Why Basket Stretchers Are Mission-Critical for Safe Patient Transport

Basket stretchers are rigid rescue litters designed to safely transport patients over rough terrain, through confined spaces, and during vertical lifts. These specialized stretchers feature a protective shell mounted on a tubular frame with multiple attachment points for ropes and harnesses.

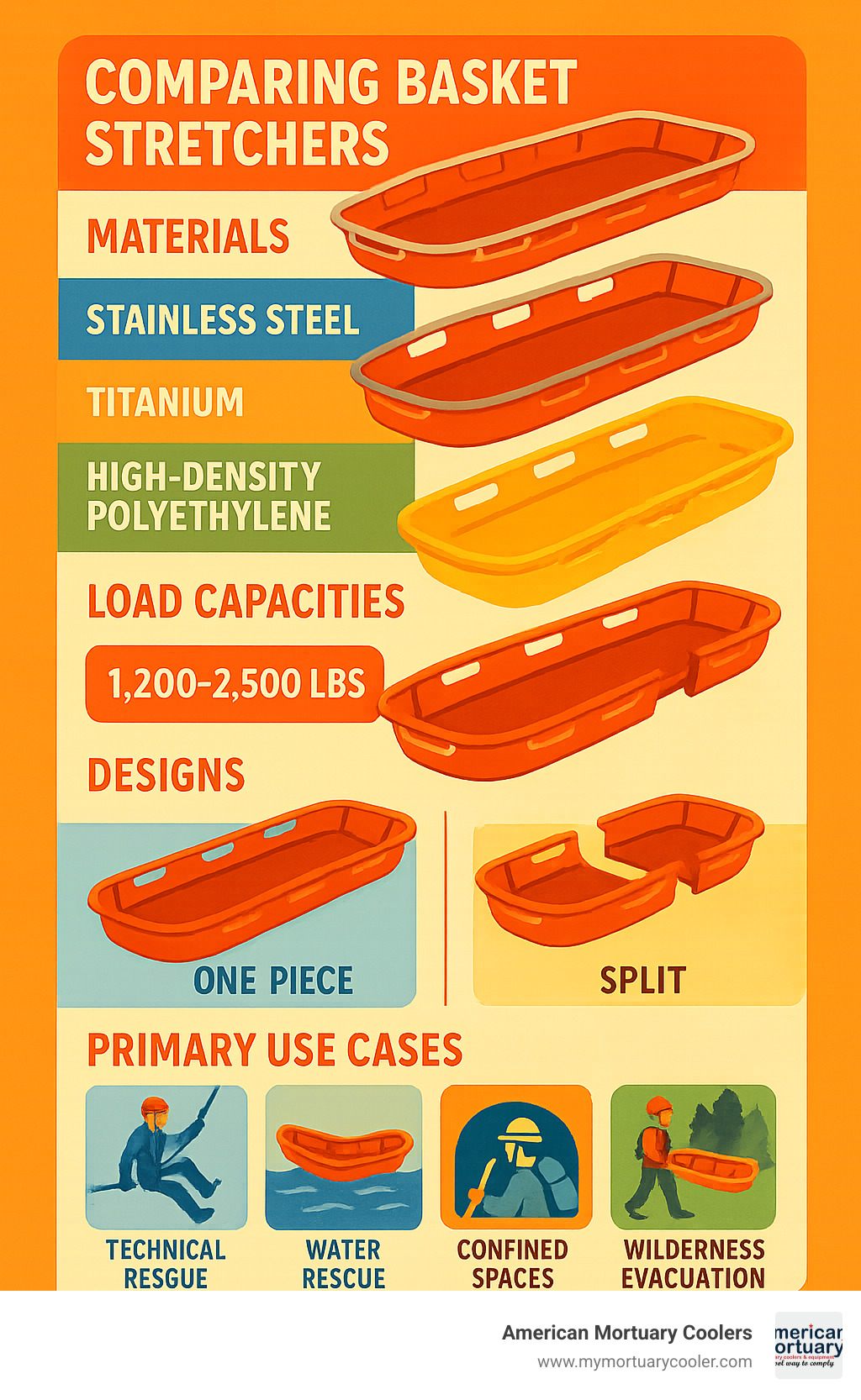

Key Facts About Basket Stretchers:

- Load capacity: 1,200 to 2,500 lbs depending on model

- Weight range: 23 to 45 lbs for portability

- Standard size: 80-85 inches long, 22-24 inches wide

- Materials: Stainless steel, titanium, or high-density polyethylene

- Certifications: NFPA 1983 and MIL-L-37957A compliant models available

- Primary uses: Technical rescue, water rescue, confined spaces, wilderness evacuation

As one fire service training manual notes: "It often has been observed that the most effective and efficient rescue tools are simple in design and have few or no moving parts." This principle perfectly describes why basket stretchers have remained the gold standard for challenging rescue scenarios for decades.

