Why Reefer Trucks Are Essential for Temperature-Controlled Transport

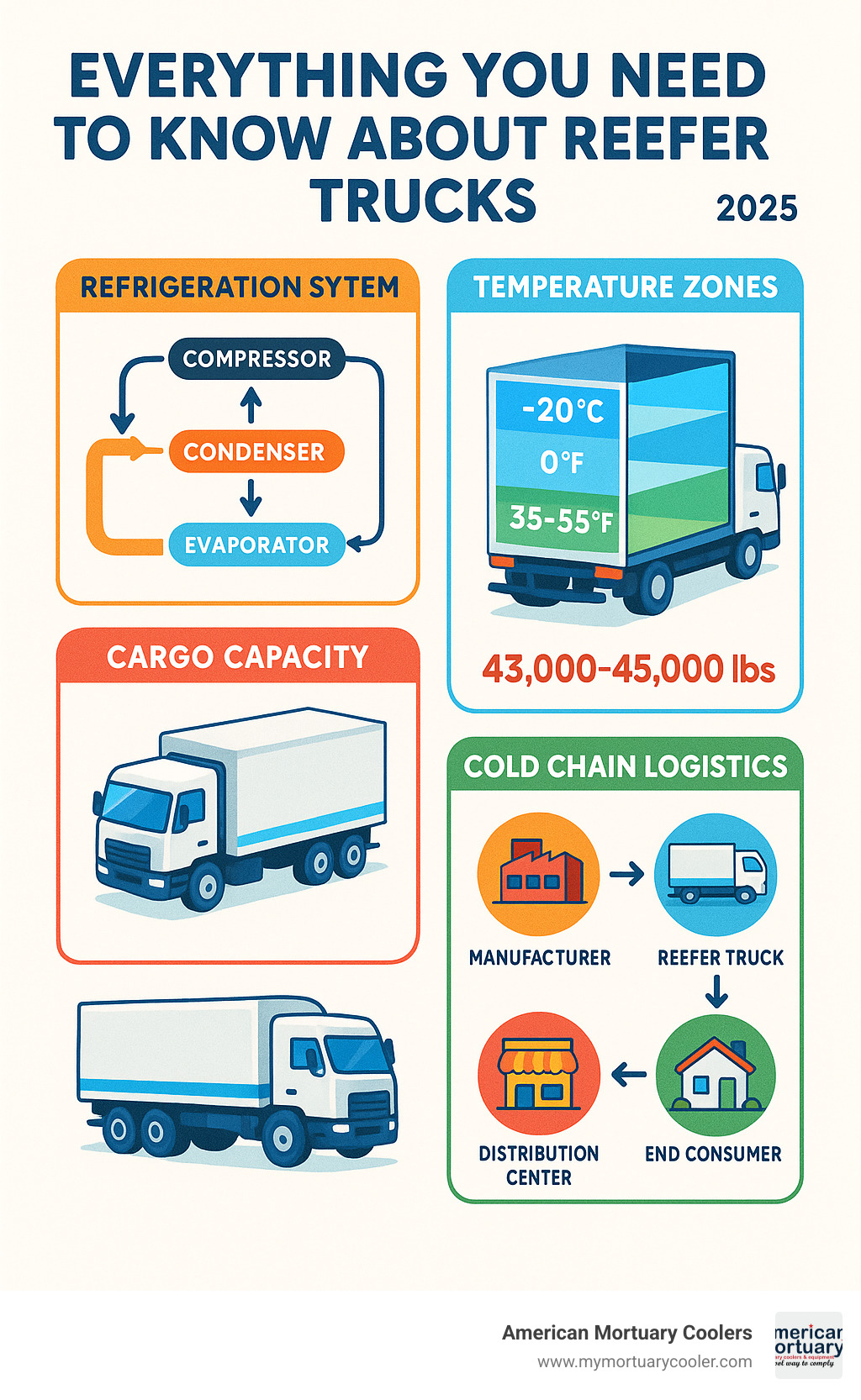

Reefer trucks are specialized refrigerated vehicles designed to transport perishable and temperature-sensitive goods while maintaining precise climate control throughout the journey. These trucks use active cooling systems - unlike simple insulated vans - to keep cargo at required temperatures ranging from -20°F to 55°F.

Key Facts About Reefer Trucks:

- Definition: Semi-trucks or box trucks with refrigerated trailers/compartments

- Temperature Range: -20°F to 55°F (-29°C to 13°C)

- Cargo Capacity: 43,000-45,000 pounds maximum load

- Standard Sizes: 14-53 feet in length

- Global Fleet: Approximately 4 million refrigerated road vehicles worldwide

- First Used: 1925 in the ice cream industry

- Power Source: Diesel generators, electric units, or cryogenic systems

The demand for reefer trucks continues growing as cold chain logistics become more critical. From fresh produce and pharmaceuticals to emergency morgue capacity during crises, these vehicles ensure product integrity across countless industries.

