Choosing the Right Cremation Equipment for Your Facility

If you're searching for a cremation furnace for sale, here's what you need to know:

| Key Information | Details |

|---|---|

| Price Range | $43,500-$58,000 (new), $15,000-$35,000 (refurbished) |

| Types Available | Human (800-1,200 lb capacity), Pet (0.63-3 m³ chambers) |

| Fuel Options | Gas, Electric, Wood-based, Hybrid |

| Processing Speed | Human: 150-400 lb/hr (45-150 min cycles), Pet: Up to 7 cremations daily |

| Key Manufacturers | US Cremation Equipment, B&L Systems, Firelake, Armil CFS |

The decision to purchase a cremation furnace for sale represents a significant investment for any funeral home or veterinary facility. Modern cremation equipment balances operational efficiency with environmental compliance, offering solutions custom to different facility needs and volume requirements. Today's market includes everything from high-capacity human cremators with touchscreen controls to compact pet units designed for small veterinary practices, with both new and refurbished options available to fit various budgets.

When evaluating cremation furnaces, consider not just the initial purchase price but also installation requirements, operational costs, and expected return on investment. A quality pet crematory can achieve payoff within 5 years while generating over $20,000 in annual net profit. For human cremation, higher-capacity units with features like Quick Change Hearth systems and remote diagnostics can significantly reduce downtime and maintenance costs over the equipment's 15-20 year lifespan.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment including cremation furnaces for sale, with extensive experience helping funeral directors identify the right cremation solutions for their specific operational needs and budget constraints.

Cremation furnace for sale glossary:

Top Cremation Furnace Models for Sale in 2024

The cremation industry has come a long way in recent years, hasn't it? As more families choose cremation across America, manufacturers have stepped up their game with equipment that's more efficient, cleaner, and easier to use than ever before. At American Mortuary Coolers, we've seen how the right cremation furnace can completely transform a funeral home or vet clinic's day-to-day operations.

Today's market offers something for everyone. Human cremators typically handle between 800-1,200 pounds and process 150-400 pounds hourly. The best part? What used to take 90-150 minutes now takes just 45-60 minutes with high-efficiency models. Pet cremators come in more compact sizes with chambers from 0.63 m³ to 3 m³, perfect for handling up to 7 cremations daily with smart scheduling.

While natural gas remains the crowd favorite for fuel, you'll now find electric cremation furnaces, wood-based systems for areas without reliable gas service, and clever hybrid models that switch between fuel types. For those serving rural communities, mobile cremation units mounted on trailers offer flexibility without permanent installation headaches.

Budget-Friendly Cremation Furnace for Sale: Pet & Small Clinics

Starting a pet cremation service doesn't have to break the bank. The Firelake Manufacturing Model A offers one of the most wallet-friendly entry points at around $21,700. What I love about this system for small rural clinics is the compelling business case it makes:

With just one cremation daily (264 annually), you could generate around $47,520 in revenue (at $180 per cremation). After operating costs of about $21,648 yearly, you're looking at a healthy $20,332 annual profit during your first five years. Not too shabby for a modest investment!

The Sierra-300 by US Cremation Equipment is another solid choice for smaller operations. With its 75 lb/hr processing rate and 300 lb capacity, it's perfect for veterinary practices wanting to bring cremation in-house rather than shipping pets out.

Here's a little insider tip: animal separation trays are absolute game-changers for efficiency. These simple accessories let you cremate multiple pets at once while keeping remains separate, essentially cutting your per-animal operating costs in half or better. Your investment pays off much faster without needing a bigger furnace.

More info about the real price of pet incinerators

High-Volume Cremation Furnace for Sale: Human Applications

For busy funeral homes handling human remains, you need equipment that won't let you down when families are counting on you. Several models have earned their stellar reputations in this space:

The Phoenix II-3 is a workhorse, handling cremations in just 45-60 minutes with its generous 1,000 lb capacity. When you're serving multiple families daily, this kind of throughput makes all the difference in the world.

The Classic-XCEL from US Cremation Equipment is another standout performer. With 60-minute average cycles, 400 lb/hr processing, and a massive 1,200 lb capacity, it's built for high-volume operations that need reliability above all else.

The CFS2300 Human Cremation Chamber by Armil CFS brings some genuinely clever innovations to the table. Its Quick Change Hearth™ System uses pre-cast refractory tiles that can be swapped in a single day—no more extended downtime waiting for traditional cast-in-place hearths to cure. The Tek Marshal Remote Diagnostics lets factory techs troubleshoot issues remotely, often fixing problems without an on-site visit (a huge plus when you're in a rural area).

