Why Mortuary Cold Room Doors Service Maintenance Is Critical for Your Facility

Mortuary cold room doors service maintenance is the foundation of reliable body storage operations. When doors fail, temperature spikes can compromise remains within hours, violate health codes, and trigger costly emergency repairs.

Here's what proper maintenance involves:

- Weekly inspections of door seals, hinges, and temperature logs

- Monthly deep cleaning with hospital-grade, non-corrosive disinfectants

- Quarterly professional checks of refrigerant systems and electrical components

- Annual comprehensive service including seal replacement and calibration

- Emergency response protocols for immediate temperature deviations

Your mortuary cold room door is more than equipment - it's the guardian of dignity and compliance. These specialized units must maintain a precise 36°F-39°F range continuously. Even a 4-hour temperature spike can violate health codes and compromise the integrity of remains.

The stakes are high. A mortuary in Texas recently faced operational turmoil when overlooked condenser issues caused refrigerator malfunction. Meanwhile, a hospital in Colorado encountered severe penalties due to delayed maintenance that resulted in complete system failure.

But there's good news. A funeral home in New York reported significant repair cost savings after implementing a robust maintenance strategy. The key? Following a systematic 3-step approach to finding and maintaining professional service.

This guide breaks down exactly how to protect your investment, ensure compliance, and avoid catastrophic failures through proper maintenance planning.

Step 1: Understand Why Door Maintenance is Non-Negotiable

Think of your mortuary cold room door as a silent, ever-vigilant guardian. It stands faithfully between the precise, controlled environment inside and the unpredictable world outside. Without careful and consistent mortuary cold room doors service maintenance, this crucial guardian can falter, leading to serious consequences for your facility, your peace of mind, and the dignity of those entrusted to your care. Understanding what makes these doors tick, and recognizing the early whispers of trouble, are your very first lines of defense.

Critical Components of Your Mortuary Cold Room Door

Each part of your cold room door works together like a well-oiled team, ensuring the integrity of the cold environment. Overlooking even one player can lead to a cascade of problems.

First, there are the Door Seals (Gaskets). These flexible, often rubber or silicone, strips are the unsung heroes. They create an airtight barrier between the door and its frame when closed, diligently stopping warm air from sneaking in and precious cold air from escaping. They're literally the glue holding your temperature control together!

Next, we have the Hinges. These sturdy metal components bear the door's weight and allow it to swing open and shut smoothly. When they're properly aligned and lubricated, they help ensure a snug, tight seal every time.

Then come the Handles & Latches. More than just a way to open the door, these mechanisms secure it firmly, compressing those vital seals for a perfect closure. They also include essential internal release mechanisms, a critical safety feature.

Don't forget the Pressure Relief Valves. Cold rooms operate at lower temperatures, which can create pressure differences. These clever valves equalize that pressure, preventing the door from becoming stubbornly hard to open or failing to seal correctly. They also protect the very structure of your cold room.

Finally, for those larger units or sliding designs, the Tracks for Sliding Doors are key. Smooth operation here, free from debris, ensures the door glides effortlessly into a perfect, tight seal.

Warning Signs Your Door Needs Service

Your cold room door is quite good at telling you when something’s not quite right, often before a small issue becomes a big headache. Learning to "listen" to these signals can save you a lot of trouble and expense.

One of the most common red flags is Condensation or frost buildup. If you see this around the door frame, on the seals, or even on the interior walls near the door, it’s a clear sign that warm, moist air is sneaking in. This almost always points to a compromised seal or insulation.

Another obvious sign is Visible cracks, tears, or hardening in seals. Over time, those hardworking gaskets can become brittle, cracked, or even torn. Run your hand along them – if they feel stiff, sticky, or show any physical damage, they're losing their ability to create that all-important seal.

Is it a struggle to close the door? Difficulty closing or latching often suggests misaligned hinges, a warped door frame, or a worn-out latch mechanism. You shouldn't have to fight your door to get it shut properly.

Keep an ear out for Unusual noises. Squeaking hinges, grinding sounds from sliding door tracks, or even the refrigeration unit sounding like it's constantly straining can all point to door-related issues forcing your system to work harder.

