Why Your Business Needs a Walk-In Cooler Specialist

If you're looking for a walk-in cooler specialist, here's what you need to know:

- A walk-in cooler specialist provides installation, maintenance, repair, and emergency services for commercial refrigeration units

- Look for specialists with EPA 608 certification, manufacturer training, and at least 5+ years of experience

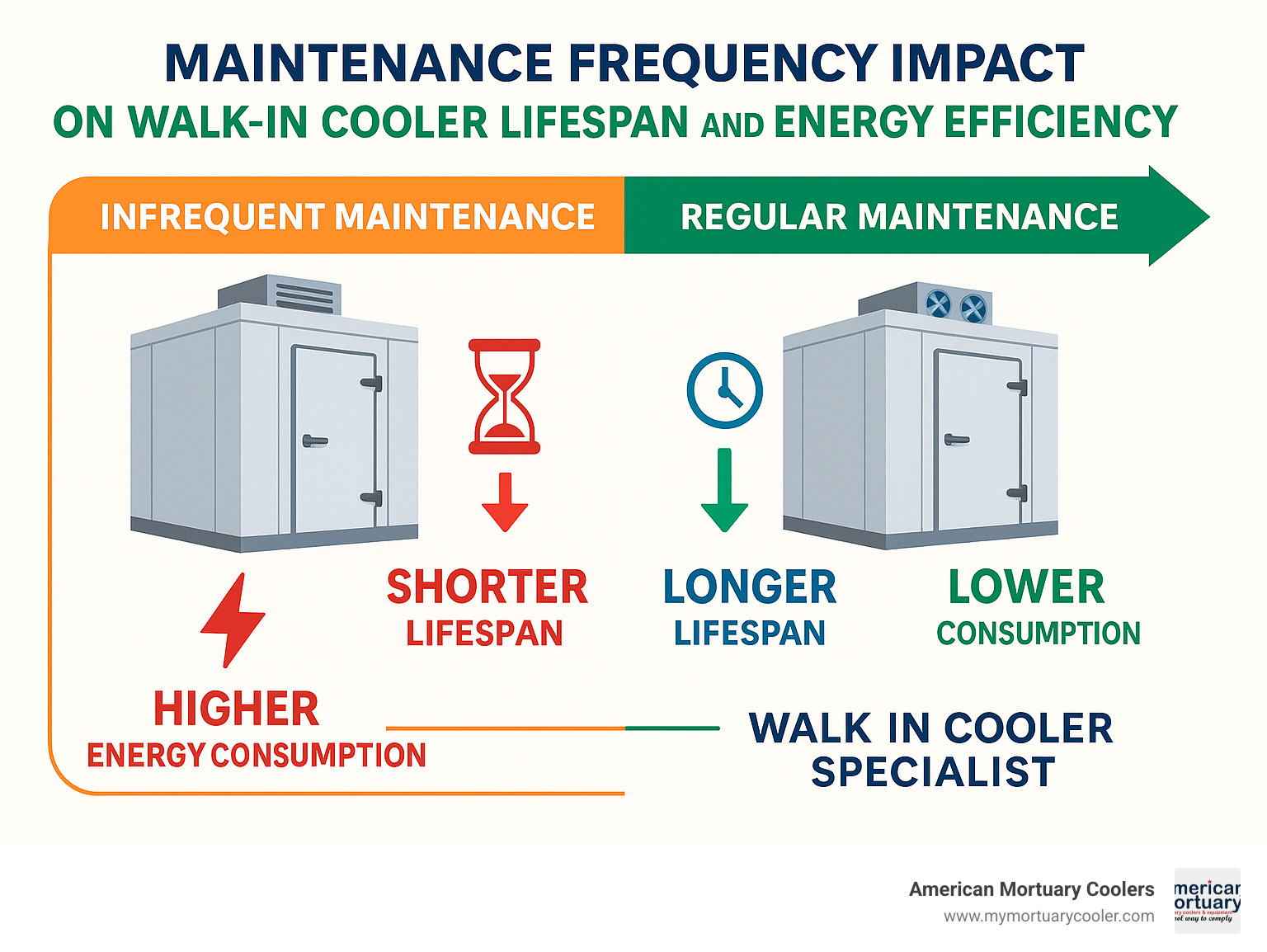

- Regular maintenance from a specialist can extend equipment lifespan by up to 40% and reduce energy costs by 10-20%

- Common signs you need a specialist: inconsistent temperatures, unusual noises, water pooling, frost buildup, and increased energy bills

A walk-in cooler specialist is a refrigeration professional who specializes in the installation, maintenance, and repair of commercial walk-in coolers and freezers. These experts are essential for businesses that rely on temperature-controlled environments to preserve inventory, comply with food safety regulations, and maintain operational efficiency.