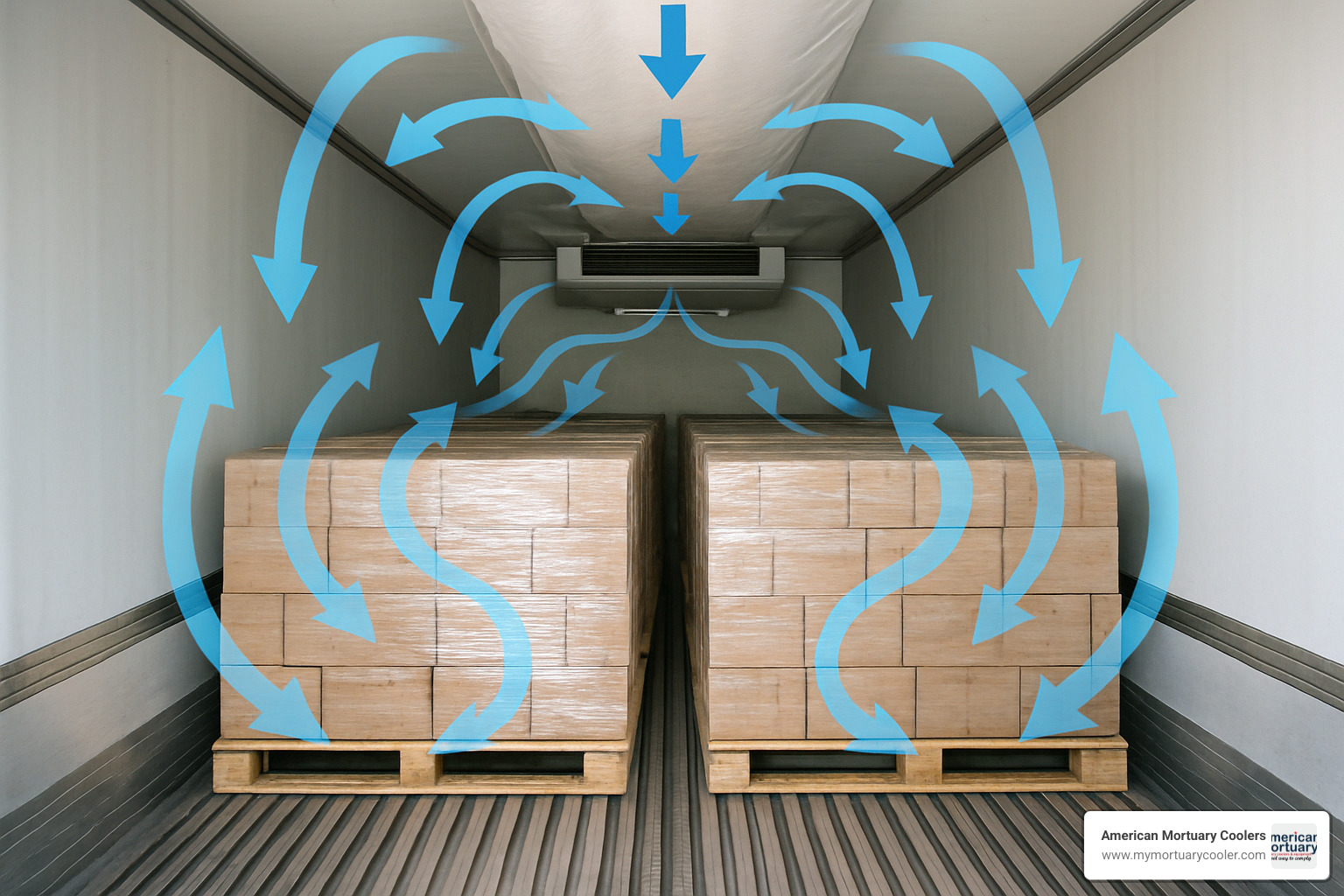

Modern reefer units work through a closed-loop refrigeration system with three main components: a compressor, condenser, and evaporator. This system cycles refrigerant to remove heat from the insulated cargo area while circulating chilled air through specialized air chutes.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in refrigerated transport solutions including reefer trucks for specialized applications. My background in cold storage systems gives me deep insight into the technical requirements and operational considerations that make reefer trucks successful in maintaining temperature-controlled environments.

