Understanding Modern Crematorium Technology

A crematorium furnace is specialized equipment used to reduce human remains to bone fragments through high-temperature combustion, typically operating at 800-1300°C (1,472-2,372°F). These advanced systems are designed for efficient, dignified, and environmentally responsible cremation.

| Crematorium Furnace Essentials | Details |

|---|---|

| Primary Components | Combustion chamber, burners, refractory lining, control system |

| Operating Temperature | 800-1300°C (1,472-2,372°F) |

| Average Cremation Time | 60-150 minutes (depending on furnace model and body size) |

| Capacity | Most handle cases up to 750+ lbs |

| Fuel Types | Gas (natural/propane), electric, wood-based, hybrid |

| Environmental Features | Secondary combustion chambers, filtration systems |

The cremation industry has evolved dramatically over recent decades, with cremation rates in North America rising from just 5% in the 1950s to over 60% today. This shift reflects changing cultural attitudes, environmental concerns, and economic considerations that have made cremation an increasingly popular choice for final disposition.

Modern crematorium furnaces represent a significant technological advancement over earlier designs, incorporating sophisticated control systems, improved safety features, and improved emission controls to meet strict environmental regulations.

I'm Mortuary Cooler, with experience in mortuary equipment including crematorium furnace technologies and their implementation in funeral facilities across North America. My work has involved consulting on crematorium furnace installations and helping funeral directors select appropriate systems for their specific needs.

What Is a Crematorium Furnace & How It Works

When we talk about a crematorium furnace, we're referring to a remarkable piece of engineering designed with one specific purpose: the dignified change of human remains into bone fragments and ash. Sometimes called cremators or retorts by industry professionals, these specialized thermal units combine precision engineering with respectful handling of the deceased.

