures, typically ranging from -20°F to 55°F (-29°C to 13°C). These specialized vehicles use diesel-powered refrigeration units to maintain precise temperature conditions during transport.

Key Facts About Reefer Lorries:

- Temperature Range: Can reach as low as -20°F (-29°C) for frozen goods

- Capacity: Standard 53-foot trailers hold 26-30 pallets with maximum payload of 43,000-45,000 lbs

- Power Source: Self-powered diesel units or vehicle-powered systems

- Lifespan: Average 8 years with proper maintenance

- Annual Operating Cost: Approximately $5,500 ($4,000 fuel + $1,500 maintenance)

Reefer lorries haul over 90% of the food Americans eat today and were first developed around 1925 for the ice cream industry by inventor Frederick McKinley Jones. With around 4 million refrigerated road vehicles in use worldwide as of 2010, these trucks are essential for maintaining the cold chain from farm to table.

The demand for reefer transport remains consistently high - even during economic downturns. In February 2022, the reefer load-to-truck ratio was 13.74 compared to just 7.33 for standard dry van loads, showing the critical need for temperature-controlled transport.

As we at American Mortuary Coolers have experience in temperature-controlled storage solutions, we've seen how reefer lorry technology has evolved to serve specialized industries beyond food transport, including medical supplies and mortuary services.

Inside the Reefer Lorry: Components & Working Principles

The heart of any reefer lorry is its refrigeration system, which operates on the same basic principles as your home refrigerator but on a much larger scale.