These stretchers excel where conventional gurneys fail - from helicopter hoists to narrow mine shafts. They can be dragged across rocky terrain, floated in water with accessory collars, or rigged for vertical rope rescues. The rigid design protects patients from impact while allowing rescuers to maintain control during transport.

I'm Mortuary Cooler, and as a national-level mortuary cooler supplier, I've worked extensively with emergency services and funeral homes to provide reliable transport equipment including basket stretchers for various challenging environments. My experience has shown that choosing the right basket stretcher can mean the difference between a successful rescue and a dangerous situation.

Basket stretchers vocabulary:

Reader-Benefit Snapshot

This comprehensive guide will help you understand everything about basket stretchers - from basic anatomy to advanced selection criteria. Whether you're a fire chief outfitting a new rescue squad, an EMS director evaluating equipment options, or a search and rescue coordinator planning for wilderness operations, we've organized this information to help you make informed decisions quickly.

We'll cover the technical specifications that matter, compare different materials and designs, explain proper patient securing techniques, and provide maintenance guidelines that extend equipment life. By the end, you'll have the knowledge to select, deploy, and maintain basket stretchers that keep both patients and rescuers safe.

What Is a Basket Stretcher and Why It Matters

When rescue teams need to transport patients through challenging terrain, they turn to what's often called a "Stokes litter" - the original military-style design that gave birth to today's basket stretchers. These aren't your typical hospital gurneys. Instead, they're built like protective cocoons with rigid shells mounted on sturdy tubular rail frames.