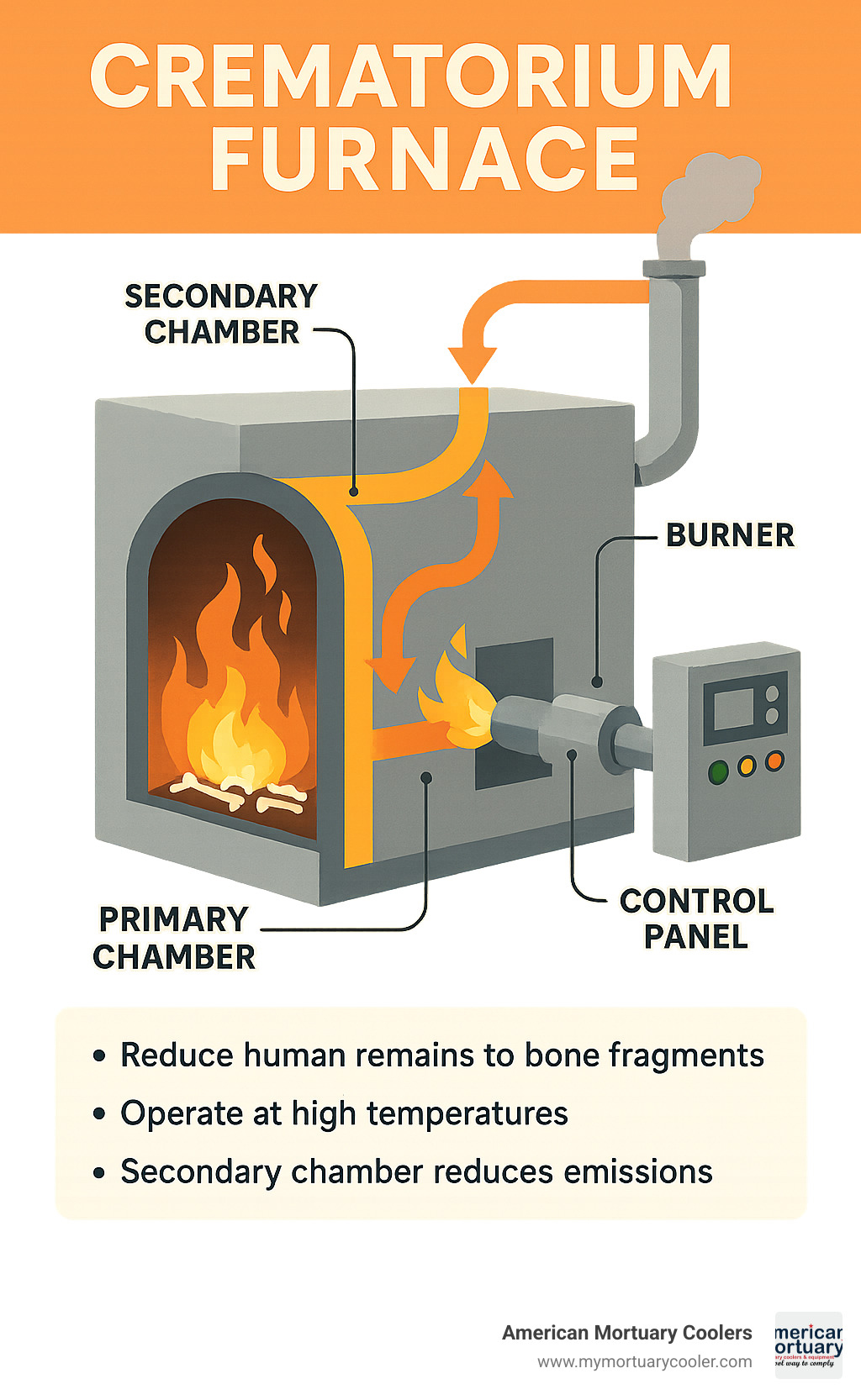

At the heart of every crematorium furnace is a primary combustion chamber—the space where the actual cremation happens. This chamber houses a powerful main burner, typically running on natural gas or propane, though you'll learn about electric and other alternatives later in this article. This primary burner creates the intense heat that makes cremation possible.

Modern crematorium furnaces operate at temperatures between 800°C and 1,300°C (that's 1,472°F to 2,372°F)—hot enough to melt aluminum! This extreme heat ensures complete combustion while preserving only the inorganic bone fragments. The process usually takes between 60 to 150 minutes, depending on several factors.

"Every cremation is as unique as the person it honors," explained one crematory operator I spoke with. "Today's equipment adjusts automatically throughout the process, ensuring everything happens with both dignity and efficiency."

One of the most important features of any modern crematorium furnace is its secondary combustion chamber, often called the afterburner. This component plays a crucial environmental role by capturing and burning off gases and particles released during the main cremation process. The result? Significantly cleaner emissions from the stack.

Key Components of a Modern Crematorium Furnace

Today's crematorium furnaces are sophisticated systems with multiple components working together seamlessly:

The retort forms the main chamber where the body rests during cremation. Manufacturers build these using specialized refractory materials engineered to withstand not just extreme heat but also the stress of heating up and cooling down thousands of times over the furnace's lifetime.

The hearth serves as the floor of the retort, supporting the casket and remains. Advanced systems feature what manufacturers call a "recessed hot hearth design" that improves efficiency and accommodates larger cases—an important consideration as average case sizes have increased over the years.

Every crematorium furnace includes a primary burner that generates the initial heat, positioned to direct flames effectively. The secondary burner sits in the afterburner chamber, where it incinerates gases and particles from the main chamber to reduce environmental impact.

The refractory lining might not sound exciting, but it's critical to efficient operation. This special heat-resistant material insulates the cremation chamber, typically combining firebrick, pre-cast shapes, and ceramic fiber to balance durability with energy efficiency.

Modern furnaces also feature sophisticated PLC control systems (Programmable Logic Controllers) that automate the process while constantly monitoring temperatures, pressure, and oxygen levels. These systems work alongside opacity sensors that keep an eye on emissions to ensure environmental compliance.

Safety features include multiple interlocks that prevent operation unless certain conditions are met, and emergency shutdown systems that activate if something unusual occurs. Many newer models even include touchscreen interfaces and internet connectivity for remote diagnostics.

The loading bier mechanism allows for respectful transfer of the casket into the hot chamber while minimizing heat loss—an important consideration for both operational efficiency and energy consumption. And finally, the ash pan collects cremated remains for processing once cremation is complete.

Want to learn more about the technical aspects of these chambers? Check out our detailed guide on cremation chambers.

Step-By-Step Crematorium Furnace Process

The journey through a modern crematorium furnace follows a carefully designed workflow that balances technical efficiency with deep respect for the deceased and their families. Here's how the process typically unfolds:

Everything begins with preheating. Before cremation starts, the furnace warms to approximately 800°C (1,472°F), ensuring optimal conditions from the moment the deceased enters the chamber.

Identification verification comes next—a critical step that maintains the chain of custody. Most facilities follow strict protocols, often including a metal identification disk that stays with the remains throughout the entire process.

During charging (or loading), staff place the casket into the cremation chamber using a mechanized charging bier that minimizes heat loss. Once the door closes securely, the main phase begins.

Primary combustion starts as the main burner ignites. The process progresses naturally through several phases—first evaporating moisture, then burning the container, followed by combustion of soft tissues, and finally calcination of the skeletal structure.

Throughout this time, gases and particles flow into the secondary combustion chamber (the afterburner), where temperatures typically reach 850-1,000°C. This extra step ensures complete oxidation and minimal emissions—a major improvement over older cremation technologies.

"Modern automated systems have transformed what was once physically demanding work into a process that's precisely controlled and dignified," shared one experienced operator. "The Set Point Programming in today's furnaces eliminates guesswork and ensures consistent results no matter who's operating the equipment."

During the entire process, the control system continuously monitors and adjusts chamber temperature, oxygen levels, pressure differentials, and emission opacity. These constant adjustments optimize the cremation while ensuring environmental compliance.

Once cremation completes, cooling begins. The cremated remains—consisting primarily of bone fragments—cool either in the chamber or in a specialized ash pan refrigerator, depending on the facility's setup.

Ash processing follows, with staff carefully inspecting the cooled remains to remove any non-combustible materials like medical implants or jewelry. The remaining bone fragments then go through a cremulator (a specialized processor) to create a uniform consistency.

