The Hidden Danger in Your Cooling System

If you're dealing with an evaporator freeze up, here's what you need to know immediately:

| Quick Fixes for Evaporator Freeze Up |

|---|

| 1. Turn off your AC/refrigeration system immediately |

| 2. Switch fan to "ON" position to help thaw the coil |

| 3. Replace dirty air filters (responsible for 80% of freeze-ups) |

| 4. Ensure all vents and returns are unblocked and open |

| 5. Once thawed, check for proper operation or call a technician |

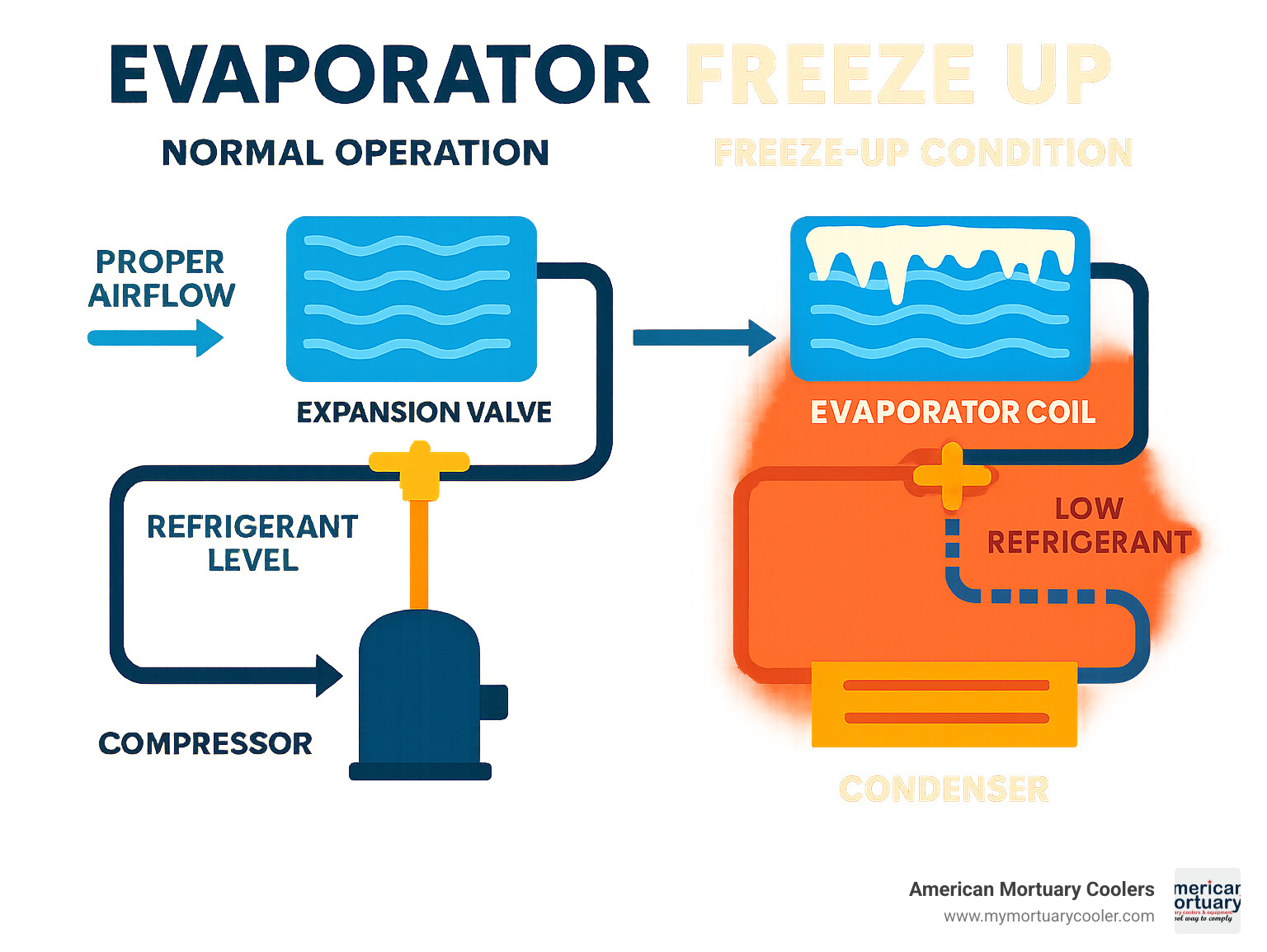

Evaporator freeze up occurs when ice forms on your cooling system's evaporator coil, blocking heat transfer and preventing proper operation. This seemingly minor issue can quickly damage your compressor—one of the most expensive components to replace at $2,500-$3,000.

