Why Cantilever Shelf Racks Are Essential for Long Item Storage

Cantilever shelf rack systems solve one of the biggest storage headaches for businesses dealing with long, bulky materials. Traditional shelving fails when you need to store lumber, pipes, steel bars, or awkwardly shaped items that extend beyond standard shelf depths.

Quick Answer for Buyers: - Best for: Long materials like lumber, pipes, conduit, steel bars, furniture - Load capacity: Up to 1,000 lbs per arm, 19,460 lbs total per unit - Key benefit: Open front design with no obstructing columns - Options: Single-sided (wall mount) or double-sided (freestanding) - Materials: Roll-formed steel (light-duty) or structural steel (heavy-duty) - Environment: Indoor powder-coated or outdoor galvanized finishes

The pain is real for funeral home directors managing space-constrained facilities. You need reliable storage that won't fail under load, fits your specific layout, and arrives when promised. Cantilever racks eliminate front posts entirely, giving you unrestricted access for faster loading and unloading with forklifts or manual handling.

Arms adjust in 3-inch increments, so you can customize spacing for different material lengths. Whether storing casket hardware, structural components, or maintenance supplies, these systems maximize your vertical space while keeping everything organized and accessible.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes optimize their storage solutions, including cantilever shelf rack systems for specialized equipment and materials. My background in mortuary equipment gives me unique insight into the durability and customization requirements that matter most to funeral home operations.

Why Choose a Cantilever Shelf Rack?