Finally, the processed cremated remains—typically weighing between 3-7 pounds—are transferred to an urn or temporary container for return to the family.

The entire process from charging to completion usually takes 1-3 hours depending on specific circumstances. However, when you include cooling, processing, and administrative procedures, the complete workflow often extends to 4-5 hours—all handled with the utmost care and respect.

Types of Cremation Furnaces: Gas, Electric, Wood & Hybrid

When it comes to crematorium furnaces, there's not just one option that fits all needs. The industry offers several types, each with its own unique benefits and considerations. Your choice of fuel type will impact everything from how you install the equipment to your day-to-day operational costs and environmental footprint.

Comparison of Crematorium Furnace Types

| Feature | Gas Furnaces | Electric Furnaces | Wood-Based Furnaces | Hybrid Systems |

|---|---|---|---|---|

| Fuel Source | Natural gas, LPG, propane | Electricity (3-phase) | Wood, biomass | Combination (e.g., gas + electric) |

| Installation Complexity | Moderate (requires gas lines) | Simpler (plug-and-play) | Complex (wood storage) | Moderate to complex |

| Startup Time | 30-60 minutes | 15-30 minutes | 60+ minutes | Varies by configuration |

| Energy Consumption | 2,350 CFH (natural gas) | ~300 kWh per cremation | Variable (20+ trees traditional) | Lower than single-source |

| Operating Cost | ~$15-25 per cremation | ~$15-30 per cremation | Variable (labor intensive) | Typically lower than single-source |

| Emissions Profile | CO2, NOx, particulates | Lower emissions, no flame | Higher particulates without filtration | Better than wood, comparable to gas |

| Throughput Rate | High (150-400 lbs/hr) | Moderate (100-200 lbs/hr) | Lower (variable) | Moderate to high |

| Best Application | High-volume facilities | Urban areas, eco-conscious markets | Rural areas, cultural traditions | Facilities seeking efficiency/backup |

Gas-powered crematorium furnaces continue to be the most popular choice throughout North America and Europe. They've earned their reputation for reliability and efficiency, processing remains at impressive rates of 150-400 pounds per hour. Most high-capacity models can handle 6-7 cremations in a standard 12-hour workday.

As one crematory manager with over 20 years in the business told me, "Gas furnaces have been our go-to for decades because they're consistent performers that can handle our busy schedule without breaking a sweat. That said, we've been getting more questions about greener options lately as folks become more environmentally conscious."

If you're interested in where the market is heading, check out our Cremation Furnace Market Insights for the latest trends and forecasts.

