What is a Shipping Container Cooler?

A shipping container walk in cooler is a refrigerated shipping container (also called a "reefer") that's been repurposed as a stationary cold storage unit. These containers maintain precise temperatures from -85°F to over 100°F using integrated cooling systems, making them ideal for businesses that need reliable refrigeration without the cost and complexity of traditional walk-in coolers.

Quick Facts About Shipping Container Coolers:

- Cost: 40ft used units available for £7-8k (about 1/4 the price of similar walk-in freezers)

- Sizes: Standard 20ft and 40ft lengths, 8ft wide

- Temperature Range: -85°F to +100°F capability

- Insulation: R-value between 20-30 (polyurethane foam)

- Power: Requires 3-phase electrical (460/480V)

- Lifespan: 10-15 years with proper maintenance

Originally designed to transport temperature-sensitive cargo across oceans, these containers feature polyurethane foamed-in-place insulation - the cold storage industry's preferred method - along with heavy-duty construction that can withstand harsh outdoor conditions.

Unlike traditional walk-in coolers, shipping container coolers offer unique advantages: they're portable, weather-resistant, and can be placed outdoors without additional building requirements. They're also considered "equipment" under IRS Section 179, potentially qualifying for significant tax deductions.

However, they're not perfect for every situation. These units work best for static storage with infrequent access rather than high-traffic applications. They require substantial electrical power and aren't designed to freeze products from room temperature - only to maintain set temperatures.

At its core, a refrigerated shipping container, or "reefer," is a temperature-controlled portable shipping container. While originally crafted for intermodal freight transportation, moving temperature-sensitive cargo across vast distances, their robust design and integrated cooling systems make them perfect candidates for conversion into static cold storage.

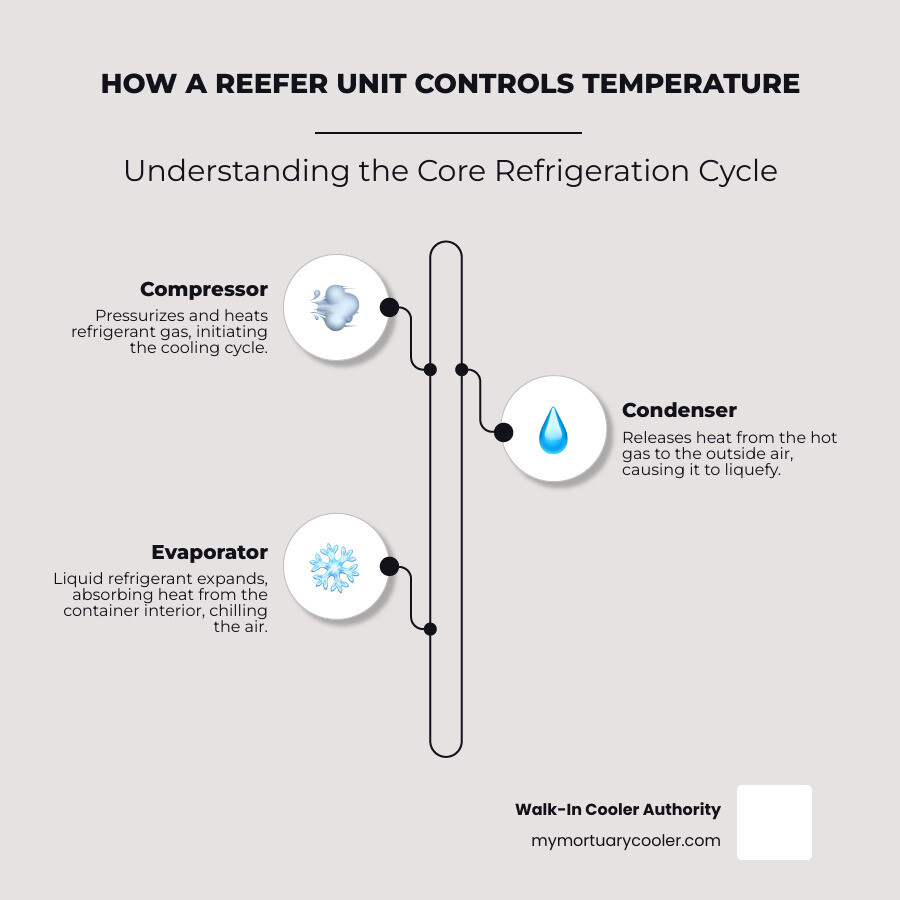

What sets a reefer apart from a standard shipping container? The most significant difference lies in its built-in refrigeration unit and superior insulation. A standard container is merely a steel box, while a reefer is a sophisticated climate-controlled environment. Reefers feature an integrated cooling unit, comprising a compressor, evaporator fans, condenser, and a precise controller, all working in harmony to maintain a set temperature. The walls aren't just steel; they're heavily insulated, typically with polyurethane foam sandwiched between a stainless steel interior and an aluminum sheet exterior, offering an impressive R-value between 20 and 30.