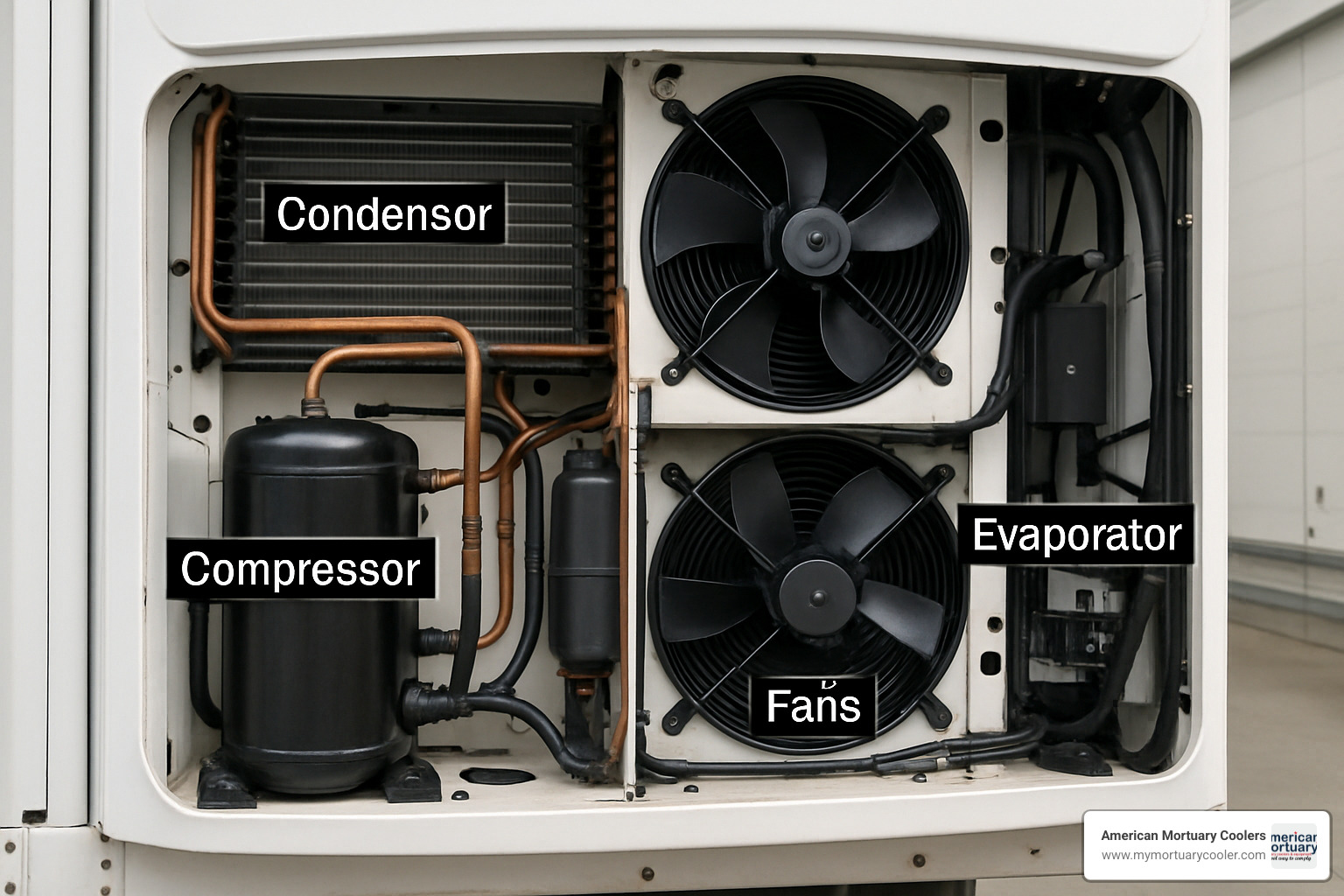

The main components include:

Core Refrigeration Components:

- Compressor: Pressurizes the refrigerant and circulates it through the system

- Condenser: Cools the pressurized refrigerant, converting it from gas to liquid

- Evaporator: Absorbs heat from inside the trailer, causing the refrigerant to evaporate back to gas

- Diesel Generator: Powers the entire system independently of the truck's engine

Power Options:

- Self-powered units: Have their own diesel fuel source and operate independently

- Vehicle-powered units: Run off the truck's engine or shore power when parked

Insulation Technology: The trailer walls use advanced insulation materials:

- PU (Polyurethane) foam: Excellent insulation with low K-factor ratings

- XPS (Extruded Polystyrene): Lightweight alternative with good thermal properties

- CFRT (Continuous Fiber Reinforced Thermoplastic): New lightweight material reducing weight by 75-150 lbs per foot

Airflow Management: An air chute runs along the ceiling to distribute cold air evenly throughout the trailer in continuous or cycle modes.

Reefer Lorry vs Dry Van

The differences between a reefer lorry and standard dry van extend beyond just the refrigeration unit:

Structural Differences:

- Walls: Reefer trailers use insulated metal or fiberglass walls versus simple aluminum or steel in dry vans

- Weight: Reefer units add significant weight, reducing maximum payload from 48,000 lbs to 43,000-45,000 lbs

- Fuel Consumption: Reefer units require their own fuel supply, typically 50-gallon tanks

How the Reefer Lorry Refrigeration Cycle Works

The refrigeration cycle works by removing heat rather than producing cold:

- Compression: The compressor pressurizes refrigerant gas, raising its temperature

- Condensation: Hot, pressurized gas flows to the condenser where it cools and becomes liquid

- Expansion: Liquid refrigerant passes through an expansion valve, dropping pressure and temperature

- Evaporation: Cold liquid refrigerant absorbs heat from the trailer interior, turning back to gas

Temperature Capabilities:

- Standard units: -13°F to 55°F (-25°C to 13°C)

- Specialized pharmaceutical units: As low as -85°F (-65°C)

- Most food transport: 32-36°F (0-2°C) for fresh goods, -10°F (-23°C) for frozen

For detailed technical information on heat transfer principles, refer to this Heat and Mass Transfer reference.