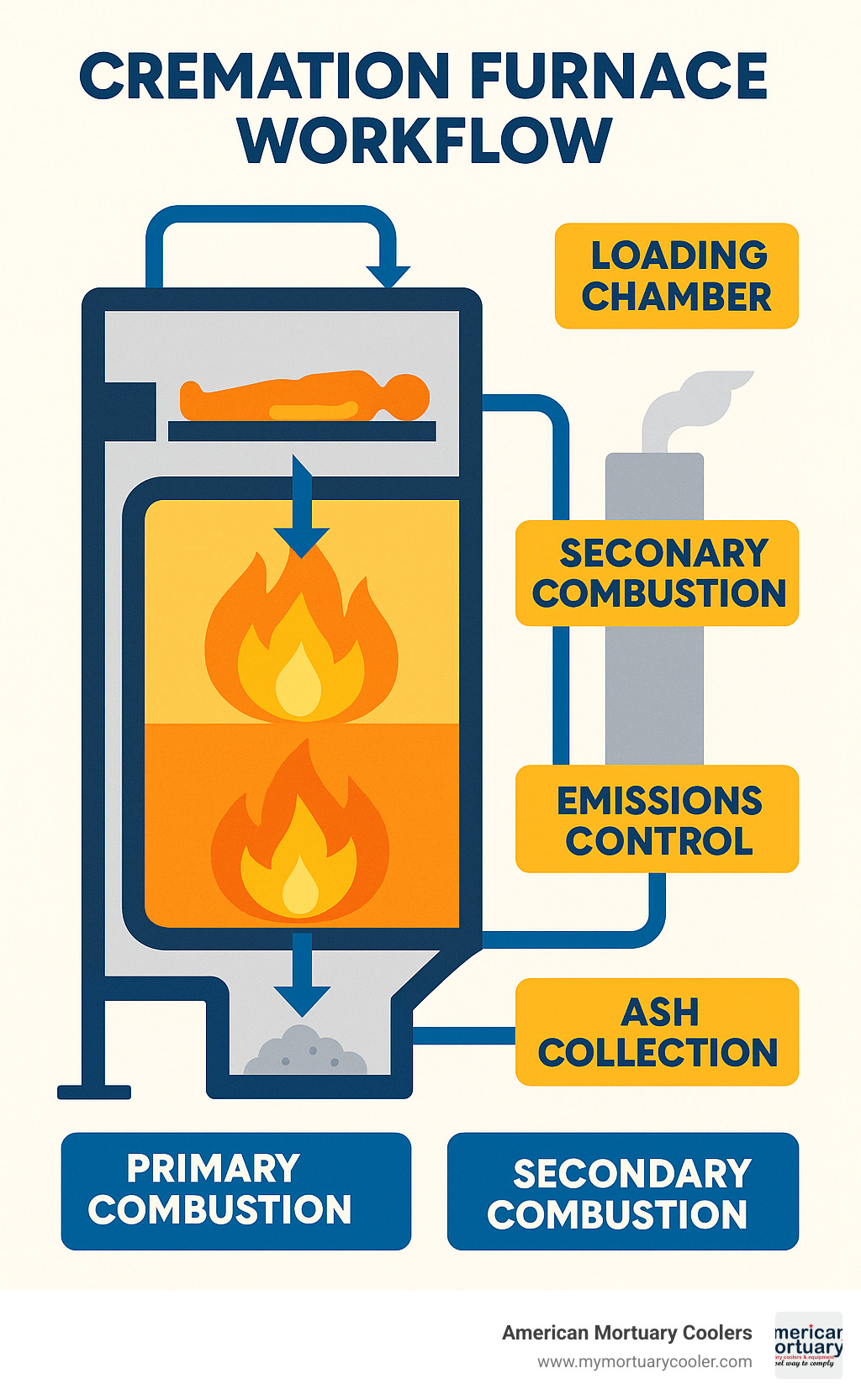

These premium units also feature opacity sensors for continuous emissions monitoring, UL listing for safety peace of mind, and touchscreen controls that make operation intuitive for your whole team. They typically run at 1,400°F to 1,800°F in the primary chamber, with secondary chambers reaching up to 2,000°F to ensure complete combustion and clean emissions.

More info about Cremation Furnace Market Insights

Specialty Lines: Electric, Wood & Mobile Solutions

Not every funeral home has the same needs or operates in the same environment. That's why specialty units have become increasingly popular.

Electric cremation furnaces make perfect sense if you're in an area with unreliable gas service or strict emissions rules. Running on 415V power, they produce fewer emissions at the point of use. While electricity costs might be higher in some regions, you'll save on gas line installation. They're especially attractive if your area has access to renewable energy.

For our friends in truly rural areas without natural gas infrastructure, improved wood-based cremation systems from companies like M.D. Enterprises offer a practical solution. Today's wood systems aren't like the smoky old units of yesteryear—they incorporate advanced secondary combustion chambers and sophisticated air control systems that dramatically reduce emissions. If wood is plentiful and affordable in your region, these can be surprisingly economical to operate.

Hybrid cremation systems offer the ultimate in flexibility, switching between natural gas, propane, or electricity based on what's available and affordable. Yes, you'll pay more upfront, but the peace of mind during utility disruptions can be priceless, especially in areas prone to weather emergencies.

For funeral homes serving sprawling rural territories, mobile trailer cremators are a brilliant solution. These self-contained units can travel between locations, allowing smaller funeral homes to offer cremation without installing permanent equipment at each location. Everything you need—including power generators and emissions controls—comes in one neat package.

Pre-Owned Deals & Refurbished Equipment

Let's talk about one of the best-kept secrets in the industry: refurbished cremation furnaces. These units typically sell for 30-40% less than new models while incorporating updated controls and combustion components. For many funeral homes and vet clinics, this represents the perfect balance of quality and affordability.

