Why Operating Room Prep Tables Are Critical for Surgical Success

Finding the right prep table for sale operating room can make or break your surgical workflow. Here's what you need to know:

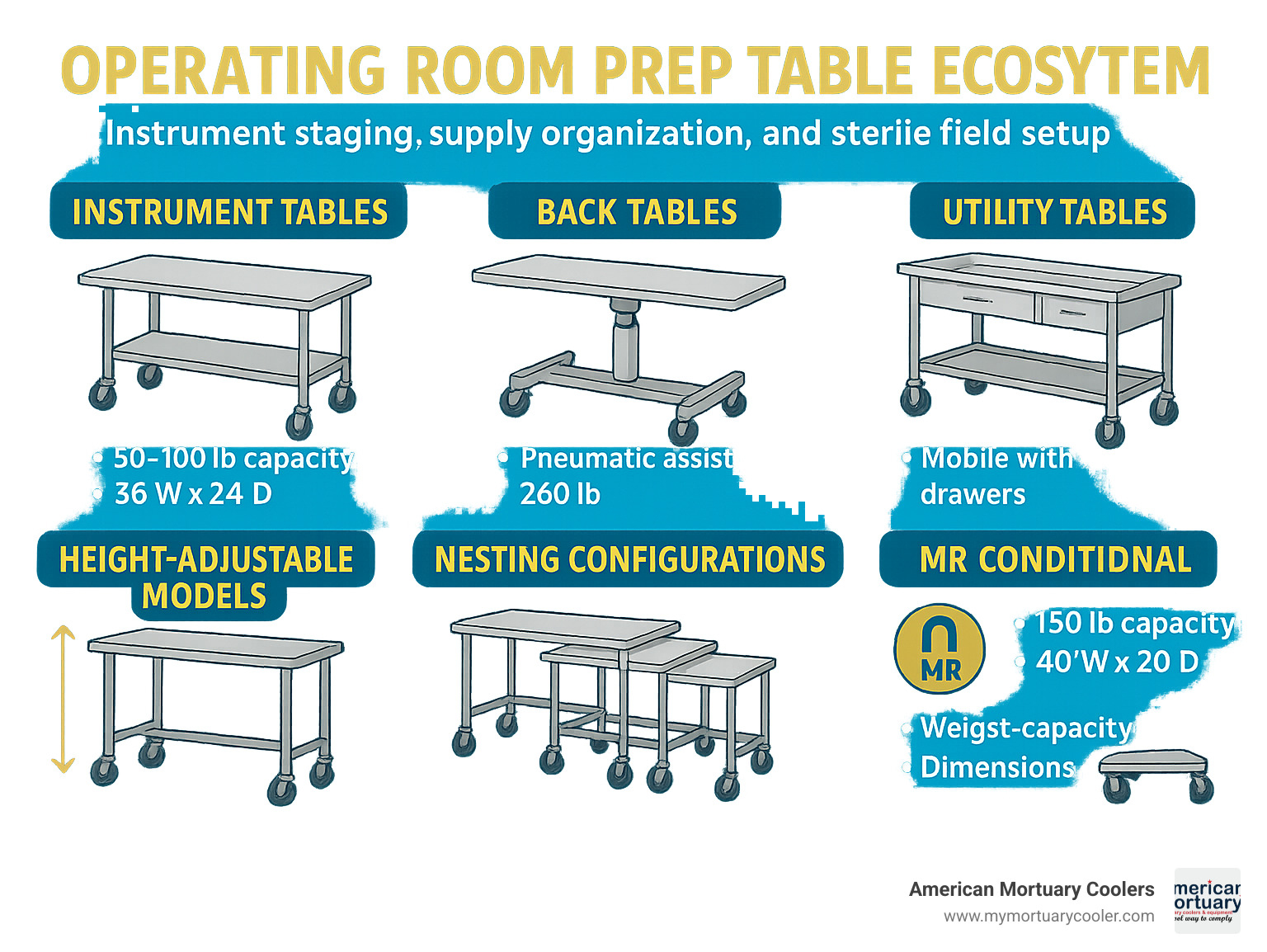

Top OR Prep Table Categories:

- Instrument Tables - 16-gauge stainless steel, 50-100 lb capacity, with/without shelves

- Back Tables - 14-gauge construction, up to 260 lb capacity, low-deflection workspace

- Utility Prep Tables - Drawer configurations, guardrails, mobile emergency room use

- Height-Adjustable Models - 34"-56" range, accommodate staff from 4'11" to 6'6"

- Nesting Sets - Up to 6 tables, space-saving storage solutions

Operating rooms depend on prep tables for instrument staging, supply organization, and sterile field setup. Unlike surgical tables that support patients, prep tables handle the critical behind-the-scenes work that keeps procedures running smoothly. Most are built from 304-grade stainless steel with locking casters for mobility and stability.

The right prep table improves case turnover times, reduces staff fatigue through proper ergonomics, and maintains infection control standards. Research shows that double-tiered back tables can reduce total knee replacement setup time by 6.8 minutes compared to using separate tables.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping facilities find the right prep table for sale operating room setups. My background in mortuary and medical equipment gives me unique insight into what makes prep tables work in demanding sterile environments.

Simple prep table for sale operating room glossary:

Why Your OR Needs a Purpose-Built Prep Table

Safety comes first in any operating room, and prep tables play a crucial role in maintaining sterile environments. Purpose-built OR prep tables feature smooth, non-porous 304-grade stainless steel surfaces that resist bacterial growth and withstand repeated sterilization cycles.

Efficiency gains are immediate when you upgrade to professional prep tables. Research shows that facilities using double-tiered back tables complete total hip arthroplasty setups 2.2 minutes faster than those using separate tables.

Infection control protocols require surfaces that can handle aggressive cleaning agents and frequent washdowns. Medical-grade prep tables use corrosion-resistant casters and sound-proofed reinforcing channels that maintain structural integrity even after years of intensive use.

What Exactly Is an OR Prep Table & Why It Matters

Think of an operating room prep table for sale operating room as the unsung hero of surgical success. While the surgical table gets all the attention supporting patients, prep tables quietly handle the behind-the-scenes work that keeps everything running smoothly.

These specialized work surfaces serve as instrument staging areas, sterile field organizers, and utility surfaces all rolled into one. They're where scrub technicians transform chaos into order, arranging surgical instruments in perfect sequence and keeping supplies within arm's reach.

The construction details separate good prep tables from great ones. Quality models use 16-gauge stainless steel for instrument tables and heavier 14-gauge steel for back tables that need serious strength. The 304-grade stainless steel resists corrosion beautifully and handles repeated sterilization like a champ.

Weight capacity varies dramatically based on what you're planning to do. Standard instrument tables typically support 50-100 pounds, which works fine for basic instrument sets. Heavy-duty back tables can handle up to 260 pounds on the main surface and 160 pounds on upper shelves - perfect for those massive orthopedic cases.

The supporting structure matters more than you might think. Low-deflection legs use 1-inch square tubing for instrument tables and beefier 1.5-inch legs for back tables. Nobody wants their sterile setup wobbling when they're trying to work.

Mobility comes from quality casters - usually 3-inch or 4-inch non-marking wheels with locking mechanisms. This lets staff position tables exactly where needed during setup, then lock them down tight during procedures.

Height ergonomics directly impact whether your staff goes home with sore backs or feeling good. Fixed-height tables typically measure 34 inches, while adjustable models range from 36-56 inches to accommodate everyone from petite to tall staff members.

Scientific research on stainless-steel infection control backs up what we see in practice: properly designed stainless steel surfaces dramatically reduce bacterial colonization compared to other healthcare materials.

Primary Functions in the Surgical Workflow

Instrument prep represents the bread and butter of what prep tables do best. Scrub technicians use these surfaces to organize surgical instruments in the exact sequence needed for procedures.

Supply storage extends far beyond just instruments. Prep tables hold gauze, sutures, implants, and countless other consumables needed during procedures. Tables with lower shelves or drawer configurations provide organized storage that keeps supplies within easy reach.