Electric Cremation Furnaces Explained

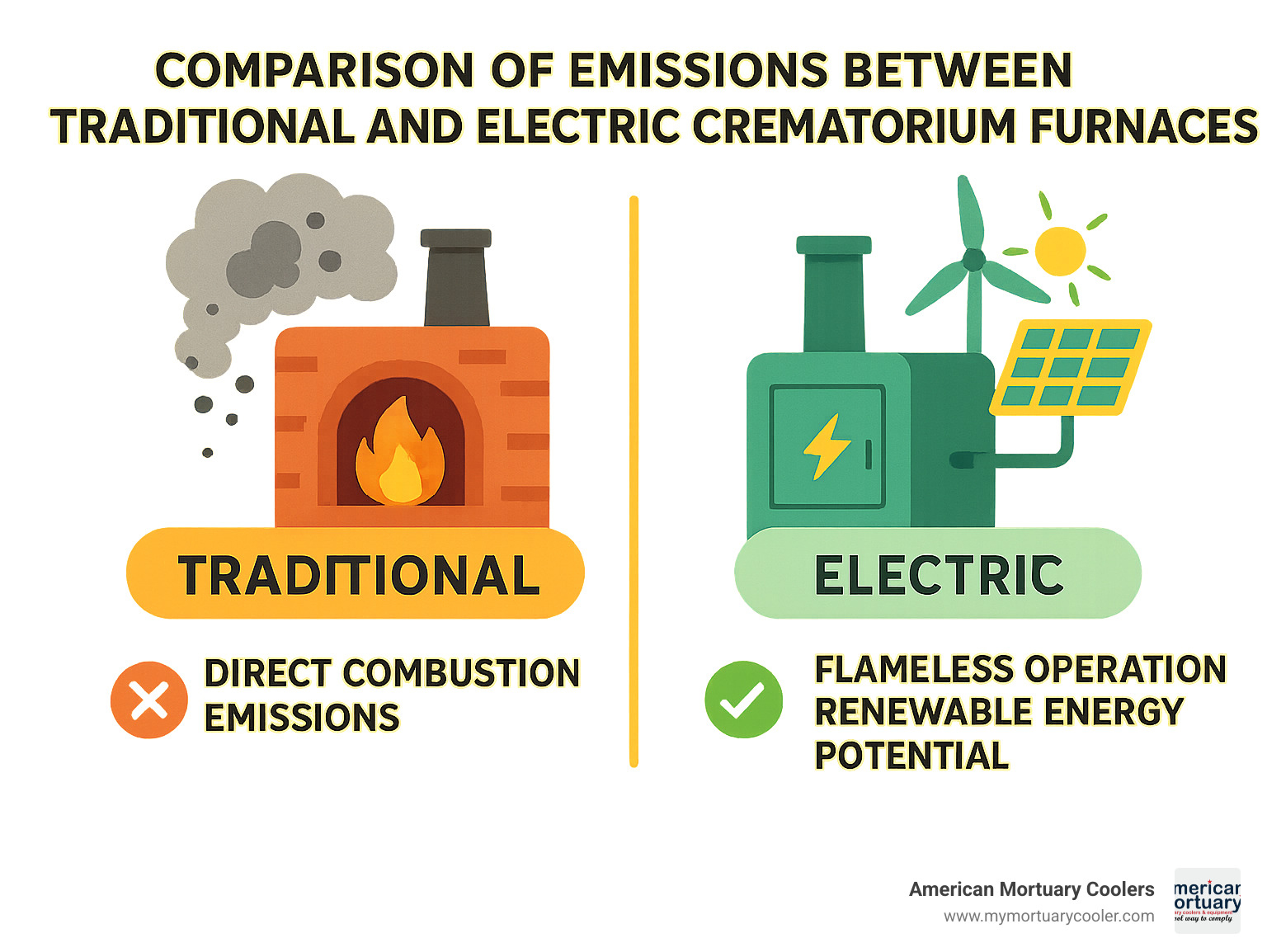

Electric crematorium furnaces are gaining traction, especially in areas with strict environmental regulations or where sustainability is a priority. Unlike their gas counterparts, these systems don't rely on an open flame for combustion, which brings several advantages.

Electric cremators typically use about 300 kWh of electricity per cremation, making them surprisingly energy-efficient. Many arrive pre-assembled and only need a three-phase electric connection—much simpler than installing gas systems with their fuel lines and complex ventilation requirements.

The environmental benefits are substantial, particularly when powered by renewable energy. When connected to solar, wind, or hydroelectric sources, electric cremation can approach carbon neutrality. Even on standard grid power, there are no on-site combustion emissions to worry about.

Day-to-day operation brings its own perks: faster startup times, precise digital temperature control, quieter operation, and less maintenance headaches. No flame means no flame monitoring systems to maintain—a small but welcome relief for busy facilities.

"Electric cremation technology has actually been around since the 1980s in India," an industry expert explained to me. "They developed it specifically to address the environmental impact of traditional wood pyres, which could consume more than 20 trees per cremation and produce significant smoke."

Electric systems make the most sense for urban facilities with limited space, areas with strict air quality regulations, or locations with reliable electricity but limited gas availability. If you're considering this option, learn more via ATI technology for detailed specifications.

Wood & Hybrid Systems

While gas and electric dominate today's market, wood-based and hybrid crematorium furnaces fulfill important needs in certain regions, especially where cultural traditions or infrastructure limitations come into play.

Traditional wood pyres have been used for thousands of years, particularly in South Asia. But these approaches face increasing scrutiny due to their environmental impact and resource consumption. In response, newer wood-based systems have been developed with more efficient combustion chambers, secondary burning for reduced emissions, and basic filtration systems. They require significantly less wood than traditional methods while honoring important cultural preferences.

These improved wood systems shine in rural areas without reliable gas or electricity, regions with strong cultural preferences for wood cremation, or areas blessed with abundant, sustainable wood resources.

Bio-oil systems represent another interesting alternative. These crematorium furnaces use oils derived from renewable sources, offering a lower carbon footprint than fossil fuels while remaining compatible with existing cremation infrastructure. For some markets, they also provide cost advantages that make the switch worthwhile.

Hybrid systems truly represent the cutting edge of cremation technology. By combining multiple fuel sources, they maximize both efficiency and flexibility. Gas-electric hybrids, for example, use electric elements for preheating and maintaining temperature, with gas burners kicking in only for peak demand periods. This smart approach optimizes energy use and keeps costs down.

Some systems integrate renewable energy sources with conventional fuels, while others are designed to operate on whatever fuel happens to be available or most affordable at the moment—natural gas, propane, diesel, or electricity.

As one manufacturer of hybrid systems told me, "The future of cremation technology is all about flexibility and efficiency. Our hybrid systems let crematoriums adapt to changing fuel prices and environmental regulations without replacing their entire setup."

These forward-thinking approaches prove especially valuable for facilities in regions with unreliable fuel supplies or for operations looking to gradually transition to more sustainable practices without breaking the bank.

Environmental Impact, Safety & Regulations

Modern crematorium furnaces have come a long way in addressing environmental concerns while maintaining the highest safety standards. Today's equipment operates under increasingly strict regulations designed to protect both our planet and the people who operate these systems.

Environmental Considerations

When it comes to the environment, cremation does create some challenges that modern technology works hard to address. Each time a crematorium furnace operates, it produces emissions including particulate matter, nitrogen oxides, carbon monoxide, and volatile organic compounds. There's also the potential release of mercury (mainly from dental fillings) and compounds like dioxins and furans.

From a carbon perspective, a typical gas-fired crematorium furnace generates about 220-270 kg of carbon dioxide per cremation – something many facilities are actively working to reduce.