Basic reefer trucks terms:

Reefer Trucks 101: How They Work & Why They Matter

Think of reefer trucks as mobile refrigerators that can travel thousands of miles while keeping your cargo at exactly the right temperature. Whether you're hauling ice cream on a scorching summer day or delivering life-saving vaccines to a remote clinic, these specialized vehicles are the unsung heroes of our modern supply chain.

The magic happens through some pretty clever engineering. Unlike a regular truck with just insulation, reefer trucks actively fight against heat trying to sneak into your cargo. They're constantly working to maintain that perfect temperature zone, whether that's keeping frozen foods solid at -20°F or ensuring fresh flowers stay crisp at 55°F.

What Is a Reefer Truck and How Does It Work?

A reefer truck gets its name from "refrigerated truck," and it's essentially a climate-controlled fortress on wheels. The key difference from a simple insulated van is that active cooling system that never stops working to protect your cargo.

Here's how the magic happens inside that refrigeration unit. The compressor takes refrigerant gas and squeezes it under high pressure, which makes it hot. That hot, pressurized gas then flows to the condenser, where it releases all that heat to the outside air and turns into liquid. Finally, the liquid refrigerant reaches the evaporator inside your cargo area, where it absorbs heat from your products and turns back into gas.

This closed-loop system doesn't actually create cold air - it's more like a heat thief that steals warmth from inside your trailer and tosses it outside. The thick foam insulation in the walls and ceiling acts like a thermal barrier, keeping the outside heat from crashing the party.

Most operators can choose how their system runs. Cycle mode saves diesel fuel by turning the unit on and off, though your temperature might fluctuate a bit. Continuous mode keeps the cooling constant, which is perfect for cargo that generates its own heat, like fresh produce that's still "breathing."

Main Refrigeration Technologies

Reefer trucks today use several different cooling technologies, and each has its sweet spot depending on your needs.

Diesel Transport Refrigeration Units (TRUs) are the workhorses of the industry. These units have their own small diesel engine that's separate from your truck's main engine. They're incredibly reliable and can keep running even when your truck is parked overnight at a rest stop.

Direct-drive units connect right to your truck's engine, which means no separate diesel engine to maintain. They're more fuel-efficient when you're cruising down the highway, but there's a catch - they can't maintain refrigeration when you're stopped.

Electric stand-by units are becoming more popular as environmental regulations tighten. When you're parked at a loading dock or truck stop with electrical hookups, you can plug in and shut off that diesel engine.

Cryogenic systems use frozen carbon dioxide or liquid nitrogen instead of mechanical refrigeration. They're whisper-quiet and produce zero emissions, which makes them perfect for urban deliveries or areas with strict noise regulations.

Solar-assisted units are the newest kids on the block. They use solar panels to help power the refrigeration system, which cuts down on fuel costs and environmental impact. Revolutionizing Refrigeration: The SolarTechTRU Story shows how this technology is really taking off in the industry.

Industries & Applications for Reefer Trucks

Reefer trucks serve way more industries than most people realize. Everyone thinks of grocery stores and restaurants, but the applications go far beyond food.

The food industry is definitely the biggest customer. From frozen pizzas that need to stay at -20°F to fresh strawberries requiring precise humidity control, reefer trucks make sure your dinner arrives in perfect condition.

The pharmaceutical industry relies heavily on temperature-controlled transport. Vaccines, blood products, and many medications lose their effectiveness if they get too warm or too cold.

Chemical companies use refrigerated transport for industrial chemicals that need specific temperature ranges to stay stable and safe.

The floral industry might surprise you. Fresh flowers are incredibly temperature-sensitive, and reefer trucks help ensure that Valentine's Day roses arrive looking perfect instead of wilted.

During emergencies, reefer trucks serve as temporary morgues when regular facilities become overwhelmed. "Refrigerated trucks requested in Texas and Arizona" during the COVID-19 pandemic showed how critical this application can be during crisis situations.

Key Specifications to Compare

When you're shopping for reefer trucks, several key specifications will determine whether a unit fits your specific needs.

Body length ranges from compact 14-foot units perfect for local deliveries to massive 53-foot semi-trailers for cross-country hauls. Most standard reefer trailers fall in the 48-53 foot range.

Payload capacity typically maxes out around 43,000-45,000 pounds, depending on the trailer's construction. A standard 53-foot trailer can accommodate up to 30 pallets.

The temperature range is crucial - most units can maintain anywhere from -20°F to 55°F, but some specialized units go even colder for specific applications.

Multi-temperature zones are a game-changer if you're hauling different products with different temperature needs. Advanced units can maintain separate temperatures in different compartments within the same trailer.