Another key differentiator is the flooring. Unlike the plywood floors of traditional containers, reefers boast specialized T-bar aluminum flooring. This design isn't just for show; it's engineered to facilitate consistent airflow beneath the cargo, ensuring even temperature distribution throughout the container. This makes them ideal for various walk-in cooler applications, from storing fresh produce on a farm to housing inventory for a busy restaurant.

Reefer vs. Traditional: A Head-to-Head Comparison

Choosing between a shipping container walk in cooler and a traditional walk-in unit isn't just about cold storage – it's about finding the right fit for your business needs, budget, and future plans. Let's break down how these two options stack up against each other.

The Advantages of a Shipping Container Cooler

The biggest game-changer with shipping container coolers is their portability. Unlike traditional walk-in coolers that become permanent parts of your building, these units can move with you. Planning to expand to a new location? Need temporary cold storage for a busy season? Your reefer can be loaded onto a truck and relocated wherever you need it. Try doing that with a traditional walk-in cooler!

Durability is another major win. These containers were built to survive ocean voyages – we're talking about 14-gauge steel construction that can handle salt spray, extreme weather, and constant movement. That same ruggedness makes them perfect for outdoor placement, giving you cold storage options that don't require valuable indoor real estate.

The quick deployment factor is hard to beat. While traditional walk-in coolers require weeks or months of construction, a shipping container cooler can often be delivered and operational within days. Once it's on level ground with proper electrical hookup, you're basically ready to go.

Weather resistance comes standard with these units. Rain, snow, heat waves – they've seen it all during their shipping careers. This outdoor capability opens up placement options that simply aren't available with traditional indoor-only units.

Here's something your accountant will love: significant tax benefits. Since these containers are considered "equipment" rather than permanent structures, they often qualify for equipment write-offs under the IRS Section 179 deduction. This could mean deducting the full purchase price in the year you buy it – definitely worth discussing with your tax professional.

Cost-Effectiveness: Purchase, Rental, and Operation

Let's talk numbers, because this is where shipping container coolers really shine.

The purchase price difference is eye-opening. A quality used 40ft refrigerated container typically runs £7,000-£8,000, while a comparable traditional walk-in cooler can cost four times that amount. Even new, modified units with fresh refrigeration systems come in at competitive prices when you factor in the total cost of traditional construction.

Rental costs make these units accessible for short-term needs too. Daily rates typically range from $30-$85, making them perfect for seasonal businesses, special events, or handling unexpected demand spikes.

The cost savings vs. traditional build go beyond just the unit price. You're eliminating construction costs, permits, and the time value of lengthy installation processes. Plus, you get more actual cold storage space for your money.

| Feature | Shipping Container Cooler (Reefer) | Traditional Walk-In Cooler |

|---|---|---|

| Upfront Cost | Significantly lower (used units 1/4 price of traditional) | Higher, includes construction and installation |

| Installation Time | Quick deployment, often plug-and-play | Weeks to months for construction and assembly |

| Portability | Highly portable, easy to relocate | Permanent fixture, difficult/costly to move |

| Site Requirements | Level ground, electrical hookup, airflow clearance outdoors | Dedicated indoor space, often requires structural modifications |

Potential Challenges and Limitations

Now, let's be honest about where shipping container coolers might not be the perfect fit.

Power requirements are substantial. These units need 3-phase electrical service – typically 460/480V with a 32-amp, motor-rated circuit breaker. If your facility only has standard 208/230V service, you'll need a transformer, which adds to your setup costs. Trying to run these on household power just won't work effectively.

Accessibility can be a challenge for high-traffic operations. Those heavy cargo doors that provide excellent security and temperature sealing aren't designed for constant opening and closing. If your staff needs to access inventory every few minutes throughout the day, the cumbersome doors become a real inconvenience. These units work best for static storage with infrequent access – maybe once or twice daily.