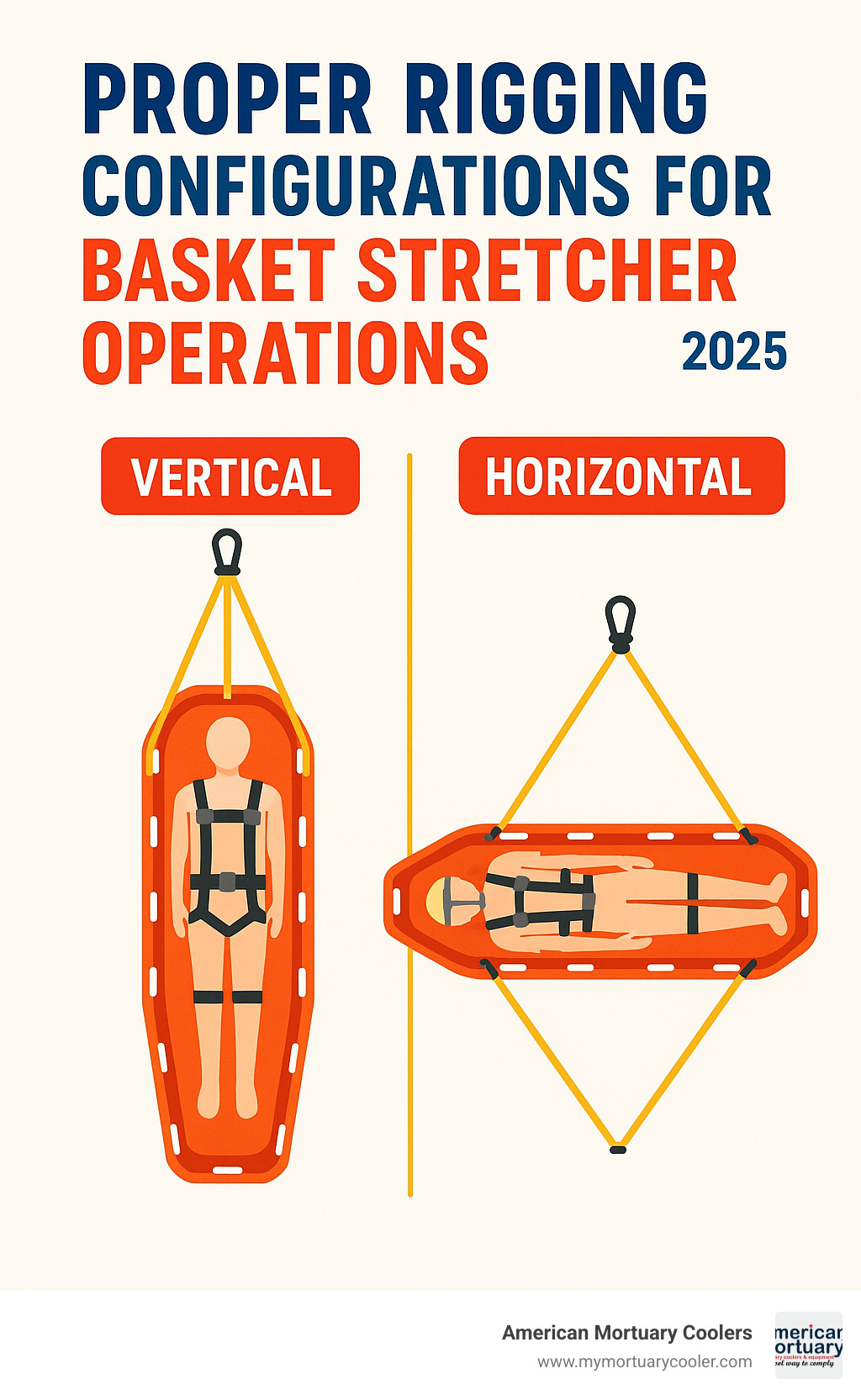

The genius of basket stretchers lies in their ability to handle both vertical and horizontal lifts without compromising patient safety. Whether you're hoisting someone up a cliff face or dragging them across rocky ground, these stretchers maintain their structural integrity. That's why they're built to meet rigorous safety standards like NFPA 1983 and MIL-L-37957A specifications.

What sets basket stretchers apart from flexible stretchers is their rigid platform design. They don't rely on the patient's body for structural support - a crucial advantage when transporting unconscious or injured individuals through unpredictable rescue environments.

Definition & Anatomy of Basket Stretchers

Think of a basket stretcher as having two main parts: the frame and the shell. The frame typically features full-diameter top rails (usually 1 inch thick) that provide comfortable carrying handles for rescue teams. The head and foot sections get extra reinforcement with double tubing - essential when you're doing vertical operations where every connection point matters.

The shell itself varies depending on what you need it for. High-density polyethylene works great for chemical resistance, while stainless steel mesh offers durability and easy cleaning. Each material has its place in different rescue scenarios.

Every quality basket stretcher includes several key components that make the difference between a successful rescue and a dangerous situation. Grommets or attachment points are rated for both vertical and horizontal lifting loads - these aren't just holes in the frame, they're engineered connection points. Backboard compatibility means you can secure spine boards or vacuum mattresses directly to the stretcher.

The patient restraint systems feature quick-release buckles that secure patients without creating mess hazards. Many models accept flotation collar attachments that provide around 45 pounds of buoyancy for water rescues. Adjustable footrests can be positioned where needed or removed entirely when space is tight.

The protective basket design acts like a shield, keeping patients safe from debris, branches, and impacts during transport through confined spaces or rough terrain.

Primary Uses Across Rescue Fields

Basket stretchers have earned their reputation across multiple rescue disciplines because they solve problems that other equipment simply can't handle.

Technical rescue teams depend on these stretchers for high-angle rope rescues, cliff evacuations, and building extractions. When you're lowering someone down a 200-foot cliff face, those rated attachment points and rigid frame construction aren't just nice features - they're lifesavers.

Confined space rescue presents unique challenges where specialized narrow models like the JSA-300-CS shine. At just 19 inches wide while maintaining a 1,500-pound capacity, these stretchers steer industrial sites, mines, and tunnels where standard equipment won't fit.

For water rescue operations, basket stretchers transform into floating platforms when equipped with flotation collars. These collars provide approximately 45 pounds of buoyancy, supporting victims up to 900 pounds in water rescue scenarios.

Wilderness search and rescue teams face the challenge of reaching remote locations on foot. Break-apart models solve this by allowing teams to backpack stretcher halves to the rescue site and reassemble them when needed - a game-changer for long-distance wilderness operations.