Fuel tank capacity for the refrigeration system is typically around 50 gallons, separate from your truck's main fuel tank.

Data logging capabilities are becoming standard on modern units. These systems continuously record temperature conditions and can alert you immediately if something goes wrong.

For detailed technical information, Scientific research on road-transport refrigeration provides comprehensive data on specifications and regulatory compliance requirements.

Choosing the Right Reefer Truck: Specs, Costs & Buying Tips

When you're ready to invest in reefer trucks, you'll face some big decisions. New units typically start around $100,000, while used trucks offer more budget-friendly options ranging from $34,000 to $89,000. The key is finding the sweet spot between upfront costs and long-term operational efficiency.

The price difference between new and used isn't just about the initial purchase. Mileage heavily impacts both purchase price and future maintenance costs. A high-mileage truck might seem like a bargain, but you could end up spending more on repairs and downtime.

Duty class matters too. A local delivery route needs different capabilities than cross-country hauling. Features like curbside doors can make loading and unloading much easier in urban environments, while multi-temperature zones let you carry different products in one trip.

Popular manufacturers in today's market include ThermoTech, Everest, and the Utility 3000R series. Truck chassis options range from the reliable Hino 268 for medium-duty work to Freightliner models for heavy-haul applications.

| Comparison Factor | New Reefer Truck | Used Reefer Truck |

|---|---|---|

| Initial Cost | $100,000+ | $34,000-$89,000 |

| Warranty Coverage | Full manufacturer warranty | Limited or none |

| Maintenance Costs | Lower first 3-5 years | Higher, varies by condition |

| Fuel Efficiency | Latest technology | Depends on age/condition |

| Resale Value | Higher depreciation initially | Already depreciated |

Popular Makes & Models of Reefer Trucks

The reefer truck market has some clear winners when it comes to reliability and resale value. Freightliner dominates the landscape - you'll find them everywhere, which means parts are easy to find and mechanics know how to work on them.

International trucks have earned a solid reputation for durability, especially in demanding applications. Isuzu focuses on fuel efficiency, making them perfect for operators watching every penny at the pump.

Hino trucks, particularly the Hino 268, offer a great middle ground between capability and efficiency. They're especially popular for regional routes where you need reliability without the bulk of a full-size semi.

On the trailer side, Great Dane leads the pack with innovative insulation systems and smart air distribution designs. Hyundai Translead provides solid value for operators who need quality without premium pricing.

