Why Professional Embalming Equipment Selection Matters

Finding the right embalming equipment for sale requires understanding your operational needs and regulatory requirements. Here's what you need to know:

Key Equipment Categories:

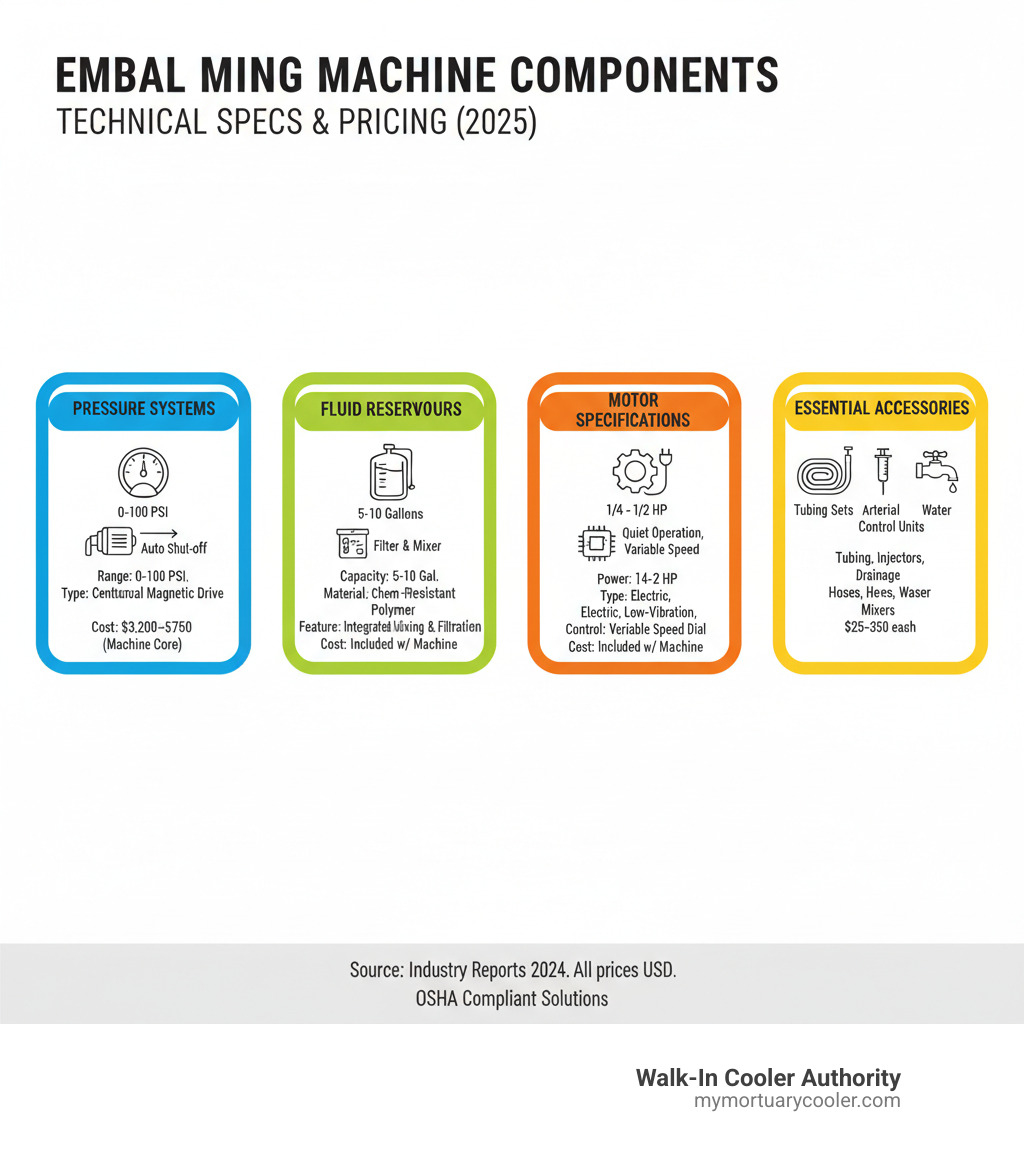

- Embalming machines - Core injection systems ($3,200-$5,750)

- Aspirators and drainage tools - Hydro and electric options ($40-$300)

- Accessories - Tubing, injectors, water control units ($25-$350 each)

- Specialized instruments - Trocars, scalpels, cavity injectors ($20-$200)

The global embalming equipment market reached $1.1 billion in 2022 and is growing at 4.8% annually, driven by technological advances and demand for compliant equipment. North America leads this market due to its established funeral service infrastructure.