Armil CFS runs an impressive refurbishment program for CFS 2300 trade-ins. They don't just clean them up and ship them out—they perform a complete hearth inspection (replacing it if needed), thoroughly check all refractory components, upgrade controls and combustion systems, and install their Fire Marshal remote monitoring. Every unit undergoes full factory testing before delivery.

When shopping for a refurbished cremation furnace for sale, look for thorough documentation of the refurbishment process, updated control systems and safety features, new or reconditioned refractory materials, emissions testing results, and warranty terms comparable to new equipment (typically 1-2 years). Installation support and operator training are just as important with refurbished units as with new ones.

Many manufacturers also offer trade-in credits for your older equipment, substantially reducing the cost of upgrading to newer, more efficient technology. This approach lets you benefit from the latest advances without straining your capital budget.

Burn Less Cash: Quality Used Cremation Equipment for Sale

Buying Checklist: Specs, Safety & Compliance

Shopping for a cremation furnace for sale can feel overwhelming with all the technical details to consider. Think of this section as your friendly guide through the maze of specifications, safety features, and compliance requirements you'll need to understand before making this significant investment.

Technical Specifications

The heart of any cremation system is its operating capacity and performance. Modern furnaces typically run at temperatures between 850-1650°C (1562-3002°F), with the primary chamber doing the heavy lifting. When I talk with funeral directors about sizing, I always emphasize matching the unit to your actual needs—human units generally handle 800-1200 lbs with chamber dimensions starting around 42" W × 89" L, while pet units range from cozy 0.63 m³ chambers to larger 3 m³ models.

Processing speed matters too, especially for busier facilities. Today's human units can process 150-400 lbs per hour, dramatically reducing cycle times to 45-90 minutes (compared to the 90-150 minutes older models required). For utilities, you'll need to ensure your facility can provide the necessary natural gas (typically 2,350 CFH at 7" water column pressure) or propane (940 CFH at 11" w.c.), plus standard 240V, single-phase, 40 amp electrical service.

Don't overlook the secondary chamber—it's crucial for emissions control and must maintain at least 1800°F to properly eliminate particulates. And remember to measure your available space carefully, accounting for the loading area and control panels, not just the furnace itself.