When your walk-in cooler malfunctions, it's not just an inconvenience—it can quickly become a financial emergency. Regular maintenance by a qualified specialist helps prevent unexpected breakdowns that lead to product loss and business disruption. In fact, properly maintained walk-in coolers can operate up to 40% longer and consume 10-20% less energy than neglected units.

"Ice build-up due to warm, humid air infiltration is the leading cause of walk-in cooler freeze-up, which can result in product loss, compressor strain, and increased operating costs," notes industry research. This is just one of many issues that a specialist can prevent through routine service.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience partnering with walk-in cooler specialists to ensure our customers receive properly installed and maintained refrigeration systems. My work with specialists across the country has shown that the right expertise makes all the difference in system longevity and performance.

Walk in cooler specialist word list:

What Does a Walk-In Cooler Specialist Do?

When your walk-in cooler starts acting up, you need more than just a handyman – you need a walk-in cooler specialist. These aren't your average repair folks; they're skilled technicians who understand the delicate dance between mechanical components, electrical systems, and the physics of keeping things cold.

At American Mortuary Coolers, we partner with specialists nationwide who do far more than emergency fixes. These professionals are the unsung heroes keeping your critical refrigeration running smoothly through:

Diagnostics and troubleshooting that gets to the root cause of problems, not just treating symptoms. Using digital thermometers, pressure gauges, and sometimes thermal imaging, they can pinpoint exactly what's gone wrong.

Installation services that ensure your new walk-in cooler starts life on the right foot. Proper setup according to manufacturer specs can add years to your system's lifespan.

Preventive maintenance that catches small issues before they become expensive disasters. This is truly where specialists earn their keep – by helping you avoid emergency situations altogether.

When emergencies do happen, 24/7 emergency response means you're never left in the lurch with rapidly warming product. For our mortuary clients, this responsiveness isn't just about convenience – it's absolutely essential.

Our specialists are also experts in refrigerant handling, following strict EPA regulations to protect both your equipment and the environment. With changing regulations around refrigerants, having someone who stays current with compliance requirements is invaluable.

Services You Can Expect

A good walk-in cooler specialist provides comprehensive care for your entire refrigeration system. Think of them as primary care physicians for your cooler – they don't just treat symptoms but maintain overall health.

Temperature calibration is a cornerstone service, ensuring your cooler maintains precise temperatures. Whether you're storing food or human remains, even small temperature variations can have serious consequences.

Coil cleaning might sound basic, but it's critical for efficiency. Dirty coils force your system to work harder, driving up energy costs and shortening equipment life. A specialist will thoroughly clean both evaporator and condenser coils to maintain optimal heat transfer.

Door and gasket repair addresses one of the biggest culprits in energy waste. A door that doesn't seal properly is like leaving your home refrigerator open – except much more costly. Specialists check door hardware, hinges, and those all-important gasket seals.

Behind the scenes, they'll inspect electrical systems, verify refrigerant levels, clear drainage systems (preventing those mysterious puddles on your floor), and assess fans and motors for proper operation. They'll even evaluate your insulation to ensure your cooler isn't losing precious cold air through the walls.

Common Problems They Solve

The issues a walk-in cooler specialist addresses daily might seem mysterious to the rest of us, but they're all too familiar to these pros:

Freeze-up and ice buildup is perhaps the most common culprit they battle. When warm, humid air infiltrates your cooler, it creates a frosty mess that strains your compressor and drives up costs. A thin layer of frost is normal, but thick ice buildup is a warning sign that shouldn't be ignored.

Temperature inconsistency – those frustrating fluctuations that put your products at risk – often stem from thermostat issues, refrigerant problems, or airflow restrictions. A specialist knows how to track down the source and restore stability.

Water leaks inside or outside your unit typically point to clogged drain lines or defrost system malfunctions. Left unaddressed, these seemingly minor issues can lead to slip hazards, mold growth, and even structural damage.