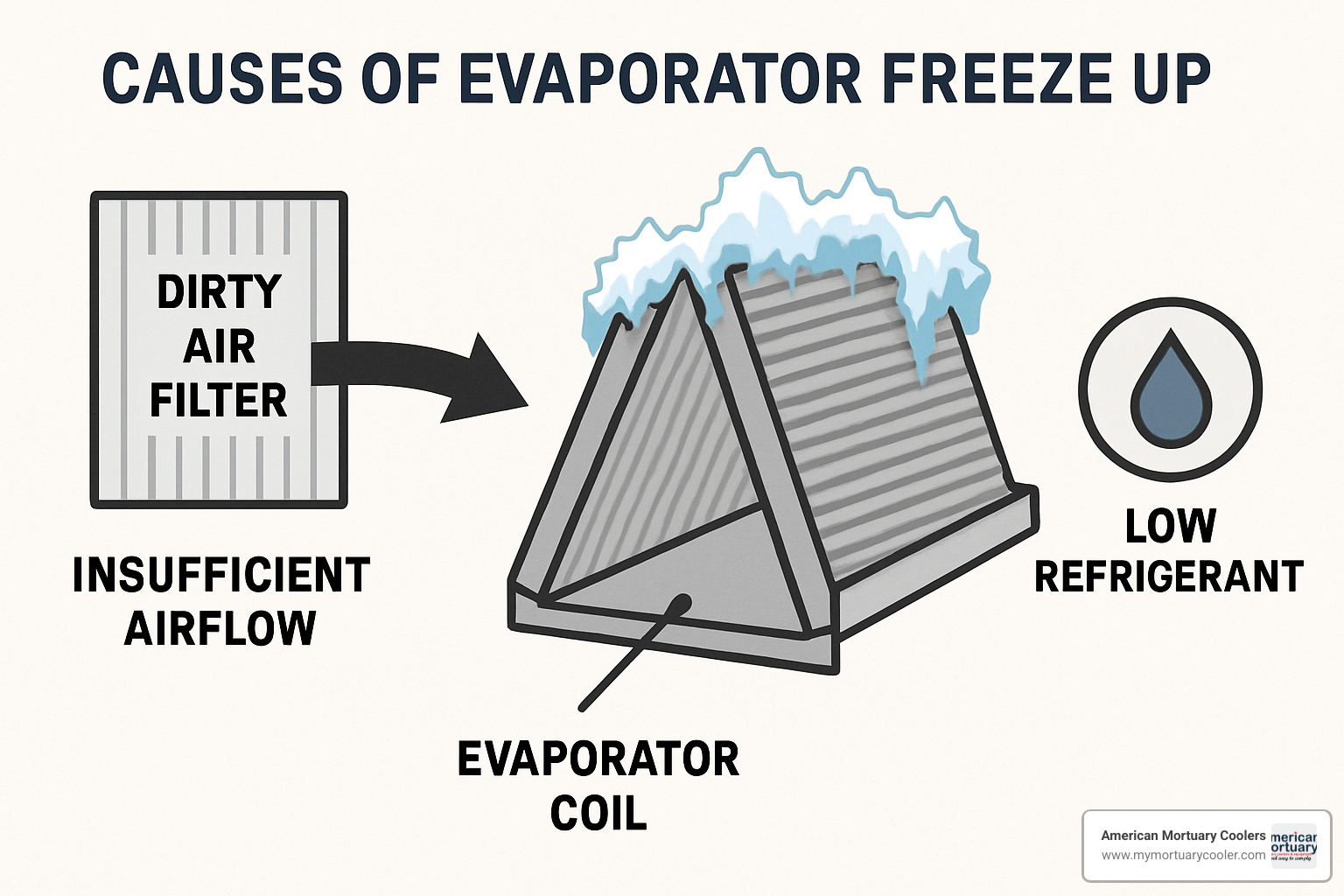

The frustrating reality is that most freeze-ups are preventable. Dirty air filters alone cause up to 80% of residential freeze-up cases, with low refrigerant levels accounting for another 15-20%. More than half of summer AC emergency calls relate to frozen evaporator coils.