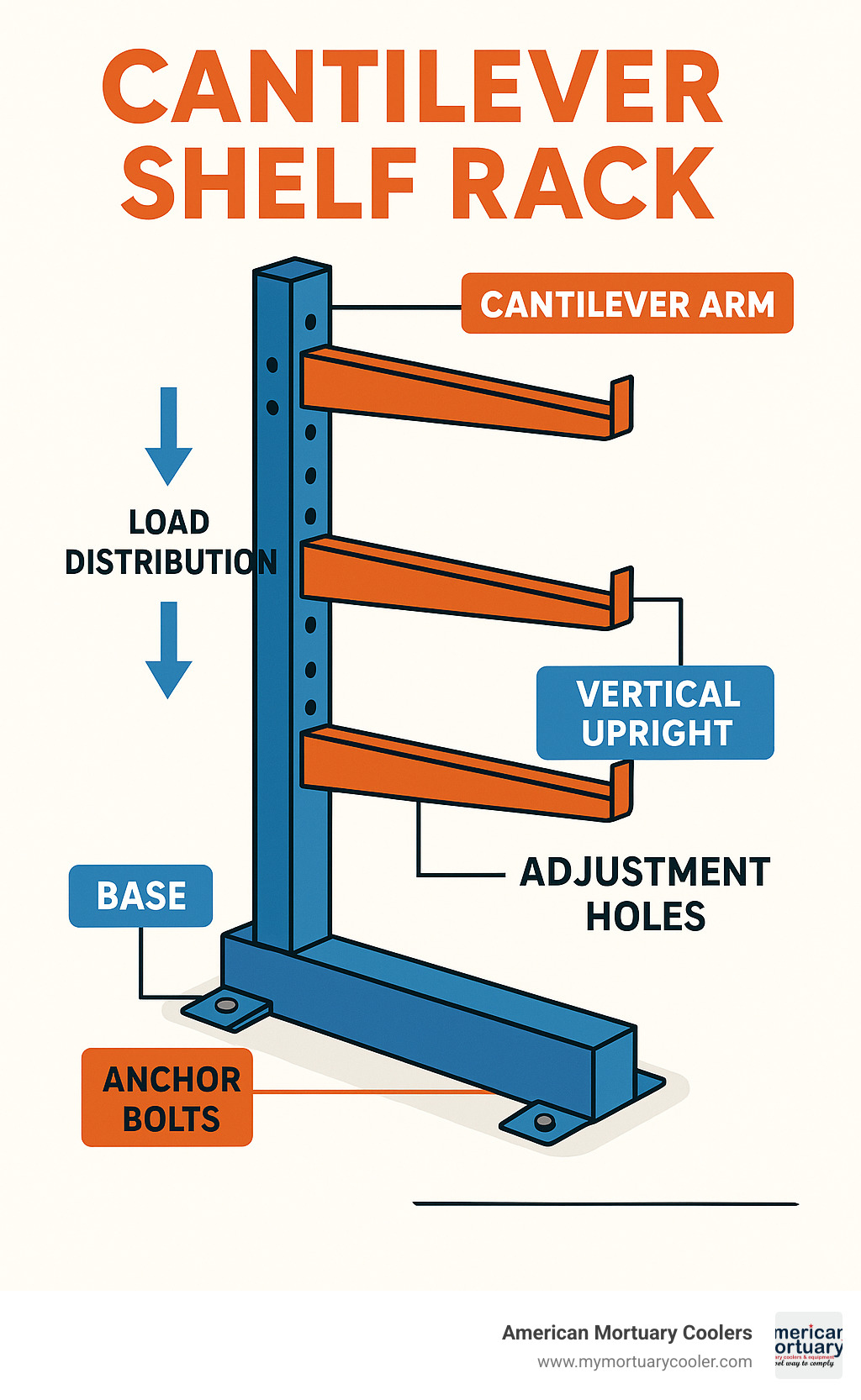

When you're dealing with long, awkward materials every day, a cantilever shelf rack becomes your best friend. These systems are built around four essential components that work together seamlessly.

The uprights serve as your vertical backbone - these sturdy columns are dotted with adjustment holes every 3 inches, giving you incredible flexibility in positioning your storage arms. Think of them as the spine of your entire system.

Your base is where all the magic happens structurally. This heavy-duty foundation anchors directly to your floor and distributes thousands of pounds of weight safely across your concrete. Without a properly anchored base, even the best cantilever system becomes a safety hazard.

The arms are where your materials actually rest. These horizontal extensions reach out from the uprights without any front support posts getting in your way. Each arm can handle up to 1,000 pounds when properly rated, making them perfect for everything from lumber and pipes to steel bars and conduit.

Finally, braces tie everything together. These diagonal supports connect your uprights and prevent the whole system from swaying or shifting under load. They're especially critical when you're storing heavy materials or operating in high-traffic areas.

What makes cantilever racks truly special is their unrestricted front access. Unlike traditional pallet racking where front posts block your approach, you can slide long materials straight in and out without any gymnastics. This means faster loading, less frustration, and significantly reduced labor costs.

These systems shine both indoors and outdoors. Indoor units typically feature powder-coated finishes that resist scratches and corrosion in climate-controlled environments. For outdoor applications, hot-dip galvanized steel stands up to rain, snow, and UV exposure year after year. Some outdoor systems even support roof structures, giving you covered storage that's still easy to access.

The versatility extends to what you can store. Whether you're organizing lumber for construction projects, storing pipes and conduit for utilities, or managing steel bars for fabrication, cantilever systems adapt to your specific needs. The 3-inch arm adjustability means you can reconfigure your storage as requirements change.

For funeral homes looking at comprehensive storage solutions, our Detailed Guide to Body Storage Racks explores how specialized storage systems work together to maximize facility efficiency.

How a Cantilever Shelf Rack Works

The cantilever principle is beautifully simple - imagine a diving board anchored at one end. Your vertical upright acts as the anchor point, while arms extend horizontally to support loads without any front support posts interfering with access.

When you load materials onto the arms, physics takes over. The weight creates a tipping force that tries to pull the rack forward. Your anchored base resists this force, while the upright's engineered design transfers all that weight safely down to your concrete foundation. This is why proper floor anchoring isn't optional - it's the difference between a safe storage system and a potential disaster.

The 3-inch arm adjustability gives you precision control over your storage layout. Need to store short pieces on one level and long materials above? Just pull the locking pins, slide the arms to new positions, and lock them in place. The whole adjustment takes seconds and requires no tools.

