Why Understanding Mortuary Freezers is Critical for Your Facility

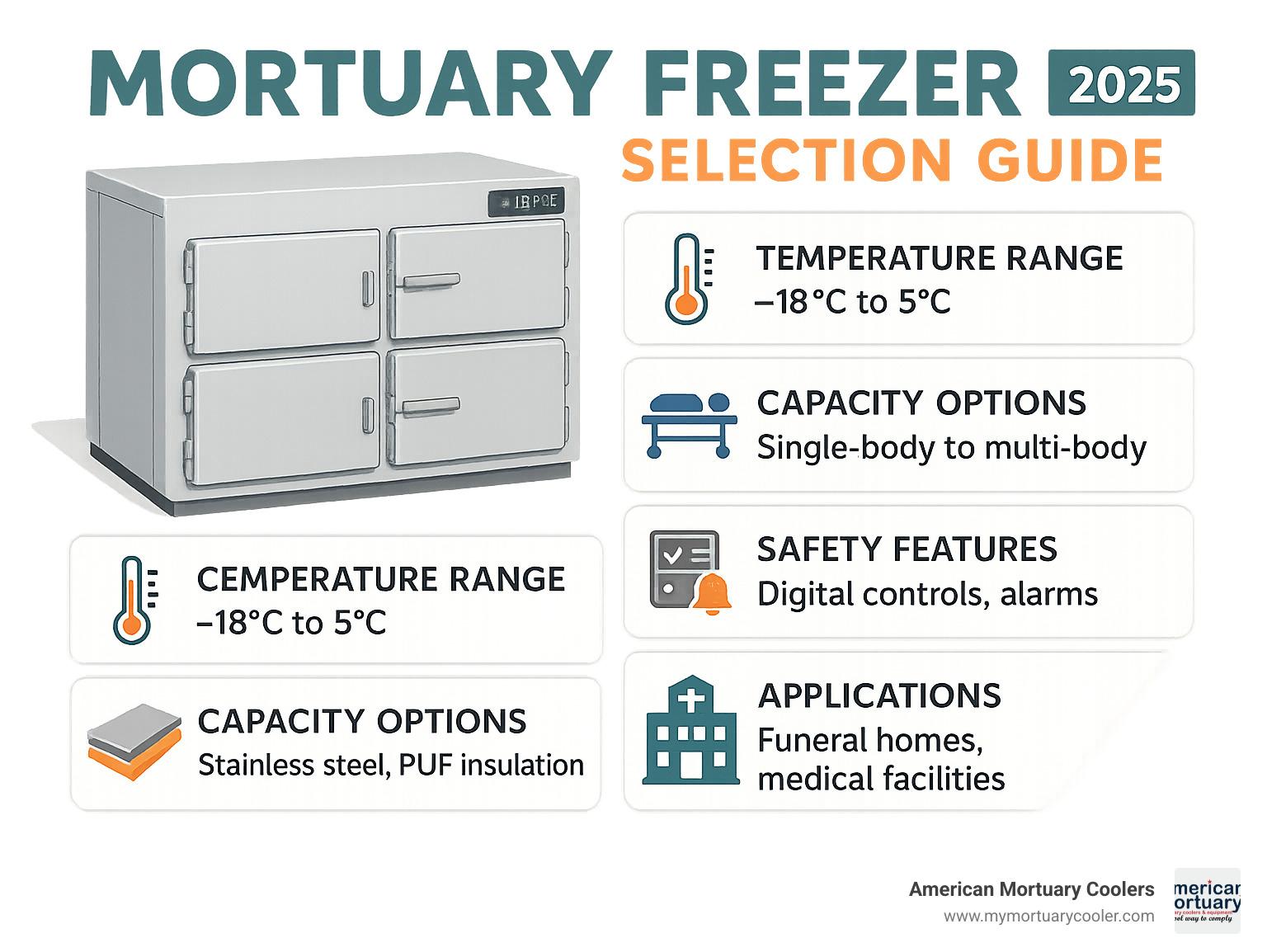

A Mortury Freezer is a specialized refrigeration unit designed to preserve human remains at controlled temperatures, typically ranging from -18°C to 5°C, preventing decomposition while maintaining dignity during storage and transport.