Industrial sites with harsh chemical environments benefit from polyethylene shells that resist corrosion and contamination. The rigid construction protects patients during transport through debris fields or unstable structures where flexibility would be a liability rather than an asset.

Comparing Types, Materials, and Specs

When you're choosing a basket stretcher, the material makes a huge difference in how it performs in the field. I've seen teams struggle with the wrong equipment, and it's not pretty when you're trying to save someone's life.

The numbers tell the story clearly: load ratings range from 1,200 to 2,500 pounds, dimensions typically run 80-85 inches long, and weights vary dramatically from 23 to 45 pounds depending on what they're made from. According to scientific research on rescue litter loads, understanding these specifications can be the difference between a successful rescue and equipment failure.

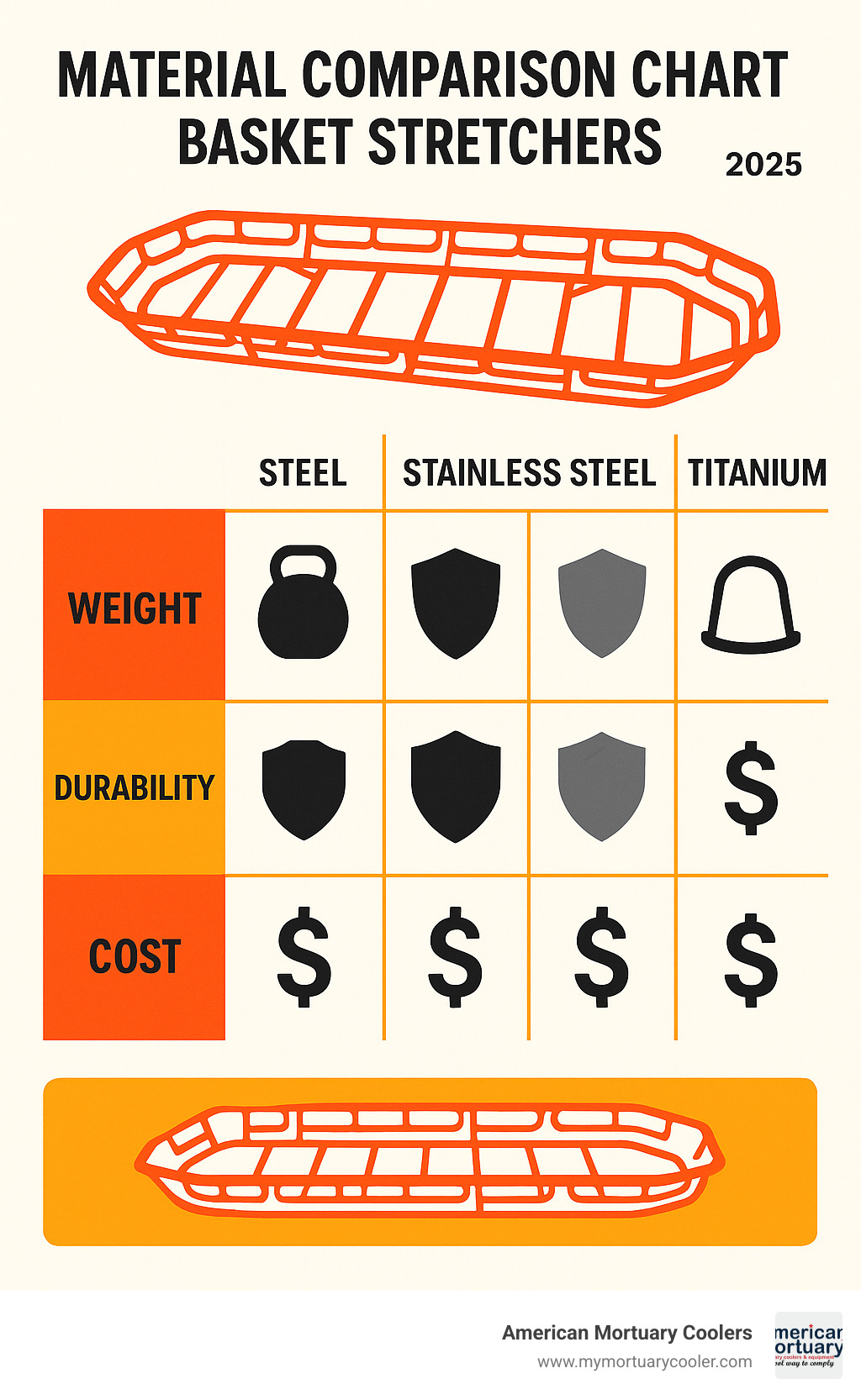

The choice between steel, stainless steel, titanium, and high-density polyethylene isn't just about budget - it's about matching your equipment to your mission. Each material has earned its place in different rescue scenarios, and understanding these differences will help you make the right call.