Lastly, a Warped door or frame is a serious concern. Physical damage, constant stress, or even significant temperature swings can cause the door or its frame to warp, making a tight seal impossible.

Consequences of Neglecting Mortuary Cold Room Door Maintenance

Ignoring these warning signs is a bit like ignoring a small leak in a boat – eventually, you'll find yourself in deep water. The consequences of neglected mortuary cold room doors service maintenance are severe and can ripple through every aspect of your operation.

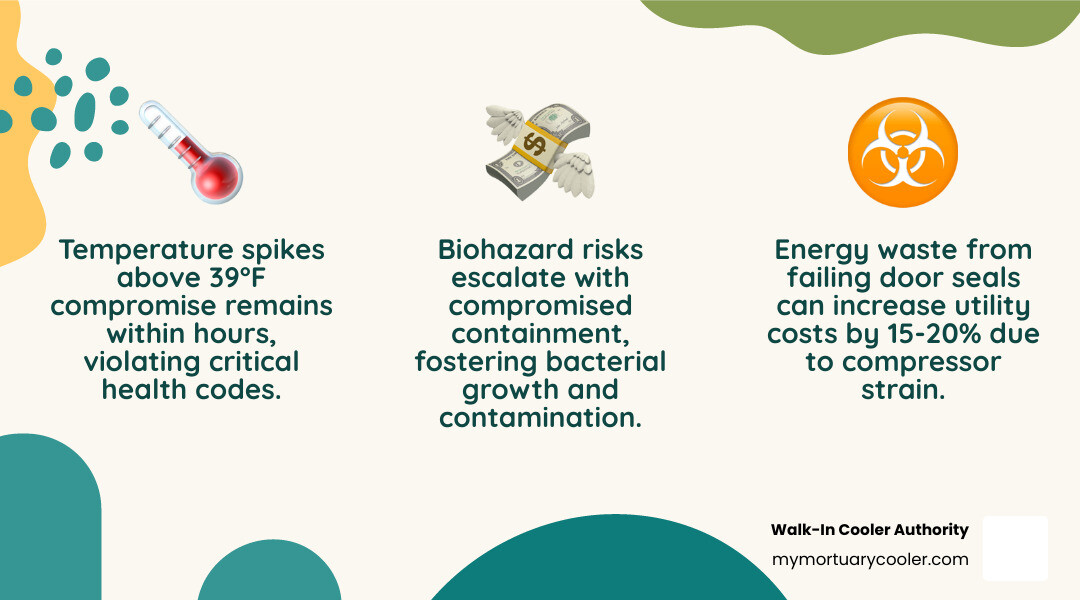

The most immediate and critical issue is Temperature instability. A faulty door allows warm air to enter, forcing your refrigeration system to work overtime. This leads to temperature fluctuations, which can compromise remains and, critically, violate strict health codes.

This constant overwork also translates directly to Increased energy costs. When cold air escapes and warm air rushes in, your refrigeration unit runs almost non-stop to maintain the set temperature. That extra workload shows up as significantly higher electricity bills.

Speaking of overwork, this continuous strain on your compressor and other refrigeration components drastically shortens their lifespan, leading to expensive and premature Equipment failure. Nobody wants an unexpected breakdown.

Beyond the practical, there are serious Health code violations & regulatory non-compliance. Mortuary cold rooms are subject to stringent regulations regarding temperature and hygiene. Failing to maintain the required 36°F–39°F range can result in hefty fines, operational shutdowns, and significant damage to your facility's reputation.

Finally, compromised doors can pose serious Biohazard risks. A properly sealed door is essential for containing potential biohazards within the cold room. Damaged seals can increase the risk of bacterial growth and cross-contamination, endangering both your staff and the public.

The Critical Role of Door Seals in Temperature Control

Door seals, or gaskets, are the unsung heroes of your mortuary cold room. They might seem like simple rubber strips, but their function is absolutely paramount. Their primary role is to create an impenetrable barrier, preventing warm, humid air from infiltrating the controlled environment inside.