Key Mortuary Freezer Features:

- Temperature Range: -18°C to 5°C for optimal preservation

- Construction: Stainless steel SS304 with 100mm PUF insulation

- Capacity Options: Single-body to multi-body configurations (2-8 bodies)

- Types: Mobile units, fixed cabinets, and walk-in chambers

- Safety Features: Digital controls, alarms, antimicrobial surfaces

- Applications: Hospitals, funeral homes, disaster sites, morgues

When dealing with the sensitive responsibility of preserving human remains, funeral home directors need equipment that combines reliability with respect. Modern mortuary freezers use advanced refrigeration technology to slow decomposition, giving families time to grieve and plan services without urgent pressure.

The research shows that most mortuary freezers operate within factory settings between -2°C and 5°C, with individual refrigeration systems for each chamber improving energy efficiency by up to 30%. Standard units accommodate 150-200 kg per body tray, constructed with durable stainless steel for easy cleaning and long-term hygiene.

As American Mortuary Coolers, we've spent years helping funeral directors steer the complex world of mortuary refrigeration equipment, specializing in matching Mortury Freezer solutions to specific facility needs and space constraints. Our experience has shown that the right equipment choice can dramatically improve both operational efficiency and service quality.

Quick look at Mortury Freezer:

Mortury Freezer Basics: Definition & Purpose

When families face the loss of a loved one, they deserve time to grieve without the pressure of rushed decisions. That's exactly where a Mortury Freezer becomes essential for your facility.

Think of a Mortury Freezer as a guardian of dignity. Its primary job is controlling the natural decomposition process through precise temperature management, creating a sterile environment that preserves human remains respectfully while giving families the breathing room they need to make thoughtful arrangements.

The science here is actually pretty straightforward. At room temperature, bacterial activity kicks into high gear, accelerating decomposition rapidly. But when you maintain temperatures between -18°C to 5°C, you dramatically slow this natural process. Most facilities we work with set their units between -2°C and 5°C as their go-to range—it provides excellent preservation without the hefty energy bills that come with deep freezing.

Now, you might wonder what makes these units different from regular commercial freezers. The answer lies in the specialized engineering designed specifically for cadaver storage.

| Feature | Mortuary Freezer | Standard Refrigerator |

|---|---|---|

| Temperature Range | -18°C to 5°C | 2°C to 8°C |

| Construction | SS304 stainless steel | Standard steel/plastic |

| Insulation | 100mm PUF high-density | 50-75mm standard foam |

| Load Capacity | 150-200 kg per tray | 5-10 kg per shelf |

| Hygiene Features | Antimicrobial surfaces | Basic cleaning |

| Safety Systems | Multiple alarms, backup | Basic temperature alert |

The construction differences are where mortuary freezers really shine. While a regular freezer might use basic insulation, Mortury Freezers employ high-density PUF (polyurethane foam) insulation that's typically 100mm thick. This isn't just overkill—it ensures minimal thermal loss and maintains rock-solid consistent temperatures even when staff need to open doors frequently throughout the day.

The SS304 stainless steel construction isn't just about looks either. This medical-grade material resists corrosion, cleans easily, and maintains the hygienic standards your facility needs to meet health regulations and family expectations.

Over our years helping funeral directors across Tennessee and beyond, we've seen facilities struggle when they try to cut corners with inadequate equipment. The wrong freezer can lead to preservation issues, sky-high energy costs, and most importantly, compromise the dignity of care that families expect during their most difficult moments.

That's why understanding these basics matters so much—your Mortury Freezer isn't just equipment, it's an essential part of providing compassionate, professional service when it matters most.

Main Types of Mortuary Freezers & When to Use Them

Choosing the right Mortury Freezer can feel overwhelming, but it doesn't have to be. After years of helping funeral directors across Tennessee, Atlanta, Chicago, and beyond, we've learned that the key is matching your equipment to your actual needs—not what you think you might need someday.