Case turnover efficiency improves dramatically with well-designed prep tables. The ability to quickly clear, clean, and reset prep surfaces between procedures directly impacts how many cases you can handle per day.

How Prep Tables Differ from Surgical, Mayo & Over-table Units

Patient support versus instrument support represents the fundamental difference between surgical tables and prep tables. Surgical tables must articulate, tilt, and adjust to position patients for optimal surgical access. Prep tables focus entirely on providing rock-solid, sterile work surfaces for instruments and supplies.

Mobility versus articulation highlights another key distinction. Mayo stands and over-table units typically feature height adjustment and positioning arms to place instruments directly over the surgical field. Prep tables prioritize smooth mobility around the OR and stable positioning once they're where you need them.

Best Prep Table for Sale Operating Room: Top Picks at a Glance

| Table Type | Load Limit | Dimensions | Height Range | Key Features |

|---|---|---|---|---|

| Standard Instrument | 50-100 lbs | 24"W x 48"L | 34" fixed | 16-gauge steel, shelf options |

| Back Table | 260 lbs | 30"W x 72"L | 34" fixed | 14-gauge steel, pneumatic assist |

| Height-Adjustable | 100 lbs | 24"W x 60"L | 36"-56" | Single-touch lift, locking casters |

| Utility Prep | 75 lbs | 16"W x 20"L | 34" fixed | Drawers, guardrails, compact |

| Nesting Set | 50 lbs each | Various sizes | 34" fixed | Space-saving, up to 6 tables |

| MR Conditional | 75 lbs | 24"W x 48"L | 34" fixed | Non-ferrous construction |

When you're searching for the perfect prep table for sale operating room, the sheer variety of options can feel overwhelming. I've spent years helping facilities steer these choices, and I know how the right table can transform your workflow while the wrong one creates daily headaches.

The comparison table above breaks down the six main categories you'll encounter. Each serves specific needs, from instrument tables that handle basic setups to back tables that support complex procedures. Utility tables work beautifully in emergency departments, while nesting sets solve space problems that keep facility managers awake at night.

What strikes me most about today's prep table market is how manufacturers have responded to real-world challenges. That MR conditional option exists because someone got tired of wheeling tables out of imaging suites. Those height-adjustable models came about because tall surgeons and shorter scrub techs were both getting backaches from fixed-height surfaces.

Height-Adjustable Stars — "Follow the Table" Solutions

The magic of height-adjustable prep tables hits you the first time you watch a 5'2" scrub tech and a 6'4" surgeon work comfortably at the same surface. These aren't just fancy gadgets – they're problem solvers that adapt to your team instead of forcing your team to adapt to them.

The STERIS MCE532 stands out as our top recommendation for prep table for sale operating room buyers who want adjustability. With its 36-56 inch range and 260-pound capacity, it handles everything from pediatric procedures to complex orthopedic cases. The single-touch pneumatic lift means one person can adjust it quickly between cases, and those 3-inch locking casters glide smoothly across any OR flooring.

What really sets these tables apart is their ability to "follow the table" – matching your surgical table's height as it moves through different positions. When the surgical table tilts for better access, your prep table can match that working height instantly. No more reaching up or bending down awkwardly during critical moments.

The return on investment becomes clear within weeks. Staff report less fatigue at the end of long days, and case turnover speeds up when teams don't waste time adjusting their workspace. One facility manager told me their OR nurses stopped complaining about back pain after switching to adjustable prep tables.

Space-Saver & Nesting Marvels for Tight Suites

If you've ever played Tetris trying to fit equipment into a cramped OR, you'll appreciate the genius of space-saving prep tables. Modern surgical suites pack more technology into the same footprint, leaving precious little room for traditional prep tables.

The Pedigo Space Station series tackles this challenge with neat engineering. Its two-tier design doubles your prep surface without doubling your floor space. The pneumatic assist feature lets one person operate the upper shelf safely, while the disposable drape option covers both levels with a single sterile barrier. With 160 pounds on the top and 260 pounds on the main surface, it replaces multiple single-tier tables.

Nesting table sets offer another brilliant solution for space-challenged facilities. These sets include up to six tables that stack like Russian dolls under the largest unit. Deploy them individually for complex procedures, then nest them back together for storage. It's like having a prep table that multiplies when you need it and disappears when you don't.