Those strange noises – the grinding, rattling, or buzzing that makes you wince – are your cooler's way of crying for help. Specialists recognize these sounds as early warning signs of mechanical problems with compressors, fans, or other vital components.

At American Mortuary Coolers, we understand that temperature stability isn't just desirable – it's absolutely non-negotiable for our clients. That's why we work with experienced walk-in cooler specialists who understand the unique requirements of specialized refrigeration applications like mortuary coolers.

For a deeper dive into maintaining your commercial walk-in cooler, check out A Comprehensive Guide to Commercial Walk-In Cooler Maintenance.

Signs You Need a Walk-In Cooler Specialist Now

Let's face it – walk-in coolers don't typically break down at convenient times. They wait until you're fully stocked on a Friday afternoon or right before a holiday weekend. Knowing when to call a walk-in cooler specialist can be the difference between a quick fix and a full-blown refrigeration disaster that costs thousands in repairs and lost inventory.

"Walk in Cooler Specialist" Red-Flag Checklist

That thin layer of frost forming on your evaporator coils? It's not just pretty winter decoration – it's your cooler's cry for help. Even a light frosting can signal the beginning of serious problems with air infiltration or your defrost system. Industry experts consistently identify this as the earliest visible warning sign before bigger issues develop. If you wait until ice completely blocks airflow, you're looking at potential compressor failure and a complete system shutdown. Not exactly what you need when storing sensitive materials.

Your digital thermometer tells the truth when humans can't feel the difference. If you're noticing temperature swings of more than a few degrees, or if the baseline temperature keeps creeping upward despite adjusting the thermostat, it's time to make that call. These fluctuations often reveal refrigerant leaks or a compressor that's struggling to keep up.

Water pooling inside or outside your walk-in is never normal. Those innocent-looking puddles indicate blocked drains or defrost system problems. Beyond creating a slipping hazard (hello, workplace injury claims!), this moisture becomes an invitation for mold growth and can deteriorate your flooring over time.

Is your walk-in cooler making strange noises? When you hear grinding, rattling, buzzing, or excessive vibration coming from your compressor or fans, your system is essentially speaking a mechanical language that translates to: "Help me now!" These sounds indicate components wearing down – a situation that only worsens with time.

Compressor short-cycling is another major red flag. That frequent on-off-on-off pattern means your compressor is working harder than a caffeine-addicted office worker on deadline day. This not only drives up your energy bills but significantly shortens the lifespan of one of the most expensive components in your system.

Even seemingly minor issues like torn door sweeps or damaged gaskets deserve immediate attention. These small openings allow warm, humid air to infiltrate your cooler – the number one cause of refrigeration problems across the industry. Your system then works overtime trying to remove this excess heat and moisture, leading to a cascade of other issues.

When your energy bill suddenly spikes without explanation, your walk-in cooler could be the culprit. Inefficient operation often shows up on your utility statement before it becomes obvious in other ways.

And never dismiss those staff complaints about performance. When employees mention products don't seem as cold as usual or that the cooler takes forever to recover after door openings, they're giving you valuable early intelligence. Trust these observations – your team members interact with the equipment daily and often notice subtle changes before they become major problems.

When DIY Stops & Pros Start

We all love saving money with a good DIY project, but walk-in cooler repair has clear boundaries where amateur efforts should end and professional expertise must begin.

Refrigerant handling isn't just technically challenging – it's legally restricted. Federal law requires EPA 608 certification for anyone working with refrigerants, with hefty fines for violations. Beyond legal issues, improper refrigerant handling poses serious environmental risks.

Working with electrical systems in refrigeration units is like playing with fire – if fire were also capable of electrocuting you. These high-voltage circuits demand specialized training and tools to handle safely.

Compressor repairs require precision diagnosis and specialized equipment. As the heart of your cooling system, amateur tinkering here often leads to complete system failure.

Modern control system programming involves complex digital controllers that maintain precise temperatures for food safety and energy efficiency. One incorrect setting can compromise both.

And let's talk about those valuable manufacturer warranties. Most require service by certified professionals to remain valid. That DIY fix might save you $200 today but cost you thousands when your warranty claim gets denied tomorrow.