Think of mortuary freezers like vehicles. You wouldn't buy a semi-truck for your daily commute, and you wouldn't use a compact car to haul furniture. The same logic applies here.

Mobile units are your go-to solution when flexibility matters most. These wheeled systems typically weigh between 100-130 kg and can be moved wherever you need them. They're perfect for emergency response, temporary overflow, or facilities that need to relocate equipment regularly.

Fixed cabinets are the reliable workhorses that most funeral homes depend on. Available in 2, 3, 4, 6, and 8-body configurations, these units feature individual refrigeration systems for each chamber. This smart design means if one compressor has issues, the others keep running—a feature that's saved countless facilities from disaster.

Walk-in chambers are for high-volume operations or forward-thinking facilities planning for growth. These modular systems handle anywhere from 8-30 bodies and can expand as your needs change. They're like the Swiss Army knife of mortuary equipment.

We've noticed that hospitals usually prefer fixed multi-body cabinets because they're reliable and space-efficient. Funeral homes often choose a mix—fixed units for daily operations and mobile units for overflow situations. Large metropolitan morgues typically invest in walk-in systems because they can scale up without starting over.

The beauty of understanding these types is that you can make decisions based on your actual workflow, not just what looks impressive in a catalog. For a deeper dive into selecting the right type for your specific situation, check out our guide on Types of Morgue Freezers and Their Uses.

Mobile Mortury Freezer Units

Mobile Mortury Freezer units have completely changed how we handle unexpected situations. These portable systems are lifesavers when you need storage capacity yesterday, not next week.

The real magic happens in their rapid deployment capability. Most units can be up and running within 30 minutes of arrival. They're designed to work with standard 2000-3000 VA generators, so power outages or remote locations aren't deal-breakers. The weather-resistant construction means they can handle outdoor conditions with proper covers.

We've supplied these units for everything from disaster response teams to facilities undergoing major renovations. The MG Classic models measure 228.6 cm × 71.12 cm × 71.12 cm and weigh just 105 kg. That means two people can position and operate them without calling in a crane.

The quick setup process is genuinely impressive. Roll it into position, plug it in, and you're ready to go. No complicated installation, no waiting for technicians, no excuses.

The trade-off is usually capacity—most mobile units handle single bodies, though some larger models can accommodate two. They're also slightly less energy-efficient than fixed units due to their portable design requirements. But when you need flexibility and speed, these compromises are worth it.

Walk-In & High-Capacity Systems

When you have the space and volume to justify it, walk-in mortuary chambers offer best flexibility and capacity. These systems use modular panel construction that meets Federal Energy Independence & Security Act requirements and can be configured for virtually any space.

The scalability factor is what makes these systems special. You can start with a 4-body configuration and expand to 30+ bodies without starting over. The modular design means you can literally disassemble, relocate, and reconfigure as your needs change.

Accessibility is another huge advantage. Oversized doors accommodate gurneys and equipment easily. You can add floor drains, adjustable shelving, and specialized lighting. The better insulation-to-volume ratios make them more energy-efficient than smaller units.

We've helped facilities expand their walk-in systems multiple times as their service areas grew. It's like having a mortuary freezer that grows with your business instead of limiting it.

For detailed specifications and technical drawings that show exactly how these systems work, you can Download Product Specifications. The engineering behind these systems is actually quite fascinating once you see how all the pieces fit together.

Critical Features, Technology & Safety Standards

When you're investing in a Mortury Freezer, you're not just buying a refrigerator - you're investing in sophisticated technology that needs to work flawlessly when families are counting on you. The difference between basic cooling equipment and professional mortuary freezers lies in the details that matter most during critical moments.

The foundation of any reliable mortuary freezer starts with stainless steel SS304 construction. This isn't just about looking professional - this grade of stainless steel resists corrosion from cleaning chemicals and maintains its integrity through thousands of cleaning cycles. We've seen cheaper units with inferior steel start showing rust and pitting within just two years.

High-density PUF insulation at 100mm thickness makes the real difference in energy efficiency and temperature stability. This polyurethane foam insulation maintains consistent temperatures even when doors are opened frequently throughout the day. Combined with R404A refrigerant, these systems provide reliable cooling while meeting environmental protection standards.