When seals are intact and pliable, they maintain the precise temperature range of 36°F–39°F (2°C–4°C) that is critical for preserving dignity and ensuring compliance. A tight seal means less work for your refrigeration unit, which directly translates to significant energy savings. Conversely, a worn-out or damaged seal allows heat to seep in, forcing the compressor to run almost continuously, straining the system, and driving up your utility bills. Think of it as leaving your refrigerator door ajar – the energy waste is immense. Regular inspection and prompt replacement of damaged seals are not just good practice; they are essential for operational efficiency and cost control. To dive deeper into optimizing your cooler's performance, you can learn more about cooler maintenance best practices.

How Proper Maintenance Ensures Health and Safety Compliance

In the sensitive environment of a mortuary, health and safety compliance aren't just good ideas – they're legal imperatives. Proper mortuary cold room doors service maintenance is a cornerstone of meeting these rigorous standards. Employers are legally required to ensure that all chiller areas are thoroughly disinfected and sanitized on a regular basis.

A well-maintained door, with intact seals and a clean surface, significantly contributes to preventing bacterial and mold growth, which can thrive in compromised environments. More critically, it helps in biohazard containment, minimizing the risk of contamination from blood-borne viruses (BBV) and other pathogens. Our facilities, serving the mortuary and funeral supplies industry across the USA, understand the critical importance of these measures.

Furthermore, maintaining detailed maintenance logs is often a requirement for OSHA audits and licensing renewals. These logs serve as documented proof of your commitment to health and safety, showing that you are proactively addressing potential risks. By adhering to a robust maintenance schedule, you're not just protecting your equipment; you're safeguarding your staff, ensuring public health, and upholding the highest ethical standards. For comprehensive guidance on maintaining a sterile environment, we recommend exploring deep cleaning protocols for mortuaries.

Step 2: Implement a Proactive Maintenance Schedule

Think of maintenance like brushing your teeth – it's much easier to do it regularly than to deal with the consequences of neglecting it. A proactive mortuary cold room doors service maintenance schedule transforms you from a firefighter constantly battling emergencies into a guardian who prevents problems before they start.

The beauty of a well-planned schedule lies in its predictability. Instead of wondering when something might break, you're taking control and staying ahead of potential issues. This approach not only saves money but also gives you peace of mind knowing your facility remains compliant and operational.

Inspection Frequency

Creating a rhythm for your maintenance tasks ensures nothing slips through the cracks. Different components need attention at different intervals, much like how you might check your car's oil monthly but only rotate the tires seasonally.

Daily temperature logs are your most critical checkpoint. These quick readings help you catch temperature deviations from the essential 36°F–39°F range before they become serious problems. Think of it as taking your cold room's pulse – a simple check that can prevent major headaches.

Weekly cleaning and seal checks keep your door in top condition. During these sessions, you'll thoroughly clean the door surfaces and examine the seals for any signs of wear, cracking, or hardening. It's amazing how much you can learn about your equipment's health just by looking closely once a week.

Monthly hardware checks dive deeper into the mechanical components. This is when you'll inspect hinges, latches, and sliding door tracks for proper alignment and lubrication. You'll also want to calibrate the thermostat or digital controls monthly to ensure accuracy.

Quarterly deep cleans represent your seasonal maintenance push. These intensive cleaning sessions go far beyond daily wipes, ensuring thorough disinfection of every surface and component. It's like spring cleaning, but for your cold room door.

Annual professional service brings in the experts. Even with diligent in-house care, an EPA-certified technician should perform comprehensive checks including refrigerant leak tests, electrical inspections, and compressor amperage measurements. They can spot technical issues that might escape routine inspections.

Best Cleaning Practices

The products you use for cleaning matter just as much as how often you clean. Your mortuary cold room door isn't just any piece of equipment – it requires specialized care to maintain both hygiene standards and structural integrity.

Hospital-grade, non-corrosive disinfectants should be your go-to cleaning agents. These products are specifically formulated to eliminate pathogens while being safe for specialized equipment. They strike the perfect balance between effectiveness and equipment protection.

Here's something many people don't realize: avoiding bleach on stainless steel is crucial. While bleach might seem like the strongest disinfectant option, it's actually highly corrosive to stainless steel surfaces. Over time, bleach can cause pitting, discoloration, and structural damage that compromises your door's integrity.

Regular cleaning after each use prevents the buildup of bacteria, mold, and odors. Clean the cooler interior and door every time a body is removed. This practice maintains the sterile environment essential for your operations.

