Why Hand Crank Lifts Are Essential for Heavy Lifting Tasks

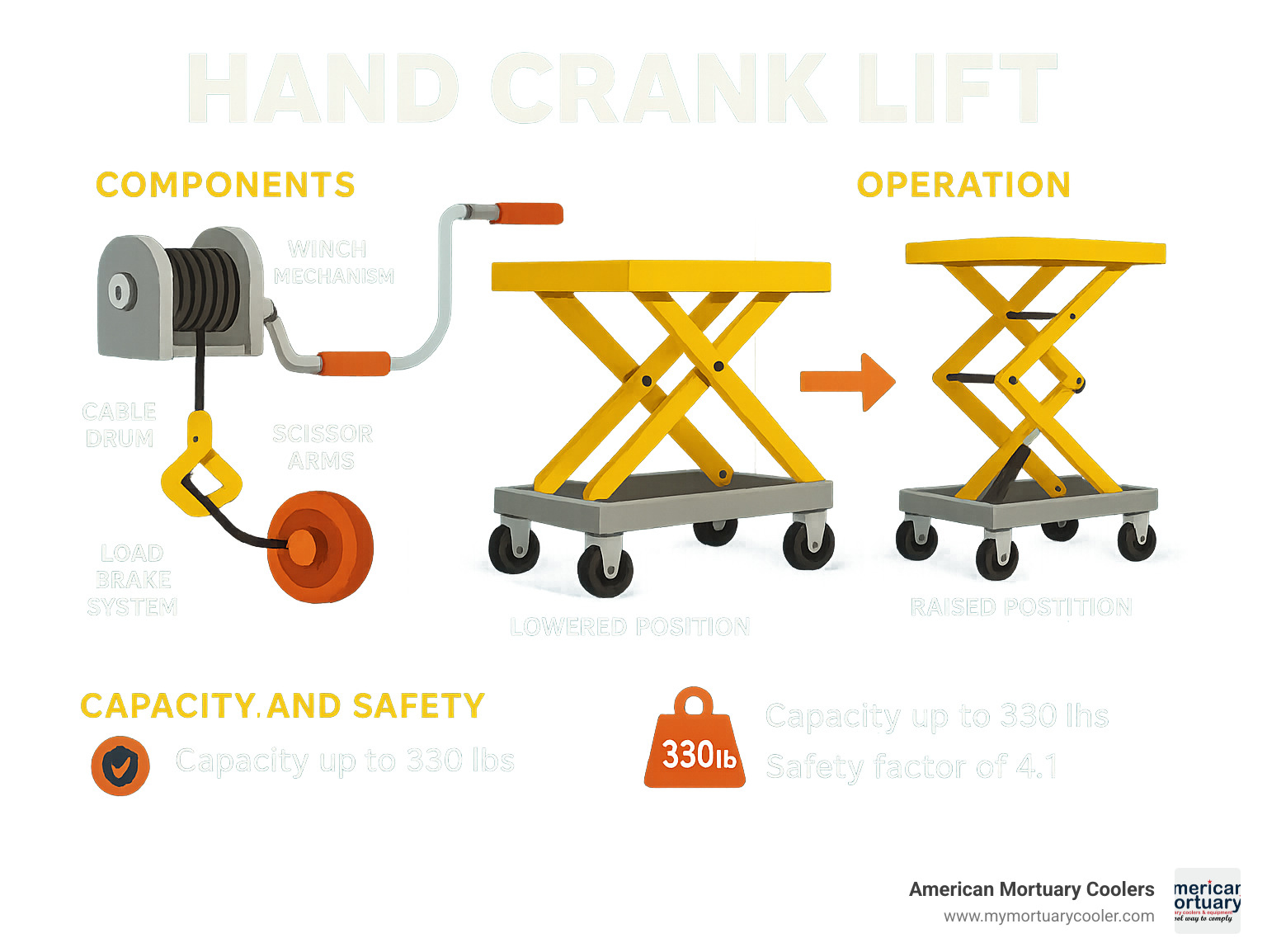

A hand crank lift is a manual lifting device that uses a hand-operated winch mechanism to raise and lower heavy loads without requiring electricity, batteries, or compressed air. These versatile tools are essential for funeral homes, warehouses, construction sites, and any workplace where reliable lifting power is needed in locations without power sources.