One-Piece vs. Split Basket Stretchers

One-piece basket stretchers are the reliable workhorses of the rescue world. They're always ready to go, no assembly required, and they offer maximum structural integrity. But here's the catch - they need about 85" x 24" x 8" of storage space, which can be a real challenge in crowded fire stations or rescue vehicles.

Split or break-apart stretchers solve the storage problem beautifully. They pack down to just 44" x 12" x 24", making them perfect for helicopter operations where every inch of cargo space matters. Wilderness rescue teams love them because you can actually backpack the pieces to remote locations.

The trade-off is assembly time at the rescue site. But here's what I've learned from talking with rescue teams: experienced crews can put together a quality split stretcher in under two minutes. That's pretty impressive when you consider the portability advantage you're getting.

Helicopter hoist operations particularly benefit from split designs because they can be pre-positioned in aircraft with limited space. The break-apart feature also makes them ideal for urban rescue units working out of cramped apparatus bays.

Material Choices & Load Capacities

Titanium stretchers are the sports cars of the rescue world - ultra-light at around 32 pounds but with a premium price tag. They offer the best strength-to-weight ratio, making them valuable for helicopter operations and those long wilderness carries where every pound matters.

Stainless steel is the reliable workhorse that most teams depend on. Models like the Titan SS series can handle 2,500-pound loads while weighing about 28 pounds. These basket stretchers exceed US Military MIL-L-37957A specifications and maintain NFPA 1983 certification, giving you confidence in demanding situations.

High-density polyethylene brings some unique advantages to the table. It's naturally chemical-resistant and buoyant, making it perfect for marine environments. The JSA-200 series shows what's possible - 1,200-pound capacity at just 31 pounds, all at a lower cost than metal alternatives.

For bariatric capacity needs, most standard models handle patients up to 1,500 pounds safely. The premium stainless steel and titanium versions can go up to 2,500 pounds, which covers even the most challenging rescue scenarios.

Stainless steel durability really shines in harsh environments where equipment takes a beating. Plastic corrosion-proof qualities make polyethylene models ideal for coastal operations or industrial sites with chemical exposure. The key is matching the material to your specific operating environment and budget constraints.

Essential Features, Accessories, and Patient Securing Techniques

Modern basket stretchers come equipped with thoughtful features that can make the difference between a smooth rescue and a dangerous situation. These aren't just add-ons - they're carefully engineered systems that work together to keep patients secure and give rescuers the control they need in challenging environments.

The attachment points on quality stretchers tell a story about their intended use. StratLoad™ points and reinforced grommets aren't randomly placed - they're positioned based on decades of real-world rescue experience. These connection points need to handle everything from gentle helicopter hoists to emergency drags across rocky terrain.

Flotation collars deserve special mention here. These aren't just life preservers strapped to a stretcher - they're engineered to provide 45 pounds of buoyancy while maintaining the stretcher's balance in water. When you're dealing with a water rescue, that collar transforms your basket stretcher into a stable platform that can support patients safely until you reach shore.

Step-by-Step Patient Tie-In

Getting the patient securing right is where many teams stumble, but it doesn't have to be complicated. The webbing lacing technique has been proven in thousands of rescues because it distributes pressure evenly and gives you multiple points of contact.

Start with your 35-foot length of tubular webbing - this isn't arbitrary, it's exactly what you need for a complete lacing pattern. Find the center point and create a girth hitch around the foot end of the stretcher. This becomes your anchor point for everything that follows.

Work your way up the stretcher using a criss-cross pattern that weaves through the frame rails. Think of it like lacing a giant boot - each crossing point adds security while spreading the load. The key is maintaining consistent tension without creating pressure points that could harm the patient during a long transport.

Blanket padding isn't optional - it's essential. Wrap the patient's arms close to their body before they go into the basket, then add padding at every contact point. A patient who arrives at the hospital with pressure injuries from the rescue hasn't really been rescued successfully.