Modern embalming equipment has evolved beyond basic injection systems. Today's machines feature magnetic drive pumps, automatic shut-off systems, and pressure ranges up to 100 PSI to handle diverse needs. Understanding these specifications is crucial when upgrading or outfitting a new facility.

The challenge is finding OSHA-compliant, durable solutions that balance initial investment with long-term operational costs. Recent supply chain disruptions have extended lead times for some manufacturers, making reliable sourcing more critical than ever.

Core Embalming Machines: Types and Technologies

When shopping for embalming equipment for sale, the embalming machine is your workhorse. These machines inject embalming fluid into the vascular system, but not all machines work the same way.

Modern embalming machines rely on centrifugal pumps, which use spinning motion to create pressure. This is a significant improvement over older gravity-fed systems, offering much greater control.

The pressure capabilities of these machines fall into two main categories. High-pressure systems can reach 60 to 100 PSI, making them ideal for challenging cases with significant vascular resistance. Low-pressure systems max out around 15 to 30 PSI and work well for cases with less resistance or when a gentler approach is needed.

Many advanced machines now include pulsating features that mimic a heartbeat's natural rhythm. This feature helps overcome vascular resistance, promotes better fluid distribution, and can reduce swelling for a more natural final appearance.

Another key technology is the magnetic drive pump. These pumps are quiet, efficient, and reliable, often featuring solid-state lining pulsators for high-speed fluid injection with consistent performance.

When choosing between portable and stationary units, consider your space and workflow. Portable machines are compact and mobile, ideal for limited prep room space or transport. Despite their size, many portable units offer impressive pressure ranges and motor power.

Stationary units are the heavy-duty champions for high-volume operations. These larger machines integrate into your prep room design and offer robust performance for facilities handling numerous cases daily.

Automation innovations continue to improve these machines. Features like automatic shut-off protect against over-injection, while digital controls allow for precise adjustments and real-time monitoring, making the process more controlled and efficient.

Key Features to Compare

When shopping for embalming equipment for sale, understanding the technical specs is crucial as they directly impact how well the machine will serve your facility's needs.

Pressure range (PSI) indicates the maximum force the machine can generate, with ranges from 60 PSI up to 100 PSI. A wider range offers more versatility.

Flow rate (gallons per minute) shows how quickly fluid is injected. Most quality machines deliver around 1 GPM, ensuring efficient timing and even distribution.

Motor power (horsepower) determines the machine's strength. Motors typically range from 1/6 HP to 1/4 HP, with more powerful motors offering more reliable performance.

Fluid capacity refers to the reservoir size, usually 2.5 to 3.5 gallons. Larger capacity means fewer interruptions for refills.

Cabinet construction is important for durability. Look for stainless steel construction that resists corrosion and is easy to clean.

Fluid reservoir material is another key detail. Borosilicate glass tanks are the standard because they are chemically resistant, durable, and allow for easy monitoring of fluid levels.

International and Electrical Considerations

Electrical specifications are critical when considering embalming equipment for sale. Getting this wrong can damage expensive equipment or create safety hazards.

Standard voltage in North America is 110-120 volts at 60 hertz. Most machines for the domestic market use this standard.

International voltage options are typically 220V/50Hz. Many manufacturers offer machines configured for these standards, but you must specify this requirement when ordering.

Power cord and plug types vary by country. Ensure the machine comes with the correct plug for your region, or have a qualified electrician make the necessary modifications.

Getting these electrical details right prevents costly delays and safety risks. For more guidance on selecting the right tools, check out our A Practical Guide to Embalming Tools: Find or Buy the Right Set.