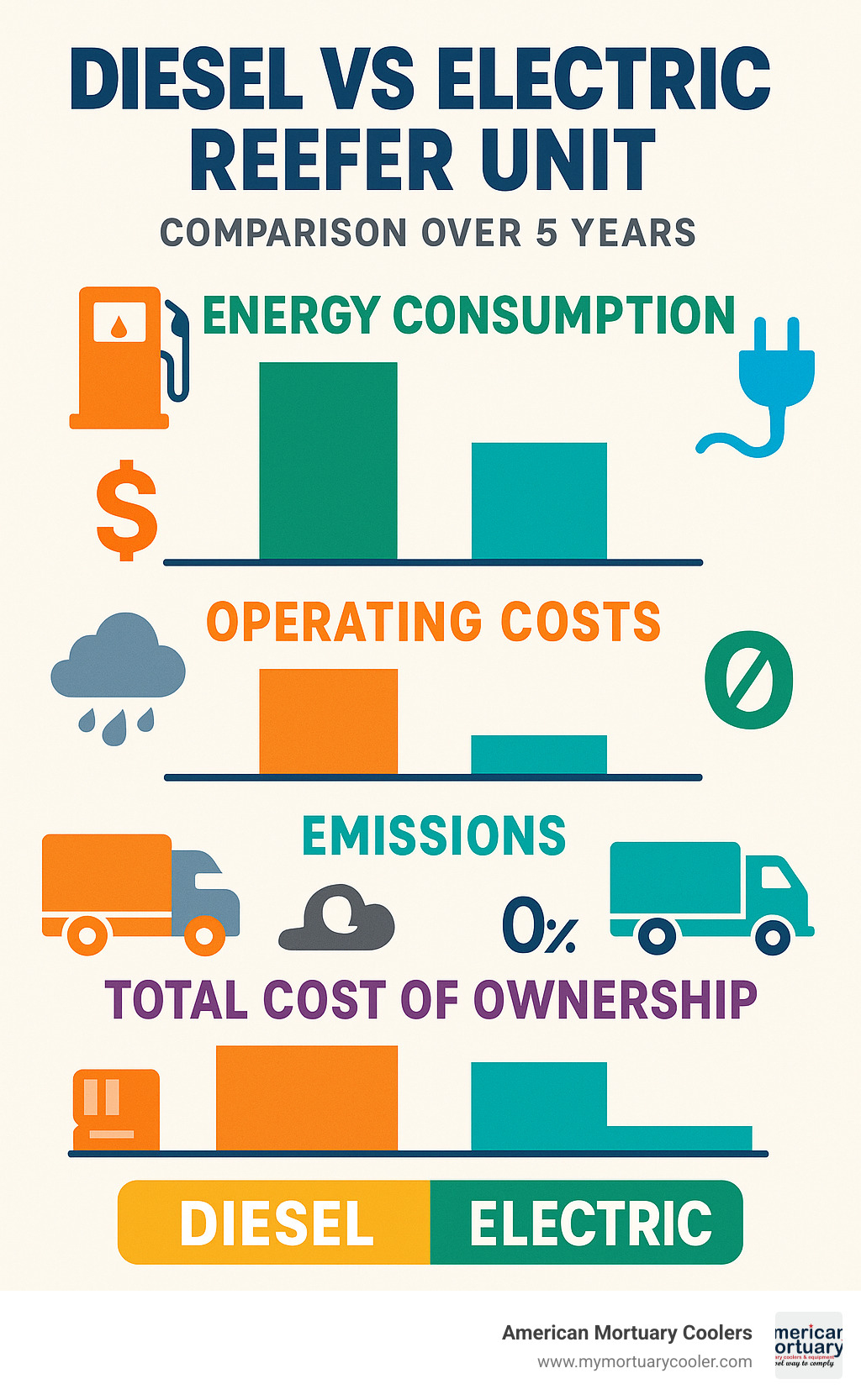

Diesel vs Electric Units – Which Wins?

This decision can make or break your operating budget. Diesel units have been the workhorse of the industry for decades, and for good reason. They run independently of your truck engine, work in any weather, and you can get them serviced almost anywhere.

A diesel reefer unit operates for thousands of hours and burns through about $4,000 worth of fuel annually. That sounds like a lot, but remember - these units run continuously, even when your truck is parked.

Electric units are the new kids on the block, and they're gaining ground fast. When you can plug into shore power at a loading dock, your operating costs drop dramatically. They're whisper-quiet too, which matters in residential delivery areas.

The catch? Electric units need infrastructure. If your routes don't have reliable electrical hookups, you'll still need diesel backup. Many operators are choosing standby plug-in capability - diesel for the road, electric when parked.

The emissions factor is huge too. Many cities are implementing low-NOx requirements, and electric units help you stay compliant while potentially qualifying for rebates and incentives.

Buying a Used Reefer Truck Checklist

Buying used reefer trucks requires detective work beyond your typical truck inspection. You're not just buying a vehicle - you're buying a mobile refrigeration system that needs to work flawlessly.

Engine hours tell only half the story. The reefer hours matter just as much, sometimes more. A truck with low mileage but high reefer hours has spent a lot of time idling with the refrigeration unit running.

Test the refrigeration performance thoroughly. Don't just check if it gets cold - verify it can reach -20°F and maintain 55°F accurately. Test both heating and cooling modes if the unit has them.

Insulation condition can make or break your efficiency. Look for any signs of damage, water intrusion, or wear around door seals. Even small compromises in insulation can cost you hundreds in extra fuel costs.

Service records are gold. A well-maintained reefer unit with documented preventive maintenance is worth paying extra for. Look for evidence of regular sensor calibration and cleaning protocols.

Don't forget about FDA sanitation requirements if you're hauling food. The trailer needs proper drainage, cleanable surfaces, and compliance with food safety regulations.

For comprehensive inspection guidance, check out A Comprehensive Guide to Reefer Trucks for detailed protocols that can save you from costly mistakes.

A good used reefer truck that's been properly maintained can serve you well for years. Take your time, do your homework, and don't rush the decision.

Operating & Maintaining Your Reefer Fleet: Costs, Compliance & Cold-Chain Safety

Running a fleet of reefer trucks isn't just about keeping wheels rolling – it's about maintaining perfect cold chain integrity while managing complex operational requirements. Understanding the full scope of ownership costs and compliance needs will make or break your refrigerated transport business.

Total Cost of Ownership Factors

The true cost of operating reefer trucks extends far beyond the sticker price. Smart fleet managers know that the refrigeration unit essentially doubles your maintenance responsibilities.

Fuel expenses hit you twice with reefers. Your truck burns diesel getting down the highway, while the refrigeration unit consumes its own fuel maintaining cargo temperatures. That separate reefer fuel averages around $4,000 annually, regardless of how efficiently you drive.

