The Legacy of Porcelain in Mortuary Science

A porcelain embalming table is a specialized preparation surface used in funeral homes from the 1890s to 1950s, featuring a porcelain-enameled top over a cast iron base, designed for embalming procedures and body preparation.

| Key Facts About Porcelain Embalming Tables |

|---|

| ✓ Manufactured primarily from 1890s-1950s |

| ✓ Typically measures 77¼" long × 30" wide × 30¼" tall |

| ✓ Weighs over 200 pounds due to cast iron construction |

| ✓ Features chemical-resistant porcelain surface |

| ✓ Often includes drainage channels and tilting mechanisms |

| ✓ Antique models range from $800-$3,000+ in today's market |

| ✓ Replaced by stainless steel models in mid-20th century |

When you look at a porcelain embalming table, you're seeing more than just a piece of funeral equipment – you're witnessing a chapter in American history. These gleaming white surfaces tell stories of how we cared for our departed loved ones during a transformative era in funeral practices.

These substantial pieces brought modern sanitation to the funeral profession when it was desperately needed. Before their introduction, wooden preparation boards were difficult to clean thoroughly and couldn't stand up to the harsh chemicals used in embalming. The non-porous, chemical-resistant porcelain surface changed everything, allowing for proper disinfection and a more dignified preparation process.

I've personally examined hundreds of these historic tables over the years, and I'm always struck by their craftsmanship. The cast iron bases were built to last generations, while the porcelain tops – often with gentle slopes for drainage – represented the height of early 20th century industrial design. Their 200+ pound weight wasn't just about sturdiness; it provided stability during delicate procedures.

Today, these pieces have found surprising new appreciation. Museums showcase them as artifacts of changing attitudes toward death and sanitation. Collectors seek them for their historical value. Some have even been thoughtfully repurposed as unique kitchen islands or display tables – though we always recommend this be done with appropriate respect for their original purpose.

While modern funeral homes have moved on to lightweight stainless steel and composite materials, the legacy of these porcelain embalming tables lives on. They represent a time when funeral directors were professionalizing their craft and bringing scientific principles into their work.

At American Mortuary Coolers, we're passionate about preserving this history while also providing today's funeral professionals with the modern equipment they need. If you're curious about how preparation equipment has evolved over time, you might find these resources helpful:

Whether you're a funeral professional interested in the history of your craft, a collector considering adding one of these pieces to your collection, or simply someone curious about this unique aspect of American history, these tables represent an important bridge between traditional and modern funeral practices.