Sizes, Capacities & Configurations

When it comes to reefer lorry options, there's truly something for every cold-chain need. From compact urban delivery vans to massive cross-country haulers, these specialized vehicles come in configurations that would make any logistics manager smile.

The smallest reefer lorry units start at just 8 feet long and can handle around 2,000-5,000 pounds of cargo. These compact workhorses are perfect for flower shops delivering wedding arrangements or pharmacies transporting temperature-sensitive medications.

14-20 foot bodies become the sweet spot for many regional operations. With payload capacities of 5,000-10,000 pounds, these medium-sized units can carry 8-16 standard pallets. Restaurant supply companies love these sizes because they offer enough capacity for multiple stops without the hassle of maneuvering a full-size trailer through downtown areas.

The 20-26 foot category serves as the bridge between regional and long-haul transport. These units can haul 10,000-20,000 pounds and fit 16-20 pallets, making them ideal for grocery distributors.

Then we reach the giants: 28-53 foot semi-trailers. The standard 53-footer can carry up to 45,000 pounds of payload and accommodate 26-30 pallets. These are the workhorses of America's food distribution system.

One of the most exciting developments is multi-temperature capability. Modern trailers can maintain different temperatures in separate compartments within the same unit. Imagine hauling ice cream at -10°F in the front section while keeping fresh lettuce at 35°F in the back - all in one trip.

The flooring in these trailers deserves special mention. T-floor decking has become the gold standard, providing excellent airflow underneath pallets while maintaining structural strength.

When it comes to manufacturers, the industry has some real heavyweights. Great Dane, Utility Trailer Manufacturing, and Hyundai Translead dominate the North American market, while European companies like Chereau (operating since 1953) and Spain's SOR Iberica (since 1970) bring decades of cold-chain expertise to the global market.

Choosing the Right Reefer Lorry for Your Operation

Selecting the perfect reefer lorry isn't just about picking the biggest one you can afford - it's about finding the right match for your specific operation.

Your cargo profile tells the whole story. Fresh produce generates heat and moisture, requiring continuous airflow and precise humidity control. Frozen goods are more forgiving with temperature fluctuations but demand rock-solid freezing capability. Pharmaceuticals often need the tightest temperature control of all.

Route characteristics matter more than you might think. Long-haul operations benefit from larger trailers with self-powered refrigeration units. Urban delivery routes favor smaller, more maneuverable units.

The eternal trade-off between payload capacity and vehicle weight becomes especially important with refrigerated transport. That powerful reefer unit and heavy insulation can reduce your available payload by 2,000-5,000 pounds compared to a standard dry van.

For detailed guidance on navigating these decisions, including financial considerations, check out our Ultimate Guide: Refrigerated Truck Lease.

Reefer Lorry vs Reefer Trailer Ownership Models

Buying new equipment gives you the latest technology and full manufacturer warranties, but means the highest upfront costs. Most financing runs 5-7 years.

The used market offers compelling alternatives, with prices typically ranging from $10,000 to $35,000 depending on age, condition, and features. Since the average reefer lorry lifespan is about 8 years with proper maintenance, a well-maintained 3-4 year old unit can provide excellent value.

Rental and leasing options provide ultimate flexibility. Daily rates run around $190 for full-size units and $160 for smaller ones, while weekly rates drop to approximately $800 and $680 respectively.

Don't forget about operating costs when calculating total ownership expenses. Budget approximately $5,500 annually for fuel and maintenance ($4,000 for diesel and $1,500 for upkeep).

Costs, Maintenance & Lifespan

Let's be honest - owning a reefer lorry isn't cheap. Beyond the initial sticker shock, these specialized vehicles demand ongoing attention and investment that can catch new operators off guard.

The numbers tell the story clearly. You're looking at roughly $4,000 annually just for fuel to keep that refrigeration unit humming. Add another $1,500 for maintenance and repairs, and you're already at $5,500 per year before considering insurance, cleaning, and unexpected breakdowns.