Safety Features

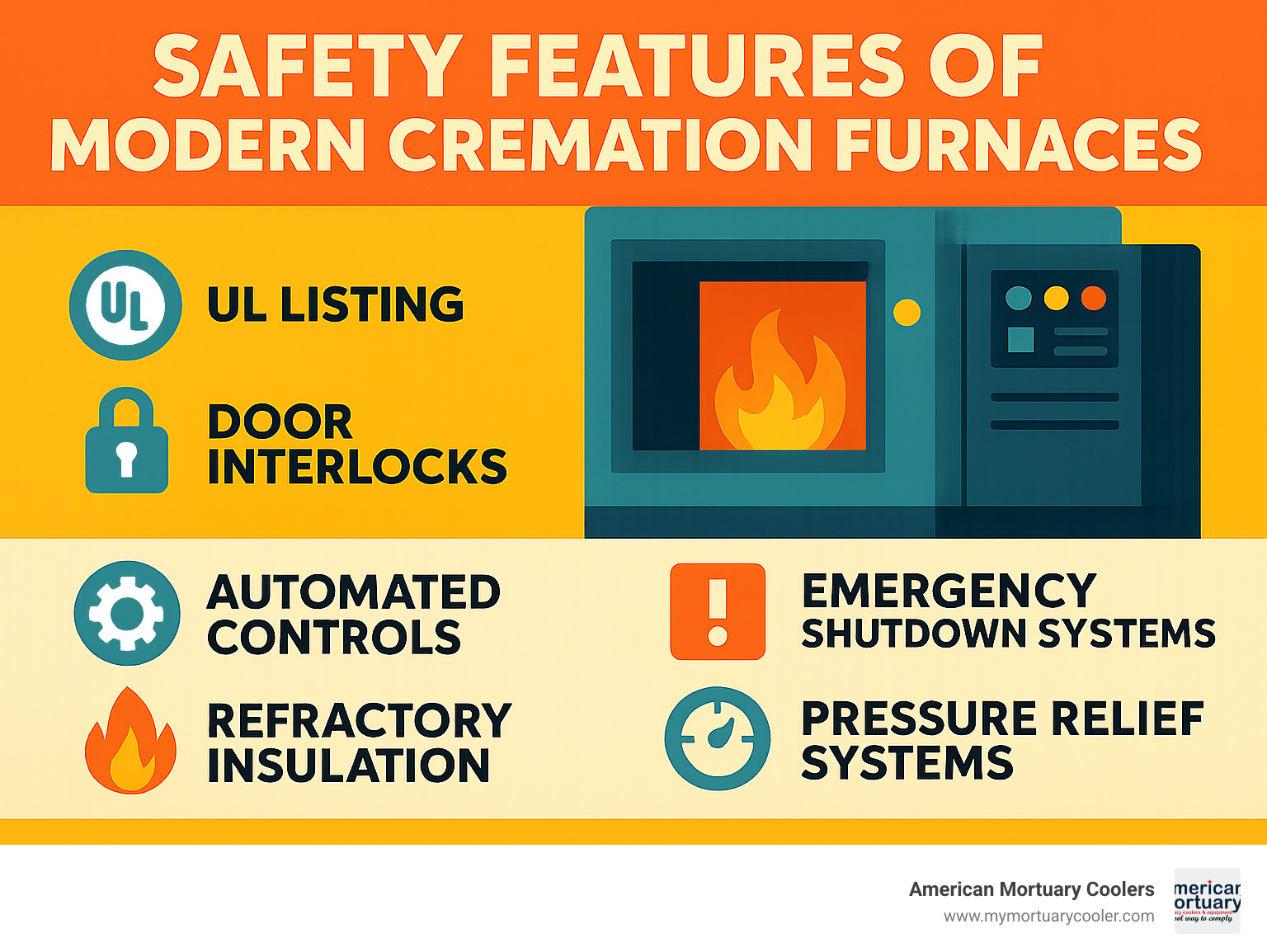

Safety isn't just about compliance—it's about protecting your team and facility every day. The best cremation furnaces incorporate multiple layers of protection:

Look for UL listing on electrical components—this isn't just a nice-to-have, it's essential for ensuring the system meets rigorous safety standards. Door interlocks prevent accidental opening during operation (which could be catastrophic), while automated controls reduce the chance of human error. Every system should include emergency shutdown capabilities that can quickly terminate operation if something goes wrong.

Quality refractory insulation keeps exterior surfaces at safe temperatures, protecting operators from burns, while pressure relief systems prevent dangerous pressure buildup inside the chamber. These features might not be the first things you think about when shopping, but they're the ones you'll be thankful for every day.

Regulatory & Environmental Considerations

Environmental compliance has become increasingly important in our industry, and for good reason. When evaluating a cremation furnace for sale, you'll need to consider:

Opacity monitoring is often required by local jurisdictions to continuously track stack emissions. Many areas also mandate periodic stack testing to verify you're meeting emissions standards. Before you even begin installation, you'll need proper air permits and to ensure you meet local zoning requirements, which can be quite specific for crematories.

Don't forget about noise and odor control—your neighbors will appreciate your thoughtfulness. Some manufacturers now offer improved green initiatives with improved emissions control options, and you might consider participating in carbon offset programs to further reduce your environmental footprint.

Here at American Mortuary Coolers, we keep up with regulatory changes across all regions we serve. We've found that working with reputable manufacturers ensures your equipment will not only meet current regulations but can be updated as requirements evolve.

Environmental permitting resources

Must-Have Technical Features

Today's cremation furnaces are technological marvels compared to systems from just a decade ago. Programmable Logic Controllers (PLCs) now automate the cremation process, maintaining optimal temperatures and airflow without constant adjustment. User-friendly touchscreen controls have replaced complicated switches and dials, making operation intuitive and reducing training time.

I'm particularly impressed with the remote monitoring capabilities in newer models—manufacturers can now diagnose issues from afar, often solving problems without an on-site service call. Modular hearth designs are another game-changer, allowing for faster repairs and significantly reducing downtime when maintenance is needed.

Other features worth prioritizing include auto loaders for improved safety, data logging for compliance documentation, and fuel efficiency systems that reduce both operating costs and environmental impact. The most sophisticated systems now incorporate weight-based operation, automatically adjusting the cremation cycle based on the actual load rather than using preset timers—a simple change that can dramatically reduce fuel consumption while ensuring complete cremation.

Essential Accessories & Ancillary Gear

While the furnace itself is the centerpiece, a complete cremation system requires supporting equipment to operate efficiently and safely. Most facilities will need:

Autoloader systems ($15,799-$35,304) eliminate manual loading, reducing both physical strain and the risk of injury. Hydraulic lift tables ($5,325-$6,795) provide similar benefits for moving remains. For processing cremated remains, you'll need a remains processor ($2,549-$11,794) and possibly a ventless processing station (around $9,394) if dedicated ventilation isn't available.

Don't forget about body storage—a quality mortuary cooler is essential for maintaining dignity and compliance before cremation. Smaller items like urn loaders ($149-$289) prevent spillage when filling urns, while high-temperature vacuum systems (around $1,749) allow for safe cleanup. Remains cooling racks (approximately $460) provide a safe place for hot cremains to cool before processing.

These accessories aren't just "nice-to-haves"—they're essential components of a safe, efficient operation. When budgeting for your cremation system, be sure to include these critical supporting items.

More info about Cremation Equipment 101

Costs, ROI & Financing Options

When you're looking at a cremation furnace for sale, the sticker price is just the beginning of your financial journey. Let's have an honest conversation about what this investment really looks like from purchase through profitability.

Initial Investment

The upfront cost for cremation equipment varies significantly based on your needs. New human cremation furnaces typically range from $43,500 to $58,000, while pet cremation units start around $21,700 and go up to $35,000. If your budget is tight, consider refurbished equipment, which offers 30-40% savings at $15,000 to $35,000.

Don't forget about installation costs! Plan for $5,000 to $15,000 to properly connect utilities and ventilation. Your accessory budget could range from $5,000 for basic setups to $50,000 for fully automated systems. And those permits and inspections? They'll add another $2,000 to $5,000 before you even start operations.