The quick-release buckles on commercial restraint systems offer speed, but experienced teams often supplement them with additional webbing for vertical operations. It's about having options when conditions change unexpectedly.

Accessory Checklist

Bridle slings are your connection to helicopter operations. These distribute lifting forces across multiple attachment points, preventing the dangerous load concentration that can damage both stretcher and aircraft. Different stretcher models require specific bridle configurations, so compatibility matters more than you might think.

Drag wheels create interesting trade-offs. They'll save your back when moving patients across parking lots or improved trails, but they can create a jarring ride on rough terrain. Some teams prefer drag-style runners that maintain better ground contact and smoother patient experience.

Protective covers do more than shield patients from weather - they maintain dignity and privacy during what's often the worst day of someone's life. The clear window panels let you monitor patient condition without constant cover removal.

At American Mortuary Coolers, we understand that rescue equipment needs to work flawlessly when lives are on the line. While our specialty is mortuary equipment, we've seen how the same attention to durability and reliability applies across all emergency transport equipment. The accessories you choose should integrate seamlessly with your primary stretcher and support your team's specific operational needs.

How to Select, Train, and Maintain

Choosing the right basket stretcher isn't just about finding the cheapest option or the fanciest model. It's about understanding your team's real-world needs and matching them with equipment that'll perform when lives are on the line.

I've worked with rescue teams from Tennessee to California, and I've seen what happens when organizations rush into purchases without proper planning. The fire department that bought lightweight stretchers only to find they couldn't handle their typical patient loads. The search and rescue team that saved money on basic models, then spent twice as much retrofitting them with necessary accessories.

The smart approach starts with honest assessment. What rescue scenarios do you actually face? A urban fire department needs different capabilities than a wilderness search team. The basket stretcher that works perfectly for technical rope rescues might be overkill for basic patient transport.

Selection Checklist for Organizations

Your operational environment tells the whole story. If you're primarily doing technical rescues with vertical lifts, you need NFPA 1983 certification and robust attachment points. Water rescue teams can't skip flotation compatibility. Confined space operations demand narrow-profile models that still maintain adequate load capacity.

Patient demographics matter more than most teams realize. The 1,200-pound capacity plastic stretcher seems adequate until you encounter your first bariatric patient emergency. Most versatile operations benefit from stretchers rated at least 1,500 pounds, providing safety margin for equipment weight plus patient loads.

Storage and transport constraints shape your options significantly. One-piece stretchers offer maximum strength but require 85 inches of storage length. Split models pack into 44-inch spaces but add assembly time at rescue sites. Helicopter operations often demand split designs regardless of storage convenience.

Standards compliance isn't optional for professional operations. Look for MIL-L-37957A compliance for military-grade durability and proper certifications for your specific rescue disciplines. These standards exist because field experience proved their necessity.

Budget planning should include the complete system cost. That $589 basic plastic stretcher becomes $1,200 once you add necessary bridles, flotation, and protective covers. Premium titanium models cost more upfront but deliver superior performance-to-weight ratios that justify the investment for specialized operations.

Training Best Practices

Hands-on practice builds the muscle memory that prevents dangerous mistakes during actual rescues. Your team needs to practice the complete sequence from patient assessment through final transport positioning. This isn't about checking training boxes – it's about developing smooth, confident operations under pressure.

Rope systems integration deserves special attention because improvised rigging kills people. Practice with your actual rope rescue systems, mechanical advantage configurations, and anchor setups. Understand how tag lines affect stretcher control and patient comfort during vertical operations.

Patient care considerations often get overlooked during training, but they're critical for successful outcomes. Teams need to practice maintaining IV access, airway management, and patient monitoring while the victim is secured in the basket. The most perfect rescue fails if you can't provide adequate medical care during transport.

Refresher training every quarter keeps skills sharp. Annual recertification ensures your procedures match current manufacturer recommendations and safety updates. Equipment evolves, techniques improve, and your training should keep pace.

Maintenance & Inspection Schedule

Pre-use inspection should become second nature for every team member. Check welds and joints for stress cracks. Inspect attachment points for wear or deformation. Verify that restraint straps and buckles operate smoothly. Ensure frame alignment and shell integrity before every deployment.

Post-use cleaning protects your investment and maintains readiness. Clean metal frames with mild soap and water, but avoid painting polyethylene shells since paint can actually damage the material. Document any damage or unusual wear patterns for trend analysis.