Noise levels from the refrigeration unit might be noticeable, especially if you're placing the container near offices or residential areas. It's not overwhelming, but it's something to consider when planning placement.

Maintenance needs are real too. Like any refrigeration equipment, these units require regular attention – seal inspections, refrigeration system servicing, and routine cleaning to keep everything running smoothly. The good news is that many refrigeration technicians are familiar with these systems since they're widely used in the shipping industry.

The bottom line? Shipping container coolers aren't ideal for high-traffic use, but they're fantastic for businesses that need reliable, cost-effective cold storage with the flexibility to adapt to changing needs.

A Buyer's Guide to the Shipping Container Walk In Cooler

Finding the perfect shipping container walk in cooler doesn't have to be overwhelming. Think of it like buying a car - you need to know what size fits your needs, what features matter most, and how to spot a quality unit that'll serve you well for years to come.

Types and Sizes to Consider

The good news? Shipping containers come in beautifully standardized sizes, so you won't be scratching your head over dozens of confusing options.

Most businesses choose between standard 20ft or 40ft lengths, both running 8ft wide. A 20ft container gives you roughly 160 square feet of cold storage - perfect for smaller operations like food trucks or boutique farms. Step up to a 40ft unit, and you're looking at around 320 square feet of space. That's enough room to handle serious inventory for busy restaurants or larger agricultural operations.

Need more headroom? High-Cube (HC) containers add an extra foot of height at 9.5ft tall instead of the standard 8ft. This extra space is a game-changer if you're planning to install tall shelving or need room for overhead equipment. Yes, they cost a bit more, but that vertical space often pays for itself in storage capacity.

Now, if your needs go beyond standard refrigeration, there are some fascinating specialized units to consider. Super Freezers can reach extreme temperatures from -40°C down to -85°C - essential for medical supplies, pharmaceuticals, or specialty frozen foods that need deeper freezing than your typical ice cream.

Controlled Atmosphere (CA) containers are the high-tech option. These units don't just control temperature; they actually manage the air inside by adjusting oxygen, carbon dioxide, and nitrogen levels. It's like putting your products in a perfectly controlled bubble that slows down aging and spoilage. Florists and produce sellers love these for extending the life of delicate items.

Key Features to Inspect Before You Buy

When you're ready to make a purchase, certain features will make or break your experience with a shipping container walk in cooler. Let's walk through what really matters.

Insulation quality is absolutely critical - it's what keeps your products cold and your energy bills reasonable. Look for polyurethane foamed-in-place insulation every time. This isn't just industry preference; it's the gold standard because it creates a seamless thermal barrier. You want an R-value between 20 and 30 - the higher the number, the better the insulation performs and the less you'll spend on electricity.

The temperature control system is the brain of your operation. Modern units come with digital controllers that precisely monitor and adjust conditions automatically. These systems can maintain temperatures from -85°F to 100°F, so make sure the controller can handle your specific range. The last thing you want is a unit that can't maintain the exact temperature your products need.

Flooring type might seem minor, but it affects both functionality and maintenance. T-rail aluminum floors are the workhorses - their corrugated design creates channels for air circulation underneath your stored items, ensuring even cooling throughout the container. They're also built tough enough for pallet jacks and forklifts. Some units have flat floors instead, which are easier to clean but don't provide the same airflow benefits.

Door type deserves serious consideration based on how you'll use your cooler. Standard cargo doors provide excellent security and tight sealing, but they're heavy and can be awkward for frequent access. If you're planning true walk-in functionality, custom walk-in doors make daily operations much smoother. These pedestrian-friendly doors often include internal release mechanisms - a crucial safety feature, especially for freezer applications.

Unit condition comes down to balancing budget with peace of mind. New units offer warranties and the latest technology, while used units can save significant money if you choose wisely. For used containers, always request a Pre-Trip Inspection (PTI). This comprehensive test checks that the machinery runs properly, the unit maintains temperature correctly, and everything is clean and damage-free.

When evaluating any used unit, ask about maintenance history and look for signs of wear on critical components like door seals, the refrigeration unit, and interior surfaces. A well-maintained used container can serve you just as well as a new one at a fraction of the cost.

For those who want to dive deeper into the technical details, A technical guide to reefer units provides comprehensive information about how these systems work and what to look for during inspection.

Setup, Customization, and Long-Term Care

Getting your shipping container walk in cooler up and running properly is easier than you might think, but there are some important details that can make or break your success. Let's walk through everything you need to know to set it up right and keep it running smoothly for years to come.