Insurance companies aren't doing you any favors either. Expect to pay 15-25% more than you would for a standard truck. Why? Because when a reefer unit fails, you're not just dealing with a broken truck - you're potentially looking at thousands of dollars in spoiled cargo claims.

Daily vigilance keeps your reefer running strong. Smart operators check their fuel levels every morning (most units hold about 50 gallons), verify temperature readings match the settings, and give those door seals a quick inspection.

Weekly maintenance becomes your best friend in this business. Clean air filters, check refrigerant levels, and test those defrost cycles. Modern telematics systems have revolutionized how we monitor these machines, sending real-time alerts about temperature excursions, fuel consumption patterns, and maintenance needs directly to your phone.

The monthly deep dive involves oil changes for the diesel generator, belt inspections, and thermostat calibration. Here's a pro tip: keeping annual operating hours under 4,000 significantly extends equipment life.

Cleaning requirements can't be ignored, especially if you're hauling food products. The FDA doesn't mess around with cross-contamination. Basic cleaning runs $50-100 per cycle, while deep sanitization can hit $150-250.

The reality is that most reefer lorry units last about 8 years with proper care. But we've seen well-maintained units pushing 12 years, while neglected ones barely make it to 5. The difference? Preventive maintenance versus reactive repairs.

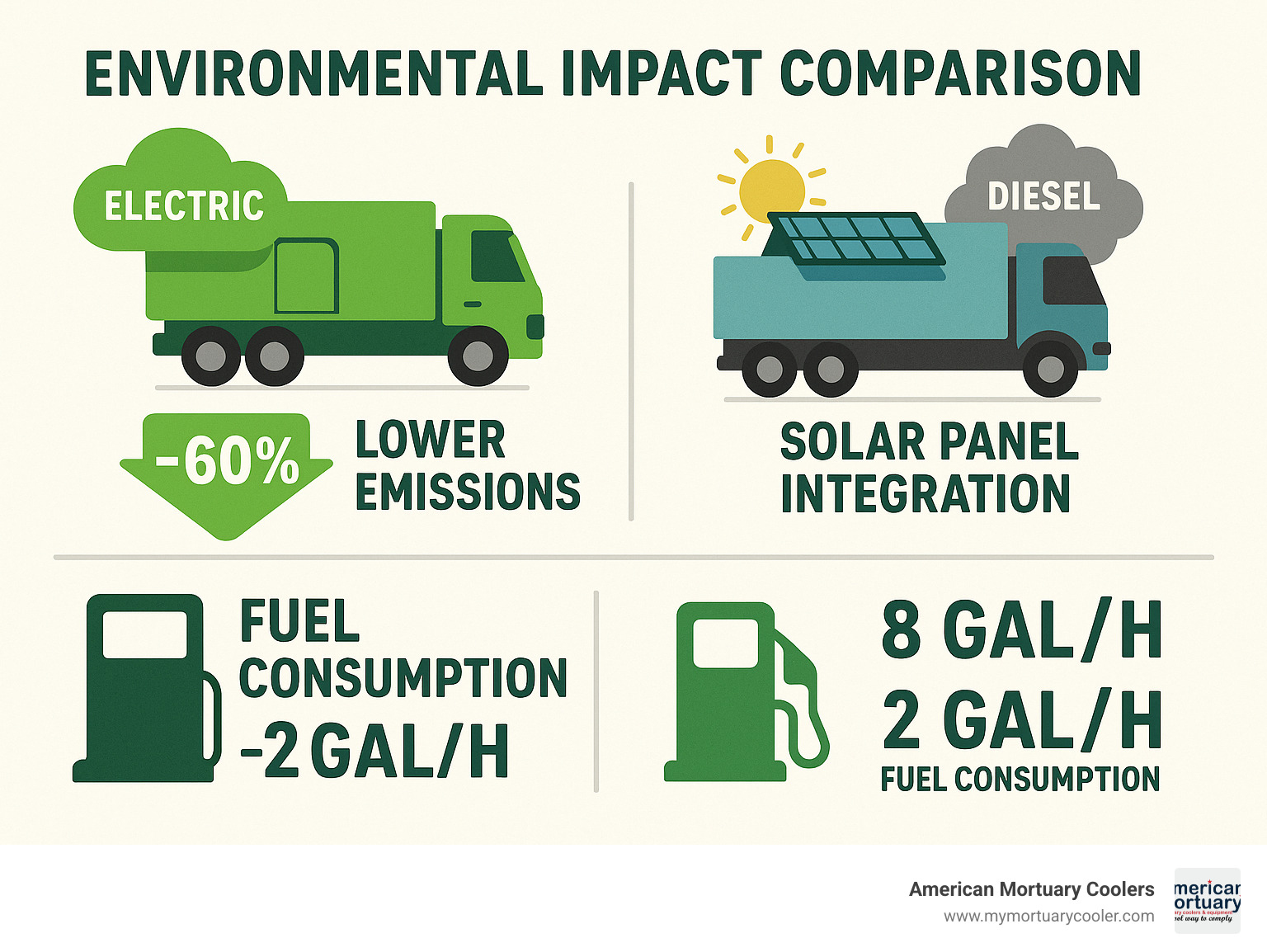

Environmental Innovations & Energy Efficiency

The refrigerated transport world is getting a green makeover, and frankly, it's about time. We're seeing innovations that would have seemed like science fiction just a decade ago.

Electric reefer units are the new kids on the block, offering zero emissions and whisper-quiet operation. They're perfect for those early morning deliveries in residential areas where diesel generators would wake the neighborhood.

Solar panels on trailers aren't just for show anymore. Modern solar-powered TRU systems can reduce diesel consumption by 20-30% in sunny conditions. For detailed insights into this technology, check out Revolutionizing Refrigeration: The SolarTechTRU Story.