Maintenance costs multiply with refrigerated units requiring quarterly preventive maintenance beyond standard truck servicing. The refrigeration system needs sensor calibration, cleaning protocols, and component inspections that average $1,500 yearly just for the reefer unit.

Insurance premiums increase significantly for refrigerated cargo due to higher product values and spoilage risks. Cargo liability coverage becomes critical when a single trailer might carry $50,000 worth of pharmaceuticals or fresh seafood.

Driver training represents an often-overlooked expense. Operators need specialized knowledge about temperature monitoring, proper loading procedures, and emergency protocols.

Downtime costs create the biggest financial risk. When a reefer truck fails, you potentially lose the entire cargo load. The total annual operating cost for refrigerated transport averages approximately $5,500 beyond standard trucking expenses.

Incentives & Green Rebates for Zero-Emission Reefers

Government agencies and utilities recognize the environmental impact of diesel refrigeration units and offer substantial incentives for cleaner alternatives. These programs can offset much of the higher upfront costs for electric and hybrid systems.

California's CARB CORE Program leads the nation with rebates reaching $165,000 for zero-emission reefer units. That's serious money that can completely change the economics of electric refrigeration.

EPA DERA funding provides grants nationwide for retrofitting or replacing older diesel units with cleaner alternatives. These federal dollars help smaller fleets access technology that might otherwise be financially out of reach.

State tax credits vary widely but can provide substantial savings. Many states offer these incentives as part of broader air quality improvement initiatives. Some programs stack with federal incentives, creating compelling financial packages.

Utility rebates for electric standby capability help reduce grid demand during peak hours while lowering your operating costs.

For detailed guidance on available programs, reference More info about Incentives & Rebates to steer the complex landscape of funding opportunities.

Ensuring Food Safety & Regulatory Compliance

Operating reefer trucks for food transport means navigating FDA regulations that can shut down your operation if ignored. The Sanitary Transportation Rule isn't just paperwork – it's about protecting public health and your business reputation.

Temperature monitoring requires continuous digital logging with real-time alerts for deviations. Modern systems automatically record temperature data and can immediately notify dispatchers when cargo temperatures drift outside acceptable ranges.

Cleaning protocols between loads follow strict FDA guidelines requiring proper drainage systems and cleanable interior surfaces. Cross-contamination between different food products can create serious liability issues.

Driver training becomes critical for regulatory compliance. Operators must understand proper loading procedures, appropriate temperature settings for different cargo types, and emergency response protocols when equipment fails.

Audit preparation requires maintaining detailed records of temperature logs, cleaning procedures, and maintenance activities. Regulatory inspectors can appear without warning, and incomplete documentation can result in fines or operating restrictions.

Regular internal audits help identify potential compliance issues before they result in product loss or regulatory violations. The investment in proper procedures and documentation pays dividends in reduced liability and smoother operations.