Key Hand Crank Lift Types:

- Scissor lift carts - 330-1,000 lb capacity for material handling

- Lift trucks - Fork-style lifts for pallets and equipment

- Cadaver lifts - Specialized mortuary equipment with telescoping masts

- Material lifts - Tower-style lifts reaching up to 20 feet

- Receiver-mounted lifts - Vehicle-mounted for roadside applications

Typical Specifications:

- Load capacities: 330 lbs to 7,500 lbs

- Lift heights: 6 inches to 20 feet

- Crank force: Never exceeds 15 kg (33 lbs)

- Safety factor: 4:1 per EN 13157 standards

The main advantages over electric lifts include zero operating costs, no maintenance of batteries or motors, and reliable operation in any weather. Hand crank lifts work anywhere - outdoors, in clean rooms, or during power outages.

As Mortuary Cooler, I've helped funeral home directors nationwide select reliable lifting equipment for their facilities, including hand crank lifts for body handling and equipment positioning. My experience with mortuary operations has shown that manual lifts provide the dependable, budget-friendly solution that funeral professionals need.

Hand crank lift vocabulary: - bioseal body bags - lysol quaternary disinfectant cleaner - scalpel blades

Understanding the Hand Crank Lift Basics

When you're looking at a hand crank lift, you're seeing decades of mechanical engineering distilled into one reliable tool. These lifts work on surprisingly simple principles - but don't let that fool you into thinking they're not powerful.

The heart of every quality hand crank lift is its worm gear system. This clever design gives you incredible mechanical advantage, meaning you can lift massive loads with surprisingly little effort. The engineering ensures that crank force never exceeds 15 kg (about 33 pounds), yet you can lift loads up to 7,500 kg. That's over 16,000 pounds lifted by hand!

The secret is in the gear reduction and load brake system. Every properly built hand crank lift includes an automatic load-pressure brake that kicks in the moment you let go of the handle. This isn't just convenient - it's a safety requirement under EN 13157 standards, which mandate a 4:1 safety factor.

Winch speed varies between manufacturers, but most lifts operate between 0.4 and 3 meters per minute. The controlled speed becomes a real advantage when handling delicate equipment or working in tight spaces.

Lift height and cable capacity depend on your specific model. Some systems can store up to 70 meters of cable for lighter loads, while heavy-duty applications typically manage around 24 meters.

How a hand crank lift works

The beauty of a hand crank lift lies in its straightforward operation. When you turn the crank, you're rotating an input shaft connected to that worm gear system. This dramatically reduces the force you need while multiplying your lifting power.

As you crank, the cable drum winds up steel cable - typically giving you about one inch of lift per complete handle rotation. It's predictable and gives you excellent control over positioning.

For scissor-arm designs, the cable connects to expanding scissor mechanisms that push upward as the cable shortens. Telescoping mast models extend or retract vertical sections for precise height control.

The automatic brake system is where safety really shines. Stop cranking, and a load-pressure brake immediately locks everything in place. To lower, you simply turn the crank counterclockwise while the brake allows controlled descent.

Main types of hand crank lifts

The hand crank lift family includes six main types, each designed for specific jobs:

Material lifts are the tall, tower-style units you'll see on construction sites. These can reach up to 20 feet high and typically handle 500-pound loads.

Lift trucks combine the mobility of a hand truck with lifting capability. Models like the Vestil A-LIFT feature fork inversion and foot brakes - perfect for moving and positioning pallets or equipment.

Scissor carts use platform designs supported by expanding scissor arms. Capacities range from 330 pounds for lighter work up to 1,000 pounds for heavy-duty applications. Some even come in clean room options for sterile environments.

Cadaver lifts serve the funeral industry specifically. These feature telescoping masts, reversible forks, and typically handle 1,000-pound loads. These specialized lifts make a huge difference in daily funeral home operations.