The refrigerant revolution is happening quietly but significantly. Low-GWP (Global Warming Potential) refrigerants like R-452A are replacing older R-404A systems. CO2 systems are gaining ground for ultra-low temperature applications.

These environmental advances aren't just good for the planet - they're increasingly good for business. Lower fuel costs, reduced maintenance, and improved efficiency all contribute to better bottom lines.

Regulations, Safety & Best Practices

Operating a reefer lorry means navigating a complex web of regulations that can seem overwhelming at first. But don't worry – once you understand the basics, staying compliant becomes second nature.

The Department of Transportation (DOT) takes charge when your vehicle weighs over 10,000 pounds. This threshold covers virtually all commercial reefer lorry operations, which means you'll need proper licensing and documentation. Your drivers will need a Commercial Driver's License (CDL) to operate these vehicles legally.

The FDA Sanitary Transport Rule adds another layer of requirements specifically for food transport. You'll need to maintain continuous temperature logs, keep calibration certificates for all monitoring equipment, and document your chain of custody for every shipment.

Temperature documentation becomes your best friend and your legal protection. Modern reefer lorry systems automatically log temperatures, but you're responsible for ensuring those logs are accurate and complete.

The COVID-19 pandemic showed us just how versatile these vehicles can be. Refrigerated trucks were requested in Texas and Arizona as morgues filled up due to coronavirus deaths, demonstrating that reefer lorry applications extend far beyond food transport.

At American Mortuary Coolers, we've seen this specialized application firsthand. We've written extensively about this topic in our article on Freezer Trucks as Morgues: A Temporary Solution or Permanent Problem.

Best Practices for Loading & Monitoring

Getting the loading process right makes the difference between a successful delivery and a costly insurance claim. The key is understanding that your reefer lorry isn't magic – it can only maintain temperatures, not fix problems caused by poor loading practices.

Pre-cooling your trailer before loading might seem like an extra step, but it's absolutely essential. Think of it like preheating your oven – you wouldn't put a cake in a cold oven and expect good results.