Porcelain Embalming Table: History & Definition

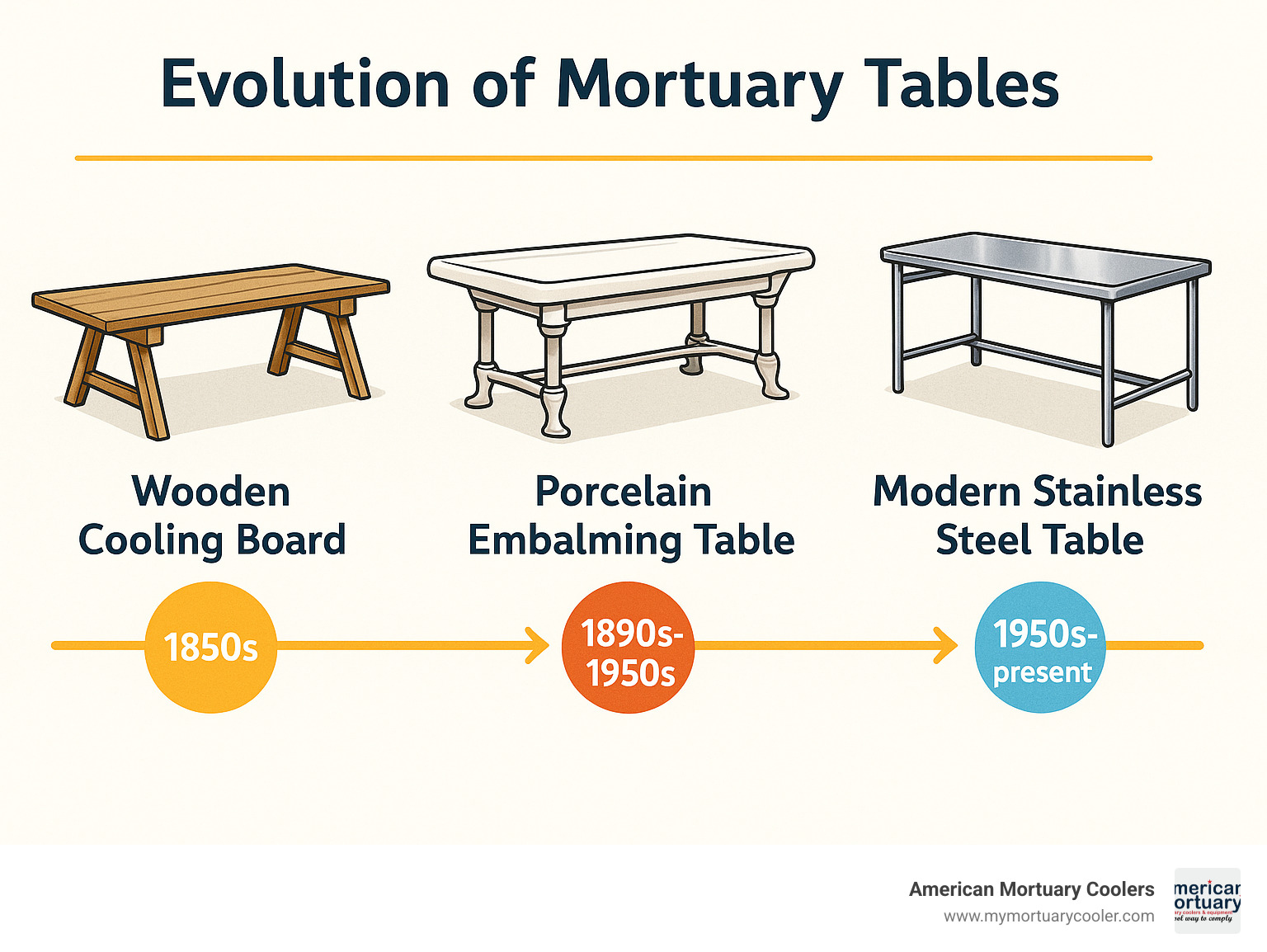

The story of the porcelain embalming table begins quite humbly in America's mid-19th century. Before these neat workstations existed, funeral directors relied on simple "cooling boards" – basic wooden platforms where the deceased would rest while awaiting burial. These straightforward boards served their purpose in a time when embalming wasn't yet common practice in American funeral homes.

Everything changed during the Civil War. With soldiers dying far from their hometowns, preserving bodies for the long journey home became essential. Embalmers during this period worked with portable wooden tables that could be quickly set up in field hospitals or family parlors – hardly ideal, but they got the job done.

By 1903, innovation arrived when The Embalmers Supply Company (ESCO) revolutionized funeral work with their patented embalming table. Historical catalogs proudly note that ESCO "produced the nation's first embalming tables in 1903," establishing a new professional standard. These early models featured a sturdy cast-iron base supporting a gleaming porcelain-enameled top – a combination that would define the industry for the next half-century.

"The porcelain surface changed everything for funeral professionals," explains Dr. Michael Echols, a mortuary science historian. "For the first time, they had a work surface that could be properly sanitized between cases, dramatically reducing cross-contamination risks."

From the 1890s through the 1950s, the porcelain embalming table reigned supreme in preparation rooms across America. Their pristine white surfaces symbolized the growing professionalization and improved sanitation standards sweeping through the funeral industry during this period.

How a Porcelain Embalming Table Was Used

The practical use of a porcelain embalming table involved a careful workflow designed for both dignity and efficiency. When a deceased person arrived at the preparation room, they would be gently transferred to the table to begin the embalming process.

The embalmer would position the body face up on the table, with the head slightly liftd using a special head block. This positioning wasn't just traditional – it was crucial for the arterial injection phase of embalming. As one experienced embalmer shared with us, "Once on the table, the corpse's arms traditionally were folded across the chest and legs bound near the feet," continuing practices that dated back to the cooling board era.

The table's tilting mechanism – a brilliant innovation – played a vital role in the process. By adjusting the angle, the embalmer could use gravity to assist with drainage and fluid distribution throughout the body. The raised edges of the porcelain surface contained fluids, while built-in drainage channels directed them to appropriate collection containers below.

