Why Choosing the Right Autopsy Sink Is Critical for Your Facility

An autopsy sink is a specialized stainless steel workstation designed for forensic pathology, morgue operations, and post-mortem examinations. These sinks provide essential fluid drainage, body cart integration, and ergonomic workspace features that standard sinks cannot offer.

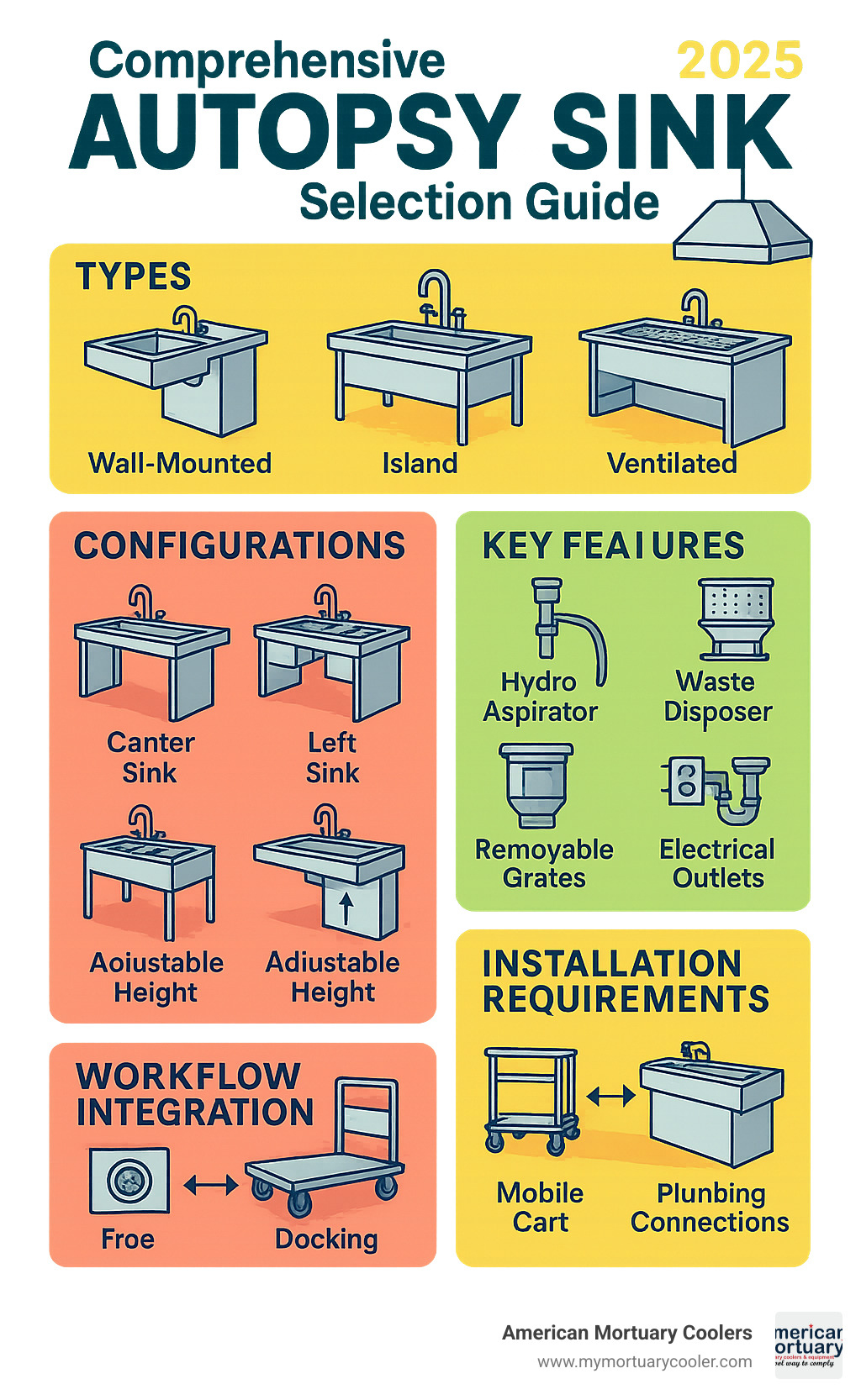

Key Autopsy Sink Features:

- Construction: 14-16 gauge Type 304 stainless steel

- Dimensions: 84-114" length, 28-31.5" width, 34-66" height

- Essential Components: Hydro aspirator, waste disposer (1/2 HP standard), GFCI outlets, removable grid plates

- Configurations: Wall-mounted, floor-mounted, center/left/right sink placement, adjustable height options

- Integration: Mobile cart docking systems with locking mechanisms

Modern autopsy sinks feature specialized components like reverse-flow hydro aspirators with 10-foot flexible hoses, commercial-grade waste disposers, and cart-to-sink locking systems that eliminate manual lifting during procedures.