At American Mortuary Coolers, we've witnessed well-intentioned DIY attempts that turned minor issues into major repairs. Our network of walk-in cooler specialists consistently saves our clients money in the long run through proper diagnosis and repair the first time. When your business depends on reliable refrigeration, professional service isn't an expense – it's an investment in operational reliability and peace of mind.

Choosing the Right Walk-In Cooler Specialist

Finding the perfect walk-in cooler specialist is a bit like choosing a doctor for your refrigeration system. The right professional can keep your equipment running smoothly for years, while the wrong choice might leave you with recurring headaches and a chilly relationship with your cooler.

Credentials and Certifications

When it comes to refrigeration experts, those letters after their name actually mean something important:

EPA 608 Certification isn't just a nice-to-have—it's actually required by federal law for anyone handling refrigerants. Without this certification, a technician shouldn't be touching your system, period.

Manufacturer Certifications show that your specialist has been properly trained on specific brands. If you've got a True or Hoshizaki unit, you'll want someone who knows those systems inside and out.

NATE Certification is the gold standard in the HVACR world, demonstrating that a technician has mastered the ins and outs of heating, cooling, and refrigeration systems.

Many states also require specific licensing for commercial refrigeration contractors, so don't be shy about asking to see those credentials.

Experience and Reputation

Certificates are wonderful, but there's something irreplaceable about hands-on experience. When we partner with specialists for our mortuary coolers, we look for professionals with at least 5+ years of commercial walk-in cooler experience.

References speak volumes, especially from businesses similar to yours. A specialist who has successfully maintained systems in your industry will better understand your specific needs. Check those online reviews too—they often tell the real story of service quality.

Don't forget to verify that your specialist carries proper insurance coverage. Both liability and workers' compensation insurance protect you in case something goes wrong during service.

Service Area and Response Time

When your walk-in cooler decides to take a vacation, time is of the essence. Before disaster strikes, confirm:

The specialist's service area definitely includes your location. Some companies look great online but don't actually service your area.

Ask directly about their typical response times for emergency situations. A good walk-in cooler specialist should be able to get to you within hours, not days, when temperatures are rising.

Weekend and after-hours availability is crucial—refrigeration emergencies rarely respect business hours. And ask whether they keep common parts for your system in stock—this can be the difference between a quick fix and days of downtime.

At American Mortuary Coolers, we've built relationships with reliable walk-in cooler specialists across our service areas including Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA. This network ensures our customers never face a cooling crisis alone.

Cost Transparency and Financing Options

Good refrigeration service isn't cheap, but it's always less expensive than replacing spoiled inventory or an entire system that failed from neglect.

Ask for detailed estimates that clearly separate parts and labor costs. Many specialists offer service plans that can significantly reduce your overall maintenance expenses while keeping your system in top shape.

For larger repairs or system replacements, inquire about financing options. And always get clarity about warranty coverage—both for parts and labor—before work begins.

Key Questions to Ask Your "Walk in Cooler Specialist"

Before signing on the dotted line, have a heart-to-heart conversation with your potential specialist. Here are the questions that separate the professionals from the pretenders:

- "What is your typical response time for emergency service calls?"

- "Do you offer preventive maintenance plans, and what do they include?"

- "What warranties do you provide on parts and labor?"

- "How do you document service visits and maintain service history?"

- "Are your technicians factory-trained on my specific equipment brand?"

- "What refrigerant types are you certified to handle?"

- "Do you provide energy efficiency assessments during service visits?"

- "How do you ensure compliance with food safety regulations?"

Staff Training & Operational Best Practices

A truly excellent walk-in cooler specialist doesn't just fix your equipment—they help you prevent problems in the first place by training your team on proper usage.

Door Management might seem obvious, but proper training can dramatically reduce energy consumption and system strain. Every time that door stays open, your compressor works harder and your utility bill grows.

Stocking Clearance is often overlooked. Products stacked too close to evaporators block airflow, causing uneven cooling and potential system damage.

Regular Temperature Monitoring helps catch issues before they become emergencies. A good specialist will show your staff how to properly document temperatures and spot warning signs.

Cleaning Protocols for accessible components can prevent many common issues. Your specialist should guide your team on what they can safely clean and what should be left to the professionals.