I've worked with funeral homes who were shocked by these "hidden" costs, so we at American Mortuary Coolers always provide a comprehensive cost breakdown upfront. No surprises means better planning.

Operating Cost Breakdown

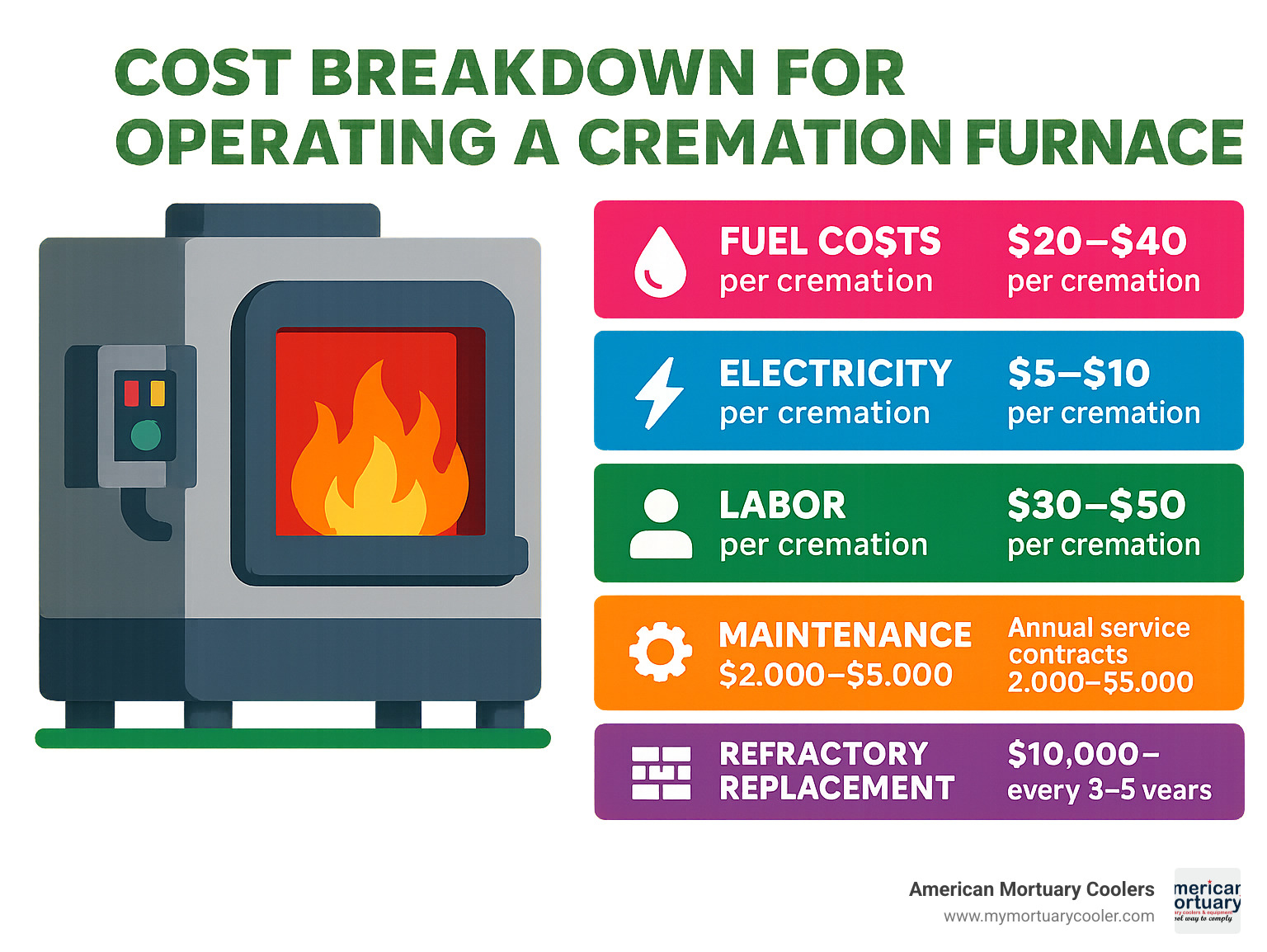

The day-to-day expenses of running your cremation furnace include:

Fuel costs run about $20-$40 per cremation, covering 3-5 hours of operation. Electricity adds another $5-$10, while labor costs typically range from $30-$50 per service. Annual maintenance isn't cheap either – service contracts run $2,000-$5,000 yearly, with major refractory replacements needed every 3-5 years at $10,000-$20,000. Don't forget annual emissions testing at $1,500-$3,000.

For perspective, a small pet crematory performing 264 cremations annually would see roughly $6,336 in fuel costs and about $15,312 in combined electricity, maintenance, and labor expenses. That's a total operating cost of $21,648 per year – important numbers to factor into your business plan.

Return on Investment

Now for the good news – these machines can generate solid returns when properly managed. Let's look at some realistic numbers:

That small pet crematory we mentioned? Charging $180 per cremation and handling 264 services annually generates $47,520 in revenue. After $21,648 in operating costs, you're looking at about $20,332 in annual net profit during your equipment payoff period. Once paid off? Your profit jumps to $25,272 annually.

