Why Commercial Refrigeration Repair Can Make or Break Your Business

Commercial refrigeration repair is a critical service that keeps your business running when cooling systems fail. Here's what you need to know:

- Service every 3-6 months to prevent costly breakdowns

- Average commercial fridge lifespan: 10-18 years (14 years average)

- Call a professional when: temperature swings, unusual noises, water leaks, or frost buildup occur

- Repair vs. replace rule: If repair costs exceed half the price of a new unit and it's over 10 years old, replace it

- Common issues: compressor failure, thermostat problems, dirty coils, refrigerant leaks

When your commercial refrigeration equipment breaks down, it's no laughing matter. A single compressor failure can spoil an entire inventory overnight. Water leaks can damage floors and create safety hazards. Temperature fluctuations can compromise product quality and violate health department regulations.

Most refrigeration emergencies are preventable with the right knowledge and maintenance approach. Smart business owners who understand the basics of commercial refrigeration repair can often catch problems early, perform simple fixes themselves, and know exactly when to call in professional help.

Commercial refrigeration repair terms at a glance:

Why Fast Commercial Refrigeration Repair Matters

When your commercial refrigeration system goes down, every minute counts. Your walk-in cooler doesn't care that it's 2 AM on a Sunday - when it fails, your products start spoiling immediately.

Food safety requires maintaining exact temperatures required by law. The FDA doesn't give you a grace period when your system fails. If your seafood warms up past 40°F or your frozen goods start thawing, you're looking at potential health code violations that could shut you down entirely.

Revenue loss hits you from multiple directions. First, there's the obvious cost of spoiled inventory - we've seen restaurants lose $15,000 worth of premium ingredients over a single weekend. Then you lose sales because you can't serve customers what they ordered.

Your brand reputation takes years to build but can crumble overnight. One customer getting sick from improperly stored food can destroy your business through bad reviews and word-of-mouth.

Energy efficiency suffers when systems struggle. A failing system works harder while cooling less effectively. Your electricity bills can jump 30% or more when components start failing.

What Is Commercial Refrigeration Repair?

Commercial refrigeration repair is the specialized service of fixing cooling systems that businesses depend on. It's much more complex than residential repair work because commercial units run constantly under heavy loads.

The process starts with proper diagnosis using specialized gauges and meters to check refrigerant pressures, electrical readings, and temperature differentials. Parts replacement often follows, using heavy-duty commercial components designed for constant operation.

Only EPA-certified techs can legally handle the refrigerants in your system. This certification is required by federal law for anyone working with commercial refrigerants.

Why Every Business Should Care

Inventory protection should be your top priority because the average restaurant loses $3,000 to $5,000 worth of food during a typical refrigeration failure. Larger operations like grocery stores can see losses of $50,000 or more.

Legal requirements vary by industry but are always serious. Whatever your business, there are regulations you must follow, and proper commercial refrigeration repair helps you meet them.

Commercial Refrigeration Repair Basics

Every commercial cooling system works like a giant heat pump, moving warmth from inside your storage space to the outside world through four main components.

Compressors are the muscle of the operation, squeezing refrigerant gas and pushing it through the entire system. Most commercial compressors last 10-15 years if properly maintained.

Condensers dump heat outside and are usually found outdoors or in well-ventilated spots. Dirty condenser coils are behind more system failures and high energy bills than almost any other single problem.

Evaporators do the actual cooling work inside your space. If you see ice building up where it shouldn't be, your evaporator is signaling problems with the defrost system or airflow.

Walk-in coolers and freezers are complete cooling rooms with insulated walls and built-in refrigeration gear. Reach-in units include prep tables and display cases that get opened frequently throughout the day. Ice machines typically serve well for 10-15 years but are picky about clean water and regular filter changes.

For more detailed information, check out our comprehensive guide to refrigeration units and how they work.

Most Common Systems That Need Commercial Refrigeration Repair

Walk-in coolers run around the clock while dealing with constant door openings and temperature swings. Common problems include failed door seals, broken defrost systems, and overheated compressors from dirty coils.

Prep tables face constant opening during rush periods while surrounded by hot cooking equipment. This creates temperature control problems and accelerated mechanical wear.

Bar coolers work in high humidity with constant door openings, creating condensation issues and door seal failures.

Key Signs You Need Commercial Refrigeration Repair Now

Temperature swings indicate your system is struggling to maintain steady temperatures or takes too long to cool down after door openings.