Future of Refrigerated Transport: Trends, Innovations & Sustainability

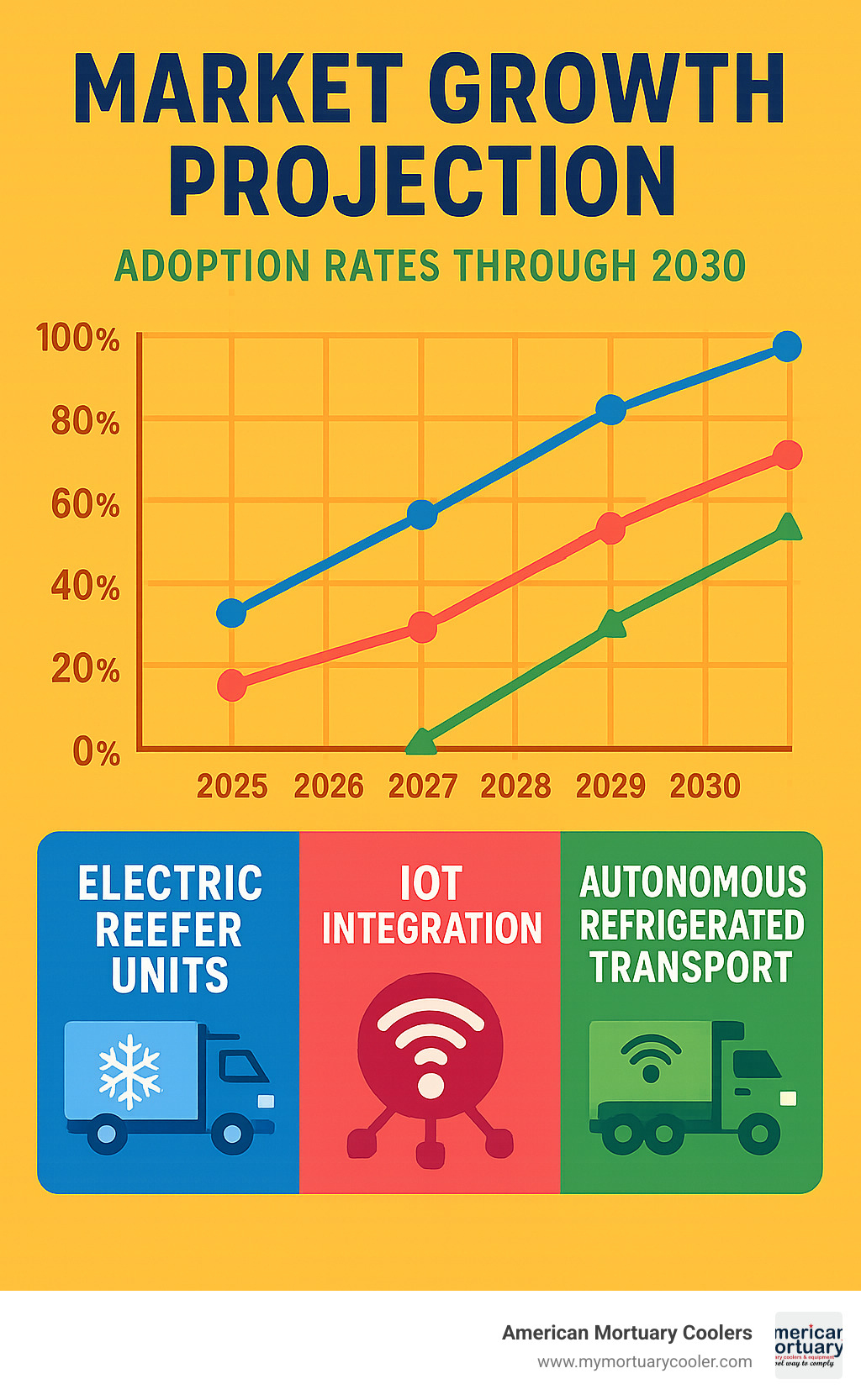

The reefer truck industry stands at an exciting crossroads where cutting-edge technology meets the timeless need for reliable cold chain transport. The innovations coming down the pipeline are genuinely game-changing.

Electric axle power represents perhaps the most significant shift we're seeing. These systems completely eliminate the need for separate diesel engines by integrating electric drive axles with battery-powered refrigeration units. It's particularly exciting for urban delivery applications where noise and emissions matter most.

The heart of this electric revolution lies in advanced battery systems. Modern lithium-ion battery packs can now power refrigeration units through entire overnight periods without needing shore power connections. This means drivers can maintain perfect temperatures even when parked at locations without electrical hookups.

Solar integration adds another layer of efficiency that's becoming increasingly practical. Roof-mounted solar panels supplement battery charging during daylight hours and reduce dependency on grid power during extended stops.

Perhaps the most transformative development is the integration of IoT and telematics systems. These internet-connected sensors provide real-time monitoring of temperature, humidity, door openings, and overall system performance from anywhere in the world. Fleet managers can now spot problems before they become disasters.

Predictive maintenance takes this connectivity a step further. AI-driven systems analyze performance data patterns to predict component failures before they actually occur. This technology dramatically reduces unexpected downtime - something that can mean the difference between a successful delivery and a trailer full of spoiled goods.

The industry is also embracing lightweight composites that reduce trailer weight while maintaining superior insulation performance. These advanced materials increase payload capacity without sacrificing temperature control.

Multi-use coldtainers represent an innovative approach to flexible cold storage. These mobile refrigerated units can function independently of trucks, providing temporary cold storage wherever it's needed.

Looking toward the future, autonomous integration promises to revolutionize refrigerated transport entirely. Self-driving technology specifically adapted for reefer trucks includes automated temperature management and intelligent route optimization.

Risk mitigation software helps operators identify potential problems before they impact deliveries. These systems analyze weather patterns, traffic conditions, and historical performance data to suggest optimal routes and timing.

The market projections show impressive growth across all these technology areas. Electric reefer trucks are expected to capture significant market share by 2030, driven by both regulatory requirements and operational advantages.

These innovations promise to make refrigerated transport more efficient, environmentally friendly, and operationally intelligent while maintaining the rock-solid reliability that cold chain logistics absolutely demand.