Hybrid ORs particularly benefit from nesting solutions. When imaging equipment dominates the room, you can keep tables nested until the exact moment you need them. Then deploy quickly for procedures requiring multiple sterile fields.

Utility Prep Tables with Drawers & Guardrails

Emergency departments and patient care areas need prep tables that think differently. These environments demand organization features and safety measures that standard OR tables don't provide.

Drawer configurations make all the difference in settings. Whether you choose zero drawers for easy cleaning or four drawers for maximum organization, each setup serves specific workflow needs. The smooth-operating slides hold up beautifully through repeated cleaning cycles, while guardrails prevent supplies from hitting the floor during transport.

The Mid Central Medical utility series exemplifies smart compact design with its 16"W x 20" footprint. Despite the small size, it maintains a solid 75-pound weight capacity and fits into spaces where larger tables simply won't work. Emergency departments love these for their ability to squeeze into treatment areas while keeping supplies organized and accessible.

Mobile utility tables serve double duty as both transport and workspace. Load supplies in drawers, wheel the unit to the point of care, then use the top surface for procedures while keeping additional supplies organized below. It's efficiency and organization rolled into one mobile package.

Materials, Features & Pricing—Smart Buying Guide

When you're shopping for a prep table for sale operating room, understanding the materials and construction details makes all the difference. These choices don't just affect your upfront costs—they determine how well your table performs over its 15-20 year lifespan.

304-grade stainless steel is the workhorse of the prep table world, and for good reason. This alloy laughs off daily cleaning chemicals, resists corrosion, and maintains its professional appearance even after years of intensive use. Most facilities find 304-grade steel provides the perfect balance of durability and cost-effectiveness.

316-grade stainless steel steps up the game with superior corrosion resistance. If your facility uses aggressive cleaning protocols or you're dealing with high humidity environments, the upgrade pays for itself.

The construction details reveal a lot about table quality. Sound-proofed reinforcing channels might seem like a small detail, but they make a huge difference during procedures. These channels stiffen the work surface while dampening that metallic clatter when instruments are moved around.

H-brace versus shelf construction presents an interesting trade-off. H-braces deliver maximum strength with minimal weight—perfect for mobile applications. Shelf configurations add convenient storage space beneath the work surface.

Lockable 3-4 inch casters determine how smoothly your table moves and how securely it stays put. Ball-bearing designs roll more smoothly and last longer than plain bearing alternatives.

Price ranges tell their own story: basic utility tables start around $400, while fully-featured adjustable back tables with pneumatic assists can reach $4,500. The investment typically pays for itself through improved efficiency and reduced replacement costs over the table's service life.

Guardrails prevent supplies from rolling off during transport, while drawers (ranging from 0-4 configurations) keep frequently used items organized and accessible. Drop-leaf extensions expand work surface when needed, then fold away for compact storage.

MR safe construction uses non-ferrous materials for imaging compatibility, while pneumatic assist features enable single-person operation of heavy tables. The warranty coverage typically spans 2-3 years, with service plans available for complex pneumatic and hydraulic systems.

New, Pre-Owned, Remanufactured — Which Fits Your Budget?

The age-old question of new versus used equipment gets interesting when you're looking at prep tables. Each option has its place depending on your facility's needs and budget reality.

New tables give you everything—latest features, full warranties, and that confidence that comes with knowing exactly what you're getting. Lead times usually run 2-8 weeks depending on customization requirements.

Pre-owned tables can slash your costs significantly, but they require a careful eye. Reputable dealers provide detailed condition reports and offer limited warranties, but you need to budget for potential repairs.

Remanufactured tables offer the sweet spot for many facilities. Quality remanufacturing means complete disassembly, component replacement, and testing to restore like-new performance. You get much of the reliability of new equipment at a fraction of the cost.

Cleaning & Maintenance for Infection Control Compliance

Keeping your prep tables clean and functional isn't just about appearance—it's about patient safety and regulatory compliance. The good news is that proper maintenance isn't complicated if you follow the right procedures.