The dual compressor design in multi-body units gives you something invaluable: peace of mind. If one compressor fails, the other chambers continue operating normally. We've had customers tell us this feature saved them from disaster during holiday weekends when service calls would have been nearly impossible.

Modern units also feature antimicrobial surfaces that actively inhibit bacterial growth. This isn't just about meeting health codes - it's about maintaining the highest standards of care and dignity that families expect from your facility.

Quality mortuary freezers must meet strict certification standards. NSF approval ensures sanitary design, while EISA compliance meets federal energy efficiency requirements. ISO 9001 certification demonstrates quality management systems, and UL listing confirms electrical safety. These aren't just letters on a spec sheet - they represent real protection for your investment and your reputation.

For a deeper dive into temperature management and safety protocols, check out our detailed guide on Morgue Freezer Temperature: Keeping Cool Under Pressure.

Digital Controls in a Mortury Freezer

The control system is where modern Mortury Freezer technology really shines. Gone are the days of simple dial thermostats that left you guessing about actual temperatures. Today's microprocessor-based controllers provide precision and documentation that can make the difference between smooth operations and costly problems.

Microprocessor-based PID control maintains temperatures within ±1°C accuracy, which is crucial for consistent preservation quality. The system constantly adjusts cooling cycles based on actual conditions rather than simple on-off switching that can cause temperature swings.

Data logging capabilities have become essential for many facilities. These systems track temperatures 24 hours a day and can provide detailed printouts showing exactly what happened and when. If you ever need to document preservation conditions for legal or insurance purposes, having months of precise temperature records can be invaluable.

Remote monitoring through SMS and email alerts means you'll know immediately if something goes wrong, even when you're not at the facility. We've helped prevent numerous potential losses by installing systems that alert managers the moment temperatures drift outside acceptable ranges.

Battery backup systems keep monitoring active even during power outages. The controller continues tracking conditions and will alert you if temperatures start rising before backup power or generators can restore full cooling.

Multi-zone control allows different temperature settings for different chambers when needed. Some facilities prefer slightly different temperatures for short-term versus long-term storage, and advanced controllers make this simple to manage.

Hygiene & Staff Safety

Working safely around mortuary equipment requires thoughtful design that protects your staff while maintaining the highest hygiene standards. Modern Mortury Freezer units incorporate multiple safety features that go far beyond basic refrigeration requirements.

Seamless construction eliminates the cracks and crevices where bacteria love to hide. Every joint is welded smooth, and corners are rounded to prevent buildup of contaminants. This makes thorough cleaning possible and helps maintain sanitary conditions between uses.

Easy-clean surfaces with smooth stainless steel and removable trays mean your staff can properly sanitize everything that comes in contact with remains. The trays slide out completely for washing, and the interior surfaces wipe clean without special tools or harsh chemicals.

Anti-drop rollers provide crucial safety protection. Double rows of silent nylon rollers support trays from underneath, preventing dangerous accidents if a tray shifts unexpectedly. We've seen too many back injuries from facilities with inferior roller systems.

Safety release handles inside walk-in units prevent accidental entrapment. While modern units have excellent sealing, the interior releases ensure staff can always exit safely even if the door mechanism malfunctions.

Proper LED lighting with pilot switches lets staff see clearly inside units without guesswork. Good visibility prevents accidents and ensures thorough cleaning and inspection.

OSHA compliance requires specific safety protocols around mortuary equipment, including proper PPE zones, ventilation requirements, and emergency procedures. When we install equipment, we work with facilities to ensure everything meets applicable safety standards from day one.

The ergonomic design of modern units reduces physical strain on staff. Appropriate heights, smooth-operating mechanisms, and logical layouts help prevent the repetitive stress injuries that can develop from poor equipment design.

Choosing, Operating & Maintaining Your Unit (FAQs Included)

Selecting the right Mortury Freezer feels overwhelming at first, but it doesn't have to be. After helping funeral directors across Tennessee, Atlanta, Chicago, and dozens of other cities find their perfect equipment match, we've learned that the best decisions come from understanding your real needs - not just what looks impressive in a brochure.