Receiver-mounted lifts attach to vehicle hitches for roadside work. They're perfect for lifting heavy manhole covers or equipment with precise positioning capability.

Wheelchair lifts help load wheelchairs into vehicles without back strain. These lightweight systems install quickly without vehicle modifications.

Advantages over electric & pneumatic options

Here's where hand crank lifts really shine compared to their powered cousins. First: no battery means no charging, no power failures, and no electrical maintenance. Once you buy it, your operating costs are zero.

Low maintenance is another huge advantage. There are no motors to service, no hydraulic fluids to leak, and no complex electrical systems to troubleshoot.

Safety in hazardous environments sets manual lifts apart too. They're inherently explosion-safe because they generate no sparks or electrical hazards. If you're working around flammable materials, this isn't just convenient - it's required.

Being outdoor-ready in any weather gives you flexibility that electric lifts can't match. Rain, snow, extreme temperatures - your manual lift keeps working when powered equipment might fail.

For funeral homes, warehouses, or any operation where reliability matters more than speed, these advantages make hand crank lifts the smart choice.

Top 7 Hand Crank Lifts You Can Buy Right Now

After years of helping funeral homes select reliable equipment, I've seen which hand crank lifts deliver real value in demanding work environments. Whether you're moving heavy caskets, positioning equipment, or handling materials, these seven models represent the best options available today across different budgets and applications.

Material & Duct Lifter — classic hand crank lift

The classic Genie-style tower lift has earned its reputation as the rental industry favorite for good reason. These workhorses handle 500-pound loads up to 20 feet high, making them perfect for HVAC installations, electrical work, and construction tasks where you need both height and stability.

What sets these lifts apart is their stable base with outriggers and telescoping mast design. The work platform includes guardrails for safety, and the hand crank winch system provides smooth, precise height control. Unlike scissor lifts that only move straight up, these material lifts offer a stable work platform where operators can work comfortably for extended periods with their tools and materials within reach.

The mechanical advantage of the worm gear system means you're not fighting against the load - even at maximum capacity, the cranking effort remains manageable throughout the entire lift range.

Vestil A-LIFT Hand Crank Lift Truck

The Vestil A-LIFT series takes the humble hand truck and transforms it into something special. With 400-pound counterbalance capacity and unique fork inversion capability, these units bridge the gap between mobility and lifting power beautifully.

The foot brake connected to the rear wheel axle provides essential safety during operation - something many competitors overlook. When fully lifted, the raised forks extend 3 inches above the frame, and the telescoping frame reaches up to 68 inches. The A-LIFT-EHP-LAD model stretches even higher with a top step height of 66.5 inches.

Here's where it gets clever: the fork inversion feature lets you flip the forks to change your lifting profile entirely. Need different height ranges for various tasks? Just invert the forks. This flexibility makes these lifts incredibly versatile for everything from warehouse operations to office furniture moving.

Manual Scissor Lift Cart

Manual scissor carts are the workhorses of material handling - and for good reason. With capacities spanning 330 to 1,000 pounds and platform sizes reaching 25×39 inches, these lifts handle the majority of heavy lifting tasks in warehouses, manufacturing facilities, and distribution centers.

The scissor mechanism provides excellent stability under load while maintaining a compact footprint when lowered. Clean room options with partial stainless steel construction make these suitable for food processing and pharmaceutical environments where hygiene matters.

High-quality casters ensure smooth movement across different floor surfaces, while the hand crank system allows precise height adjustment. This means workers can position loads at the perfect ergonomic height for loading and unloading - saving backs and reducing workplace injuries.

JD710 Hand Crank Cadaver Lift

The JD710 represents mortuary-specific engineering at its finest. With a 1,000-pound capacity and reversible forks, this lift handles the demanding requirements of funeral home operations where reliability isn't just important - it's essential.

The telescoping mast provides precise positioning from 6 inches minimum to 125 inches maximum with forks reversed (103 inches standard). The heavy-duty steel frame with aluminum housing includes four 5-inch swivel casters with brakes and removable handles for compact storage.