Your weekly door maintenance should include verifying interior temperatures remain stable between 36–39°F, inspecting door seals for cracks or warping, cleaning seals thoroughly with approved disinfectant, sanitizing interior surfaces of the door and frame, inspecting hinges for smooth operation, and checking latches for secure closure.

A Guide to Cleaning and Lubricating Door Hinges and Tracks

Smooth operation isn't just about convenience – it's essential for maintaining the tight seal that keeps your cold room functioning properly. When hinges stick or tracks bind, doors can't close completely, compromising temperature control and energy efficiency.

Lubricating hinges and rollers should be done with food-grade lubricant applied to all pivot points. This reduces friction, prevents rust, and ensures doors swing or slide freely without sagging. For sliding doors, pay special attention to the rollers that guide movement along the track.

Checking alignment while you lubricate helps catch problems early. If a door isn't hanging straight or sliding smoothly, it can't create a proper seal. Minor adjustments can often be made during routine maintenance, but significant misalignment requires professional attention.

Removing debris from tracks is particularly important for sliding doors. Dust, dirt, and small debris can accumulate and impede smooth movement. Regular vacuuming or wiping keeps tracks clear and prevents rollers from binding or derailing.

Using food-grade lubricant isn't just a recommendation – it's essential for mortuary environments. If lubricant accidentally contacts the interior of your cold room, food-grade products won't contaminate the environment or pose health risks. This attention to detail reflects the stringent hygiene requirements of mortuary settings.

Creating a schedule for mortuary cold room doors service maintenance

A structured approach to mortuary cold room doors service maintenance prevents oversights and ensures comprehensive coverage. Think of your schedule as a roadmap that guides you through all necessary tasks at the right intervals.

Daily visual checks are quick but vital. Verify the door closes completely and latches securely, look for obvious condensation or frost around the door frame, and check temperature logs for consistency. These simple observations can catch problems before they escalate.

Weekly cleaning routines maintain hygiene and equipment condition. Thoroughly clean door exterior and interior surfaces with hospital-grade, non-corrosive disinfectants, inspect door seals for damage or deterioration, and wipe down sliding door tracks to remove surface debris.

Monthly hardware inspections focus on mechanical components and safety features. Test the internal emergency release mechanism to ensure it functions correctly, inspect hinges for wear or loose fasteners while applying food-grade lubricant as needed, check latches and locking mechanisms for smooth operation, inspect rollers and tracks on sliding doors, and verify pressure relief valves are clear and functioning.

Quarterly deep cleans provide intensive maintenance that goes beyond routine care. Perform comprehensive cleaning of the entire cold room including all door components using professional-grade cleaning agents, and reassess insulation condition around the door frame.

Annual professional servicing brings expert evaluation to your maintenance program. Schedule visits from EPA-certified technicians specializing in mortuary-grade refrigeration. They'll conduct thorough inspections of all door components, perform refrigerant leak tests and electrical inspections, and calibrate controls to ensure optimal performance and compliance.

This comprehensive schedule ensures your mortuary cold room doors remain reliable, efficient, and compliant while protecting both your investment and operational integrity.

Step 3: Finding a Professional Mortuary Cold Room Doors Service Maintenance Provider

Even with the most careful daily checks and diligent cleaning, there comes a time when you need a little extra help. Complex repairs, in-depth system diagnostics, or specialized adjustments often call for the expertise of a professional. Finding just the right expert for your mortuary cold room doors service maintenance isn't just about fixing a problem; it's about ensuring long-term reliability, peace of mind, and continued compliance. It's an important step in protecting your vital equipment.

Qualities of a Professional Technician

When it comes to the specialized world of mortuary equipment, not all refrigeration technicians are the same. You need someone who truly understands the unique demands of your facility. When we look for a professional, we seek out specific qualities that ensure they can meet these critical needs.

First and foremost, they should be EPA-certified. This certification isn't just a fancy title; it means they're qualified to handle refrigerants safely and in a way that respects our environment. For any work on refrigeration systems, this is a must-have. Just as crucial is their experience with mortuary-grade refrigeration. A technician who's great with a restaurant walk-in might not fully grasp the precise temperature requirements, strict biohazard protocols, and regulatory rules specific to mortuary coolers. Always look for professionals who clearly state they have experience with mortuary equipment or similar specialized environmental chambers.