In busy funeral homes of the early 20th century, the preparation room workflow centered around these substantial tables. Their incredible durability meant a single table could serve a funeral home for decades, making them a significant but worthwhile investment for funeral businesses of the era.

Evolution from Cooling Boards to Porcelain Embalming Tables

The journey from simple wooden cooling boards to sophisticated porcelain embalming tables shows how funeral care evolved from a family practice to a professional science.

Those early cooling boards served a basic but crucial function: preserving the body before burial in an era without refrigeration. Historical documents reveal that "perforated examination tables were known as 'cooling boards' because cold air from ice blocks preserved the body." Funeral directors would place blocks of ice beneath these perforated wooden planks, allowing cold air to circulate around the deceased person.

These early boards were typically collapsible for easy storage – often just doors placed across barrels or sawhorses. While functional, they offered virtually nothing in terms of sanitation or specialized features for proper body preparation.

As embalming became more common around 1900, equipment needs grew more sophisticated. The 1908 patent for a tilting mechanism marked a huge advancement, allowing for better fluid drainage during the embalming process. This innovation appears on many surviving tables today, with "PAT March 1908" stamped into the metal components.

The industrial production of porcelain-enameled surfaces completed the picture. Manufacturers could now create durable, non-porous surfaces ideal for mortuary work. As noted in The Embalmers Supply catalog, "By 1908, porcelain enamel tops and tilting mechanisms were incorporated into embalming tables for improved fluid drainage."

The resulting porcelain embalming table perfectly combined function and sanitation – a sturdy, easily cleanable surface with specialized features for professional embalming. This fundamental design remained largely unchanged until stainless steel began replacing porcelain in the 1950s, marking the end of the porcelain era in American funeral homes.

For more detailed information about the science behind these tables, check out our article on Scientific research on mortuary sanitation.

Key Features & Material Comparisons

What made a porcelain embalming table special? If you've ever run your hand across one of these historical pieces, you'd immediately notice the smooth, glass-like surface that defined these workhorses of the funeral industry.

These weren't just ordinary tables. The porcelain surface was actually a specialized glass-like coating fused to metal at extremely high temperatures, creating a non-porous glaze that laughed in the face of harsh embalming chemicals. One industry veteran told me, "These tables could handle anything we threw at them - formaldehyde, phenol, you name it - without a single stain."

The thoughtful design included raised edges that kept fluids contained (a crucial feature, as you might imagine), along with a cleverly engineered drainage gutter leading to a drain opening. Each table featured a slight slope toward this drain, allowing gravity to do the work of directing fluids exactly where they needed to go.

Supporting all this ingenuity was a substantial cast iron base that kept everything rock-solid during procedures. Early 20th century models often sported neat claw feet that added a touch of dignity to these utilitarian pieces, while later versions adopted a more practical pedestal base design.

| Material Comparison | Porcelain | Wood | Stainless Steel |

|---|---|---|---|

| Chemical Resistance | Excellent | Poor | Good |

| Stain Resistance | Excellent | Poor | Good |

| Weight | Heavy (200+ lbs) | Light (50-100 lbs) | Medium (150-180 lbs) |

| Maintenance | Easy cleaning, difficult repair | Regular oiling, easier repair | Easy cleaning, moderate repair |

| Durability | 50+ years with proper care | 10-20 years | 30+ years |

| Temperature Stability | Excellent | Poor | Poor (cold to touch) |

| Visual Contrast | High (white surface) | Low | Medium |

| Historical Era | 1890s-1950s | Pre-1900s | 1950s-present |

| Typical Cost (period) | High | Low | Medium |

| Collector Value Today | $800-$3,000+ | $300-$800 | $200-$1,000 |

Caring for a porcelain embalming table was surprisingly straightforward - a welcome relief for busy funeral directors who needed to maintain perfect sanitation between cases. The smooth surface could be thoroughly cleaned with simple disinfectants, unlike wooden tables that might harbor bacteria in their grain. However, this ease came with tradeoffs - these beauties were substantially more expensive than wooden alternatives and weighed a ton (well, not literally, but at 200+ pounds, they weren't exactly portable).

Advantages of a Porcelain Embalming Table

What made funeral directors fall in love with the porcelain embalming table for over 50 years? The benefits were clear from the first day these gleaming white surfaces entered preparation rooms across America.