Thankfully, today's furnaces include impressive environmental safeguards. Secondary afterburners maintain temperatures between 850-1000°C in a separate chamber, ensuring gases and particles from the main chamber burn completely. Many systems also incorporate sophisticated filtration technology – from cyclonic separators that catch larger particles to activated carbon filters that trap mercury and VOCs.

"The days of visible emissions from crematorium stacks are largely behind us," shared one regulatory compliance officer I spoke with. "Modern equipment, when properly operated and maintained, should produce virtually no visible emissions and minimal environmental impact."

Continuous monitoring systems keep everything in check, with opacity sensors alerting operators immediately if something's amiss. This real-time feedback ensures facilities stay compliant with regulations while minimizing their environmental footprint.

Regulatory Framework

Operating a crematorium furnace means navigating a complex web of regulations that vary by location but typically include air quality permits specifying emission limits, stack height requirements, and reporting obligations.

Stack height isn't arbitrary – proper dispersion of emissions often requires minimum heights calculated using formulas like EPA's Good Engineering Practice (H + 1.5L). This scientific approach ensures emissions disperse properly rather than affecting nearby areas.

Organizations like the Cremation Association of North America (CANA) have established best practices that many facilities follow, while equipment certification requirements (like UL listing in North America) ensure crematorium furnaces meet rigorous safety and performance standards before installation.

If you're interested in learning more about the filtration systems that make modern cremation more environmentally friendly, check out this detailed information on filtration systems.

Electric vs Gas: Which Is Greener?

The environmental comparison between electric and gas crematorium furnaces isn't straightforward – it's nuanced and depends on several factors.

Gas crematorium furnaces produce direct emissions on-site, typically 220-270 kg of CO2 per cremation, along with NOx and particulates that require specialized afterburner and filtration systems. While they rely on fossil fuels, they do achieve high thermal efficiency within the cremation chamber itself.

Electric crematorium furnaces, on the other hand, produce no direct on-site emissions since there's no flame or combustion happening. Their carbon footprint depends entirely on the electricity source. When powered by renewable energy, they can approach carbon neutrality. A typical electric cremation consumes around 300 kWh of electricity.

One environmental assessment I reviewed found that "Electric cremation powered by a grid with at least 30% renewable energy generally produces a lower lifecycle carbon footprint than gas cremation." This makes electric systems particularly attractive in regions with cleaner energy grids based on hydro, nuclear, wind, or solar power.

Electric systems also tend to face fewer permitting challenges in areas with strict air quality regulations, since they eliminate many of the combustion-related emissions concerns entirely.

Built-In Safety Features & Codes

The safety features in modern crematorium furnaces are impressive and comprehensive. Emergency shutdown systems automatically trigger if the equipment detects abnormal conditions like excessive temperatures, bypassed door safety interlocks, control system failures, or flame issues in gas systems.

Advanced monitoring systems like the Fire Marshal continuously watch stack temperatures with programmable thresholds – typically sounding an audible alarm at 400°F (204°C), sending email alerts at 450°F (232°C), and automatically shutting down at 500°F (260°C).

Operator protection is built into every aspect of these systems. Crematorium furnaces now feature cool-touch exterior insulation, viewing ports with heat-resistant glass, automated charging systems that minimize heat exposure, and radiation shields around doors.

Of course, all this equipment must adhere to various safety codes including National Fire Protection Association (NFPA) standards, local building and fire codes, occupational safety requirements, and electrical/gas code compliance.

As one crematory safety trainer wisely noted during my research, "The most advanced safety features are worthless without proper training and procedures. Operator education remains the cornerstone of crematory safety."

Operators themselves use appropriate personal protective equipment including heat-resistant gloves, face shields, protective clothing, and respiratory protection during certain maintenance procedures. This human element of safety remains crucial even as technology advances.

Most crematorium furnaces today include comprehensive documentation, clear warning labels, and detailed emergency procedures. Many manufacturers now offer virtual training programs to supplement hands-on instruction, ensuring operators fully understand both routine operations and emergency protocols – keeping both people and the environment safe.

Capacity, Costs & Maintenance

When you're considering a crematorium furnace for your facility, understanding its capacity, what it'll cost to run, and how to keep it in top shape are crucial pieces of the puzzle. These practical considerations can make or break your operation's efficiency and profitability.

Modern crematorium furnaces come in various sizes to match different operational needs. Most standard models can handle cases up to 750 pounds, while high-capacity systems like the Classic-XCEL or CFS3000 accommodate larger cases up to 1,000-1,200 pounds. When it comes to throughput, these workhorses typically process between 150-400 pounds per hour, with the more efficient models pushing that upper limit.

"On a busy day, our high-capacity furnace can handle 6-7 cremations in a 12-hour shift," explains one crematory manager. "That's a game-changer compared to our old system that maxed out at 3 per day."

The actual cremation time varies based on several factors: the size of the remains, the type of container, the furnace model, and even the operating temperature. Each cremation is unique, just like the person being memorialized.