Site Preparation and Power Requirements

The foundation of a successful container cooler setup starts with proper site preparation. Think of it like setting up a really big appliance – you want everything just right before you plug it in.

Your container needs to sit on level ground that's stable and well-draining. This isn't just about looks – an uneven surface can actually twist your container over time, which messes up door seals and creates expensive air leaks. A simple concrete pad or even well-compacted gravel works great.

Here's something many people don't consider: your refrigeration unit is basically a giant heat pump that needs room to breathe. Make sure you have at least 3-5 feet of clear space around the unit for proper airflow clearance. When that airflow gets blocked, your unit works overtime trying to stay cool, which drives up your electric bill and shortens its life.

Now, let's talk about the elephant in the room – electrical setup. These units are serious power consumers, typically requiring 460/480V 3-phase power with at least a 30-amp motor-rated circuit breaker (that's a D-rated breaker, not your standard household type). If you only have 208/230V available, you'll need transformers and a beefier 50-amp breaker to handle the load.

Don't try to cut corners here – always have a licensed electrician handle the installation. The startup current on these units can be significant, and improper wiring isn't just inefficient, it's dangerous.

Modifying Your Shipping Container Walk In Cooler for Optimal Use

Right out of the box, your reefer is ready to keep things cold. But with a few smart modifications, you can transform it into a truly functional workspace that meets your specific needs.

Interior shelving is usually the first upgrade people make, and for good reason. Whether you go with simple wire racks or heavy-duty stainless steel shelving depends on what you're storing and how much weight you're dealing with. The key is choosing materials that can handle the cold and humidity without rusting or warping.

Good LED lighting makes all the difference when you're trying to find something in a cold, dark space. LEDs are perfect for this application because they're energy-efficient, produce almost no heat, and give you bright, clear visibility. Just make sure the fixtures are rated for cold, damp environments.

If you're planning to wash down the interior regularly, adding drainage systems will save you countless headaches. This might mean sloping the floor toward a drain that connects to your exterior waste system. Many quality reefers already have drainage features built in, but you might need to connect them to your site's drainage.

Here's where things get interesting for frequent access: replacing those heavy cargo doors with a proper walk-in door installation. Standard cargo doors are great for security and sealing, but they're not exactly user-friendly for daily operations. A custom walk-in door makes life so much easier and can include safety features like internal release mechanisms.

Even with a walk-in door, consider adding thermal curtains just inside the entrance. These simple additions dramatically reduce cold air loss every time someone opens the door, which keeps your energy costs down and helps maintain consistent temperatures.

Lifespan, Maintenance, and Safety

With reasonable care, your shipping container walk in cooler should give you solid service for 10-15 years. The key word there is "reasonable care" – these units are tough, but they're not maintenance-free.

Routine cleaning is your first line of defense against problems. We're talking about wiping down surfaces, keeping drainage clear, and preventing ice buildup around the refrigeration unit's interior components. A clean unit is an efficient unit, and it prevents those nasty odors and bacterial growth that can contaminate your stored goods.

The most common problem we see? Failed seals. Seal inspection should be part of your regular routine because even small leaks can cause major temperature fluctuations and waste energy. Check door seals, panel joints, and anywhere two surfaces meet. If you spot damage, get it fixed quickly – small problems become big problems fast in refrigeration.

Your refrigeration unit needs professional attention periodically. Servicing the refrigeration unit includes checking refrigerant levels, cleaning coils, and inspecting electrical components. This isn't DIY territory – you want qualified technicians who understand these systems. When you need professional help, the Reefer machinery service locator can connect you with certified technicians in your area.

Safety isn't optional, especially if people will be entering the unit regularly. Safety regulations vary by location, but freezer units typically require man-trap alarms and internal release mechanisms to prevent anyone from getting accidentally locked inside. Proper lighting and clear safety signage aren't just good ideas – they're often required by local codes.

The bottom line? Treat your container cooler like the valuable piece of equipment it is, and it'll serve you well for many years to come.

Frequently Asked Questions about Shipping Container Coolers

Over the years, we've helped countless businesses find the benefits of shipping container walk in coolers. Here are the questions we hear most often – and the honest answers that help you make the right choice.

What industries commonly use shipping container coolers?

You might be surprised by how many different businesses find these versatile units perfect for their needs. The Food & Beverage industry leads the pack – think restaurants needing extra cold storage during busy seasons, farms storing fresh produce right where it's harvested, and catering companies bringing refrigeration to outdoor events. Breweries and wineries love them too, especially for overflow storage during peak production times.