First was the incredible stain resistance. If you've ever tried to remove a coffee stain from an unprotected wooden table, imagine the challenges funeral directors faced with bodily fluids and chemicals. The non-porous porcelain surface prevented absorption, keeping the workspace pristine year after year. As one old-timer told me, "You could wipe that table down after the messiest case, and it would look brand new again."

Chemical compatibility was another game-changer. Formaldehyde-based solutions are notoriously reactive, but porcelain remained completely inert when exposed to these harsh substances. No chemical reactions, no surface degradation - just a reliable work surface that never interfered with the embalming process.

The bright white surface created excellent visual contrast, something easily overlooked by non-professionals but deeply appreciated by embalmers who needed to see subtle details in their work. This practical advantage improved both efficiency and quality of preparation.

Perhaps most impressive was these tables' remarkable longevity. With basic care, a porcelain embalming table could serve faithfully for decades. The fact that collectors today are finding tables manufactured in the 1910s and 1920s still in serviceable condition speaks volumes about their construction quality. As one collector recently shared, "These weren't built with planned obsolescence in mind - they were built to last generations."

An often-forgotten advantage was temperature stability. In unheated preparation rooms (common in earlier decades), the porcelain surface maintained a more consistent temperature than metal alternatives, helping slow decomposition during lengthy procedures - a subtle but important benefit in the days before modern climate control.

Limitations & When Stainless Steel Took Over

Despite their many virtues, porcelain embalming tables weren't without their challenges, which eventually led to their replacement by stainless steel models starting in the 1950s.

Weight was the elephant in the room. At over 200 pounds, these tables weren't going anywhere once installed. One funeral director who started his career in the late 1950s remembered, "My first day on the job, the owner pointed to that porcelain table and said, 'That's been in that exact spot since 1928, and that's where it'll stay until this building comes down.'" As the industry became increasingly concerned with worker safety and ergonomics, this immobility became problematic.

Durability had limits too. While the porcelain surface was resistant to chemicals, it wasn't immune to physical damage. Drop a heavy instrument, and you might chip the enamel coating, creating a vulnerable spot where fluids could reach the metal underneath. These chips were both difficult and expensive to repair properly, often requiring specialized skills that became increasingly scarce.

The 1950s brought advances in metallurgy that made stainless steel a viable alternative. These newer tables were significantly lighter, more resistant to impact damage, and dramatically less expensive to manufacture. One industry publication from 1955 noted that "stainless steel tables can be manufactured at about 60-70% the cost of comparable porcelain models" - a compelling argument for budget-conscious funeral homes.

Stainless steel also made it easier to incorporate hydraulic lift mechanisms, allowing embalmers to adjust table height for comfort during lengthy procedures. As workplace safety regulations evolved, this ergonomic advantage became increasingly important for funeral home compliance and worker health.

By the early 1960s, manufacturers' catalogs showed the writing on the wall - new porcelain embalming tables had all but disappeared, replaced by the stainless steel models that continue to dominate the industry today. The era of porcelain had ended, but not before leaving behind thousands of these durable artifacts that now capture the imagination of collectors and historians alike.

Collecting, Buying & Shipping Antique Porcelain Embalming Tables

The hunt for a genuine porcelain embalming table has become something of an trip in recent years. I've watched with fascination as these once-overlooked pieces of funeral history have captured the imagination of collectors, designers, museum curators, and even Hollywood set decorators.

If you're considering adding one of these historic pieces to your collection, you'll want to familiarize yourself with the major manufacturers that dominated the industry. Dodge Chemical Company tables are among the most coveted, known for exceptional craftsmanship that has stood the test of time. Surprisingly, Royal Doulton – yes, the same company famous for fine china – produced some truly exquisite mortuary equipment with distinctive maker's marks that collectors prize.

The Enterprise "Climax" model remains particularly sought-after, easily identified by its distinctive brass plaque. And let's not forget The Embalmers Supply Company (ESCO), who proudly claimed to have produced "the nation's first embalming tables in 1903" – a boast that has some historical merit based on patent records.

"I've been collecting funeral antiques for twenty years, and nothing gets the same reaction as a pristine porcelain table," one collector told me recently. "They're conversation pieces that connect us to practices and craftsmanship that simply don't exist anymore."