The biggest mistake we see? Facilities choosing based on their current average needs instead of planning for peak demand. That quiet Tuesday afternoon storage requirement means nothing when you're dealing with a weekend accident or unexpected surge. Smart planning means calculating your highest historical demand and adding a 20% buffer for those situations you can't predict.

Capacity planning starts with honest numbers. Pull your storage records from the last year and identify those peak periods. Space utilization comes next - measure everything twice, including door clearances and ceiling height. We've seen too many perfect units that couldn't fit through doorways or left no room for maintenance access.

Power requirements often surprise facility managers. A 6-body unit might need 220V service that your current electrical system can't handle. Energy efficiency becomes crucial over time - that cheaper unit might cost thousands more in electricity over five years. Finally, service access planning prevents headaches later when you need repairs or routine maintenance.

Financing options have made equipment upgrades much more manageable. We offer 0% down financing with deferred payments for qualifying orders, which helps facilities invest in proper equipment without straining their cash flow. Many directors tell us this flexibility let them choose the right system instead of settling for what they could afford upfront.

Customization capabilities have become a game-changer. Standard units work fine for basic needs, but we frequently modify door configurations, add specialized shelving, or integrate specific monitoring systems. Your facility is unique, so your equipment should be too.

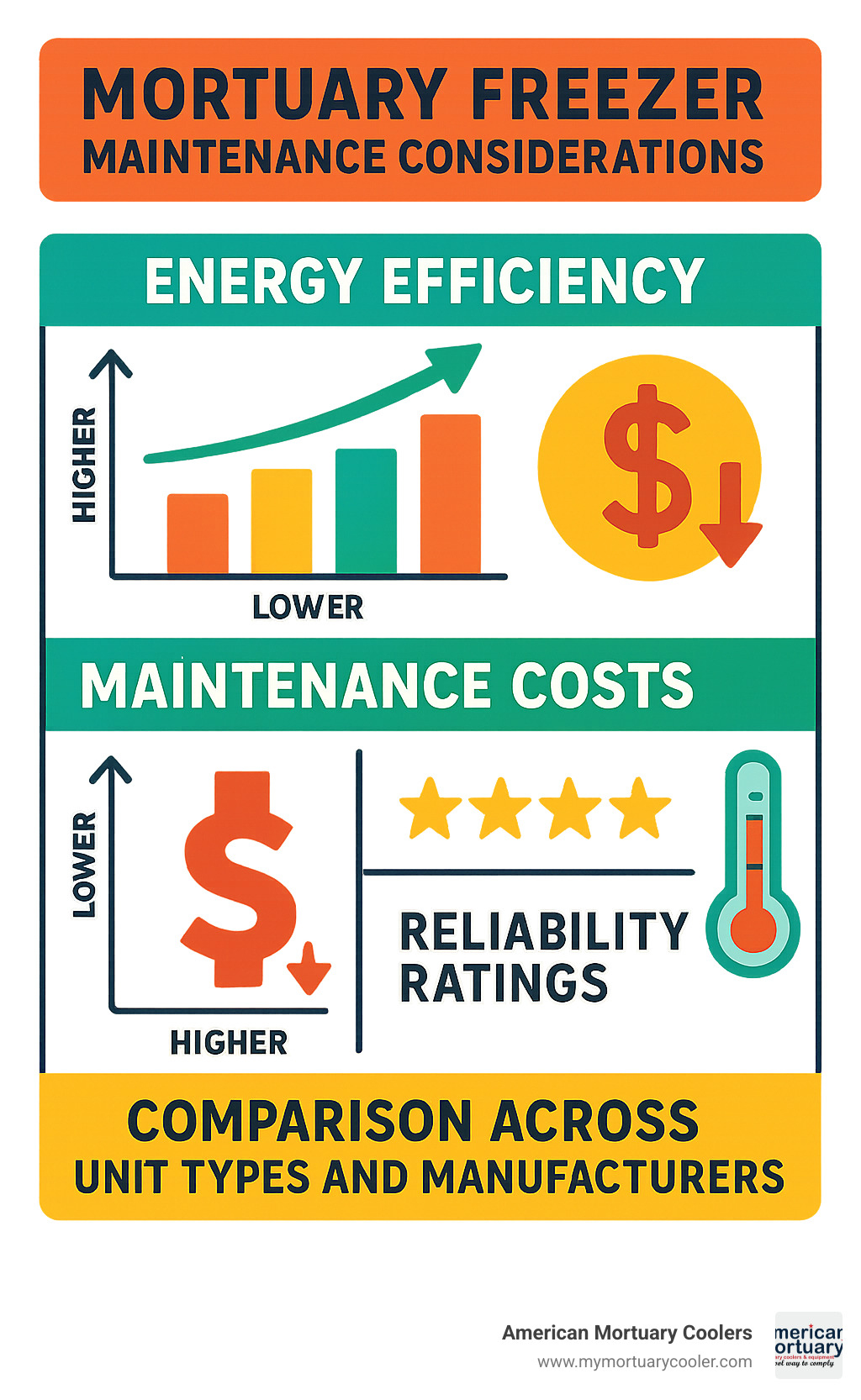

Energy efficiency varies dramatically between different Mortury Freezer designs. Units with individual compressors for each chamber typically slash energy costs by 20-30% because they only cool occupied spaces. High-quality insulation and efficient compressors can reduce consumption to just 1-2.5 units per day for smaller models. That difference adds up quickly on your monthly bills.

For detailed information about financing alternatives, check out our comprehensive guide: Lease or Rent? Your Guide to Morgue Freezer Rentals.

How Do I Pick the Right Mortury Freezer?

Choosing the right Mortury Freezer becomes straightforward when you follow a systematic approach. We've refined this process through hundreds of installations, and it consistently leads to satisfied customers who get exactly what they need.

Start with capacity analysis by reviewing your actual storage needs from the past 12 months. Look for seasonal patterns - many facilities see higher demand during winter months or around holidays. Add that 20% buffer we mentioned earlier, then consider your growth plans. Are you expanding services or coverage areas?