When an evaporator coil freezes, your system can't properly cool your space. In residential settings, this means uncomfortable temperatures. In commercial refrigeration or mortuary coolers, it can mean spoiled inventory or compromised remains.

I'm Mortuary Cooler, a national-level supplier specializing in cooling systems with extensive experience diagnosing and resolving evaporator freeze up issues in critical cold storage applications.

Evaporator freeze up terms to learn:

Why This Guide Matters

When your cooling system experiences an evaporator freeze up, the consequences extend beyond discomfort. In residential settings, you'll notice warm air blowing from vents despite your system running constantly. For businesses relying on refrigeration, the stakes are much higher.

In mortuary settings, where we at American Mortuary Coolers specialize, temperature stability is non-negotiable. A frozen evaporator can lead to temperature fluctuations that compromise the dignified preservation of remains.

The financial impact is concerning too. Emergency service calls for frozen evaporators often exceed $300, even before repairs begin. If the compressor fails due to prolonged operation with a frozen coil, replacement costs typically range from $2,500 to $3,000.

According to industry data, regular maintenance can prevent up to 90% of evaporator freeze-up incidents. This guide will help you understand, diagnose, fix, and prevent this common yet serious problem.

What Is an Evaporator Coil and Why Does It Freeze?

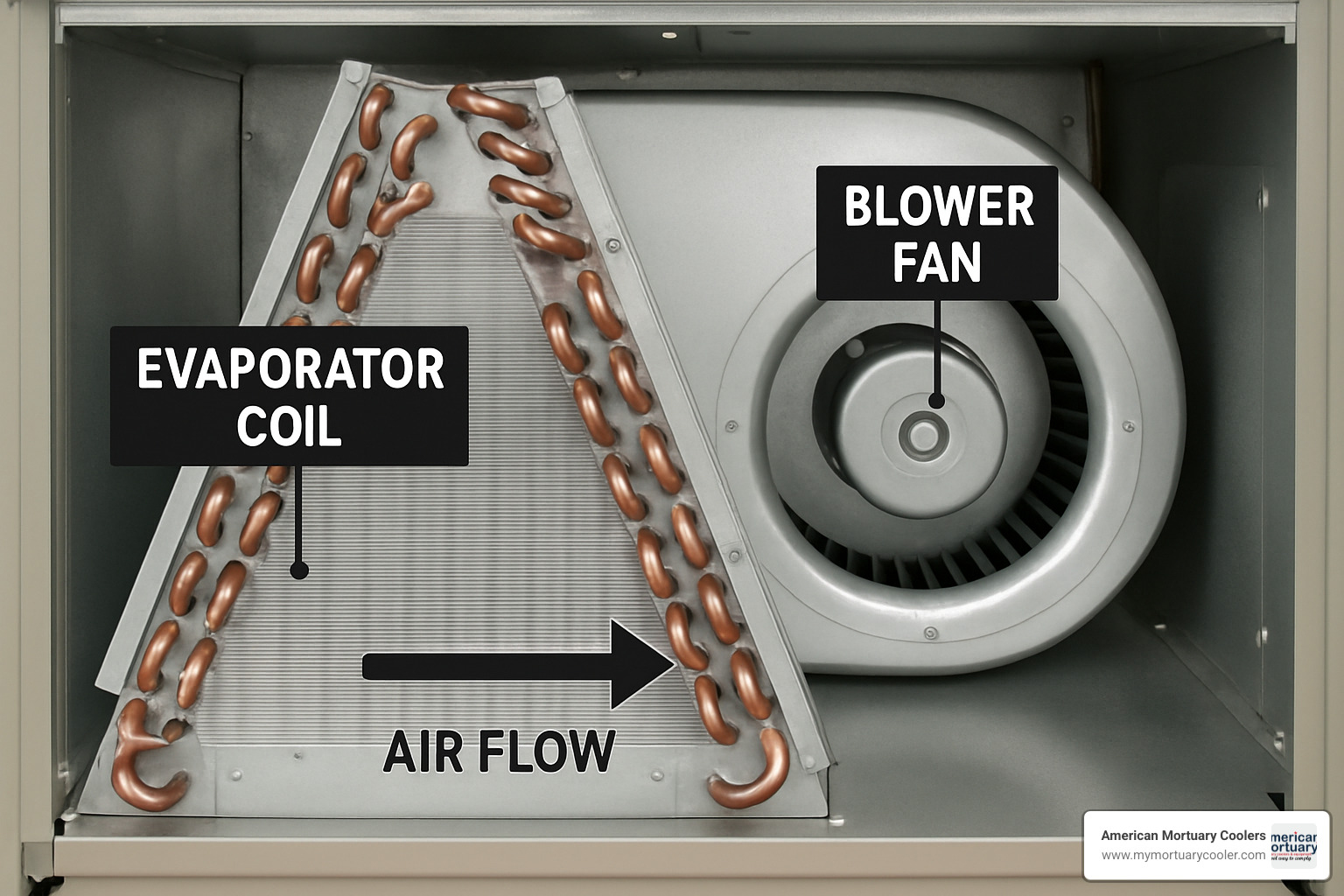

Meet the unsung hero of your cooling system—the evaporator coil. This critical component consists of copper or aluminum tubes surrounded by metal fins that work together to make cooling possible. Whether tucked inside your home's air handler or within a commercial refrigeration unit, this is where the real magic of cooling happens.

When everything's working properly, liquid refrigerant flows through these coils and absorbs heat from the surrounding air. As this happens, the refrigerant transforms from liquid to gas (that's why we call it an "evaporator"), cooling the air that passes over it before circulating throughout your space.

In normal operation, your evaporator coil maintains a temperature of around 40°F—perfectly balanced to cool your space without freezing up. As air passes over these coils, it typically drops 15-20°F in temperature.

But when this delicate balance gets disrupted, the coil temperature can plummet below 32°F—the freezing point. When this happens, moisture in the air freezes on contact with the coil surface, creating what we call an evaporator freeze up.

The Science Behind "Evaporator Freeze Up"

To understand why your evaporator freezes, we need to explore some basic refrigeration science.

Your refrigerant has a special relationship between pressure and temperature. In a well-designed system, the evaporator operates at a pressure that keeps the refrigerant at about 40°F—warm enough to prevent freezing but cold enough to cool effectively.