Operational Costs

The dollars and cents of running a crematorium furnace are surprisingly reasonable. Gas furnaces typically cost less than $15 per case to operate, while electric models run about $15-30 per cremation depending on your local utility rates. As one operator noted with a smile, "The technology has come so far that our new furnace uses about 40% less fuel than our old 1990s model—it practically pays for itself."

Modern systems have significantly reduced labor costs too. With automated controls, a single trained operator can manage the entire cremation process, though you'll still need staff for preparation and finishing steps.

Maintenance represents another cost factor. Budget for $2,000-$5,000 annually for routine service, plus the occasional bigger expense like refractory replacement every 3-7 years. The good news? Innovations like quick-change hearth systems have dramatically reduced both the cost and downtime associated with these major repairs.

Don't forget about regulatory compliance in your budget. Emissions testing might run $1,000-$3,000 per year, plus whatever permits and inspections your local jurisdiction requires.

Routine Service Checklist

Keeping your crematorium furnace running smoothly isn't complicated, but it does require consistency. Daily checks are your first line of defense—a quick visual inspection of the refractory, cleaning the loading area, checking door seals, and making sure the control systems are functioning properly.

Weekly maintenance ups the ante a bit: testing safety interlocks, cleaning sensors and probes, inspecting burners and ignition systems, and verifying that emission monitoring systems are on point.

Monthly, you'll want to do a more thorough cleaning of the cremation chamber, inspect the secondary chamber, verify temperature sensors, and test those emergency shutdown systems that you hope you'll never need.

"Consistent daily and weekly checks can prevent 90% of major issues," shares a maintenance director who oversees multiple cremation units. "It's much easier to spot and address small problems before they become catastrophic failures."

Annually, you'll need a complete inspection of the refractory lining, calibration of all sensors and controls, emissions testing, and burner tuning. Every few years, plan for that hearth replacement (every 2-5 years) and eventually a full refractory reline (every 5-10 years).

Troubleshooting & Downtime Prevention

Nothing disrupts a crematory's operations quite like unexpected downtime. Modern crematorium furnaces include several features to keep you up and running.

Remote monitoring systems like Tek Marshal are revolutionary—they allow technicians to access your furnace controls via internet connection, often diagnosing and even fixing issues without an on-site visit. "Our tech logged in from 300 miles away and had us back up and running in 20 minutes," one grateful operator shared. "Before this technology, we'd have been down for days waiting for a service call."

Smart crematory managers keep critical spare parts on-site—things like ignitors, sensors, and control components that commonly need replacement. Many also maintain service contracts that include regular preventative maintenance visits and priority response for emergencies.

Perhaps the most underrated preventative measure is thorough operator training. When your team understands how to identify early warning signs and perform basic troubleshooting, they can often resolve minor issues before they escalate into major problems that shut you down.

For facilities with multiple units, staggering your maintenance schedules ensures you'll always have at least one furnace operational. And it never hurts to develop relationships with nearby facilities that might be able to help in a pinch—crematory operators are a tight-knit community that understands the importance of helping each other out when equipment issues arise.

How to Choose the Right Crematorium Furnace

Selecting the appropriate crematorium furnace is a significant decision that impacts operational efficiency, compliance, and financial performance for years to come. Here's a comprehensive guide to making this important choice:

Key Considerations

-

Facility Requirements:

- Available space dimensions and layout

- Ceiling height and door access for installation

- Existing utilities (gas, electric, water)

- Ventilation and stack placement options

-

Operational Volume:

- Projected number of cremations per day/week

- Peak demand periods and seasonal variations

- Growth projections for 5-10 years

- Need for specialized capabilities (oversized cases, etc.)

-

Fuel Availability and Preferences:

- Natural gas availability and pressure

- Electrical capacity (particularly for electric furnaces)

- Local utility costs and reliability

- Environmental considerations and preferences

-

Budget Considerations:

- Initial purchase price ($100,000-$500,000+ depending on model)

- Installation costs (typically $25,000-$75,000)

- Operational costs per cremation

- Maintenance and lifecycle costs

-

Regulatory Environment:

- Local air quality regulations

- Permitting requirements

- Zoning restrictions

- Emission standards and monitoring requirements

A funeral director who recently installed a new cremation system advised, "Don't just focus on the initial price. We chose a slightly more expensive system with better efficiency and lower maintenance costs, and it's already paying for itself in reduced operating expenses."

Return on Investment Calculation

When evaluating crematorium furnaces, a comprehensive ROI analysis should include:

- Capital Costs: Equipment purchase, shipping, installation, permits

- Operating Costs: Fuel/energy, labor, maintenance, compliance

- Revenue Potential: Number of cremations × average revenue per cremation

- Efficiency Factors: Throughput capacity, energy efficiency, maintenance downtime

- Financing Costs: Interest rates, lease terms if applicable

- Tax Considerations: Depreciation schedules, potential tax incentives

Most modern, efficient cremation systems will show positive ROI within 3-5 years depending on volume and local market conditions.