Human cremation services typically command higher fees ($300-$700) and higher volumes (300-800 cremations annually), potentially generating $90,000 to $560,000 in annual revenue with 30-40% net profit margins after expenses.

Most cremation equipment lasts about 15 years with proper maintenance, giving you a decade of increased profits after the typical 5-year payoff period. One of our clients in Memphis told me their furnace was "the best investment they ever made" after hitting year six of operations.

Financing Options

Don't have $50,000 sitting in your business account? No problem. Several financing paths can make this investment more accessible:

Equipment leasing offers monthly payments over 3-7 years with purchase options at the end. SBA loans provide government-backed financing with favorable terms for small businesses like funeral homes. Many manufacturers offer in-house financing programs with competitive rates, while traditional bank loans typically require 10-20% down payments. Some distributors (including us) partner with financial institutions for turnkey solutions.

For example, financing a $50,000 cremation furnace for sale might look like this: $10,000 down payment (20%), a 5-year term at 6% interest, monthly payments around $775, with a total cost of $56,500 over the life of the loan. Not bad when the equipment will be generating revenue from day one.

Maximizing Return on Investment

Smart operators use several strategies to boost their returns:

Multi-load techniques using separation trays for pet cremations can double or triple your throughput while maintaining individual cremation integrity. Energy recovery systems on advanced models capture waste heat, reducing overall consumption and lowering your monthly bills. Preventive maintenance isn't just good practice – it directly impacts your bottom line by reducing costly downtime and extending equipment life.

Marketing packages that position cremation as part of comprehensive service offerings can increase your margins substantially. Some of our most successful clients offer volume discounts to veterinary clinics or hospice organizations to keep their furnaces running consistently. And thoughtful scheduling that minimizes warm-up and cool-down cycles can significantly reduce fuel costs.

At American Mortuary Coolers, we don't just sell you equipment – we partner with you to develop business models that maximize return while maintaining the highest standards of dignity and service. We've helped hundreds of funeral homes transform their financial outlook with the right cremation equipment and operational strategy.

Learn more about product matching AI

Installation, Maintenance & Service Support

Setting up a cremation furnace isn't as simple as plugging in a kitchen appliance. It requires careful planning, professional installation, and ongoing maintenance to ensure years of reliable service. Let's walk through what you can expect when bringing a cremation furnace for sale into your facility.

Planning Your Install Timeline

The journey from purchase to operation typically spans several months, so patience is key. First comes the permitting phase, which can take 2-6 months depending on your location. You'll need to secure air quality permits, zoning approvals, and building permits – paperwork that moves at the speed of government.

Once permits are in hand, site preparation begins. Over 2-4 weeks, you'll need to prepare a reinforced concrete pad, install utility connections, and set up your ventilation system. This foundation work is crucial – your furnace will operate at extreme temperatures, so cutting corners here isn't an option.

Equipment delivery requires coordination 4-8 weeks in advance. These aren't exactly Amazon packages – cremation furnaces are massive, heavy pieces of equipment requiring specialized shipping logistics and often crane services to position them properly.

The actual installation takes 3-7 days, including equipment placement, connecting utilities, and curing the refractory material if required. This is followed by 2-3 days of testing and training, where technicians will fire up the system, verify temperatures, check emissions, and certify your operators. Finally, a one-day final inspection ensures regulatory compliance and proper documentation.

At American Mortuary Coolers, we've guided countless funeral homes through this process. While it might seem daunting, having experienced professionals coordinate these phases makes all the difference in avoiding costly delays and complications.

Installation Requirements

Your cremation furnace for sale will have specific site requirements that must be addressed before delivery day arrives. You'll need a minimum area of 15' x 20', plus additional clearances and loading space. Access is critical – double doors or removable wall sections may be necessary for equipment delivery.

On the utility front, you'll need a robust gas line delivering natural gas at 1,000 Btu/cu ft (2,350 CFH at 7" w.c.) or propane at 2,500 Btu/cu ft (940 CFH at 11" w.c.). Electrical requirements typically include 240V, single phase, 40 amp service – standard for industrial equipment but more substantial than most residential connections.

Ventilation is another critical factor. Your stack height and diameter must comply with local codes, usually extending 15-20 feet above roof level. This isn't just about smoke – it's about ensuring proper draw and minimizing any impact on surrounding properties.

Most reputable manufacturers include installation in the purchase price or offer it as a reasonably priced add-on service. This typically covers equipment delivery and placement, utility connections, initial testing and calibration, and the all-important operator training and certification. Having the manufacturer's team handle installation ensures everything is set up to factory specifications.

Keeping the Furnace Running Smoothly

A well-maintained cremation furnace can provide 15-20 years of reliable service, but this longevity depends entirely on how well you care for it. Think of it like maintaining a car – regular attention prevents major breakdowns.

Daily maintenance is simple but essential. Your operators should perform visual inspections of the refractory material, clean the loading area, check door seals and gaskets, and verify the control system is operating normally. These quick checks take minutes but can prevent serious issues.

On a weekly basis, clean combustion air intakes, inspect burners for proper operation, check the exhaust system, and test safety interlocks. Monthly maintenance should include a more thorough inspection of the refractory for damage, cleaning and inspecting burner assemblies, checking electrical connections, and verifying temperature sensor calibration.