Price-wise, the market has seen steady growth. Entry-level tables with minor damage or missing components typically start around $800-$1,200. If you're looking for a well-preserved example with all original hardware intact, expect to invest $1,500-$2,500. For museum-quality pieces with documented history – perhaps from a notable funeral home or with historical significance – prices can easily exceed $3,000.

The dimensions alone make these substantial pieces: typically measuring about 77¼" long × 30" wide × 30¼" tall. Add in weight exceeding 200 pounds, and you quickly understand why shipping requires careful planning. I strongly recommend professional crating and freight shipping, along with appropriate insurance. I've heard too many heartbreaking stories of damaged tables arriving after inadequate packaging and handling.

Evaluating a Porcelain Embalming Table in Person

There's simply no substitute for examining a porcelain embalming table in person before purchase. When I'm evaluating a table, I always bring a small flashlight to create raking light across the surface. This simple trick reveals crazing – those fine networks of cracks in the glaze that develop naturally over decades.

Some crazing is perfectly normal and even desirable as proof of age, but extensive networks might indicate the table has experienced thermal stress or impact damage. I remember one table I examined that looked flawless under direct light, but when I shined my flashlight across it at a low angle, it revealed a spiderweb of fine cracks that significantly reduced its value.

"The porcelain surface tells a story if you know how to read it," as Eleanor Rigby, a restoration specialist I've worked with, often says. She always cautions: "The most common mistake we see is inappropriate DIY repairs using modern materials that damage the historical integrity." Be particularly wary of amateur repair attempts using epoxy or modern fillers – they can dramatically reduce both historical and monetary value.

Don't neglect the cast iron base during your inspection. Check for excessive rust, missing components, or improper replacements. Original casters should move freely, though some wear is expected after a century of use. For hydraulic models, test the lifting mechanism if possible, though many collectors understand that original systems often leak after decades of disuse.

Documentation can substantially increase value. Original sales receipts, funeral home provenance, or period photographs showing the table in use connect the piece to its historical context. One collector shared this eye-opening experience: "I once misidentified a 'military field bed' that turned out to be an Enterprise 'Climax' table. The brass plaque had been removed, but the mounting holes revealed its true identity."

Where to Find Porcelain Embalming Tables Today

The search for an authentic porcelain embalming table can lead you down some fascinating paths. Estate sales from defunct funeral homes often yield the most exciting finds. When older funeral establishments close or modernize, their vintage equipment frequently appears at liquidation sales. These events typically offer fair pricing, though you'll need to rely entirely on your own judgment regarding condition and authenticity.

Online platforms have revolutionized the market for these specialty items. eBay and specialty auction sites regularly feature these tables, though shipping such massive items presents obvious challenges. One collector who's purchased several tables online shared this advice: "Always ask for at least 20 detailed photos, including close-ups of maker's marks, drainage systems, and any damage. Never buy sight unseen without this documentation."

Specialty auctions focusing on medical antiques or funeral memorabilia occasionally include these tables. While prices tend to run higher due to buyer competition, these venues often provide expert descriptions and condition reports that can justify the premium.

The film industry has developed a surprising appetite for these historic pieces. Prop houses and production suppliers have been actively acquiring authentic tables for period productions. "Tables from our collection were featured on Apple TV's 'Bad Monkey' as set pieces," one owner told me proudly. These businesses sometimes sell or rent pieces when updating their inventory.

Museum deaccessions represent rare but valuable opportunities. When museums consolidate collections or shift focus, they may release duplicate or peripheral items that no longer serve their core mission. These pieces typically come with excellent provenance and condition documentation.

At American Mortuary Coolers, we occasionally locate authentic vintage porcelain embalming tables for clients throughout our service regions. Our nationwide presence allows us to source and deliver these substantial pieces to collectors across the contiguous 48 states. While our primary focus remains on modern mortuary equipment, we appreciate the historical significance of these beautiful artifacts and enjoy connecting them with appreciative new owners.

For more information about finding and evaluating these unique pieces of funeral history, check out our guides on antique embalming tables for sale and Porcelain Embalming Tables: A Buyer's Guide.

Care, Restoration, Ethical Display & Modern Use

Owning a porcelain embalming table is a bit like caring for any treasured antique – it requires knowledge, patience, and a gentle touch. These historic pieces deserve thoughtful preservation to ensure they continue telling their unique story for generations to come.