Vendor Support and Service

The quality of manufacturer support is often as important as the equipment itself:

- Installation Support: Turnkey installation including air permits, utility connections

- Training Programs: Comprehensive operator training and certification

- Technical Support: Availability of phone/remote support and on-site service

- Parts Availability: Stocking of critical spare parts and delivery timeframes

- Warranty Terms: Coverage period and what's included/excluded

- Software Updates: Frequency and cost of control system updates

"The relationship with your equipment provider doesn't end at installation," explained one crematory manager. "We've had our current furnace for over 10 years, and the ongoing support from the manufacturer has been crucial to our operational success."

Human vs Animal Crematorium Furnace Design

While there are similarities between human and animal cremation equipment, important differences exist in crematorium furnace design for these distinct applications:

Human Cremation Furnaces:

- Typically larger with capacities of 750+ pounds

- Designed for standard casket dimensions

- Single-case operation per cycle

- Higher regulatory scrutiny

- Wider door openings (typically 42" wide × 25" high)

- Often feature more sophisticated control systems

- Higher throughput rates (150-400 lbs/hr)

Animal Cremation Furnaces:

- Available in various sizes from small (300 lb capacity) to large (1,200 lb capacity)

- Often designed for multiple-case capability (partitioned cremation)

- Specialized for different animal sizes (pet vs. livestock)

- May offer private, partitioned, or communal cremation options

- Sometimes feature multiple chambers for concurrent operation

- Typically smaller door dimensions

- May have specialized loading systems for different animal sizes

A veterinary cremation specialist explained, "The fundamental technology is similar, but animal cremation equipment often requires more flexibility to handle everything from small pets to large livestock, sometimes within the same facility."

For facilities offering both services, separate equipment is typically required due to regulatory and operational considerations. However, some manufacturers offer modular systems that can be configured for either purpose with appropriate modifications.

Human & Pet Cremation Chambers

Accessories & Future Innovations

The cremation industry continues to evolve with new technologies and accessories that improve efficiency, environmental performance, and dignity of the process:

Essential Accessories:

-

Ash Processors (Cremulators): These specialized machines process cremated remains to a consistent, fine texture. Modern versions like the US 30SSP include:

- Stainless steel construction

- Dust-free operation

- Magnetic separation of non-combustible materials

- Processing times of 3-5 minutes per case

-

Hydraulic Lift Tables: These assist with loading and may include:

- Electric or manual hydraulic systems

- Integrated scales for weight verification

- Height adjustment for different furnace models

- Capacity ratings up to 1,000 pounds

-

Ventless Processing Stations: Comprehensive workstations that combine:

- Cremulated remains processing

- Built-in dust collection

- Packaging area

- Storage for supplies

-

Automated Charging Systems: Reduce operator effort and extend furnace life by:

- Minimizing door-open time

- Providing consistent loading

- Reducing thermal shock to the refractory

Emerging Innovations:

The future of crematorium furnace technology includes several promising developments:

-

IoT-Enabled Controls: Internet of Things connectivity allowing:

- Remote operation and monitoring

- Predictive maintenance based on operating patterns

- Automated reporting for compliance

- Integration with facility management systems

-

Energy Recovery Systems: Capturing waste heat from the cremation process for:

- Facility heating

- Hot water production

- Potential electricity generation

- Preheating combustion air

-

AI-Optimized Operation: Using artificial intelligence to:

- Optimize cremation parameters based on case characteristics

- Minimize fuel consumption

- Reduce emissions through combustion optimization

- Predict maintenance needs before failures occur

-

Advanced Emission Controls: Next-generation systems featuring:

- Catalytic reduction of NOx

- Mercury capture systems

- Ultra-fine particulate filtration

- Continuous emissions monitoring with cloud reporting

-

Hybrid Energy Systems: Combining multiple energy sources:

- Solar preheating

- Electric-gas hybrid operation

- Waste heat recovery

- Renewable gas integration

An industry technology expert predicted, "Within the next decade, we'll see cremation systems that operate with near-zero emissions and significantly reduced energy consumption through the integration of AI controls and hybrid energy systems."

Hot Chambers and Cool Facts: Crematory Retorts Explained

Frequently Asked Questions about Crematorium Furnaces

What temperatures does a crematorium furnace reach?

When people ask about cremation, temperature is often the first thing they wonder about. A crematorium furnace operates at incredibly high temperatures - typically between 800°C and 1,300°C (1,472°F to 2,372°F). This intense heat isn't just for show; it's absolutely necessary to ensure complete and dignified cremation.

The process is methodical and precise. Before the body is introduced, the chamber is preheated to approximately 800°C. Once the actual cremation begins, temperatures in the primary chamber climb to 900-1,100°C. The secondary chamber (often called the afterburner) runs even hotter, usually between 850-1,000°C, ensuring gases and particles are completely combusted.

These extreme temperatures serve a specific purpose - they reduce the body to its basic elements through a series of scientific processes: drying, evaporation, breaking down organic compounds, and finally converting bone to a brittle, porous structure that can be processed into the ashes returned to families.

What's impressive about modern crematorium furnaces is their sophisticated temperature control. Today's systems constantly monitor and adjust burner output throughout the cremation cycle, responding to the natural variations that occur as different tissues are processed. This precision wasn't possible with older equipment, and it's one of many ways the industry has evolved to provide more consistent, dignified services.

How long does a single cremation take?