Annual service is where professionals should step in. This more comprehensive maintenance includes complete burner tuning and efficiency testing, thorough refractory inspection, control system updates, emissions testing, and safety system verification. Most manufacturers offer service contracts ranging from $2,000 to $5,000 annually – an investment that pays for itself by preventing major failures and downtime.

Modern cremation furnaces often include remote diagnostic systems like Tek Marshal that allow technicians to monitor equipment performance and troubleshoot issues from afar. This technology has been a game-changer, dramatically improving response times and reducing maintenance costs by often resolving problems without requiring an on-site visit.

With proper care, you'll only need major refractory replacement every 3-5 years, depending on your usage patterns. When your cremation furnace for sale becomes your cremation furnace in operation, establishing these maintenance routines from day one will ensure you get the maximum return on your investment.

At American Mortuary Coolers, we understand that your cremation equipment is the heartbeat of your operation. That's why we emphasize not just quality equipment, but also proper installation and ongoing support to keep your business running smoothly for years to come.

How to Choose Reliable Manufacturers & Suppliers

Selecting the right manufacturer or supplier for your cremation furnace for sale is as important as choosing the equipment itself. Here's how to identify reputable partners:

Leading Manufacturers in the Industry

US Cremation Equipment: Known for their Classic and Sierra series, offering both human and animal cremation systems with a focus on reliability and efficiency.

B&L Cremation Systems: A family-owned company recognized for innovations like fuel-saving ceramic materials and the Hot Hearth System. They offer worldwide service and distribution.

Armil CFS/Cremation Systems: Manufacturers of the CFS2300 with its innovative Quick Change Hearth system and remote diagnostic capabilities.

Firelake Manufacturing: Specializes in cost-effective pet cremation systems with excellent ROI models for veterinary practices.

Addfield: UK-based manufacturer with over 40 years of experience and distribution in more than 140 countries, recently expanding their US presence.

Matthews Environmental Solutions: Offers both standard and custom-engineered solutions for various cremation applications.

International manufacturers like M.D. Enterprises also offer competitive options, though considerations around import logistics, parts availability, and service support become more important.

When evaluating manufacturers, consider these factors:

- Years in Business: Look for established companies with proven track records

- Manufacturing Location: US-made equipment often means faster parts availability

- Service Network: Ensure coverage in your geographic area

- BBB Ratings and Reviews: Check for customer satisfaction patterns

- Industry Association Membership: CANA membership indicates industry engagement

- Warranty Terms: Compare coverage periods and what's included

- Parts Availability: Ensure critical components are readily available

- Technical Support: 24/7 hotline access is invaluable during operational issues

Vetting a Seller Before You Buy

Before committing to a purchase, take these steps to verify a seller's credibility:

- Request a Factory Visit: See the manufacturing process firsthand

- Speak with Current Customers: Ask for references of facilities similar to yours

- Verify Certifications: UL listing, ISO certifications, and environmental compliance

- Review Parts Inventory: Ensure critical components are stocked

- Check Response Time: Test their customer service by asking technical questions

- Evaluate Training Programs: Comprehensive operator training is essential

- Review Installation Support: Who handles the installation, and what's included?

- Check Financing Options: Reputable manufacturers often have established financing partners

At American Mortuary Coolers, we maintain relationships with top manufacturers across the country, helping our clients steer these considerations to find the best match for their specific needs. Our nationwide presence, with locations from New York to Los Angeles and service across all regions, ensures consistent support regardless of your location.

When Refurbished Beats New

For many facilities, especially those with budget constraints or lower volume needs, refurbished equipment offers compelling advantages:

- Cost Savings: Typically 30-40% less than new equipment

- Updated Controls: Most refurbished units receive modern control systems

- Warranty Coverage: Many refurbished units include 1-2 year warranties

- Faster Availability: Often available for immediate delivery

- Proven Performance: Established track record in actual operation

- Trade-In Value: Many manufacturers offer credits for your existing equipment

When considering refurbished equipment, look for:

- Comprehensive Refurbishment Process: Not just cosmetic updates

- New Refractory Materials: Critical for efficiency and longevity

- Modern Control Systems: Should meet current safety standards

- Emissions Testing: Verify the unit meets current environmental standards

- Detailed Documentation: Complete records of the refurbishment process

- Installation Support: Same level of support as new equipment

A quality refurbished cremation furnace from a reputable manufacturer can provide the same reliability and performance as new equipment at a significantly lower cost, making it an excellent option for many facilities.

Frequently Asked Questions about Buying a Cremation Furnace

What size furnace do I need for my facility volume?

Choosing the right size cremation furnace is a bit like finding the perfect pair of shoes - it needs to fit your specific needs. Your expected daily cremation volume is the most important factor here.

If you're handling just 1-2 cremations per day, a standard efficiency unit with 150-minute cycles will likely meet your needs. For human remains, models like the N-20SA or similar entry-level units work beautifully. Pet facilities with this volume would do well with the Model A or Sierra-300 - both reliable workhorses without breaking the bank.

For medium-volume facilities (3-5 cremations daily), you'll want to look at units with faster 60-90 minute cycles. The Phoenix II-1 or Classic-PRO strike that sweet spot between efficiency and reasonable cost. These units let you maintain a steady workflow without keeping families waiting too long.