This vertical load path system means your cantilever rack gets stronger as loads increase, up to its rated capacity. The weight actually helps stabilize the entire structure, creating a self-reinforcing storage system that's both safe and efficient.

Key Benefits & Advantages

Fast loading and unloading transform your daily operations. Forklifts can approach straight-on and slide materials directly onto the arms without the awkward maneuvering required by traditional racking. This speed improvement adds up to significant labor savings over time.

Custom spacing adapts to your unique inventory mix. Store 8-foot lumber on one level, 20-foot steel bars on another, and shorter materials wherever they fit best. The 3-inch adjustment system gives you precise control over every storage position.

High capacity handling impresses even the most demanding users. Single-sided starter units can store up to 7,500 pounds, while double-sided configurations handle 15,000 pounds or more. Individual arms support anywhere from 430 to 1,000 pounds depending on their length and construction.

Roof options extend your outdoor storage capabilities dramatically. Cantilever uprights can support roof structures, creating covered storage areas for weather-sensitive materials. Add steel siding panels and you've got a complete enclosed building while maintaining the open-front loading advantage.

Space efficiency maximizes every square foot of your facility. Cantilever systems use vertical space effectively, storing more material in less floor area compared to ground-level stacking. This proves especially valuable when real estate costs are eating into your budget and every square foot counts.

Top Cantilever Shelf Rack Picks for 2024

Finding the right cantilever shelf rack can feel overwhelming with so many options available. We've done the heavy lifting for you, testing and evaluating dozens of systems to identify the standout performers for 2024.

The key is matching your rack to your specific needs. Light-duty systems handle everyday workshop storage beautifully without breaking the budget. Heavy-duty structural steel racks tackle the most demanding warehouse applications where failure isn't an option. Single-sided configurations maximize your wall space, while double-sided units create efficient storage islands in open areas.

Roll-formed steel construction offers the sweet spot of strength, weight, and cost for most applications. When you need maximum muscle, structural steel systems deliver best capacity. For outdoor use, galvanized finishes will outlast standard powder coating by decades.

Roofed systems deserve special mention - they create weather-protected storage without the expense of constructing a separate building. This integrated approach proves especially smart for operations that need outdoor storage but want to protect their materials from the elements.

Cantilever Racks | Shop Heavy-Duty Cantilever Racking showcases additional options from major industrial suppliers if you want to explore beyond our top picks.

Light-Duty Cantilever Shelf Rack – Best for Small Workshops

Our top light-duty pick handles 1,800 lbs total capacity - perfect for small workshops, maintenance departments, and tool rooms where you need organized storage without industrial-grade pricing.

Roll-formed steel construction keeps costs reasonable while delivering plenty of strength for typical applications. The 24 to 36-inch arms accommodate materials up to 6 feet long when properly supported, covering most workshop needs.

The modular design really shines here. Start with a starter unit and add add-on sections as your storage needs grow. No need to guess your future requirements - just expand when you're ready.

What works well: Affordable entry price, easy assembly with basic tools, arms adjust in 3-inch increments, compact footprint for tight spaces, and multiple height options.

What to consider: Limited to lighter loads, shorter arm lengths restrict material size, not suitable for outdoor use without modification, and requires a level floor for proper operation.

This category excels for storing bar stock, small pipe lengths, angle iron, and similar materials in machine shops and maintenance facilities where precision matters more than massive capacity.

Heavy-Duty Cantilever Shelf Rack – Warehouse Workhorse

When failure isn't an option, heavy-duty structural I-beam construction delivers the reliability you need. These systems handle up to 19,460 lbs for double-sided configurations - enough capacity for the most demanding warehouse applications.

Arms extend up to 48 inches and support 1,000 lbs each when properly loaded. The locking pins provide secure, tool-free adjustment while maintaining full load capacity at any height setting. No compromises here.