Frost buildup on evaporator coils means your defrost system isn't working or something's blocking airflow. Ice buildup can destroy entire coil systems.

Water leaks come from clogged drain lines, worn door seals, or excessive condensation. The water damage to floors and surrounding areas makes this worse than it initially appears.

Loud noises signal mechanical problems. Grinding sounds usually mean worn bearings, clicking might indicate electrical issues, and excessive shaking could mean loose parts or compressor problems.

Troubleshooting & DIY Checks Before You Call

Many common refrigeration problems have simple solutions you can try before calling for emergency commercial refrigeration repair. While you should never attempt complex repairs yourself, several safe checks could save you hundreds in service calls.

Start with the power supply - check that your unit is plugged in, look for tripped circuit breakers, and ensure external disconnect switches are "on." Many emergency calls are solved by simply resetting a tripped breaker.

Check thermostat calibration using a separate thermometer to compare against your display reading. If there's a significant difference, your thermostat might need adjustment.

Clean dirty coils using a soft brush or compressed air to remove dust and debris. This simple task can improve efficiency by 15-20% and prevent many failures.

Inspect door gaskets for tears, warping, or buildup. Test by closing a dollar bill in the door - if it slides out easily, your seal needs attention.

Ensure proper airflow clearance around units. Poor airflow makes compressors work harder and fail sooner.

For detailed guidance, check out our guide on how to do walk-in cooler repair (even if you've never tried it before).

Quick Fixes That Save Money

Resetting circuit breakers should be your first move when a unit stops working. If the breaker keeps tripping, you have a bigger electrical problem needing professional attention.

Clearing drain lines using warm water and a basic plumber's snake prevents water buildup that causes expensive damage.

Monthly condenser coil cleaning prevents most cooling problems before they start and can add years to equipment life.

Safety First: Precautions & PPE

Lockout and tagout procedures are essential when working around electrical equipment. Always disconnect power and use lockout devices to prevent accidental startup.

Wear gloves and eye protection when cleaning coils or working around equipment with sharp metal fins and edges.

Never attempt refrigerant handling without proper EPA certification and equipment. This requires professional expertise for safety and legal compliance.

For safety guidelines, review this scientific research on refrigerant safety.

When to Call a Pro & How to Choose One

Some repairs require specialized tools that cost more than the repair itself, involve refrigerant handling that legally requires EPA certification, or happen during emergencies when you need immediate help.

24/7 service availability separates real professionals from "we'll get back to you Monday" companies. Ask about actual response times, not just whether they offer emergency service.

Warranty coverage shows a company's confidence in their work. Look for comprehensive warranties on both parts and labor - good companies offer at least one year guarantees.

Flat-rate pricing protects you from surprise bills. Get firm prices upfront, including diagnostic time.

Parts-stocked trucks mean faster repairs. The best companies keep common components like compressors, fans, and thermostats on their trucks.

Certifications and insurance aren't optional. Verify EPA certification, business licenses, and liability insurance. Never let uninsured technicians work on your property.

For help finding qualified professionals, check out our complete guide to commercial refrigeration repair near you.

Repair vs. Replacement: Cost Calculator

Age of unit is your first clue. Equipment under five years old is almost always worth repairing. Units over fifteen years old will likely keep breaking down. The five to fifteen year range requires careful consideration.

The half-cost rule provides clear guidance: if repair costs exceed half the price of a new unit and your equipment is over ten years old, replacement usually makes more financial sense.

Energy savings from modern equipment can tip the scales toward replacement. New units can cut energy bills by 30% compared to old, inefficient equipment.

| Equipment Age | Repair Cost vs New Unit | Recommendation |

|---|---|---|

| Under 5 years | Any reasonable repair | Repair |

| 5-10 years | Less than 50% of new cost | Repair |

| 10-15 years | Less than 40% of new cost | Consider replacement |

| Over 15 years | Any major repair | Replace |

Questions to Ask Before Hiring

Response time promises need specifics. Get guaranteed response times in writing for both business hours and emergency calls.

Insurance coverage must be current and adequate. Ask for certificates of insurance for both general liability and workers' compensation.

Brands serviced should include your specific equipment. Ensure they regularly service and stock parts for your units.

Guarantees on work separate professionals from parts-changers. Good companies will return and fix recurring problems at no charge.