When an evaporator freeze up begins, it follows a predictable pattern:

First, something goes wrong that causes the evaporator temperature to drop below freezing. As this happens, moisture in the air condenses on the cold coil surface. But because the coil is below freezing, these droplets quickly turn to ice.

A thin layer of ice might actually improve heat transfer initially. But as ice continues to build up, it acts like a blanket, insulating the coil and reducing heat transfer. This makes the coil even colder, causing more ice to form in a vicious cycle. Before long, your coil becomes completely encased in ice, blocking airflow entirely.

According to scientific research on insufficient airflow, maintaining proper airflow across your coil is absolutely critical. When airflow decreases (often due to dirty filters or blocked vents), less heat reaches the refrigerant, causing its temperature to drop below freezing.

While a small amount of frost is normal in some refrigeration applications like freezers, any ice formation on your air conditioning evaporator is a clear signal that something needs attention—and fast.

Top Causes of Evaporator Freeze Up & How to Diagnose Them

When your cooling system develops an evaporator freeze up, you're always looking at the same symptom – ice coating your evaporator coil. But figuring out why it's happening requires some investigation.

Different cooling systems tend to freeze up for different reasons:

| System Type | Primary Freeze-Up Triggers | Secondary Causes | Unique Considerations |

|---|---|---|---|

| Residential AC | Dirty air filters (80%) | Low refrigerant (15-20%) | Closed vents, thermostat issues |

| Commercial Refrigeration | Defrost system failure | High humidity infiltration | Door seals, traffic patterns |

| Mortuary Coolers | Airflow restrictions | Refrigerant issues | Critical temperature stability |

| Walk-In Coolers | Door seal failure | Defrost timer malfunction | Staff training on door usage |

| Automotive AC | Expansion valve issues | Blower motor failure | Intermittent usage patterns |

Let's examine each major cause.

Airflow Restrictions: Filters, Fans & Ducts

Dirty Air Filters are the biggest offender – responsible for about 80% of residential freeze-ups. When dust and debris clog your filter, they prevent air from flowing freely across your evaporator coil. Less airflow means less heat transfer, and your coil temperature drops below freezing.

High-MERV Filters (rated 9-13) might be great for air quality, but they can be too restrictive for some systems. Sometimes switching to a less restrictive filter solves the problem.

A failing Blower Motor can also be the culprit. Test by setting your system to "fan only" mode. If airflow feels weak or you hear strange noises, your blower motor might be failing.