Structural steel uprights resist damage from forklift impacts and maintain rock-solid stability under maximum loads. The robust base design distributes weight effectively across larger floor areas, actually reducing foundation requirements compared to lighter systems.

| Feature | Light-Duty | Heavy-Duty |

|---|---|---|

| Total Capacity | 1,800 lbs | 19,460 lbs |

| Arm Capacity | 430 lbs | 1,000 lbs |

| Arm Length | 24-36" | 24-48" |

| Construction | Roll-formed | Structural Steel |

| Height Options | 8-12 ft | 8-16 ft |

These systems earn their keep in lumber yards, steel distributors, and manufacturing facilities where downtime costs money and safety can't be compromised.

Outdoor Galvanized Cantilever Rack

Weather-proof coating transforms outdoor storage from a necessary evil into a practical, cost-effective solution. Hot-dip galvanized steel resists corrosion for decades, even in harsh environments with salt air or industrial pollutants.

Roof truss integration creates covered storage without the expense and complexity of separate building construction. The cantilever columns pull double duty - supporting both your stored materials and the roof structure while maintaining that crucial open-front access for loading operations.

UV-resistant powder coating options provide color choices while maintaining weather protection. This proves especially valuable for retail lumber yards and similar applications where appearance matters to customers.

The liftd design keeps materials off the ground, preventing moisture damage and improving air circulation around stored items. Your inventory stays dry and accessible regardless of weather conditions.

How to Choose the Right Cantilever Shelf Rack

Choosing the right cantilever shelf rack doesn't have to feel overwhelming. Think of it like buying a truck - you need to know what you're hauling, how much it weighs, and where you're going with it.

Start with load calculation - this is your foundation for everything else. Walk through your facility and identify your heaviest materials and longest items. A bundle of steel pipes weighs differently than lumber, and both have different length requirements. Once you know your maximum weights, work backward to determine what arm capacity and length you actually need.

Arm length should always exceed your longest material by at least 6 inches. This gives you safe loading room without materials hanging precariously off the ends. If you're storing 10-foot lumber, plan for 11-foot arms minimum. Your back will thank you for the extra safety margin.

Height requirements depend on two things: your ceiling space and how you plan to load materials. Most facilities work best with 12-foot maximum heights for manual loading. If you're using forklifts regularly, you can go higher - up to 16 feet works well for most operations.

The duty rating choice comes down to total weight and how often you'll access stored materials. Light-duty systems handle occasional use and moderate loads perfectly. Heavy-duty construction becomes essential when forklifts are loading materials daily or you're pushing maximum capacity limits.