Preventive Maintenance & Budgeting Tips

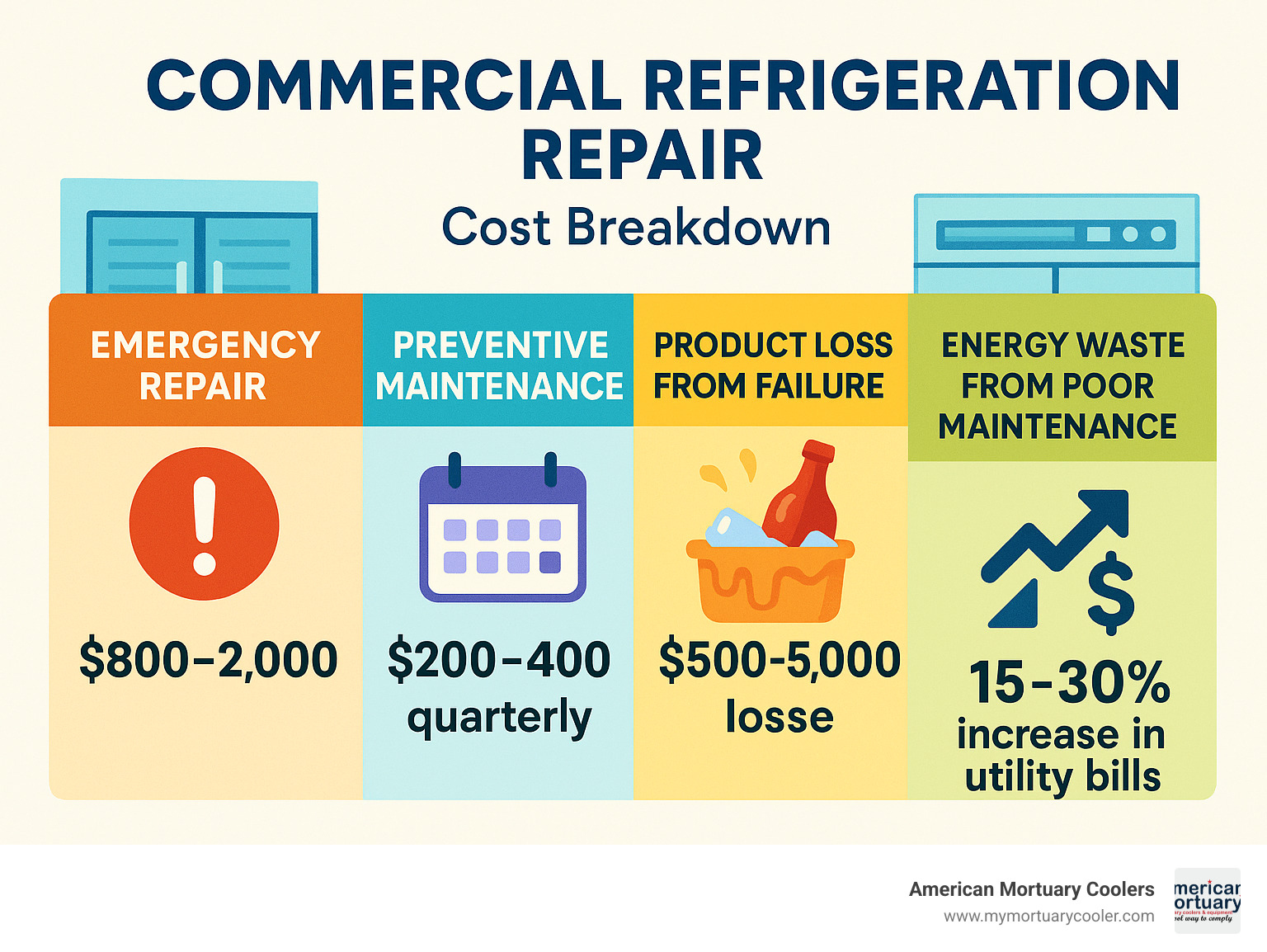

Scheduled service every 3-6 months is your insurance policy against disaster. Spending $200-400 per visit prevents $5,000 emergency repair bills that hit at the worst times.

Regular maintenance catches small problems before they become big ones. A $20 belt replacement during routine service beats emergency repairs, spoiled inventory, and lost revenue.

Coil cleaning deserves special attention as the most important maintenance task. In dusty environments, coils need monthly cleaning. This simple task improves efficiency by 15-20% and adds years to equipment life.