Here are five simple Employee Training Tips your specialist should cover:

- Check door seals regularly for damage or wear

- Close doors quickly to minimize warm air infiltration

- Report unusual sounds, temperature changes, or water leaks immediately

- Follow a regular cleaning schedule for accessible cooler areas

- Keep emergency contact information for your walk-in cooler specialist posted visibly

At American Mortuary Coolers, we understand that proper maintenance is just as important as quality equipment. That's why we connect our customers with specialists who don't just fix problems—they prevent them through education and partnership.

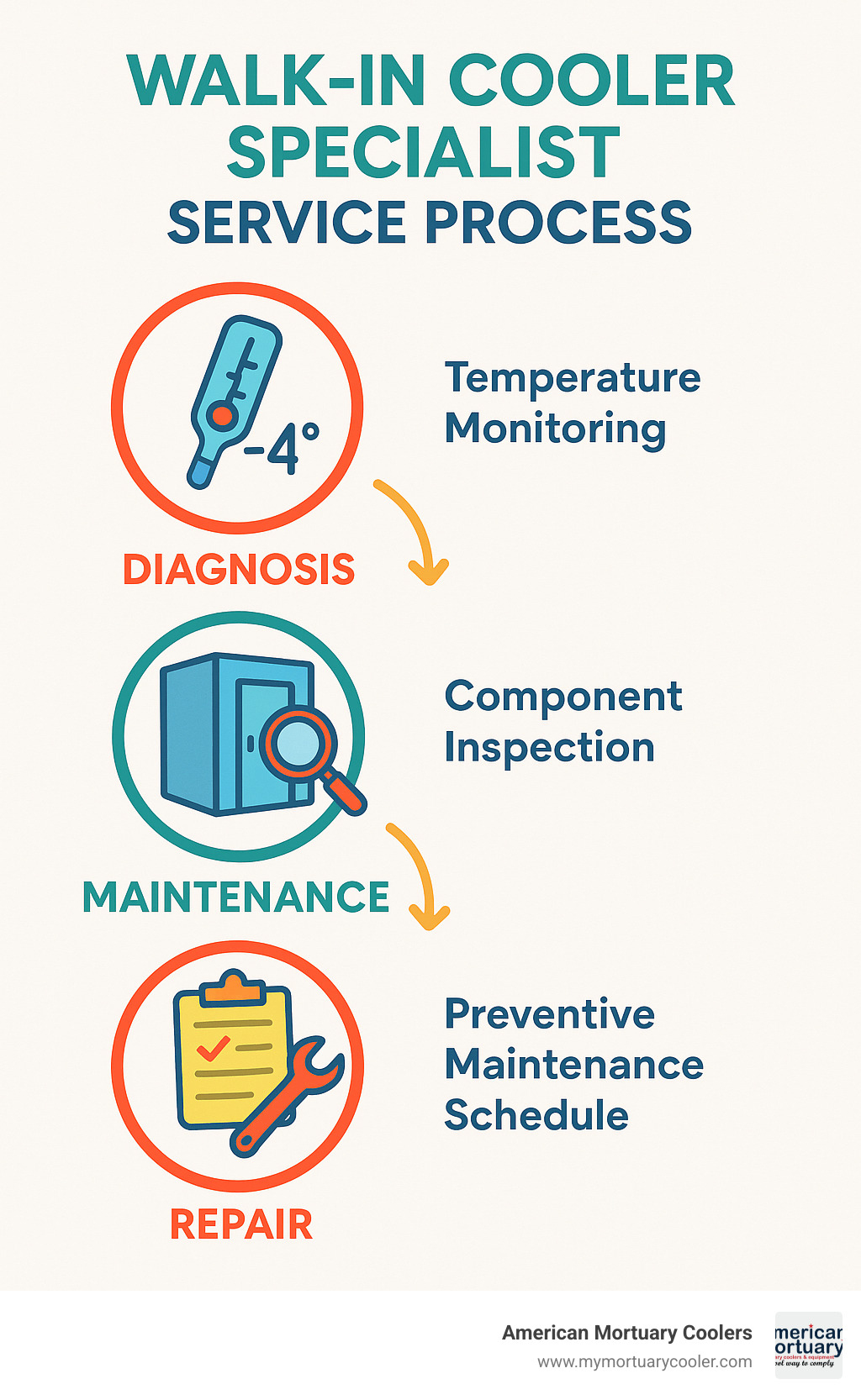

Inside the Service Call: Diagnosis, Repair & Maintenance Process

Ever wondered what actually happens when a walk-in cooler specialist arrives at your facility? Let me pull back the curtain on this process that's equal parts detective work and precision repair.