High-volume operations handling 6+ cremations daily need the big guns - high-efficiency models with 45-60 minute cycles like the Phoenix II-3 or Classic-XCEL. These units keep things moving smoothly even during your busiest periods.

Chamber capacity (maximum weight) and throughput (processing speed) are different specifications. A furnace with 1,000 lb capacity that processes at 150 lb/hr will take significantly longer than one running at 400 lb/hr. This distinction matters when you're planning your daily schedule.

For pet cremation specifically, consider whether you'll offer individual or communal services. If individual cremations are your focus, separation trays can dramatically increase your effective capacity without requiring a larger (and more expensive) furnace.

How long does shipping and installation usually take?

The journey from placing your order to performing your first cremation involves several steps, and timing varies based on what you're purchasing.

For new cremation furnaces for sale, expect 8-16 weeks from order to delivery. This timeline depends on the manufacturer's current production schedule and any customizations you've requested. Custom configurations naturally take longer than standard models.

If you're going the refurbished route, you're in luck - these units are often available much more quickly, sometimes within just 2-4 weeks of placing your order.

Once your equipment arrives on-site, basic installation typically takes 3-7 days, followed by 2-3 days of testing and training to ensure everything works perfectly and your team knows how to operate it safely.

The permitting process is often the most time-consuming part of the entire journey, potentially taking 2-6 months depending on your location. This is definitely something you'll want to start early!

From initial order to being fully operational, a realistic timeline is 3-8 months for new equipment, potentially less for refurbished units. We always recommend beginning the permitting process while your equipment is being manufactured to avoid unnecessary delays.

At American Mortuary Coolers, we help coordinate this entire timeline, ensuring all components align for a smooth, efficient installation process. We've guided many funeral homes through this process and can help you avoid common pitfalls that cause delays.

Are electric cremation furnaces truly greener than gas units?

The environmental question isn't as straightforward as it might seem - the "greener" choice depends on several important factors.

Electric cremation furnaces produce zero emissions at your facility, which is a significant advantage in urban locations or areas with strict air quality regulations. This can simplify your permitting process and create a cleaner immediate environment around your facility.

However, the true environmental impact of electric units depends heavily on your local power grid. In regions powered primarily by renewable energy like solar, wind or hydroelectric, electric units genuinely reduce your carbon footprint. In areas still heavily dependent on coal power, a gas unit might actually have a lower overall environmental impact.

Modern gas cremation furnaces have come a long way in environmental performance. With advanced secondary combustion chambers and sophisticated emission controls, today's units burn extremely clean, often exceeding regulatory requirements by a comfortable margin.

Your operational patterns matter too. Electric units can be more efficient for facilities with intermittent usage patterns, as they don't require the same warm-up and cool-down cycles as gas units. If you perform cremations on a regular schedule, this advantage becomes less significant.

For most facilities, the most environmentally responsible choice depends on your specific situation - your local energy sources, regulatory environment, and how you'll use the equipment. At American Mortuary Coolers, we can help analyze these factors for your specific location to determine which option aligns best with your environmental values while meeting your operational needs.

More info about cremation equipment tools of the trade

Conclusion

Selecting the right cremation furnace for sale is much more than a simple purchase—it's a decision that will shape your facility's service quality, operational efficiency, and financial health for many years to come. As we've explored throughout this guide, several key factors should guide your decision-making process.

Finding the perfect balance between capacity and your facility's needs is essential. Whether you're a high-volume funeral home requiring a sophisticated human cremator or a veterinary clinic looking for a compact pet unit, the right equipment creates the foundation for efficient, dignified service. The lowest-priced option isn't always the most economical in the long run.

Beyond the sticker price, understanding the complete financial picture makes all the difference. When you factor in operating costs, maintenance requirements, and expected lifespan, a quality cremation furnace often pays for itself through improved efficiency and reduced downtime. The financing options we discussed can help make this important investment more accessible while maintaining healthy cash flow.

Today's cremation technology offers remarkable advances that weren't available even a few years ago. Touchscreen controls make operation intuitive, remote diagnostics can prevent costly service visits, and modular hearth systems dramatically reduce maintenance downtime. These features aren't just bells and whistles—they translate directly to improved service and profitability.

Environmental and safety compliance shouldn't be an afterthought. Working with a reputable manufacturer ensures your equipment meets or exceeds all regulatory requirements, preventing the headaches and potential liabilities that come with non-compliant equipment. This is an area where cutting corners simply isn't worth the risk.

At American Mortuary Coolers, we've helped countless funeral homes and veterinary facilities find their perfect cremation solution. Based in Tennessee but serving clients nationwide from New York to Los Angeles, we understand that every facility has unique needs. We take pride in our personalized approach, taking the time to understand your specific requirements before recommending equipment options.

The cremation industry continues to evolve, with new technologies improving efficiency and environmental performance every year. By partnering with experienced professionals who understand both the technical and business aspects of cremation, you'll be well-positioned to provide exceptional service while maintaining a healthy bottom line.

Whether you're expanding your current operation, replacing aging equipment, or entering the cremation market for the first time, we're here to help you steer the options and find the perfect solution for your facility. After all, when you succeed, we succeed—and that's the foundation of every relationship we build.