The single-speed winch includes an idler roller that feeds cable evenly onto the drum - a small detail that prevents costly cable damage over time. Optional JD717 fork extensions are available, though they reduce capacity to 200 pounds. The leg-lock mechanism makes storage and transport simple.

For funeral professionals seeking comprehensive guidance on body handling equipment, More info about body lift options provides detailed comparisons and selection criteria.

PowerArm™ Receiver-Mounted Manual Crank Lift

The PowerArm™ tackles a very specific problem: safely lifting 400-pound manhole covers without breaking your back or risking injury. This receiver-mounted system transforms any pickup truck into a mobile lifting platform with an 8-inch, 180-degree swing radius.

The operation is straightforward - drive within one foot of the manhole center, adjust the arm to position the magnet, lock onto the cover, and crank the winch to lift. The swing capability lets you move the cover away from the opening without repositioning your vehicle.

At just 30 pounds total weight with dimensions of 20.5" height, 30.88" length, and 9" width, this system stores easily when not in use. The hitch-mount design requires no permanent vehicle modifications, making it perfect for utility crews and maintenance teams.

Wheels Up Wheelchair Hand Crank Lift

The wheelchair lift market has been dominated by expensive, complex powered systems requiring tow hitches and electrical connections. The Wheels Up system changes this game with a simple hand crank mechanism that installs in minutes without any vehicle modifications.

This lightweight metal frame uses manual cranking to lift and lower wheelchairs, eliminating the back-saving design that manual lifting demands. No tow hitch, no batteries, no electrical connections - just reliable mechanical advantage when you need it.

Made in the USA with a 90-day warranty, this lift offers an economical alternative to traditional powered systems. The simple mechanical design means fewer failure points and lower long-term costs - exactly what families need for reliable wheelchair transport.

DIY Tower & Boat Hoist Solutions

For specialized applications like amateur radio towers or boat lifting, DIY solutions using quality hand winches offer significant cost savings. Harbor Freight winches rated at 12,000 pounds provide 6,000-pound capacity when used with a snatch block for doubled line configuration.

Forum-tested tips from radio operators reveal practical insights: a 1,320-pound capacity lift costs only $110 compared to $1,600 for industrial units. However, proper sizing is critical - a typical 50-foot tower with antenna weighs around 1,600 pounds, requiring adequate safety margin.

Key considerations include limit switch placement, weatherproofing, and backup power options. Many operators install 110V AC units with portable inverters for power outage scenarios. For specialized applications requiring industrial-grade components, McMaster-Carr manual hoists provides reliable solutions with proper engineering documentation.

Choosing & Comparing the Best Hand Crank Lift

Choosing the right hand crank lift doesn't have to be overwhelming. After helping countless funeral home directors select lifting equipment over the years, I've learned that the best approach is to start with your specific needs and work from there.

The decision matrix below shows the key specifications you'll encounter when shopping for a hand crank lift. I've found that most buyers focus too heavily on price and miss the features that really matter for their daily operations.

| Model Type | Capacity | Lift Height | Weight | Price Range | Key Features |

|---|---|---|---|---|---|

| Material Lift | 500 lbs | 20 ft | 200-300 lbs | $2,000-4,000 | Tower design, work platform, outriggers |

| Vestil A-LIFT | 400 lbs | 68" | 396-449 lbs | $1,720-2,069 | Fork inversion, foot brake, counterbalance |

| Scissor Cart | 330-1,000 lbs | 36-48" | 150-250 lbs | $800-2,500 | Platform design, clean room options |

| Cadaver Lift | 1,000 lbs | 125" | 300-400 lbs | $6,000-8,000 | Telescoping mast, reversible forks |

| PowerArm | 400 lbs | N/A | 30 lbs | $3,000-4,000 | Receiver mount, 180° swing |

| Wheelchair Lift | 300 lbs | 24" | 25 lbs | $500-800 | Vehicle loading, no modifications |

What surprises many buyers is how much the rated capacity can change with accessories. Take the JD710 cadaver lift - it handles 1,000 pounds normally, but drop fork extensions on it and you're down to just 200 pounds. That's a detail that can make or break your purchase decision.