Step-by-Step Repair Workflow

When your specialist arrives, they don't just start replacing parts. Instead, they begin with a conversation. "What have you noticed?" they'll ask your staff, gathering clues about when the problems started and how they've progressed. This detective work is crucial - sometimes what seems like the problem is actually just a symptom of something deeper.

Next comes the hands-on investigation. Your walk-in cooler specialist will break out their professional toolkit: digital thermometers to check temperature differentials, pressure gauges to assess refrigerant levels, and multimeters to test electrical components. This isn't guesswork - it's precise diagnostic science.

The visual inspection that follows is methodical and thorough. They'll examine evaporator and condenser coils for dirt buildup or damage, check electrical connections for security, look for telltale oil stains that might indicate refrigerant leaks, and inspect door seals for proper alignment. They're not just looking at the obvious - they're searching for the root cause of your issue.

For trickier problems, your specialist might employ some impressive technology. Thermal imaging cameras can reveal temperature anomalies invisible to the naked eye, while electronic leak detectors can find refrigerant escapes too small to spot visually. These advanced tools help pinpoint exactly what's happening inside your system.

Once they've identified the culprit, your walk-in cooler specialist will explain the problem in terms you can understand and present repair options with transparent pricing. After getting your approval, they'll get to work, often pulling needed parts right from their service vehicle. This efficiency is why working with specialists pays off - they come prepared.

After completing repairs, they'll run the system through comprehensive testing to ensure everything's working properly. Before leaving, they'll document everything in detail and take time to explain what was done and how to prevent similar issues. This education piece is invaluable - the more your team understands, the better they can help maintain your equipment.

Preventive Maintenance Schedule

An ounce of prevention is worth a pound of cure - especially when it comes to walk-in coolers. A good walk-in cooler specialist doesn't just fix problems; they help prevent them through regular maintenance visits.

Quarterly maintenance visits focus on the basics: cleaning those all-important condenser coils, checking refrigerant pressures, inspecting door gaskets, clearing drain lines, and verifying thermostat operation. Think of these as your system's regular check-ups.

Semi-annual visits dig deeper, adding evaporator coil cleaning, fan motor inspection, electrical system checks, defrost cycle testing, and compressor evaluation to the quarterly tasks. These more comprehensive visits catch developing issues before they become emergencies.

The annual maintenance visit is the grand inspection, combining all previous tasks with a complete system performance evaluation, thorough refrigerant leak testing, comprehensive electrical inspection, lubrication of all moving parts, and close examination of insulation integrity. This yearly deep-dive keeps your system running at peak efficiency.

At American Mortuary Coolers, we've seen how bi-annual professional maintenance strikes the perfect balance between cost and reliability. For specialized applications like mortuary refrigeration, where temperature stability is non-negotiable, this preventive approach isn't just smart—it's essential.

Modern walk-in cooler specialists are also adapting to industry changes, becoming proficient with new A2L refrigerants that have lower global warming potential, energy-efficient EC motors that reduce power consumption, and smart monitoring systems that can alert you to problems before they cause equipment failure.

Food-code compliance is another area where specialists provide tremendous value, ensuring your system meets all regulatory requirements. Their leak detection protocols help protect both your investment and the environment, identifying small issues before they become major refrigerant losses.

For more detailed information about maintaining your walk-in cooler, check out this comprehensive guide to commercial walk-in cooler maintenance.

Installation & Upgrades with a Walk-In Cooler Specialist

When it's time for a new walk-in cooler or an upgrade to your existing system, partnering with a qualified walk-in cooler specialist makes all the difference between a smooth installation and years of headaches. I've seen how proper installation sets the foundation for decades of reliable service.

Project Assessment and Planning

Think of the planning phase as the blueprint for success. A good walk-in cooler specialist starts by thoroughly evaluating your space, measuring not just the dimensions but checking floor strength, electrical capacity, and drainage options. They're looking at the big picture – not just where the cooler will sit today, but how it will function in your workflow for years to come.