Collapsed or Blocked Ducts restrict airflow just like a dirty filter. Check for crushed flexible ducts or obstructions.

Blocked Return Vents are often overlooked. Keep at least 2 feet of clearance around all return vents – your system needs that air!

Low Refrigerant & Line Restrictions

Refrigerant Leaks create a domino effect. As refrigerant levels drop, so does the pressure in your evaporator, causing temperatures to fall below freezing. Look for oily residue around refrigerant lines or listen for hissing sounds.

Restricted Liquid Lines can be trickier to spot. Blockages in the refrigerant path create pressure drops that lead to freezing.

TXV Issues are another potential cause. The Thermostatic Expansion Valve regulates refrigerant flow, and if it's stuck or improperly adjusted, you're likely to see an evaporator freeze up.

Electrical & Control Failures

A Faulty Thermostat might cause your system to run continuously, never giving the coil a chance to warm up. If your system never cycles off or turns on and off rapidly, your thermostat could be the problem.

In refrigeration systems, Defrost Timer Failure is particularly problematic. These systems need scheduled defrost cycles, and when the timer fails, ice accumulates unchecked.

Fan Delay Switch Problems might seem minor, but they serve an important purpose. This switch ensures the fan runs long enough to clear condensation from the coil after the compressor stops.

For those managing walk-in coolers specifically, our guide on how to do walk-in cooler repair offers more detailed troubleshooting steps.

Step-by-Step Guide to Fixing and Thawing a Frozen Coil

When you find an evaporator freeze up, don't panic! Your immediate goal is to safely thaw that icy coil without causing additional damage to your system.

Immediate Actions for Homeowners or Operators

First, turn your cooling system OFF completely. This step is critical. Running your system while the evaporator is frozen can seriously damage your compressor.

Next, switch your thermostat to the fan-only mode. This circulates room-temperature air over the frozen coil, gently accelerating the thawing process. Make sure all your supply and return vents are fully open and unobstructed.

If you spot a dirty filter, replace it immediately. Dirty filters are often the culprits behind freeze-ups in the first place.

Prepare for meltwater by placing towels or a bucket beneath areas where leakage might occur to prevent water damage.

Never chip or scrape ice off your evaporator coil. Those coil fins are incredibly delicate, and the refrigerant tubes can be easily punctured.

DIY Cleaning & Restart Checklist

Once your coil has completely thawed (which might take 1-24 hours depending on severity), it's time for basic maintenance.

Inspect the evaporator coil if accessible. Look for dirt buildup, which can restrict airflow. If you can safely access the coil, give it a gentle cleaning. Turn off all power, spray with a commercial coil cleaner or mild detergent solution, let it work for about 15 minutes, then gently rinse with warm water. Allow the coil to dry completely before restarting.

Check your condensate drain line. A clogged drain can cause water to back up and refreeze on the coil. Use a wet/dry vacuum to suction out any blockage or flush with a mixture of bleach and water (1:10 ratio).

With a clean coil and new filter installed, your system should now have proper airflow. When you restart, the supply air should be 15-20°F cooler than the return air, the system should cycle normally, and you shouldn't hear unusual noises.

When to Call a Professional HVAC Technician

Call a technician if:

- The ice returns shortly after thawing and restarting

- You suspect refrigerant problems (hissing sounds or oil stains)

- Your system short-cycles or struggles to maintain temperature

- You notice electrical problems like tripping breakers

- Your blower motor is failing or making unusual noises

- You're working with critical systems like mortuary coolers

According to scientific research on professional maintenance, regular professional service prevents up to 90% of evaporator freeze up incidents. This is particularly important for commercial and mortuary refrigeration systems where temperature stability is absolutely critical.

Preventive Maintenance to Stop Evaporator Freeze Up Forever

The best way to handle evaporator freeze up is to prevent it from happening in the first place. A good maintenance routine isn't just about avoiding problems—it's about peace of mind.

Monthly DIY Tasks

A few simple monthly checks can save you thousands in repairs:

Perform a quick visual ice check of accessible parts. Even small frost patches are warning signs.

Replace filters every 30-90 days, depending on your environment. During high-pollen seasons or in dusty areas, change them more frequently.

Maintain proper vent clearance. Make sure furniture hasn't migrated in front of vents and keep at least 75% of your registers open.

For commercial settings, monitor humidity levels. Higher humidity means more condensation on coils, increasing freeze-up risk.

Check your drain pan monthly. A clogged drain line can cause water to back up and refreeze on the coil.