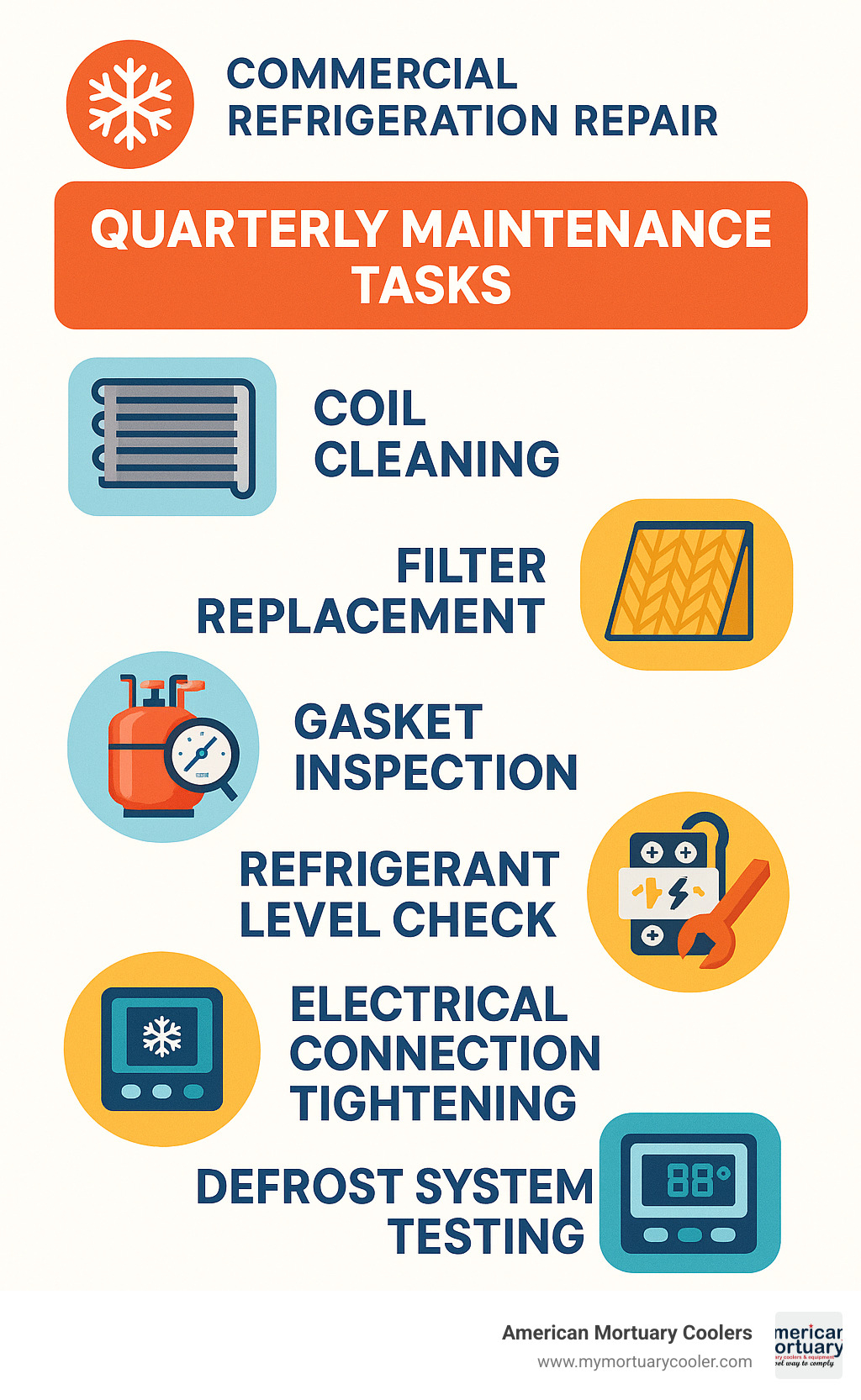

Filter changes every three months keep systems breathing properly. Clogged filters reduce efficiency and cause premature equipment failure.

Gasket replacement every 3-5 years prevents energy waste. Failing door seals make equipment work overtime while driving up energy bills.

Refrigerant checks during every service visit catch leaks early, preventing expensive compressor damage.

Remote monitoring systems watch equipment 24/7, tracking temperatures and performance patterns. Some can predict failures before they happen.