Space planning requires precise measurements, not estimates. Check door clearances, ceiling height, and ventilation requirements. Plan workflow patterns too - your staff shouldn't have to steer obstacle courses during their most stressful moments. Leave adequate space around units for maintenance access because you'll need it eventually.

Load requirements matter more than many people realize. Standard trays support 150-200 kg, but verify this matches your specific needs. Some facilities require higher capacity trays for larger individuals or specialized applications that standard specifications don't cover.

The modular versus fixed decision impacts both immediate costs and future flexibility. Modular systems offer incredible adaptability but require higher initial investment. Fixed systems provide simplicity and lower maintenance needs but can't grow with changing requirements. Consider where your facility will be in five years, not just today.

Future expansion planning saves money and headaches down the road. Walk-in systems excel at growth capability - you can literally add panels and increase capacity. Fixed cabinets require complete replacement for expansion, which means losing your entire investment in the original unit.

What Certifications Should My Mortuary Freezer Meet?

Proper certifications protect your facility, your staff, and the families you serve. These aren't just bureaucratic hoops to jump through - they represent real safety and performance standards that prevent problems before they start.

UL-NSF certification combines electrical safety standards with strict sanitary design requirements. This dual certification ensures your unit won't create electrical hazards while meeting the highest cleanliness standards for handling human remains. It's non-negotiable for professional facilities.

CE marking appears on imported equipment and indicates compliance with European safety standards. While not always legally required in the US, it demonstrates the manufacturer's commitment to international safety standards.

ISO 9001 certification tells you the manufacturer has documented quality control processes. This translates directly to more consistent product quality, better long-term reliability, and fewer unexpected failures. Equipment from ISO 9001 certified manufacturers typically lasts longer and performs more consistently.

EISA compliance ensures energy efficiency that directly impacts your operating costs. Non-compliant units can consume 40-50% more energy than certified models. Over a 15-year equipment lifespan, this difference can cost thousands of dollars.

Local health codes vary by jurisdiction but typically include sanitary design requirements, ventilation standards, and documentation needs. Your local health department can provide specific requirements for your area.