The time needed for cremation is one of those "it depends" questions that funeral professionals hear often. In a modern crematorium furnace, the process typically takes between 60 to 150 minutes - quite a range! Several factors influence this timeline:

Body size and composition make a significant difference - larger bodies naturally require more processing time. The furnace type and efficiency plays a major role too - high-efficiency models like the Classic-XCEL can complete cremations in as little as an hour, while standard models might need 90-120 minutes.

Even the container type affects timing. A simple cardboard container burns away quickly, while a hardwood casket extends the process. The operating temperature of the furnace and the facility's specific cremation protocol also influence the duration.

As one crematory operator I spoke with explained, "While the actual cremation might take 90 minutes, we typically schedule three hours between cases to allow for cooling, processing, cleaning, and preparation for the next cremation."

It's worth noting that the complete process - including cooling, processing the cremated remains into the fine consistency families receive, and completing all documentation - typically takes 3-4 hours from start to finish. This is why most crematories can handle about 4-6 cremations per day in a single unit, even though the actual cremation time is shorter.

Are electric crematorium furnaces really eco-friendly?

The environmental question is becoming increasingly important to both funeral professionals and families. Electric crematorium furnaces do offer several genuine environmental advantages over traditional gas-fired systems, though their overall eco-friendliness depends on several factors.

The environmental benefits are significant. Electric cremators don't burn fossil fuels on-site, eliminating direct emissions of combustion byproducts like nitrogen oxides and particulate matter. Their flameless operation reduces the formation of certain pollutants, and they can be more precisely controlled than gas systems, typically using about 300 kWh per cremation.

Perhaps most importantly, when powered by renewable electricity (solar, wind, hydro), electric cremation can approach carbon neutrality - something impossible with fossil fuel systems. Without combustion, there's also no need for complex afterburner systems, reducing equipment complexity.

However, the reality has some important nuances. The electricity source matters tremendously - in regions where electricity comes primarily from coal, the overall carbon footprint may be comparable to or even higher than gas cremation. A proper environmental evaluation must consider the full lifecycle: manufacturing impacts, operational efficiency, and end-of-life disposal of the equipment.

Independent studies suggest that electric cremation becomes clearly advantageous when powered by a grid with at least 30% renewable energy. In regions with predominantly renewable electricity, the benefits are substantial.

One crematory operator who made the switch told me, "Beyond the emissions benefits, we've found the electric system to be cleaner, quieter, and easier to maintain. The precise temperature control also provides more consistent results."

Some forward-thinking facilities are now pairing electric cremation equipment with on-site solar panels, creating truly sustainable end-of-life options that resonate with environmentally conscious families.

Conclusion

The journey through crematorium furnaces reveals a fascinating blend of engineering precision, environmental responsibility, and dignified end-of-life care. As cremation rates continue their upward trend across North America—expected to surpass 70% in the coming years—understanding these sophisticated systems becomes increasingly valuable for both funeral professionals and the families they serve.

Today's cremation technology has come a long way from earlier designs. Modern crematorium furnaces offer remarkable efficiency, reduced environmental impact, and exceptional reliability that would have seemed impossible just a generation ago. Whether powered by natural gas, electricity, or innovative hybrid systems, these advanced machines balance the solemn responsibility of dignified cremation with growing environmental concerns.

Throughout our exploration, several key insights have emerged:

The technological sophistication of modern furnaces is remarkable. Advanced refractory materials withstand extreme temperatures year after year, while computerized controls maintain precise conditions throughout each cremation. These advancements represent quantum leaps beyond earlier equipment designs.

Environmental considerations now drive much of the innovation in the industry. Secondary combustion chambers, advanced filtration systems, and alternative energy sources have dramatically reduced emissions and ecological impact, addressing growing concerns about cremation's environmental footprint.

The operational efficiency of today's equipment is equally impressive. Innovations like Quick Change hearth systems have transformed what was once days of downtime into hours, while remote diagnostics allow technicians to troubleshoot issues without even visiting the facility.

Funeral homes now enjoy unprecedented fuel flexibility when selecting cremation equipment. With gas, electric, and hybrid systems all available on the market, facilities can choose technologies that align with their specific operational needs, values, and local utility infrastructure.

Looking ahead, the future promises even more innovation. Internet connectivity, artificial intelligence optimization, and energy recovery systems are already beginning to appear in next-generation equipment, pointing toward even more efficient and sustainable cremation practices.

While American Mortuary Coolers specializes in high-quality refrigeration solutions for funeral homes, we understand that cremation equipment represents a critical component in the comprehensive planning of modern funeral facilities. The decisions made about cremation technology will impact operations, finances, and family satisfaction for years to come.

For funeral professionals considering new or upgraded cremation equipment, we encourage thorough research, careful vendor evaluation, and comprehensive planning that looks beyond initial purchase price to long-term operational efficiency and environmental performance.

The evolution of crematorium furnace technology continues to advance toward greater efficiency, reduced environmental impact, and improved dignity in end-of-life care. By understanding both the fundamental principles and latest innovations in cremation equipment, funeral professionals can make informed choices that best serve both their operational needs and the families who place their trust in them.