During this stage, your specialist will ask detailed questions about your specific needs. How cold do you need it? What's going in there, and how often will it turn over? Will you need frequent access? These aren't just casual questions – they're helping tailor a system that works specifically for your operation.

The specification process gets a bit technical, but it's where a specialist really earns their keep. They'll recommend the right insulation R-value (typically R-29 for coolers or R-32 for freezers), appropriate panel thickness, and the ideal door configuration for your space. They'll also steer the maze of local building codes, health department requirements, and energy efficiency standards so you don't have to.

Installation Process

The actual installation is where craftsmanship meets science. Your walk-in cooler specialist will start with proper site preparation – ensuring you have a level foundation with appropriate vapor barriers to prevent moisture problems down the road.

The panel assembly is like watching a giant puzzle come together. Those cam-lock connections you see in the image above need to be perfectly aligned and tightened to create an airtight seal. A skilled specialist makes this look easy, but there's real technique involved in getting those panels to form a perfect enclosure.

The refrigeration system installation is where the magic happens. Your specialist will mount the evaporator, position the condensing unit, run the copper line sets, and charge the system with just the right amount of refrigerant. It's precision work that requires specialized tools and knowledge – especially with today's evolving refrigerant regulations.

Before wrapping up, they'll handle all the finishing touches – sealing penetrations, installing shelving, adding safety features, and programming your control system. Then comes the commissioning process, where they'll verify the system pulls down to temperature properly and operates efficiently.

At American Mortuary Coolers, we work with walk-in cooler specialists across the country to ensure our mortuary coolers are installed correctly. We've learned that even the best equipment will underperform if not properly installed – that's why we're so particular about the installation process.

Latest Technologies & Best Practices

The refrigeration world keeps evolving, and a good specialist stays current with the latest innovations. Today's high-density polyurethane insulation provides better thermal performance in thinner panels than older materials. LED lighting has replaced traditional fixtures, reducing both energy use and heat generation inside the cooler.

Smart controls have revolutionized refrigeration management. Your walk-in cooler specialist can now set you up with IoT temperature monitoring systems that alert you before small issues become big problems. Variable speed compressors and electronic expansion valves deliver more precise temperature control while using significantly less energy.

Environmental considerations are also driving change. The refrigeration industry is transitioning to eco-friendly refrigerants with lower global warming potential. A knowledgeable specialist will help you steer these changes, ensuring your system is both compliant and future-proof.

Brands & Models Specialists Service

A qualified walk-in cooler specialist should be comfortable working with all major manufacturers. True Manufacturing and Hoshizaki are household names in commercial refrigeration, known for their reliability and performance. Kolpak offers highly customizable solutions, while Norlake specializes in scientific and foodservice applications.

Other respected brands include Turbo Air, known for energy efficiency; Manitowoc, with their comprehensive refrigeration solutions; American Panel, specializing in custom walk-ins; and Arctic Industries, offering modular solutions.

At American Mortuary Coolers, we've designed our mortuary coolers to industry standards, ensuring that any qualified specialist can service them. This compatibility gives you flexibility in choosing local service providers, whether you're in Johnson City or Los Angeles.

For more detailed information about large walk-in cooler installations, check out our guide on All About Large Walk-In Coolers, which covers additional considerations for larger installations.

Frequently Asked Questions about Walk-In Cooler Specialists

How much do typical repairs cost?

Let's talk money – because we all know refrigeration repairs can feel like a shock to the system (and your wallet) when you're not prepared.

The truth is, walk-in cooler repair costs vary widely based on what's gone wrong. Think of it like car repairs – fixing a flat tire costs much less than replacing an entire transmission.

For minor repairs like replacing door gaskets, thermostats, or fan motors, you're typically looking at $200-$600. These are the "maintenance" level fixes that, while necessary, won't break the bank.

When you move into moderate repairs – things like defrost system issues or evaporator problems – costs typically range from $600-$1,200. These are the "needs attention soon" category of repairs.

For those dreaded major repairs like compressor replacements or control system overhauls, prepare for $1,200-$3,500+. These are the "oh no" moments every business owner hopes to avoid.

Here's where I'll share something that might save you thousands: preventive maintenance plans generally cost between $400-$1,200 annually, depending on your system's size and complexity. Yes, that's an expense – but it's an investment that can prevent those panic-inducing emergency repairs and extend your equipment's life by up to 40%. The math makes sense when you look at the long view.