Essential Accessories and Complementary Equipment

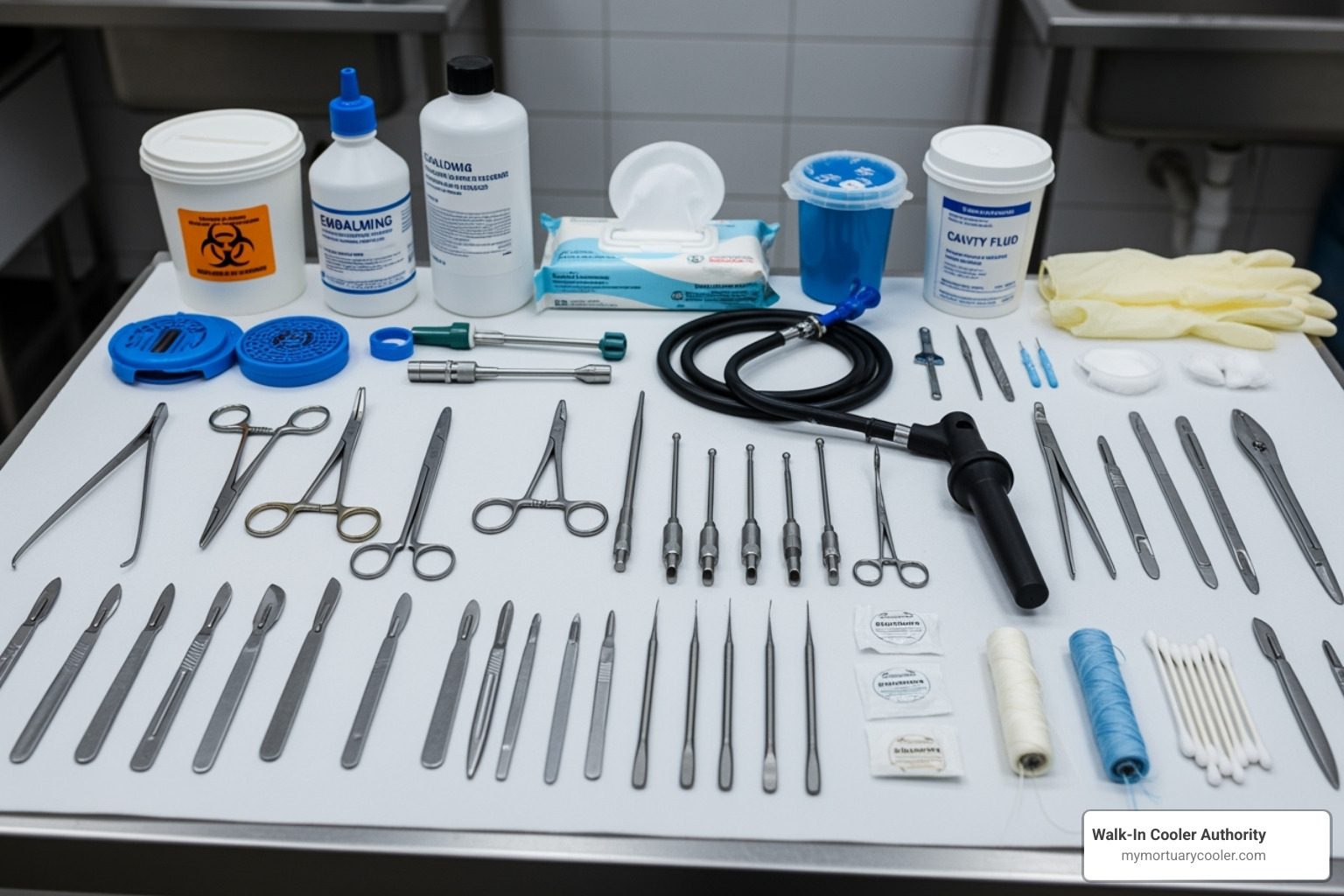

While the embalming machine is the engine of the prep room, essential accessories and complementary equipment are what allow for precision and care. When evaluating embalming equipment for sale, look beyond the main machine to ensure a complete, functional setup.

Like a professional kitchen, a prep room needs more than just the main appliance. From aspirators to specialized tubing, each piece plays a vital role in creating a seamless workflow. The beauty of modern embalming equipment for sale is how these accessories integrate into a complete system. For professionals looking to understand the full scope of what's available, our Mortuary Equipment: The Complete Authority Guide offers comprehensive insights.

Aspirators and Drainage Tools

Effective drainage is critical to successful embalming, making aspirators and drainage tools essential. These tools remove fluids and gases from body cavities, preparing them for preservation.

Hydro-aspirators are the workhorses of most prep rooms. They connect to a water source and use the Venturi effect to create powerful, non-electric suction. They are crafted from durable materials like chrome-plated brass or Delrin plastic and often feature backflow preventers. Sight view attachments can be added to monitor the aspiration process.

Electric aspirators provide a steady, powerful vacuum and are ideal for facilities where water pressure is unreliable.

Nasal aspirators are smaller, specialized tools for clearing fluids from nasal passages, available in infant and adult sizes.

After aspiration, trocar buttons are used to cleanly seal puncture sites. Meanwhile, specialized drain tubes facilitate efficient blood removal during arterial injection, ensuring proper circulation of your embalming solution.

The foundation supporting all this equipment matters, which is why we recommend Investing in Excellence: Why a High-Quality Embalming Table Matters for your prep room.