Creating a Maintenance Schedule

Monthly tasks include visual inspections, temperature checks, and cleaning accessible coils. These 15-30 minute checks often catch problems when they're still small and cheap to fix.

Quarterly tasks involve professional service calls, filter changes, and refrigerant level checks. Schedule these during slower business periods.

Annual tasks provide comprehensive system inspections, compressor analysis, and replacement of wear items like belts and gaskets.

Environmental & Regulatory Considerations

R-404A refrigerant is being phased out due to environmental concerns. Plan for eventual replacement or conversion if your equipment uses R-404A.

EPA rules carry serious penalties. Venting refrigerants can result in fines up to $37,500 per day. Only EPA-certified technicians can legally handle refrigerants.

Leak logs are required for systems containing more than 50 pounds of refrigerant. Keep detailed records because EPA inspectors can request them anytime.

Emergency Action Plan: Minimize Downtime

Having a solid emergency plan is the difference between losing a few hundred dollars and losing your entire weekend's inventory when refrigeration systems fail unexpectedly.

Backup storage should be your first line of defense. Establish relationships with nearby businesses that have extra cooler space or set up formal agreements with non-competing neighbors.

Ice suppliers who can deliver large quantities quickly become essential during equipment failures. Find suppliers who can bring 500-1000 pounds of ice on short notice, even weekends.

Portable coolers and refrigerated truck rentals go fast during widespread outages. Call rental companies early, even if you're unsure you'll need the unit.

Inventory triage means having a plan for what to save first. Your most expensive items get priority - premium ingredients go to backup storage before less valuable products.

Insurance claims need immediate filing when equipment failure causes product loss. Take photos of failed equipment and spoiled products, keep detailed lists with costs and purchase dates.

24/7 Strategies That Save Product

Alarm alerts that send notifications to multiple people through phone calls, texts, and emails can save thousands by catching problems early. Set alerts to reach at least three different people.

Spare parts kits for common failures can save expensive emergency service calls. A $50 contactor on your shelf can prevent a $500 Sunday evening emergency call.

Service hotlines with guaranteed response times provide peace of mind, but establish relationships with at least two different service companies for backup coverage.

Frequently Asked Questions about Commercial Refrigeration Repair

What's the average service interval?

Most experts recommend service every 3-6 months, depending on usage. Busy restaurants with frequently-opened walk-in coolers need monthly attention, while low-use equipment can stretch to 6 months between visits. Consistency beats perfection - stick to regular schedules rather than skipping appointments.

How do I know if my compressor is failing?

Unusual noises are the biggest warning sign - grinding sounds, clicking noises, or vibrations that make the whole unit shake. Temperature struggles where units can't keep up with demand or take forever to cool down indicate compressor problems. Higher energy bills from struggling compressors using 30% more electricity while delivering worse performance are another red flag.

Are maintenance contracts worth it?

Maintenance contracts almost always pay for themselves by preventing just one major repair per year. Typical contracts cost $800-1,200 annually while emergency repairs often run $1,500-3,000. Contract customers get priority service, discounted repair rates, and regular maintenance doesn't get forgotten during busy seasons.

Conclusion

When your commercial refrigeration repair needs arise, you're not powerless. The knowledge you've gained here puts you in control of your cooling systems instead of at their mercy.

Every business owner faces the same refrigeration challenges. The difference between those who thrive and those who struggle often comes down to preparation. You now know how to spot problems early, perform basic maintenance, and choose the right professionals when repairs are needed.

At American Mortuary Coolers, we've built our reputation on understanding that reliability isn't negotiable when it comes to cooling systems. While our specialty is crafting custom mortuary coolers for funeral homes across Tennessee and the contiguous 48 states, we know that proper refrigeration fundamentals apply everywhere.

Your refrigeration system works for you 24/7 - return the favor with consistent care. A few minutes of weekly attention and quarterly professional service prevent thousands in emergency repairs and product loss.

The businesses that succeed long-term treat their equipment as valuable partners rather than disposable appliances. Custom solutions might be necessary for unique situations, but consistent care and professional service are universal requirements.

Remember: the cost of doing nothing is always higher than the cost of prevention. Whether it's cleaning coils monthly, checking door seals weekly, or scheduling regular maintenance visits, small investments prevent big disasters.

Ready to explore professional-grade cooling solutions? Visit our refrigeration collections to see how American Mortuary Coolers approaches reliability and custom design. Because when your business depends on staying cool, settling for anything less than the best just doesn't make sense.