Daily wipe-down should use approved disinfectants that play nice with stainless steel surfaces. Here's a critical tip: avoid chlorine bleach at all costs. It causes pitting and corrosion that will ruin your table's surface over time.

Weekly deep cleaning involves taking apart removable components, thoroughly cleaning all surfaces, and inspecting for wear or damage. Pay special attention to caster mechanisms—they love to collect debris that interferes with smooth operation.

When polishing stainless steel surfaces, always polish in the direction of the grain. This maintains the surface's appearance and actually reduces bacterial adhesion.

More info about cleaning protocols provides detailed guidance on maintaining sterile surfaces and extending equipment life.

How to Choose the Right Prep Table for Your OR

Choosing the perfect prep table for sale operating room doesn't have to feel overwhelming. I've helped countless facilities find their ideal setup, and there's a straightforward approach that works every time.

Start by watching how your team actually works. Spend a morning observing your busiest OR and you'll quickly spot the pain points. Maybe your scrub techs are constantly stretching to reach instruments, or perhaps tables get jammed up during case turnovers.

Different surgeries need different table setups, and this matters more than most people realize. Orthopedic procedures often require those big back tables to hold all the specialized instruments and implants. Meanwhile, minimally invasive procedures work beautifully with compact instrument tables that don't crowd the already tight space around laparoscopic equipment.

If you're working in a hybrid OR with imaging equipment, compatibility becomes crucial. Those C-arms need to swing freely around your prep tables, and MR conditional tables eliminate any safety worries in imaging suites.

Here's something facilities often overlook: staff height variations. If your team ranges from 5'2" to 6'4", adjustable tables aren't a luxury—they're essential for preventing back injuries and maintaining good working posture.

Floor space constraints often drive decisions more than we'd like. Measure carefully, accounting for caster clearance and maneuvering room. Those nesting tables might look compact when stored, but they need space to deploy when you actually need them.

Think about your facility's future too. Are you planning to add new service lines? Expecting procedure volume growth? Choosing modular systems or standardizing on one manufacturer makes future expansions much smoother.

Latest research on ergonomics shows that proper table height selection can reduce musculoskeletal injuries among OR staff by up to 40%.

Must-Have Accessories & Add-Ons

The right accessories can transform a good prep table into a great one. Over-shelves create additional sterile surfaces without eating up precious floor space. They're lifesavers for procedures requiring extensive instrument sets or when you need multiple sterile fields but don't have room for another full table.

Drop-leaf extensions offer flexibility that many facilities don't realize they need until they have it. The leaves stay folded during routine procedures, then extend for complex cases requiring extra prep space.

Don't overlook ID card holders—they might seem minor, but they're essential for maintaining proper chain of custody documentation. These holders attach securely to table frames and keep patient identification visible and accessible throughout procedures.

Foot switches for powered height adjustment prove invaluable when scrub technicians need to adjust table height while maintaining sterile technique.

More info about fold-down solutions explores additional space-saving accessories that maximize functionality in compact ORs.

Frequently Asked Questions about Operating-Room Prep Tables

When you're shopping for a prep table for sale operating room, certain questions come up again and again. I've helped hundreds of facilities steer these decisions, so let me share the answers that matter most.

What weight capacity should I look for?

The weight capacity you need depends entirely on what you're doing in your OR. If you're handling basic general surgery instruments, a standard instrument table with 50-100 pound capacity will serve you well. But if you're dealing with orthopedic trays loaded with heavy hardware or extensive cardiac instrument sets, you'll want those robust back tables that can handle 200+ pounds.

Here's what many people don't realize: it's not just about total weight. How that weight sits on your table matters enormously. Picture a heavy drill set concentrated in one corner versus instruments spread evenly across the surface. That concentrated load creates much higher stress points than the distributed weight, even if the total pounds are the same.

Tables with reinforcing ribs or H-braces handle these concentrated loads much better than simple flat surfaces. And don't forget about dynamic loads - when you're pushing a loaded table quickly across the OR floor, those forces can be significantly higher than the static weight alone.

Always choose tables with appropriate safety margins for your real-world usage patterns. A table rated at exactly your maximum load is cutting things too close for comfort.