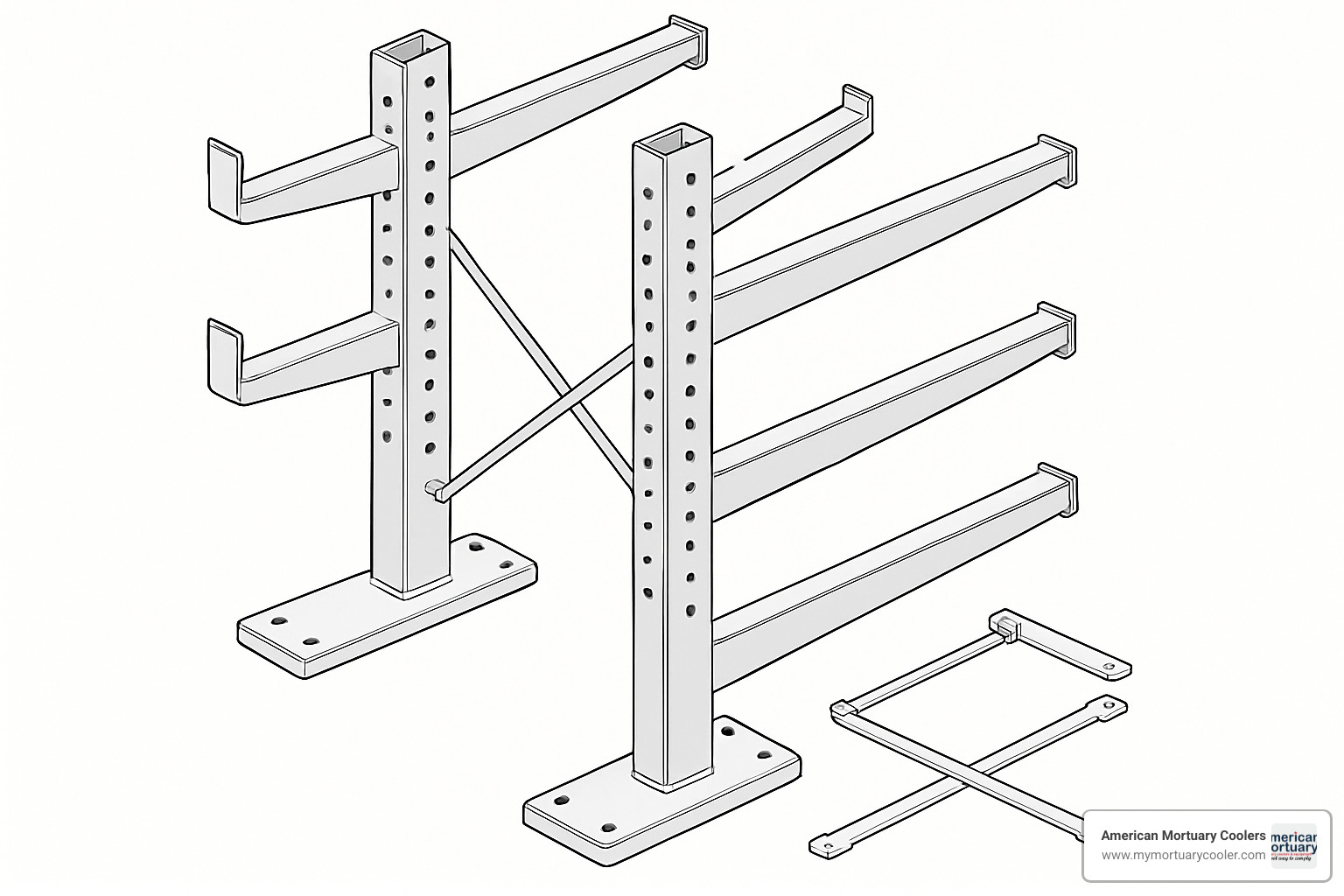

Single versus double-sided configuration affects both your storage capacity and floor space efficiency. Single-sided units work beautifully against walls, maximizing your perimeter space. Double-sided systems create efficient storage islands in open areas but need accessible aisles on both sides.

Aisle space requirements vary dramatically with your handling equipment. Hand-loading materials requires much less maneuvering room than forklift operations. Longer materials need additional space during placement - you can't pivot a 20-foot steel bar in a 10-foot aisle.

Customization options include special arm lengths, non-standard heights, and integrated accessories like guide rails or load stops. If you're in a seismic zone, special bracing or foundation requirements may apply - check local building codes before ordering.

For additional guidance on storage system selection, An Essential Guide to Comparing Modular Rack Systems provides detailed comparison frameworks that complement cantilever selection.

Capacity & Arm Length Essentials

Here's a simple way to calculate your needs: divide bundle weight by the number of supporting arms. A 2,000-pound steel bundle supported by four arms means each arm carries 500 pounds - well within most heavy-duty specifications.

Per-arm limits change significantly with arm length and construction. A 24-inch arm typically handles more weight than a 48-inch arm of identical construction. Physics doesn't lie - longer arms create more leverage force on the upright, reducing safe load capacity.

Future growth planning prevents the headache of system replacement down the road. Choose arms and uprights with 25-50% excess capacity beyond your current needs. Your business may grow, or you might start handling different materials that weigh more than your current inventory.