Injection and Fluid Handling Tools

These precision instruments ensure every drop of fluid reaches its intended destination, which is the key to exceptional results.

Arterial tubes are your direct connection to the vascular system. They come in various configurations—slip hub, curved, and different sizes—to accommodate all vessels and ensure optimal fluid distribution without trauma.

Cavity fluid injectors handle the concentrated chemicals that preserve internal organs. Modern injectors deliver precise application, while traditional models provide reliable operation for high-volume facilities.

Hypo-valves provide instant flow control for hypodermic syringes or cavity injectors, allowing you to regulate fluid flow with precision.

Specialized hoses and tubing options connect the system. Standard rubber and clear plastic tubing handle general fluid conveyance, while shorter splash tubing is useful for close-quarters work. Longer aspirator tubing provides freedom of movement around the table.

Quick connect assemblies allow for secure attachment and detachment with minimal effort. For high-pressure applications, specialized hoses combine durability with immediate flow control through an integrated stopcock valve.

When you're ready to source these supplies, The Ultimate Guide to Finding Mortuary Supplies Online can help you steer the procurement process.

Navigating the Market: Where to Find Embalming Equipment for Sale

Finding quality embalming equipment for sale is easier when you know where to look and what each supplier type offers. The right supplier can make all the difference, whether you're setting up a new prep room or upgrading old equipment.

The mortuary supply market has evolved into a diverse marketplace. Today, options include specialized mortuary suppliers, online platforms offering convenience and competitive pricing, and direct-from-manufacturer purchasing for better support and pricing.

Specialized mortuary suppliers are the backbone of the industry, carrying comprehensive inventories and employing knowledgeable staff. They often provide value-added services like training and technical support.

Online retailers and marketplaces have opened up new avenues for finding embalming equipment for sale. While caution is needed regarding condition and seller reputation, these platforms can be a source for specific models or competitive pricing on new and used items.

Direct-from-manufacturer purchasing has become more attractive, especially with recent supply chain challenges. This approach can cut out middleman markups and may offer better access to technical information and shorter lead times. For example, some manufacturers have recently shipped in 8-10 weeks while others faced 20+ week delays.

Your choice of supplier will depend on urgency, budget, and the level of support you need.

Key Considerations for Finding Embalming Equipment for Sale

Shopping for embalming equipment for sale involves more than comparing prices. The decision between new and used equipment requires careful consideration of factors that will impact your long-term operation.

New versus used equipment is a trade-off between upfront cost and long-term value. New equipment includes a manufacturer's warranty (typically two years), the latest technology, and full support, but at a higher initial cost and with potential lead times.

Used equipment offers significant savings and immediate availability. However, it comes with existing wear and tear, potentially outdated technology, and usually no warranty.

Warranty and support are crucial. A comprehensive warranty protects against defects and provides access to manufacturer support and parts. With used equipment, you are often on your own for repairs, and parts for older models can be hard to find.

Lead times and availability are now critical factors. Always confirm current lead times before purchasing, as they can vary significantly between manufacturers.

Shipping costs can be substantial. A machine's price can increase significantly once freight is included. Some suppliers offer free shipping, while others charge based on actual costs.

For those considering used equipment, our guide on Buying Used Embalming Tables Without Getting Stiffed offers valuable insights.

Budgeting for Embalming Equipment for Sale

Budgeting for embalming equipment for sale requires understanding the total cost of ownership, not just the initial purchase price. A smart budget includes accessories and long-term maintenance.

Embalming machines are the largest investment, ranging from $3,200 for entry-level portable units to $5,750+ for high-end stationary models. Price reflects features like pressure range, motor power, and build quality.

Essential accessories add up but are necessary. Aspirators can range from $40 to nearly $300, while water control units can cost around $3,200. Smaller items like tubing and injectors are also essential.

The entry-level versus high-end decision depends on volume and usage. Entry-level machines suit smaller operations, while high-end models justify their price through superior performance and durability in high-volume settings.

Long-term value considerations favor quality equipment. Reliable machines have lower maintenance costs, longer lifespans, and consistent performance. Downtime from equipment failure is costly. Consider the total cost of ownership over 5-10 years, not just the purchase price.

Direct purchasing often provides better value. For strategies on reducing costs, check out Affordable Funeral Supplies: Direct from the Manufacturer.

Maintenance, Durability, and Safety

Properly maintaining your embalming equipment is the foundation of a safe, reliable operation. When you invest in quality embalming equipment for sale, maintenance protects that investment and ensures team safety.

Stainless steel construction is crucial for longevity. It withstands harsh chemicals and constant cleaning, resists corrosion, and is easy to maintain. This durability is why it's used for everything from machine cabinets to fluid reservoirs.