Life doesn't stick to business hours, and neither do equipment malfunctions. That’s why 24-hour emergency service is a non-negotiable quality. A reliable service provider will offer round-the-clock emergency response, understanding that even a short temperature spike can violate health codes and compromise the dignity of remains. Here at Walk-In Cooler Authority, our goal is to connect you with such expertise across the USA, including key locations like Johnson City, Atlanta, Chicago, Dallas, Los Angeles, and New York. Finally, a truly good technician possesses comprehensive diagnostic skills. They don't just fix the obvious; they dig deeper to find the root cause of an issue. They should be able to look at how energy is being used, suggest ways to save on maintenance costs, and improve overall operational efficiency.

How to Vet and Hire a Qualified Technician

Choosing a professional for your mortuary cold room doors service maintenance is a big decision. To make sure you're getting the best possible care for your critical equipment, we recommend a thorough vetting process. Think of it like an interview for a very important job!

Start by asking some pointed questions. For instance, "Do you have specific experience with mortuary coolers or specialized environmental chambers?" This helps weed out generalists. You'll also want to confirm, "Are your technicians EPA-certified?" and "What certifications or specialized training do your technicians hold?" Because emergencies happen, ask about their emergency availability: "Do you offer 24/7 emergency service, and what is your typical response time for critical issues?" Don't forget compliance: "Can you provide a detailed maintenance log for our records, as required for OSHA audits and licensing renewals?" And naturally, you'll want to know about their guarantee: "What kind of warranty do you offer on parts and labor?"

Beyond questions, references are incredibly valuable. Ask for contacts from other funeral homes, hospitals, or morgues they’ve worked with. Hearing from their current clients can give you a real sense of their reliability and the quality of their work. A reputable provider will also be very transparent about their pricing. Always ask for a detailed quote that breaks down labor, parts, and any call-out fees. This ensures there are no surprises. And finally, look for specialized knowledge. A technician who truly understands the critical storage temperature range of 36°F–39°F, and the serious implications of even short temperature deviations, is an invaluable partner for your facility.

Common Professional Repairs for your mortuary cold room doors service maintenance

When you bring in a professional technician for mortuary cold room doors service maintenance, they'll tackle issues that go beyond your daily cleaning or lubrication. These specialized repairs are vital for getting your door back to perfect working order and keeping your cold room environment stable.

One of the most common professional repairs is door seal (gasket) replacement. Over time, these seals can harden, crack, or tear, letting warm air sneak in. A technician will carefully remove the old seal and install a brand new, pliable gasket, ensuring a perfectly airtight fit. Another frequent fix is hinge repair or replacement. Worn, rusted, or bent hinges can cause the door to sag, making it hard to close properly and compromising that all-important seal. Professionals can repair these hinges or replace them entirely, realigning the door so it swings smoothly.

A malfunctioning latch mechanism can be a real headache, meaning the door isn't securely closed and temperature is being lost. Technicians can adjust the latch to ensure it compresses the seal correctly, or if it's beyond repair, they’ll replace the faulty mechanism. For facilities with sliding doors, track realignment is often necessary. If a sliding door is sticking, grinding, or not closing completely, the tracks might be out of alignment or damaged. Professionals can realign or replace sections of the track, ensuring the door glides effortlessly and seals effectively.

Don't overlook the pressure relief port. If it’s blocked or faulty, the door can become incredibly difficult to open, or it can even stress the door's structure. Technicians will clear any obstructions or replace the valve if it's no longer working. In cases of physical damage, like dents or punctures to the door panel itself, professionals can perform door panel repair or replacement to restore both insulation and structural integrity. Sometimes, door issues might be linked to the refrigeration system as a whole. That’s why refrigerant leak tests and electrical inspections are often part of a comprehensive service call. Fixing leaks or electrical faults can prevent wider problems and help the system maintain temperature properly, which in turn reduces strain on your door's sealing ability.

For any replacement parts or professional service needs, we encourage you to contact Walk-In Cooler Authority for replacement parts and service. We’re here to help you find the highest quality solutions for your mortuary equipment.