These certifications matter because they prevent expensive problems. UL-NSF certification prevents equipment failures that could compromise preservation or endanger staff. Energy efficiency certification keeps operating costs manageable. Quality certifications reduce the likelihood of costly repairs and replacements.

How Often Should Preventive Maintenance Be Done?

Regular maintenance extends equipment life, prevents costly failures, and ensures the consistent performance families depend on during their most difficult times. We recommend a systematic approach that addresses different components based on their criticality and wear patterns.

Quarterly maintenance keeps your Mortury Freezer running smoothly between professional service visits. Clean condenser coils and check airflow - dirty coils force compressors to work harder and use more energy. Inspect door seals and gaskets for wear or damage that could compromise temperature control. Test alarm systems and verify temperature accuracy with calibrated thermometers. Check refrigerant levels and pressures for signs of leaks or system problems. Clean and sanitize all interior surfaces thoroughly.

Annual maintenance requires more detailed attention and often benefits from professional service. Complete refrigerant system inspection catches problems before they cause failures. Replace worn gaskets and seals that could compromise performance. Calibrate temperature controllers to ensure accurate readings. Inspect all electrical connections for corrosion or looseness. Update system documentation with any changes or repairs.

Emergency maintenance can't be scheduled but must be addressed immediately. Replace failed components quickly to prevent preservation problems. Address temperature deviations promptly - even small changes can impact preservation quality. Clean up spills or contamination immediately to prevent sanitary issues. Update software and firmware as manufacturers release improvements.

Service contracts make sense for most facilities, especially those with complex multi-chamber or walk-in systems. Good contracts include scheduled preventive maintenance, emergency repair response within four hours, parts and labor coverage, temperature monitoring and alerts, and annual calibration and certification.

Service contract costs typically run 8-12% of equipment value annually, but they prevent much higher costs from emergency repairs and potential preservation failures. We've seen facilities save thousands by catching problems early through regular professional maintenance.

Conclusion

When it comes to preserving human remains with dignity and respect, your choice of Mortury Freezer isn't just about buying equipment—it's about investing in your facility's reputation and the peace of mind of grieving families.

The mortuary refrigeration industry has transformed dramatically over the past decade. What started as basic refrigeration boxes have evolved into sophisticated preservation systems with microprocessor controls, energy-efficient dual compressors, and antimicrobial surfaces that meet the highest safety standards.

At American Mortuary Coolers, we've seen how the right equipment choice transforms operations. A small funeral home in Tennessee recently upgraded from an aging single-compressor unit to our dual-system mobile mortuary freezer. The energy savings alone paid for the upgrade within two years, and the reliability improvement eliminated their middle-of-the-night emergency calls.

Whether you're managing a busy metropolitan morgue that needs a custom walk-in chamber for 20+ bodies, or operating a family funeral home that requires a reliable two-body cabinet, we understand that one size definitely doesn't fit all. That's why we've built our reputation on custom solutions delivered nationwide across all 48 contiguous states.

Our experience serving facilities from Johnson City TN to Los Angeles, from Chicago IL to Dallas TX, has taught us that successful mortuary refrigeration isn't just about temperature control. It's about energy efficiency that keeps operating costs manageable, reliability that prevents preservation emergencies, and construction quality that lasts 15-20 years with proper maintenance.

The investment in quality mortuary equipment pays dividends in ways that extend far beyond the purchase price. Proper temperature control, advanced monitoring systems, and antimicrobial construction materials protect both the dignity of those in your care and the reputation you've worked years to build.

Ready to explore how the right Mortury Freezer can improve your facility's operations? We'd love to discuss your specific needs and show you why funeral directors from the Midwest to the Pacific region trust us for their mortuary refrigeration needs.

Contact us today for a custom consultation, and find why American Mortuary Coolers has become the trusted name in mortuary refrigeration across Tennessee, Atlanta, Columbia, Pittsburgh, New York, and beyond.

For comprehensive information about all your mortuary freezer options, including detailed specifications and selection guidance, check out The Ultimate Guide to Mortuary Freezer Options.