Daily cleaning should be routine. After each use, flush the fluid tank thoroughly and run clean water through all hoses to prevent chemical buildup, which can clog systems and create hazards. Modern machines often include features like magnetic and mix/clean port filters to simplify this process.

Use tank cleaners designed for embalming equipment to remove stubborn residues that regular flushing might miss, keeping your fluid reservoir clear and sterile.

Regularly perform a hose inspection. Look for cracks, kinks, or wear during routine checks and replace damaged hoses immediately to prevent leaks and safety issues.

Formalin scavenging systems are vital for protecting your team. These systems minimize formaldehyde exposure, which is crucial for compliance with OSHA's Formaldehyde standard. Your health and safety are paramount.

Operational Best Practices

Smart operation extends your equipment's life and improves results.

Always follow manufacturer guidelines. They are your roadmap to optimal performance and care, and following them keeps your warranty valid.

Proper fluid mixing is essential for good results. Use tools like arterial solution calculator apps to ensure you get the right chemical proportions every time.

Understanding your machine's pressure and flow settings is key. Too much pressure can cause tissue damage, while too little can mean inadequate fluid distribution. Adjust settings based on each case's unique condition.

Chemical safety protocols protect everyone. This means wearing proper PPE (gloves, masks, eye protection), ensuring adequate ventilation, and having clear procedures for spills. These practices are essential for OSHA compliance.

By integrating these practices into your daily routine, you build a foundation for consistent, professional results. For more insights on durable equipment, our guide A Practical Guide to Comparing Stainless Steel Embalming Tables offers valuable perspectives.

Frequently Asked Questions about Embalming Equipment

Here are answers to common questions about embalming equipment for sale, based on our industry experience.

What routine maintenance does an embalming machine require?

Consistent maintenance is key to your embalming machine's longevity. Key tasks include:

- Regular cleaning of the fluid tank after every use. Drain the tank, rinse it with clean water, and use a proper tank cleaner to eliminate chemical residue.

- Flushing hoses after each use with clean water to prevent crystallization and blockages.

- Inspecting gaskets and connections for cracks, wear, or leaks.

- Checking motor function by listening for unusual noises, which may require attention from a technician.

What is the purpose of a pulsator on an embalming machine?

A pulsator feature makes a significant difference by simulating heart action, creating a natural, rhythmic flow instead of a constant stream. Its main benefits are:

- Helping overcome vascular resistance: The pulsating action can work through constrictions or blockages more effectively than steady pressure.

- Better fluid distribution: Intermittent surges help the solution reach smaller capillaries and remote tissues for more thorough preservation.

- Reduces swelling: By encouraging more natural fluid movement, pulsation can lead to fewer tissue distension issues and a more natural appearance.

Are there eco-friendly considerations for embalming equipment?

Yes, eco-friendly considerations are increasingly important when choosing embalming equipment for sale. Key aspects include:

- Compatibility with formaldehyde-free fluids: Modern machines are often designed to work with greener embalming solutions, giving you more options.

- Energy-efficient motors: Newer machines typically draw less power, reducing your facility's carbon footprint and operating costs.

- Durable construction for longevity: Investing in quality equipment made from materials like stainless steel reduces replacement frequency and minimizes waste.

- Proper waste disposal systems: While separate from the machine, systems like formalin scavengers are crucial for minimizing chemical release into the environment and protecting staff.

Conclusion

Selecting the right embalming equipment for sale is a critical decision for your facility. This guide has covered everything from the technical specifications of machines to essential accessories. The goal is to find reliable equipment that will serve you for years.

The global embalming equipment market reached $1.1 billion in 2022 and is growing, leading to innovations in magnetic drive pumps, automated safety features, and pressure control systems. These tools help you provide better care while protecting your team.

Whether you're considering a portable machine with a wide PSI range or investing in a full stationary system, quality equipment directly impacts operational efficiency, service quality, and team safety. The initial investment pays for itself through durability, warranty coverage, and reliable performance.

At Walk-In Cooler Authority, we understand what mortuary professionals need. We are your partners in creating prep rooms that meet OSHA compliance standards while delivering dependable performance. By working directly with us, you skip the middleman markup and get professional-grade equipment at prices that make sense for your budget.

The prep room is where compassionate care meets technical precision. Having the right tools ensures you can focus on providing dignified, professional services to families. We're here to help you make that happen with equipment you can trust.

Ready to take the next step? Explore our complete guide to essential embalming tools and find how the right equipment makes all the difference.