Frequently Asked Questions About Mortuary Cooler Door Care

When it comes to mortuary cold room doors service maintenance, we hear the same questions from funeral directors and morgue operators across the country. These concerns are completely understandable – after all, your cold room door is protecting both your investment and the dignity of those in your care.

What is the most critical part of maintaining a mortuary refrigerator door?

Without question, the door seal (gasket) is the most crucial component of your entire door system. Think of it as the silent guardian that never takes a break – it's working 24/7 to keep your cold room at that critical 36°F–39°F range.

This humble rubber strip does three vital jobs at once. First, it maintains consistent temperature by creating an airtight barrier against heat infiltration. Second, it ensures energy efficiency by preventing your compressor from working overtime. Third, it prevents contamination by keeping potential biohazards contained within the controlled environment.

The key to gasket care is regular inspection. Run your hand along the seal weekly, checking for cracks, hardening, or that sticky feeling that indicates deterioration. A compromised seal doesn't just mean higher energy bills – it can lead to temperature fluctuations that violate health codes and put your facility at risk.

How often should mortuary cold room doors be professionally serviced?

Here's where we see facilities make costly mistakes. The standard recommendation is annual professional service by an EPA-certified technician who specializes in mortuary-grade refrigeration. But that's just the baseline.

High-usage facilities – busy funeral homes, hospital morgues, or multi-location operations – benefit from quarterly professional checks. Why? Because the more your door gets used, the faster components wear out. Those extra inspections catch emerging issues before they become emergency repairs.

Think of it like car maintenance. You wouldn't wait for your brakes to fail before checking them, especially if you're driving cross-country every week. The same logic applies to your cold room door. Proactive maintenance prevents those middle-of-the-night emergency calls that nobody wants to deal with.

Can I use standard cleaning products on my mortuary cooler door?

This is where good intentions can lead to expensive mistakes. Never use standard cleaning products, especially anything containing bleach, on your mortuary cooler door.

Stainless steel surfaces require hospital-grade, non-corrosive disinfectants specifically designed for medical environments. Bleach might seem like the strongest option, but it's actually your door's worst enemy. It causes pitting, discoloration, and can compromise the structural integrity over time.

Hospital-grade disinfectants do double duty – they eliminate the broad spectrum of pathogens you're dealing with in mortuary environments while protecting your equipment investment. These specialized cleaners understand that your door isn't just furniture; it's critical safety equipment that must perform flawlessly every single day.

The bottom line? When in doubt, stick with products specifically approved for medical-grade stainless steel. Your door will thank you with years of reliable service.

Conclusion: Protecting Your Investment and Upholding Standards

Your mortuary cold room door stands as a silent guardian at the heart of your operation. It's not just a piece of equipment – it's the protector of dignity, the enforcer of compliance, and the foundation of operational efficiency. Every time that door closes, it carries the weight of your professional commitment and the trust families place in your care.

Throughout this guide, we've walked through the essential 3-step process that transforms reactive scrambling into proactive confidence. When you understand why mortuary cold room doors service maintenance is non-negotiable, implement a systematic maintenance schedule, and partner with qualified professionals, you're not just maintaining equipment – you're safeguarding your entire operation.

The numbers don't lie. Proactive maintenance saves money and prevents catastrophic failures. That funeral home in New York we mentioned? They're now saving thousands annually simply by following a structured approach. Meanwhile, facilities that ignore maintenance warning signs face the harsh reality of emergency repairs, regulatory violations, and compromised operations.

Think about it this way: a few minutes of daily attention, weekly cleaning routines, and monthly inspections can prevent the nightmare scenario of a complete system failure during your busiest period. The alternative – scrambling for emergency service while temperatures spike and compliance hangs in the balance – is a risk no professional should take.

At Walk-In Cooler Authority, we understand the unique pressures you face. Our commitment to providing reliable, OSHA-compliant equipment stems from decades of serving professionals who demand excellence. We've seen how proper maintenance transforms not just equipment performance, but entire facility operations.

Your investment in quality mortuary refrigeration deserves protection. Your commitment to families deserves the reliability that only proper maintenance can provide. And your peace of mind? That comes from knowing you've done everything right.

Ready to dive deeper into optimizing your entire facility? Explore our complete guide to mortuary tools and best practices and find how attention to detail in every aspect of your operation creates the professional excellence your community depends on.