When it comes to cleaning your table, grandma's wisdom applies here too: gentle is best. Use only neutral pH cleaners specifically formulated for porcelain surfaces. As my friend Margaret, a restoration expert with thirty years of experience, always says, "The number one rule with antique porcelain is to avoid abrasives at all costs." Even those supposedly mild kitchen scrubbers can permanently scratch the glazed surface, immediately diminishing both its beauty and value.

Your table will be happiest in a climate-controlled environment with humidity between 40-50%. This sweet spot prevents those cast iron components from developing the dreaded orange bloom of rust. Keep your treasure away from heating vents, crackling fireplaces, and sunny windows – those temperature swings are the enemy of stable porcelain, often leading to that fine network of cracks called "crazing" that collectors recognize all too well.

If your table needs more serious attention, please resist the urge to DIY. I've seen well-intentioned owners cause irreparable damage with home remedies and hardware store solutions. Professional porcelain restoration is truly an art form. As James Winters at the American Restoration Guild once told me, "Proper porcelain restoration is as much art as science – matching the original glaze composition and firing temperature requires years of experience."

For those cast iron legs and supports, period-appropriate treatments include boiled linseed oil or specialized waxes designed for antique metal. I've found that applying these with a soft cloth every six months works wonders for preservation. Those modern rust converters might seem tempting, but they'll create an unnatural finish that serious collectors spot immediately.

The ethical display of these tables has become an increasingly important conversation. Patricia Moreland, a thoughtful curator I met at a medical history conference, puts it beautifully: "These artifacts tell important stories about how our society has cared for the dead. Their display should be respectful of this context while acknowledging the technical innovation they represent."

Many of our customers at American Mortuary Coolers have found creative ways to showcase their porcelain embalming tables – from home libraries and studies to spacious living areas where they serve as fascinating conversation pieces. The key is finding that thoughtful balance between honoring history and creating a space that feels right for your home.

Can a Porcelain Embalming Table Be Used Today?

While technically possible, using an antique porcelain embalming table for its original purpose today would be a bit like trying to perform modern surgery with Civil War medical instruments – possible, but not practical or advisable.

First, there's the regulatory reality. Most vintage tables simply don't meet current sanitation codes or OSHA requirements for mortuary equipment. Modern standards require seamless surfaces, fully cleanable components, and materials certified for today's disinfection protocols. As Frank, a third-generation funeral director in Ohio, explained to me, "Even if I found my grandfather's table in perfect condition, it wouldn't pass inspection in our state."

Then there's the physical comfort of the embalmer to consider. The fixed height of most antique tables (typically around 30¼" tall) doesn't accommodate professionals of different heights. I'm 6'2", and I can tell you from experience that leaning over a fixed-height surface for hours leads to the kind of backache that makes you question your life choices. Modern tables feature hydraulic height adjustment specifically to prevent this occupational hazard.

From a preservation standpoint, active use would accelerate deterioration. Modern embalming chemicals differ significantly from those used a century ago and may interact differently with aged porcelain surfaces. It's a bit like using a 100-year-old china teacup for your daily coffee – technically possible, but each use brings it closer to damage.

For those who love the classic look but need modern functionality, there are excellent alternatives. Several manufacturers offer contemporary tables with porcelain-like finishes that provide the traditional appearance with updated features like height adjustment, improved drainage systems, and full regulatory compliance.

As one of our customers at American Mortuary Coolers shared, "I chose to display my grandfather's porcelain embalming table in our arrangement room rather than use it in our prep room. It honors our funeral home's history while we use modern equipment where it matters most."

Creative Yet Respectful Ways to Repurpose

Finding new life for these historic pieces requires creativity balanced with respect for their original purpose. I've seen some truly inspired changes over the years that honor craftsmanship while creating something uniquely beautiful for contemporary homes.

Kitchen islands represent perhaps the most popular adaptation. There's a wonderful irony in the fact that the chemical-resistant porcelain surface that once protected against embalming fluids now provides an ideal work surface for rolling pastry and preparing family meals. The raised edges that once contained clinical fluids now conveniently keep flour from dusting your kitchen floor. As interior designer Sophia Reeves told me, "With proper sealing of drainage openings and thorough cleaning, these tables make extraordinary kitchen centerpieces. Their history adds depth to a home's story."