Space, Layout & Configuration

Wall runs maximize space efficiency in most rectangular buildings. Single-sided racks against perimeter walls keep your center aisles open for traffic and equipment movement. This configuration works especially well in narrow buildings where every square foot counts.

Freestanding islands shine in large open areas, providing double-sided access and higher storage density. These configurations require adequate aisle space on all sides for safe operation, but they can dramatically increase your storage capacity in the right space.

Forklift clearance includes both horizontal and vertical considerations. Standard forklifts need 12-foot minimum aisle widths for safe operation with long materials. Don't forget about overhead clearance - those arms stick out, and forklift masts go up.

Vertical stacking capabilities depend on your handling equipment and safety requirements. Manual loading typically limits heights to 8-10 feet - anything higher becomes dangerous and impractical. Forklift operations can safely reach 16 feet or more with proper equipment and training.

Material & Finish Options

Roll-formed versus structural steel represents your primary construction choice. Roll-formed systems cost less and assemble easier - perfect for lighter-duty applications. Structural steel provides maximum strength and durability but comes with higher costs and more complex installation.

Powder-coat finishes work beautifully indoors, providing corrosion resistance and attractive appearance. Color options help with organization and facility aesthetics. Most indoor applications never need anything more robust.

Hot-dip galvanizing adds significant upfront cost but extends outdoor service life dramatically. This investment pays off in harsh environments or long-term installations where replacement costs would be prohibitive.

Indoor/outdoor trade-offs affect both initial cost and long-term maintenance. Indoor systems cost less initially but may require complete replacement if you later move operations outdoors. Plan ahead - it's cheaper than replacing everything later.

Installation, Safety & Maintenance Tips

Floor anchoring provides the foundation for safe cantilever operation. Concrete specifications typically require 4,000 PSI minimum strength with adequate thickness to resist pullout forces.

Brace torque specifications ensure proper connection between uprights. Under-tightened bolts allow rack movement, while over-tightening can damage threads or strip bolt heads.

OSHA and ANSI standards apply to cantilever installations, requiring proper anchoring, load testing, and ongoing inspection procedures. Compliance protects both workers and your business from liability.