For walk-in coolers and mortuary refrigeration, inspect door seals for damage and review proper door usage with staff.

Seasonal & Professional Milestones

Beyond monthly routines, schedule these professional maintenance tasks:

Spring professional tune-up before cooling season hits. This should include thorough cleaning of evaporator and condenser coils, refrigerant level checks, electrical component testing, and defrost system verification.

For year-round systems like mortuary coolers, add a fall system check to prepare for winter operation.

Professional coil cleaning at least annually removes dirt and debris that restrict airflow and heat transfer.

Every 2-3 years, have a professional perform airflow balancing to ensure proper distribution throughout your space.

For walk-in coolers and mortuary units, conduct periodic insulation audits. Degraded insulation allows moisture infiltration, creating conditions perfect for freeze-ups.

Consider installing vinyl strip curtains in commercial refrigeration and mortuary coolers to reduce warm air infiltration.

Work with your technician to optimize defrost schedules based on your specific usage patterns.

Consider upgrading to smart controls that can detect early signs of freeze-up and adjust operation automatically.

For more specific information on preventing ice buildup in commercial refrigeration, check out our guide on how to fix an iced evaporator.

Frequently Asked Questions About Evaporator Freeze Up

Why does low refrigerant cause evaporator freeze up?

This is confusing - you'd think less refrigerant would make your system less cold, not more likely to freeze!

The answer lies in the pressure-temperature relationship of refrigerants. When refrigerant leaks, the pressure inside the evaporator drops significantly. This lower pressure forces the remaining refrigerant to evaporate at a much lower temperature—often well below freezing. As this super-cold refrigerant circulates through your coil, moisture in the passing air freezes on contact.

A system low on refrigerant also struggles to reach the set temperature, causing it to run longer cycles. This extended runtime gives ice more opportunity to build up on the coil.

Can I keep the system running while the coil is frozen?

Absolutely not! Running your system with a frozen evaporator coil is one of the most expensive mistakes you can make.

You risk serious compressor damage. When your evaporator coil is frozen, liquid refrigerant may return to your compressor instead of fully evaporating first. Since compressors are designed to compress gas—not liquid—this "liquid slugging" can cause catastrophic mechanical failure.

Your energy bills will skyrocket because a frozen coil cannot transfer heat effectively. Your system will run continuously without achieving the desired temperature.

Continued operation actually makes the freeze-up worse, creating a vicious cycle. The only safe approach is turning off the cooling operation immediately and using only the fan to help thaw the coil gradually.

How long should a full thaw take before restart?

Thawing times vary based on several factors:

Severity of ice buildup: Light frost might disappear in 1-2 hours, while solid ice completely encasing the coil might need 24 hours.

Room temperature: Warmer ambient temperatures speed up thawing.

Airflow: Using your system's fan (never in cooling mode) circulates warmer air across the frozen surfaces.

Coil accessibility: Open, easily accessible coils thaw faster than those enclosed in tight compartments.

For typical home AC systems, most moderate freeze-ups will thaw within 3-8 hours using the fan-only method. Commercial refrigeration and mortuary coolers often take longer due to their larger coil size.

Important: Make absolutely sure the coil is completely thawed before restarting your system. Partial thawing often leads to immediate refreezing.