Monthly detailed inspections with proper documentation create the paper trail that supports warranty claims and helps predict replacement schedules. Annual load testing, where required by your organization's policies, ensures continued safe operation after months of regular use.

Professional inspection after any high-load incident isn't optional. The stretcher that handled a difficult rescue successfully might have sustained damage that compromises future safety. Better to find problems during controlled inspection than during the next emergency.

Record keeping seems tedious until you need those records for warranty claims or incident analysis. Detailed logs of inspections, repairs, and usage patterns help you understand equipment lifecycle and plan replacements before failures occur.

At American Mortuary Coolers, we understand that reliable equipment saves lives. Whether you're outfitting a new rescue squad or upgrading existing capabilities, the right basket stretcher selection, training, and maintenance program ensures your team stays ready for whatever emergencies come next.

Frequently Asked Questions about Basket Stretchers

What standards certify a rescue-grade basket stretcher?

The primary standards are NFPA 1983 (National Fire Protection Association Standard on Life Safety Rope and Equipment) and MIL-L-37957A (US Military specification for strength). NFPA 1983 certification ensures the stretcher meets fire service requirements for technical rescue operations. Models exceeding MIL-L-37957A demonstrate military-grade durability. Additionally, UL classification and CE marking indicate compliance with safety and quality standards.

How do I rig a basket stretcher for a helicopter hoist?

Use an adjustable lifting bridle that distributes forces across multiple attachment points. The bridle should be rigged to maintain patient stability during lifting and transport. Always use tag lines to control basket rotation and prevent contact with the aircraft. Ensure the pilot and crew are familiar with your specific stretcher and bridle configuration. Practice ground-based drills before attempting actual hoist operations.

Can one basket stretcher fit bariatric patients safely?

Yes, many modern basket stretchers accommodate bariatric patients. The Titan series handles up to 2,500 lbs, while standard models typically support 1,500 lbs. However, consider the total system load including patient weight, medical equipment, and rescuer safety factors. Extra-wide models like the Titan 32 provide additional patient space while maintaining structural integrity. Always verify your specific model's capacity and ensure your rigging systems match the stretcher's capabilities.

Conclusion

When rescue calls come in, basket stretchers are the equipment that stands between life and death in challenging environments. These aren't just pieces of gear - they're lifelines that have evolved over decades to handle everything from narrow mine shafts to helicopter hoists over churning seas.

The difference between a successful rescue and a tragedy often comes down to having the right equipment for the job. A titanium stretcher might save precious seconds during a helicopter evacuation, while a chemical-resistant polyethylene model could be the only safe choice in an industrial accident. The key is understanding your mission before you need to execute it.

Smart purchasing means looking beyond the price tag. That $589 basic model might seem appealing until you're facing a 300-pound patient in a vertical rescue scenario. Meanwhile, investing in a $2,599 titanium split-apart stretcher could pay for itself the first time your team needs to backpack equipment three miles into wilderness terrain.

Training isn't optional - it's insurance. The most expensive basket stretcher becomes worthless if your team can't deploy it properly under pressure. Regular drills with patient tie-in techniques and rope system integration build the muscle memory that saves lives when seconds count.

Maintenance schedules might seem tedious, but they're what keep equipment reliable for decades. A cracked weld finded during routine inspection is far better than one finded mid-rescue. Simple cleaning protocols and documented inspections protect both your investment and the lives depending on it.

At American Mortuary Coolers, we understand mission-critical equipment from a different angle. While we focus on custom mortuary coolers and funeral industry transport solutions, we've seen how proper equipment selection and maintenance makes the difference between success and failure. Our experience delivering durable, custom solutions across Tennessee and the contiguous 48 states has taught us that quality equipment, properly maintained, serves faithfully for years.

The rescue community deserves equipment that performs when everything else goes wrong. Whether you're outfitting a new technical rescue team or upgrading aging equipment, basket stretchers are investments in the lives you'll save tomorrow.

For deeper insights into specialized transport equipment, explore our guides on mortuary stretcher selection and Junkin Stokes basket features. Emergency equipment suppliers like Life-Assist EMS offer hands-on demonstrations that help teams make informed decisions.

For the engineering science behind rescue equipment standards, Carimus research publications provide the technical foundation that makes modern rescue operations possible. When lives hang in the balance, understanding both the equipment and the science behind it makes all the difference.