What certifications should my specialist carry?

When it comes to who's working on your walk-in cooler, credentials matter – both for safety and for your peace of mind.

At the bare minimum, your walk-in cooler specialist needs EPA 608 Certification. This isn't just a nice-to-have; it's required by federal law for anyone handling refrigerants. Without this, they shouldn't be touching your system, period.

A valid State Contractor's License is essential where local regulations require it. This tells you they're operating legally in your area and have met basic competency requirements.

Manufacturer Training is particularly important if your equipment is under warranty. Some manufacturers will void warranties if unqualified technicians perform the work – an expensive lesson you don't want to learn firsthand.

Liability Insurance protects both the technician and your business if something goes wrong during service. An uninsured technician is a risk you simply shouldn't take.

For extra reassurance, look for specialists with NATE (North American Technician Excellence) certification and training on digital control systems. These additional qualifications often separate the good technicians from the truly excellent ones.

How often should maintenance be scheduled?

Think of your walk-in cooler like your car – skip too many oil changes, and eventually, you'll be stranded on the roadside wondering what went wrong.

The industry consensus is clear: at the very minimum, schedule bi-annual (twice yearly) professional maintenance visits. This is the absolute baseline for keeping your system healthy.

For high-use systems or in particularly demanding environments, quarterly maintenance provides optimal protection. Yes, it's more frequent, but the peace of mind and extended equipment life are worth it.

We also strongly recommend additional inspections after extreme weather events or power outages, which can stress refrigeration systems in ways that aren't immediately obvious.

During these regular maintenance visits, your walk-in cooler specialist should be cleaning both condenser and evaporator coils, checking refrigerant levels, inspecting door seals and hinges, testing defrost cycles, verifying temperature accuracy, examining electrical connections, and cleaning drain lines.

At American Mortuary Coolers, we've seen how proper maintenance extends the life of our mortuary coolers. When you're preserving something as important as human remains, there's simply no room for equipment failure – which is why we're such strong advocates for regular professional maintenance. The same principle applies whether you're preserving food, pharmaceuticals, or any temperature-sensitive items. Regular maintenance isn't an expense – it's protection for your business, your products, and your peace of mind.

Conclusion & Next Steps

Finding the right walk-in cooler specialist isn't just a maintenance decision—it's a crucial investment in your business's operational stability. At American Mortuary Coolers, we've seen how proper refrigeration maintenance makes all the difference, especially in our specialized field where temperature control isn't just about convenience—it's absolutely essential.

We've built our reputation on creating mortuary coolers that stand the test of time. Each unit features premium insulation with carefully calculated R-values, hardware that can handle daily use for years, and refrigeration systems designed with serviceability in mind. And yes, we've made sure everything meets or exceeds industry regulations—because we understand what's at stake when refrigeration fails.

One of the things our customers appreciate most is our nationwide reach. We deliver our custom mortuary coolers directly to customers throughout the lower 48 states, and we've cultivated relationships with qualified walk-in cooler specialists across regions including Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA.

Your Action Plan:

Ready to ensure your walk-in cooler keeps running at its best? Here's where to start:

First, assess your current situation by revisiting our red-flag checklist. Those small issues you've been noticing? They're probably trying to tell you something important.

Next, find a qualified specialist in your area using our guidelines. The cheapest option rarely turns out to be the most economical in the long run. Look for those certifications and ask about experience with your specific equipment.

Then, establish a regular maintenance schedule. I can't emphasize this enough—preventive maintenance is like changing the oil in your car. Skip it, and you're asking for trouble down the road.

Don't forget to train your staff on proper cooler operations. Simple habits like minimizing door opening time and reporting unusual sounds immediately can dramatically extend your equipment's life.

Finally, consider strategic upgrades when the time is right. A good specialist can recommend targeted improvements that pay for themselves through energy savings and extended equipment life.

I've seen it countless times—the businesses that partner with qualified walk-in cooler specialists for regular maintenance avoid those middle-of-the-night emergency calls and budget-busting repairs. Your refrigeration system is too important to leave to chance.

For more information about our mortuary walk-in solutions and to connect with qualified specialists in your area, contact American Mortuary Coolers today. We're not just selling coolers—we're providing peace of mind through reliable refrigeration solutions you can count on for years to come.