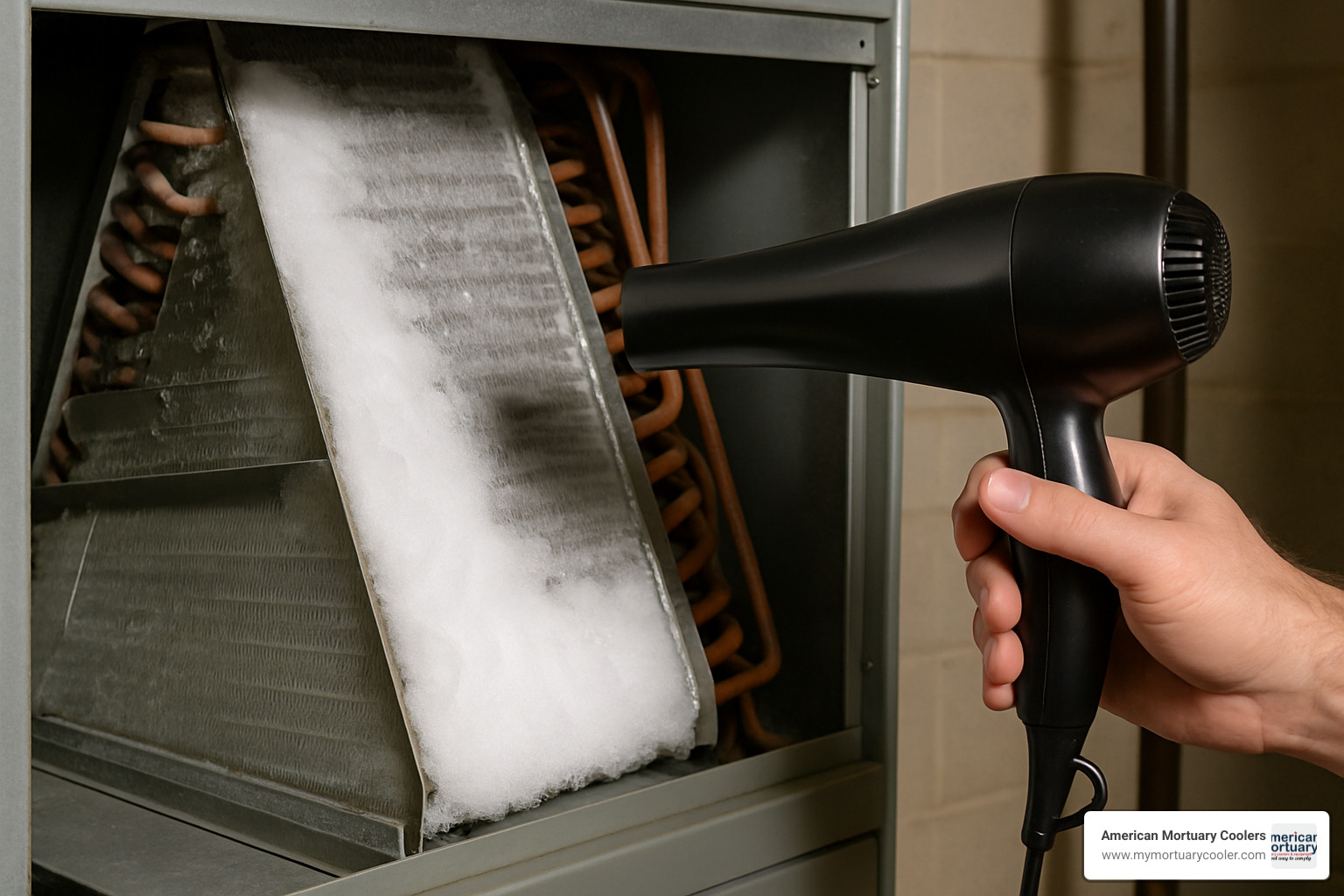

If you need to speed up the process safely, you can use a hairdryer on a low heat setting, keeping it at least six inches from the coil. Never use sharp objects to chip away ice—this can puncture refrigerant lines.

Conclusion

When it comes to evaporator freeze up, knowledge truly is power. At American Mortuary Coolers, we've seen everything from minor frost buildup to completely iced-over evaporators in critical storage facilities. Our experience serving funeral homes nationwide has taught us valuable lessons about preventing and resolving these issues where temperature control is essential.

Remember these critical points:

Act quickly when ice appears. Turn off cooling and switch to fan-only mode immediately to prevent compressor damage.

Fix the real problem, not just the symptom. Most freeze-ups indicate a specific issue with your system—whether it's restricted airflow, refrigerant problems, or control issues.

Accept preventive maintenance. Regular filter changes, seasonal coil cleaning, and professional inspections can eliminate up to 90% of potential freeze-ups.

Know when to call professionals. While many freeze-up causes can be addressed yourself, refrigerant-related problems always require certified technicians.

Consider your system's design. Properly sized cooling systems with adequate airflow naturally resist freeze-ups.

By applying these principles, you'll not only resolve current freeze-up problems but also prevent future occurrences. The reward? Lower energy bills, extended equipment life, and reliable cooling.

For those managing funeral homes or facilities with critical cooling needs, explore our custom-designed solutions that minimize freeze-up risk through thoughtful engineering. Our practical guide to mortuary coolers offers additional insights specific to funeral service applications.

When it comes to cooling system reliability, consistency beats emergency response every time. After all, there's never a "convenient" time for an evaporator freeze up—especially when you're responsible for maintaining dignity in death care.