Your loading technique directly affects air circulation throughout the trailer. Leave 2 inches of clearance from the side walls, 4 inches from the rear doors, and 9 inches from the ceiling. These aren't suggestions – they're requirements for proper airflow.

The choice between continuous mode and start/stop mode depends on your cargo. Fresh produce generates heat as it respires, so it needs continuous airflow. Frozen goods don't generate heat, so you can use start/stop mode to save diesel fuel.

Real-time monitoring systems have revolutionized reefer lorry operations. These systems send alerts to your phone when temperatures drift outside acceptable ranges, giving you time to respond before cargo spoils.

Safety & Compliance Checklist

Staying compliant doesn't have to be complicated if you develop good habits. Your Daily Vehicle Inspection Report (DVIR) should become as routine as checking your mirrors before driving.

Every morning, check your refrigeration unit's fuel level – running out of diesel in the middle of a delivery is both embarrassing and expensive. Verify that your temperature settings match your bill of lading.

Weekly maintenance keeps small problems from becoming big headaches. Clean or replace air filters, check refrigerant levels, and test your defrost cycles.

Monthly calibration ensures your temperature readings are accurate. A sensor that's off by just a few degrees can result in spoiled cargo or regulatory violations.

Sanitization procedures vary depending on what you're hauling, but the basics remain the same. Use approved cleaning agents, follow proper rinse and dry procedures, and document everything.

Frequently Asked Questions about Reefer Lorries

How cold can a reefer lorry get, and how is temperature maintained?

Most reefer lorry units can chill down to -20°F (-29°C), which handles pretty much everything you'd need for regular food transport. For everyday hauling, you'll see fresh produce riding at a comfortable 32-36°F (0-2°C), while frozen goods stay nice and solid at around -10°F (-23°C).

Now, if you're dealing with something really specialized like vaccines or certain medical supplies, some pharmaceutical units can drop all the way down to -85°F (-65°C). That's seriously cold – we're talking about temperatures that would make a Minnesota winter feel tropical!

The magic happens through a closed-loop refrigeration system that runs off its own diesel generator. Think of it like a giant refrigerator on wheels that never stops working. The system constantly checks the temperature inside and adjusts the compressor to keep things within 1-2 degrees of your target temperature.

Modern units are pretty smart too. They run automatic defrost cycles so ice doesn't build up on the coils, have backup temperature sensors in case one fails, and send real-time alerts to your phone if something goes wrong. Plus, they're always logging data to keep the FDA happy.

The real secret to keeping temperatures steady? Proper airflow through the trailer's air chute system and making sure you leave enough space around your cargo for the cold air to circulate.

What is the difference between a reefer lorry and a standard box truck?

The most obvious difference is that big refrigeration unit mounted on the front of a reefer lorry – it looks like a giant air conditioner with its own diesel engine and 50-gallon fuel tank. You can't miss it.

But the differences go way deeper than what you can see. Reefer trailers are built with specialized insulated walls – think metal or fiberglass with foam cores that keep the cold in and the heat out. Regular box trucks? They've got about as much insulation as a cardboard box.

All that refrigeration equipment comes with a price though. It adds 2,000-5,000 pounds of weight, which means your maximum payload drops from 48,000 lbs down to 43,000-45,000 lbs. That's a lot of cargo capacity you're trading for temperature control.

Your wallet will feel the difference too. Operating costs run about $5,500 higher each year – that's roughly $4,000 for refrigeration fuel and $1,500 for specialized maintenance. Regular box trucks just don't have these extra expenses.

Then there's all the regulatory paperwork. With a reefer lorry, you're dealing with FDA Sanitary Transport rules, temperature documentation requirements, and specialized cleaning protocols between loads. It's a whole different level of complexity.

How long does a reefer lorry typically last, and what affects its lifespan?