Can I use the same prep table in an MRI suite?

This is a critical safety question, and the short answer is no - standard stainless steel prep tables are absolutely not safe in MRI environments. Those powerful magnetic fields can turn a regular prep table into a dangerous projectile, creating serious hazards for everyone in the room.

MR conditional prep tables are your only safe option for MRI suites. These specialized tables use non-ferrous materials like aluminum or specially formulated stainless steel alloys that won't interact with the magnetic field. Yes, they cost more than standard models, but there's simply no compromising on MRI safety.

Some facilities work around this by setting up prep areas outside the MRI suite, then transferring prepared instruments on non-magnetic trays. This approach lets you keep using your standard prep tables while maintaining strict MRI safety protocols. It requires more coordination, but it's a viable solution for many workflows.

How often should stainless prep tables be deep-cleaned?

Most facilities I work with have settled on weekly deep cleaning as their standard protocol, combined with daily cleaning between cases and immediate attention after any contamination event. But your specific situation might call for something different.

High-volume ORs or facilities handling particularly infectious cases often need more frequent deep cleaning. Some do it after every major case or at the end of each surgical day. The key is establishing consistent protocols and documenting everything for regulatory compliance.

When I say deep cleaning, I mean the full treatment: complete disassembly of removable components, thorough cleaning of all surfaces including those hidden areas, and careful inspection for wear or damage. This typically takes 30-45 minutes per table and should always be done by trained personnel using approved cleaning agents.

Remember to avoid chlorine bleach, which can cause pitting and corrosion over time. Stick with quaternary ammonium compounds or hydrogen peroxide-based cleaners designed specifically for medical equipment. Your tables will look better and last longer with proper care.

Conclusion

Finding the perfect prep table for sale operating room doesn't have to feel overwhelming. Throughout this guide, we've walked through everything from basic instrument tables to sophisticated height-adjustable systems, and one thing becomes clear: the right prep table transforms your surgical workflow in ways you'll notice immediately.

The investment in quality prep tables creates a ripple effect of improvements. Your staff experiences less fatigue thanks to proper ergonomics. Case turnover speeds up when instruments are organized efficiently. Infection control becomes more manageable with surfaces designed for repeated sterilization.

At American Mortuary Coolers, we've seen how the right equipment makes all the difference. While our specialty lies in mortuary equipment, the principles of durable construction and thoughtful design apply equally to OR environments. Our experience delivering custom solutions across the contiguous 48 states has taught us that every facility has unique needs.

Your prep table journey starts with honest assessment. Look at your current workflow bottlenecks - are staff members constantly adjusting their posture around fixed-height tables? Do you run out of prep space during complex procedures? These pain points guide you toward the features that matter most.

Weight capacity and construction quality separate professional-grade tables from budget alternatives. That orthopedic instrument set weighing 180 pounds needs a back table built to handle it safely, not a light-duty table that deflects under load.

Space constraints often drive the final decision more than ideal specifications. Nesting tables might not be your first choice, but they could be the perfect solution for a compact OR that needs flexibility.

The choice between new and remanufactured equipment deserves careful consideration. A remanufactured table with a solid warranty can deliver excellent value, especially for lower-volume facilities. High-volume ORs typically benefit from the reliability and full warranty coverage that comes with new equipment.

Accessories and add-ons shouldn't be afterthoughts. That over-shelf could eliminate the need for a second table. Drop-leaf extensions provide flexibility for complex cases without permanent footprint expansion.

Ready to move forward with confidence? Your facility's needs are unique, and the right prep table configuration should reflect that. Whether you need a single prep table for sale operating room or a complete system overhaul, the key is working with suppliers who understand that durability and functionality matter more than flashy features.

More info about prep room tables that make mortuary work easier explores similar principles from our mortuary expertise - the same attention to workflow efficiency and equipment durability that serves funeral homes well applies perfectly to OR environments.

Contact us to discuss how the right prep table setup can improve your surgical workflow. We're committed to helping you find solutions that work reliably for years to come, backed by the kind of customer service that makes equipment decisions feel less stressful and more strategic.