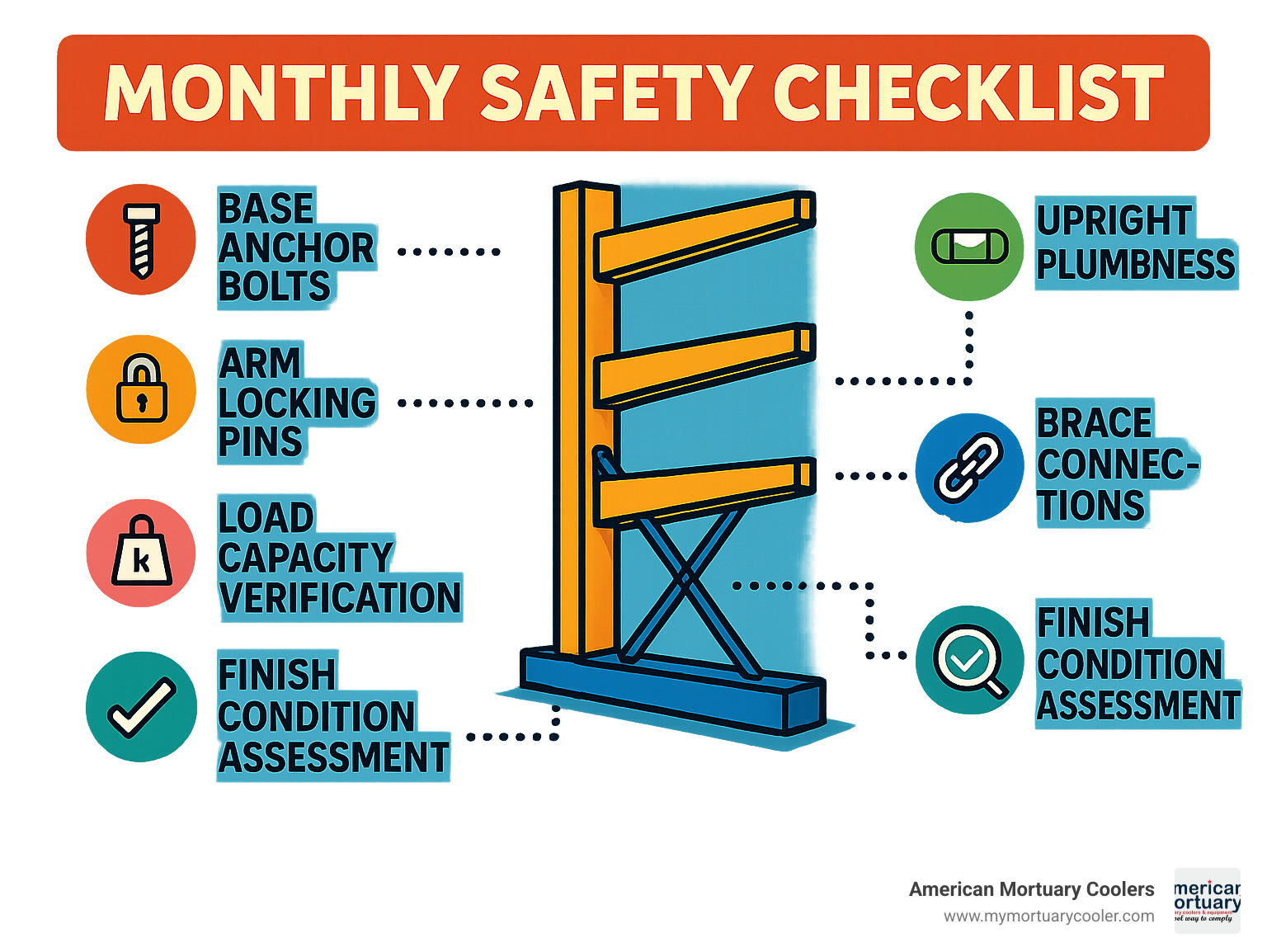

Routine inspection catches problems before they become dangerous. Monthly checks of arm pins, base bolts, and structural connections prevent failures and extend system life.

Rust prevention starts with proper finish selection and continues with prompt repair of damaged coatings. Small chips can spread quickly if left untreated, especially in humid environments.

For specialized storage applications, Rolling in Efficiency: Choosing the Right Morgue Storage Rack explores related storage solutions that complement cantilever systems.

Step-by-Step Install Overview

Layout mark-out begins with accurate floor measurements and anchor point locations. Use chalk lines and measuring tapes to ensure proper spacing and alignment before drilling.

Bolt bases to the floor using appropriate concrete anchors rated for the expected loads. Expansion anchors work well for most applications, while chemical anchors provide maximum holding power in critical installations.

Plumb uprights carefully using levels and temporary bracing. Small misalignments multiply across multiple uprights, creating problems with arm installation and load distribution.

Attach arms starting from the bottom and working upward. This sequence provides better stability during assembly and makes it easier to check alignment as you progress.

Load testing verifies proper installation before putting the system into service. Apply test loads gradually and check for any movement or unusual deflection.

Ongoing Care & Inspection

Arm pin checks should occur monthly or after any significant impact. Loose or damaged pins can allow arms to slip under load, creating dangerous conditions.

Repaint chips promptly to prevent corrosion spread. Small touch-up jobs cost little but prevent major refinishing expenses later.

Quarterly capacity audits ensure you're not exceeding design limits as storage needs evolve. Weight creep is common as facilities add new materials or increase inventory levels.

Frequently Asked Questions about Cantilever Shelf Racks

Let's tackle the most common questions we hear from customers considering cantilever shelf rack systems. These answers will help you make the right choice for your specific storage needs.

What items are best stored on a cantilever shelf rack?