A well-maintained reefer lorry will typically serve you for about 8 years, though we've seen some units still running strong after 10-12 years with excellent care. On the flip side, neglected units might need major repairs or replacement after just 5-6 years.

The biggest factor in longevity is operating hours. Keep your unit under 4,000 hours annually, and you'll likely see it last well into its second decade. Push it over 6,000 hours a year, and you're asking for trouble.

Regular maintenance makes all the difference. We're talking about daily fuel and temperature checks, weekly air filter cleaning, and monthly oil changes for that diesel generator. It might seem like a lot, but it beats the alternative of a breakdown with a trailer full of spoiled food.

Operating conditions matter too. Units running in extreme heat or cold, hauling corrosive chemicals, or dealing with frequent temperature cycling from constant door openings will wear out faster. It's just the nature of the beast.

Modern telematics systems are game-changers for extending equipment life. They track everything and alert you to problems before they become expensive failures. Think of it as having a mechanic riding along who never sleeps.

The bottom line? Treat your reefer lorry right with proactive maintenance and reasonable operating conditions, and it'll take care of your business for years to come.

Conclusion & Next Steps

The journey of the reefer lorry from Frederick McKinley Jones's 1925 ice cream truck invention to today's sophisticated multi-temperature trailers shows just how essential these vehicles have become. They're not just trucks with coolers attached – they're the invisible heroes keeping our food fresh, our medicines effective, and our cold chain intact.

What strikes us most about this industry is its resilience. Even during economic downturns, that reefer load-to-truck ratio of 13.74 compared to just 7.33 for dry vans tells a powerful story. People always need fresh food, medical supplies, and temperature-controlled goods.

The numbers don't lie about opportunity. With over 90% of American food depending on refrigerated transport and 4 million refrigerated vehicles worldwide, this isn't a niche market – it's fundamental infrastructure. The consistent demand, combined with advancing technology like electric units and solar power assistance, creates exciting possibilities for both new operators and established fleets.

At American Mortuary Coolers, we've seen how critical temperature control becomes during unexpected situations. When COVID-19 overwhelmed morgue capacity, reefer lorries stepped in as temporary solutions across Texas and Arizona. This versatility demonstrates why understanding this equipment matters beyond just food transport.

Technology is making operations smarter and more profitable. Modern telematics systems help keep those annual operating hours under 4,000, extending that 8-year average lifespan significantly. Real-time monitoring prevents costly spoilage. Improved insulation materials reduce energy consumption.

The environmental innovations particularly excite us. Solar-assisted units, low-GWP refrigerants, and electric systems aren't just good for the planet – they're becoming good business. As regulations tighten and fuel costs fluctuate, these technologies offer competitive advantages.

Compliance remains non-negotiable. FDA Sanitary Transport rules, temperature documentation, and proper cleaning protocols protect both your business and public health. The good news is that modern monitoring systems make compliance easier than ever.

Our Tennessee headquarters and network across all 48 contiguous states gives us unique insight into regional differences in reefer lorry operations. What works in Florida's humidity differs from Colorado's altitude challenges.

The future looks bright for refrigerated transport. As consumers demand fresher food, faster delivery, and better traceability, the role of reefer lorries will only grow. Whether you're considering your first refrigerated vehicle or optimizing an existing fleet, the fundamentals we've covered here provide the foundation for smart decisions.

For operators looking at the bigger picture of cold storage solutions, our Comprehensive Solutions for Mortuary Needs guide shows how mobile and stationary cooling systems work together in specialized applications.

The *reefer lorry industry rewards those who understand both the technical details and business fundamentals.* From choosing between self-powered and vehicle-powered units to managing that $5,500 annual operating cost, success comes from making informed decisions based on real data rather than assumptions.

Whether you're hauling fresh produce from California farms or medical supplies to rural hospitals, these vehicles represent more than just transportation – they're essential links in chains that feed families and save lives.