Library and study consoles offer another natural fit. The substantial size and height of a porcelain embalming table creates an ideal surface for displaying large format books, maps, or collections. I visited a collector in Nashville whose table now showcases his rare book collection in his home library. "Visitors are always intrigued when they learn the history," he told me. "It sparks fascinating conversations about changing funeral practices and the evolution of design."

The film and television industry has acceptd these tables as authentic props for period productions. Shows set in early 20th century hospitals, morgues, or funeral homes seek out these pieces for historical accuracy. We're particularly proud that tables from our collection at American Mortuary Coolers were featured in Apple TV's "Bad Monkey," bringing these historical artifacts to new audiences who might never otherwise encounter them.

Photography studios have finded that these tables make excellent staging areas. The clean white surface provides perfect contrast for product photography, while the raised edges keep small items from rolling away during shoots. The substantial construction eliminates vibration issues during detailed close-up work – a benefit photographers particularly appreciate.

Whatever new purpose you find for your table, maintaining its historical integrity honors both the craftsmanship and cultural significance it represents. As Patricia reminds us, "These tables represent an important chapter in how our society cared for the deceased. Their new uses should acknowledge this heritage rather than erase it."

For more detailed guidance on caring for these unique pieces, our article Porcelain and the Past: Exploring Antique Embalming Tables offers additional restoration tips and creative display ideas.

Frequently Asked Questions about Porcelain Embalming Tables

Why choose porcelain over wood or steel?

When you look at the history of mortuary equipment, the porcelain embalming table stands out as the gold standard for decades – and for good reason. These tables weren't just beautiful; they solved real problems that funeral directors faced every day.

Think about what happens in a preparation room. Bodily fluids, strong chemicals, constant cleaning – it's a demanding environment. Porcelain simply handled these challenges better than anything else available at the time. Unlike wooden tables that would soak up fluids like a sponge (yikes!), porcelain's glass-like surface kept everything on top where it could be wiped away completely.

"I remember my grandfather talking about those old wooden tables," one funeral director told me. "They'd get so saturated with chemicals that you could smell them from across the room, even after scrubbing. When they got their first porcelain table in the 1920s, it was like moving from the Dark Ages into the modern world."

The chemical resistance of porcelain was truly remarkable. Those powerful formaldehyde-based embalming fluids that would quickly eat away at wood or corrode early metal tables? They just beaded up on porcelain, ready to be wiped away without leaving a trace.

There's also something about working on a bright white surface that just makes sense. The visual contrast helped embalmers see exactly what they were doing – a practical advantage that improved their work. One collector I spoke with actually tapped his knuckle on his restored table, smiling at the distinctive clear "ping" sound. "That's the sound of quality," he said. "Embalmers used to know that sound by heart."

Perhaps most surprising was porcelain's temperature stability. Before consistent climate control, this mattered tremendously. The porcelain surface didn't get ice-cold like metal or absorb ambient heat like wood, helping to maintain more consistent conditions during the embalming process.

While stainless steel eventually won out due to being lighter and less expensive, many old-school embalmers maintained that nothing ever quite matched the working properties of a good porcelain embalming table.

How do I verify authenticity and maker?

Authenticating a porcelain embalming table is part detective work and part treasure hunt. With reproductions and misidentified pieces floating around, knowing what to look for can save you from an expensive mistake.

First, check for maker's marks – these are your best friends when verifying authenticity. The major manufacturers weren't shy about branding their products. Look for brass plaques from companies like Dodge Chemical Co., Enterprise (famous for their "Climax" model), or Royal Doulton. Sometimes you'll find stamps impressed directly into metal components or cast marks in the iron base.

"The most exciting find for me was finding a partially obscured 'PAT March 1908' stamp on the tilting mechanism of a table I bought at an estate sale," shared one collector. "That patent date instantly confirmed both its age and authenticity."

The porcelain itself tells a story too. Genuine period porcelain has a depth and character that modern materials simply can't duplicate. Try this expert trick: examine the surface under "raking light" (light shining across at a low angle). Authentic old porcelain develops distinctive crazing patterns – those tiny networks of cracks in the glaze that form over decades. These patterns are nearly impossible to fake convincingly.