The lift height range is another area where people get caught off guard. You need to consider both your minimum clearance for loading and your maximum working height. A material lift that reaches 20 feet sounds impressive until you realize you need to position it 8 feet away from walls due to the outrigger requirements.

Key features checklist for a hand crank lift

The rated Working Load Limit should be your starting point, but don't just match it to your heaviest load. I recommend adding at least 25% safety margin because real-world conditions aren't always perfect. You might need to lift at an angle, or the load might shift during operation.

Frame dimensions matter more than most people realize. The Vestil A-LIFT series adjusts from 21" to 43" straddle width, which sounds great until you find your typical load is 44" wide. Measure your actual loads, not just the specifications on paper.

The brake system is where you absolutely cannot compromise. Automatic load-pressure brakes engage the instant you release the crank handle - no thinking required. Manual brakes depend on you remembering to set them, which isn't ideal when you're focused on positioning a heavy load safely.

Caster quality separates the good lifts from the great ones. Cheap casters will fail when you need them most, usually when you're moving a full load across uneven flooring. Look for swivel casters with brakes on at least two wheels, and consider pneumatic wheels if you'll be working outdoors.

Accessory compatibility can extend your lift's usefulness for years. Deck platforms, ladders, and specialized attachments might seem like nice-to-have features now, but they often become essential as your operations grow.

Safety standards & certifications

When it comes to safety standards, this isn't an area to cut corners. EN 13157 requires that lifts handle four times their rated load before failure - that's your real safety margin right there. Any quality hand crank lift should meet this standard without question.

OSHA 1910.179 covers the inspection and maintenance requirements you'll need to follow in the United States. These aren't suggestions - they're legal requirements that protect both your workers and your business from liability.

ANSI/ASME B30 standards get into the technical details of how lifting equipment should be designed and operated. While you don't need to memorize these standards, any manufacturer worth buying from will prominently display their compliance.

CE marking isn't required in the US, but I've noticed that manufacturers who pursue CE certification often build better equipment overall. It indicates they're thinking about quality and safety from the design stage, not just adding it as an afterthought.

For funeral homes and medical facilities, ATEX certification becomes important if you're working around any chemicals or in areas where explosive atmospheres might develop. It's not common, but it's absolutely critical when you need it.

Safe Operation & Maintenance Tips

Operating a hand crank lift safely isn't complicated, but it does require attention to detail and consistent habits. After years of helping funeral home directors maintain their equipment, I've seen what works - and what doesn't.

Start every day with a quick inspection. Check your cables for fraying or kinks, test that brake function by lifting a light load and releasing the handle, and make sure your crank handle operates smoothly. This takes less than two minutes but prevents most accidents.

Operating your hand crank lift safely & efficiently

Your stance matters more than you might think. Stand with your feet shoulder-width apart and keep your back straight while cranking. Quality lifts ensure the crank force never exceeds 15 kg (about 33 pounds), so if you're straining, something's wrong.

Always use a spotter when lifting loads around people or expensive equipment. Your spotter should watch the load path while you focus on operating the lift.

Slope limits are critical for wheeled lifts. Most scissor carts and lift trucks shouldn't be operated on slopes steeper than 5 degrees when loaded. I've seen lifts tip over on ramps that looked perfectly safe.

Load positioning affects everything. Center your load on the platform and secure it before lifting. An off-center load can turn a routine lift into a dangerous situation.

Routine maintenance schedule

Weekly lubrication keeps your winch mechanism running smoothly. Most systems need standard bearing grease on the drum bearings and light machine oil on the gear teeth. Don't over-lubricate - excess grease attracts dirt.

Monthly fastener checks catch problems before they become dangerous. Walk around your lift and check that all bolts and pins are tight. Examine cables closely for any broken wire strands or unusual wear patterns.

Annual load testing verifies your lift still meets its safety ratings. This involves lifting 125% of the rated capacity and holding it for 15 minutes while checking for signs of distress.

Keep detailed records of all maintenance and inspections. A simple logbook works fine - the key is consistency. Good documentation protects your business and proves you're operating safely.