The pharmaceutical sector relies heavily on these units because of their precise temperature control. Vaccines, insulin, and other life-saving medications need exact temperatures, and reefers deliver that reliability. We've seen medical facilities use them as backup storage and research labs rely on them for temperature-sensitive samples.

Florists have become big fans of shipping container coolers. Those delicate flowers and plants need just the right cool environment to stay fresh, and a reefer gives them that control without the cost of building a traditional cold room.

Event catering is where the portability really shines. Whether it's a wedding in a remote location or a festival that needs cold storage for thousands of meals, these units go where traditional coolers simply can't. Disaster relief operations use them the same way – bringing refrigeration to areas where infrastructure has been damaged or doesn't exist.

Can a reefer container freeze products from room temperature?

This is probably the most important thing to understand about these units: no, a reefer container is not designed to freeze products from room temperature. It's a common misconception that can lead to disappointment and equipment problems.

Think of your shipping container walk in cooler as a really good thermostat, not a blast freezer. Its job is temperature maintenance – keeping things that are already cold or frozen at exactly the right temperature. If you load it up with warm products and expect it to bring them down to freezing, you're asking for trouble.

This kind of strain on the unit leads to higher energy bills, poor performance, and potentially expensive repairs. The refrigeration system works overtime trying to do something it wasn't designed for, and that's when things break down. If you need to freeze products from room temperature, you'll need specialized blast freezing equipment first, then transfer everything to your reefer for long-term storage.

Are there special tax benefits for buying a reefer container?

Yes, and this is where things get really interesting from a business perspective! Since relocatable containers used for business are considered "equipment" under Section 179 of the IRS tax code, you might qualify for some substantial tax breaks.

This classification means you could potentially deduct the full purchase price of your container in the year you put it into service, rather than spreading that deduction over many years like you would with a building. For a business buying a $30,000 reefer, that could mean $30,000 in immediate tax deductions – subject to Section 179 limits, of course.

The potential for full purchase price deduction makes these units even more attractive when you're comparing them to traditional walk-in coolers. We always recommend using a Section 179 tax calculator to see what this might mean for your specific situation, and definitely talk to your accountant. Tax laws change, and every business situation is different, but this benefit alone has convinced many of our customers to make the switch to container-based cold storage.

Conclusion: Is a Shipping Container Cooler Your Best Choice?

After exploring all the ins and outs of shipping container walk in coolers, you're probably wondering if one is right for your business. The answer really depends on your specific needs, but we've seen these versatile units transform operations across countless industries.

The financial benefits alone make them worth considering. A used 40ft reefer at roughly a quarter the price of a traditional walk-in cooler? That's hard to ignore. Add in the cost-effectiveness of quick deployment without construction headaches, and you're looking at serious savings both upfront and long-term.

But it's not just about the money. The portability factor is a game-changer for many businesses. Need to relocate? No problem. Seasonal operation? Perfect. Outdoor placement without building permits? You got it. These units are built like tanks - they're durable enough to handle whatever Mother Nature throws at them while keeping your products at the perfect temperature.

Of course, they're not magic boxes. You'll need to consider some practical realities. The power supply requirements are substantial - we're talking 3-phase electrical that might need transformers and professional installation. If your operation involves constant access with doors opening every few minutes, a traditional walk-in might serve you better. And like any piece of complex equipment, regular maintenance is essential to keep everything running smoothly.

The sweet spot for these units? Static storage where you're accessing inventory once or twice a day rather than constantly. Think farms storing seasonal produce, restaurants needing overflow space, or any business where reliable cold storage trumps high-traffic convenience.

At Walk-In Cooler Authority, we've built our reputation on understanding exactly what businesses need for effective cold storage. While we're known as America's trusted authority in mortuary and funeral supplies, our expertise in refrigeration extends far beyond that specialty. We know that whether you're preserving flowers, food, or pharmaceuticals, the principles of reliable cold storage remain the same.

The tax benefits under Section 179 can make the decision even easier - potentially deducting the full purchase price in the first year is nothing to sneeze at. Just remember to consult with your tax professional to see how this applies to your situation.

Ready to crunch some numbers and see if a shipping container walk in cooler makes sense for your operation? We're here to help you steer the options and find the perfect solution for your cold storage needs. Learn more about the costs of walk-in freezers and find how these innovative containers might just be the answer you've been looking for.