Construction methods offer another verification pathway. Look for hand-forged iron components, visible casting marks, and period-appropriate hardware like square-head bolts. Modern reproductions typically use contemporary fasteners that stand out like a sore thumb to the trained eye.

When in doubt, compare your table to examples in historical catalogs. Companies like The Dodge Company and ESCO published illustrated catalogs that can help confirm whether your table matches period-appropriate designs. Many of these catalogs have been digitized by museums and collectors.

For high-value pieces, consider consulting with specialists in medical or funeral antiques. A professional assessment might cost a few hundred dollars, but that's a small price to pay when authenticating a table worth several thousand.

What are best practices for shipping these heavy, fragile items?

Shipping a porcelain embalming table is not for the faint of heart! These beauties typically weigh over 200 pounds and combine extremely durable cast iron with surprisingly delicate porcelain surfaces – a challenging combination that requires special handling.

I'll never forget when Frank, one of our long-time customers, called about shipping his grandfather's embalming table from Maine to Arizona. "I wrapped it in moving blankets and bubble wrap," he told me, "but the shipping company looked at me like I was crazy when I tried to explain what it was!"

Here's the truth: standard moving materials simply aren't sufficient for these pieces. Professional crating is absolutely essential. We recommend custom wooden crates with foam inserts specifically molded to your table's unique contours. This approach prevents the table from shifting during transport while distributing pressure evenly across that valuable porcelain surface.

Before your table goes into its crate, document everything. Take detailed photos from every angle, focusing on any existing damage or repairs. This documentation serves two vital purposes: it establishes proof of condition before shipping (crucial for insurance claims) and provides reference for reassembly if components need to be separated.

Speaking of components – those drain pipes, hydraulic mechanisms, and sometimes even legs can often be carefully removed for safer transport. Just be sure to label everything clearly and include reassembly instructions for the recipient.

"White glove" freight service with climate-controlled transport is worth every penny for valuable tables. These specialized services include careful loading and unloading by people who understand the value of what they're handling. Yes, it costs more – sometimes significantly more – but the peace of mind is priceless.

Don't forget proper insurance! Standard carrier coverage rarely provides adequate protection for these specialized items. For tables valued over $2,000, consider a separate insurance policy specifically designed for antique transport.

At American Mortuary Coolers, we've developed specialized protocols for safely shipping these historical treasures throughout our service regions. Our experience delivering modern mortuary equipment across the contiguous 48 states has given us unique insights into handling these challenging pieces with the care they deserve.

Conclusion

The porcelain embalming table represents a fascinating chapter in mortuary history—a time when craftsmanship merged with function to create something both beautiful and practical. These tables witnessed a profound change in how we care for our deceased loved ones, bridging the gap between simple wooden cooling boards and today's modern stainless steel equipment.

What makes these pieces so special isn't just their striking appearance. It's the story they tell about changing attitudes toward death, growing concerns about sanitation, and the professionalization of funeral services. Each table carries with it decades of history—silent witnesses to countless families' final moments with their loved ones.

Today, these historic tables have found new life and appreciation. Some grace museum exhibits where they educate visitors about funeral traditions. Others have been thoughtfully repurposed as unique furniture pieces that spark conversation. And many rest in the hands of dedicated collectors who preserve them for future generations.

If you're considering bringing one of these substantial pieces of history into your own collection, we hope our guide has provided valuable insights—from authenticating genuine pieces to understanding their proper care and transportation. These aren't simple items to acquire or maintain, but their historical significance makes them worth the effort.

"These artifacts tell important stories about how our society has cared for the dead," as historian Patricia Moreland reminds us. By preserving these remarkable tables, we maintain a tangible connection to funeral traditions that shaped our modern practices and understanding of death care.

At American Mortuary Coolers, we deeply respect this rich heritage while embracing innovation in mortuary equipment. From our locations across the country—including Johnson City, Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, and Pittsburgh—we provide modern solutions built on this foundation of excellence and craftsmanship.

Whether you're searching for a historic porcelain embalming table or need modern equipment for your funeral establishment, we're here to help. Our custom mortuary coolers and equipment continue the tradition of quality that began with these classic porcelain tables, delivered directly to funeral professionals across the contiguous 48 states.

Like the skilled craftsmen who created these enduring porcelain tables, we remain committed to excellence in serving the funeral profession—honoring the past while building for the future.