Frequently Asked Questions about Reefer Trucks

When you're considering reefer trucks for your business, certain questions come up again and again. Let me address the most common concerns I hear from customers looking into refrigerated transport solutions.

What temperatures can reefer trucks maintain?

Reefer trucks are remarkably versatile when it comes to temperature control. Most standard units can maintain temperatures from -20°F (-29°C) all the way up to 55°F (13°C), which covers just about everything you'd need to transport.

For frozen goods like ice cream or frozen vegetables, you'll typically run at -10°F to 0°F. Fresh produce usually travels between 32°F and 40°F, while pharmaceuticals might need very specific temperatures like 36°F to 46°F for vaccines.

The really impressive part is that these units don't just cool - they can heat cargo too. If you're transporting something sensitive to cold weather, the system will warm the cargo area to prevent damage. Some specialized units can even reach -40°F for ultra-frozen products, though that's getting into pretty specialized territory.

How often should a reefer unit be serviced?

Here's where reefer trucks differ significantly from regular trucks - the refrigeration system needs its own maintenance schedule. Plan on preventive maintenance every 500 to 1,000 operating hours, which typically works out to about quarterly service.

During these service visits, technicians will check refrigerant levels, clean or replace air filters, inspect belts and hoses, and calibrate temperature sensors. It might seem like a lot, but trust me - this regular maintenance prevents the kind of catastrophic breakdowns that can cost you an entire load of spoiled cargo.

Many smart operators schedule their maintenance during slower business periods to avoid downtime during peak seasons. The few hundred dollars you spend on quarterly maintenance can save you thousands in emergency repairs and lost cargo.

Are electric reefers eligible for federal rebates?

This is where things get exciting for fleet operators looking to go green. Electric and hybrid reefer trucks qualify for some pretty substantial incentives that can make the higher upfront costs much more manageable.

The EPA DERA program offers grants that can cover a significant portion of your upgrade costs. State programs vary, but California's CARB CORE program is particularly generous, offering up to $165,000 for qualifying zero-emission refrigeration units.

Don't forget about utility rebates either - many electric companies offer incentives for equipment that can plug into the grid instead of running diesel generators. The exact incentives available depend on where you're located and what type of operation you're running, but it's not unusual to see 50-80% of the premium cost covered by various programs.

The paperwork can be a bit involved, but most reefer truck dealers can help you steer the application process and identify which programs you qualify for.

Conclusion

The journey of reefer trucks from their humble beginnings in 1925 to today's sophisticated mobile refrigeration systems tells a remarkable story of innovation and necessity. What started as a solution for ice cream delivery has evolved into the backbone of our modern cold chain, moving everything from life-saving vaccines to fresh strawberries across millions of miles every day.

These specialized vehicles do more than just keep things cold - they're the invisible heroes ensuring our food stays fresh, our medicines remain effective, and our economy keeps moving. With approximately 4 million refrigerated vehicles worldwide working around the clock, they've become as essential to daily life as electricity or running water.

The technology continues advancing at an impressive pace. Electric and hybrid systems are making these trucks cleaner and quieter, while IoT sensors and predictive maintenance are making them smarter and more reliable. Government incentives are helping offset the higher costs, making the transition to greener technology financially attractive for fleet operators.

For businesses considering adding reefer trucks to their operations, the math often works in your favor. Yes, the upfront costs are higher - sometimes $50,000 or more above a standard truck. But the premium freight rates, reduced empty miles, and growing demand for temperature-controlled transport often more than compensate for these additional costs.

At American Mortuary Coolers, we've spent years perfecting refrigeration technology for specialized applications. From our Tennessee headquarters, we've delivered custom cooling solutions across all 48 contiguous states, and we understand what it takes to maintain precise temperature control when it matters most. While our expertise focuses on mortuary cooling equipment, we deeply appreciate the engineering excellence that makes reefer trucks such reliable workhorses.

The cold chain depends on these remarkable vehicles more than most people realize. Every time you grab fresh produce at the grocery store, pick up a prescription at the pharmacy, or receive a package of frozen goods, there's a good chance a reefer truck played a role in getting it there safely.

Whether you're a fleet manager evaluating your next equipment purchase, a driver considering specializing in refrigerated transport, or simply someone curious about the technology that keeps our modern world running smoothly, understanding these vehicles helps you appreciate the complex logistics that make our interconnected economy possible.

The future looks bright for refrigerated transport. As sustainability goals drive continued innovation and technology makes these systems even more efficient and intelligent, reefer trucks will continue evolving to meet our growing needs for reliable, environmentally responsible cold chain solutions.

For more detailed information about refrigerated transport solutions, visit More info about Refrigerated Truck Options.