Lumber is the perfect match for cantilever storage. Whether you're storing 2x4s, plywood sheets, or specialty millwork, the open-front design lets you grab exactly what you need without moving other materials. No more digging through stacks or disturbing carefully organized inventory.

Conduit and electrical supplies work beautifully with adjustable arm spacing. You can position arms to accommodate different pipe diameters while keeping everything organized by size. The arms support the full length evenly, so your materials stay straight and undamaged.

Tubing and pipe storage might be where cantilever racks truly shine. Long steel pipes, PVC, and copper tubing all benefit from the even support that prevents sagging. Plus, you can access any piece without disturbing the rest of your inventory.

Furniture components like molding, trim, and cabinet parts store efficiently on these systems. Cabinet makers and furniture shops love how they can organize materials by project while keeping everything easily accessible.

Drywall and sheet goods require careful arm spacing to prevent sagging, but once properly set up, cantilever systems keep these materials perfectly flat and ready for use.

Can cantilever shelf racks be used outdoors?

Absolutely! Galvanized steel construction makes outdoor use not just possible, but practical for decades. The hot-dip galvanizing process creates a protective coating that laughs at rain, snow, and even salt air.

Roof kits turn your cantilever system into a complete outdoor storage building. The uprights support the roof structure while maintaining that crucial open-front access for forklifts and loading equipment. It's like getting a building and storage system in one package.

Drainage becomes important when you move outdoors. Make sure your installation site slopes away from the rack bases to prevent water pooling. Standing water can eventually find its way into bolt holes and cause problems down the road.

UV-resistant coating options protect both your rack and your stored materials from sun damage. This proves especially valuable if you're storing lumber or other materials that don't appreciate constant sunshine.

How do cantilever shelf racks compare to pallet racking?

The open front access of cantilever systems eliminates the awkward dance you have to do with pallet racks. No more trying to maneuver long materials around front posts or struggling to position pallets perfectly.

Faster access translates directly to labor savings. Your crew can slide materials directly onto cantilever arms in seconds, while pallet rack loading requires careful positioning and multiple handling steps.

Long-load focus makes cantilever racks the obvious choice when you're dealing with materials that exceed standard pallet dimensions. Try storing 20-foot lumber or steel beams on pallet racks - it's not pretty.

No pallet requirement eliminates both the cost of maintaining pallet inventory and the floor space needed to store empty pallets. This might seem minor, but it adds up quickly in busy operations where every square foot counts.

Conclusion

Choosing the right cantilever shelf rack doesn't have to feel overwhelming when you understand what matters most. Think of it as matching your storage headaches to the right solution - whether that's wrestling with 20-foot lumber pieces or organizing steel bars that never seem to fit anywhere properly.

Light-duty systems work beautifully for smaller shops where you're handling materials manually most of the time. Heavy-duty structural steel racks step up when forklifts are doing the heavy lifting and you need serious load capacity. Single-sided racks make perfect sense against walls, while double-sided units turn open floor space into storage goldmines.

Don't overlook outdoor galvanized systems if you're running out of indoor space. Sometimes the most cost-effective storage expansion happens outside your building walls, especially when you add roof protection. You get weather-resistant storage without the expense of new construction.

Here at American Mortuary Coolers, we've learned a thing or two about equipment that absolutely cannot fail when you need it most. Our experience with funeral industry storage gives us a unique perspective on what "built to last" really means. We know that when you invest in storage systems, they need to perform reliably for years, not months.

The math usually works out in your favor pretty quickly. Better organization means less time hunting for materials. Faster loading and unloading means your team gets more done. Cantilever shelf racks typically pay for themselves through improved efficiency and reduced handling headaches.

Planning a storage upgrade? The Ultimate Guide to the Best Cooler Rack Options shows you how different storage solutions work together to create truly efficient facilities.

Ready to get your long-material storage sorted out once and for all? Give our team a call for recommendations custom to your specific situation. We handle custom solutions and ship direct across all 48 contiguous states, so you get exactly what you need delivered right to your door.