Frequently Asked Questions about Hand Crank Lifts

When I talk to funeral directors and facility managers about hand crank lifts, the same questions come up repeatedly. Let me share the answers that will help you make the right choice.

What load capacities and lift heights are typical?

The capacity range for hand crank lifts spans from 330 pounds for compact scissor carts up to 1,000 pounds for heavy-duty models. These are perfect for funeral homes handling various load sizes.

Workbench lift systems like the Movotec "Bolt-On" handle 750 pounds with a 15.7-inch adjustment range. These are excellent for preparation room tables where you need precise height control.

Material lifts reach impressive 20-foot heights while maintaining 500-pound capacity. At the extreme end, professional winch systems can handle loads up to 7,500 kg (16,534 lbs) by hand, though these are typically used for pulling applications.

How does a hand crank lift compare to chain hoists or scissor carts?

The main difference comes down to how and where you can use them. Chain hoists only move loads straight up and down - they need something overhead to hang from. Hand crank lifts often include wheeled bases or platforms, so you can move loads horizontally too.

Platform support is where scissor-style hand crank lifts really shine. Unlike chain hoists that just dangle a load in the air, scissor carts provide a stable work surface throughout the entire lifting process.

Speed considerations: Hand winches typically lift between 0.4 and 3 meters per minute, averaging around 1 meter per minute. Chain hoists can be faster, but they require more physical effort from the operator.

The horizontal movement capability of wheeled hand crank lifts often makes them more practical for funeral home use, where you frequently need to position equipment precisely within rooms.

Are there specific safety standards I should look for?

Absolutely - and this is where you don't want to cut corners. EN 13157 is the gold standard that requires every hand winch to have a safety factor of 4. This means the lift can safely handle four times its rated load before failure.

ANSI/ASME B30 standards cover lifting equipment in the United States, with specific requirements for inspection schedules, operator training, and maintenance procedures. These aren't just suggestions - they're often required by insurance companies.

Automatic load brakes are non-negotiable for safe operation. Every quality hand crank lift should include a brake system that kicks in immediately when you release the crank handle.

The bottom line? Don't compromise on safety certifications. The small extra cost upfront can save you from massive liability issues down the road.

Conclusion

Choosing the right hand crank lift comes down to understanding your specific needs and matching them with proven equipment. Whether you're running a busy funeral home in Tennessee or managing warehouse operations in California, these manual lifting systems offer something that powered equipment simply can't match - complete reliability without the headaches.

Think about it: no dead batteries when you need to move a heavy load, no motor repairs eating into your budget, and no worrying about whether your equipment will work in the rain or during a power outage. That's the peace of mind that comes with quality hand crank lifts.

From our experience serving funeral professionals across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania, we've seen how the right equipment makes all the difference. The 330-pound scissor carts handle everyday material moving tasks with ease, while specialized cadaver lifts with 1,000-pound capacity provide the precise control and dignity that funeral operations demand.

The numbers speak for themselves. When you consider zero operating costs, minimal maintenance requirements, and weather-resistant operation, manual lifts often cost less over their lifetime than their powered counterparts. Plus, that explosion-safe operation opens up applications where electric equipment simply isn't allowed.

At American Mortuary Coolers, we've helped countless funeral homes select lifting equipment that works as hard as they do. The telescoping masts, reversible forks, and heavy-duty construction of professional cadaver lifts aren't just features - they're the foundation of efficient, respectful operations.

But here's what really matters: getting equipment that fits your specific situation. Whether you need a PowerArm™ system for roadside work, a Vestil A-LIFT for versatile material handling, or a specialized mortuary lift for body handling, the key is matching capacity, height requirements, and safety features to your actual needs.

For funeral professionals who need something beyond standard equipment, we're here to help. Our team understands the unique challenges of mortuary operations, from space constraints to the need for quiet, dignified equipment operation. More info about heavy-duty mortuary lifts provides detailed guidance on comprehensive handling solutions.

The best hand crank lift is the one that's properly maintained and safely operated. Invest in quality equipment, train your staff properly, and follow those maintenance schedules we outlined. Your back, your budget, and your peace of mind will thank you for years to come.