The stakes are high when selecting mortuary equipment. A poorly chosen autopsy sink can disrupt workflows, create safety hazards, and fail to meet regulatory requirements. Conversely, the right system improves efficiency, ensures compliance, and provides decades of reliable service.

As Mortuary Cooler, a national-level mortuary cooler supplier, I've helped countless funeral homes and pathology labs select the perfect autopsy sink for their specific needs and space constraints.

Simple guide to autopsy sink terms:

Autopsy Sink Fundamentals: Definition, Function & Benefits

An autopsy sink serves as the command center of any forensic pathology lab, combining specialized fluid management with ergonomic design for post-mortem examinations. Unlike basic lab sinks, these units are built specifically for handling biological materials with every detail optimized for forensic work.

Autopsy sink primary function & workflow

The autopsy sink transforms complex specimen processing into smooth workflow through body drainage and fluid control and seamless cart integration. Mobile autopsy carts slide and lock into place over the sink basin, with cart overhangs directing fluids naturally into the drainage area without manual handling.

This cart-to-sink interface dramatically improves workflow efficiency. The locking mechanism is accessible from both sides, and adjustable heights (32-40 inches) provide ergonomic benefits for all staff members. Large radius inside corners accelerate cleaning and improve sanitation.

Key components of an autopsy sink

Autopsy sinks are engineered systems with integrated components. Construction uses 14-16 gauge Type 304 stainless steel with heliarc-welded seams for watertight, bacteria-resistant performance.

The hydro aspirator with reversing flow valve includes a 10-foot flexible hose and vacuum breaker for efficient waste removal. Commercial waste disposers (standard 1/2 HP, upgradeable to 1-2 HP) provide serious waste management capability.

Safety features include GFCI duplex electrical outlets with waterproof covers, back-siphon protection, and wrist-blade mixing valves for hands-free operation. Removable grid plates, vapor-proof LED lighting, instrument drawers, and 12-inch specimen shelves complete the workspace.

Autopsy sink vs embalming & scrub sinks

Autopsy sinks differ fundamentally from alternatives. Embalming sinks (60-84 inches) focus on body preparation but lack specialized cart integration. Scrub sinks (24-48 inches) handle basic cleaning without complex specimen processing capabilities.

The key distinction is cart integration and waste management. Autopsy sinks require heavy-duty disposers, specialized aspirators, multiple GFCI outlets, and vapor-proof lighting for complex specimen processing with maximum safety. Biohazard decontamination demands features like large-radius corners and removable components unavailable in standard sinks.

More info about autopsy tables that complement your sink selection perfectly.

Types & Configurations: Selecting the Right Autopsy Sink

Choosing the right autopsy sink configuration depends on your specific space and workflow requirements. After helping facilities nationwide, the best choice always matches your team's actual working patterns.

Autopsy sink configurations overview

Wall-mounted systems maximize floor space while providing full functionality. These units (84-114 inches long) bolt to load-bearing walls with center approach models (CC100, CC200) placing the basin centrally for dual-sided work surfaces.

Left and right approach configurations (CA100, CB100) optimize workflow around existing equipment. Dual approach systems (CC300) extend to 150 inches for simultaneous multi-technician operations.

Floor-mounted systems offer adjustable height flexibility (58.5-66.5 inches total height). Island configurations (CE800, CE850) create central command centers measuring 100" x 52" with 360-degree access.

Compact units at 84 inches maintain essential functionality while fitting tighter urban spaces.

How to choose an autopsy sink size

Standard autopsy sink dimensions range 84-114 inches long, 28-31.5 inches wide, and 34-66 inches high for adjustable models.

Space planning requires 36 inches clearance on all accessible sides for cart maneuvering. Ceiling height, door access, and utility connections need careful consideration during planning.

Traffic flow positioning minimizes interference while maintaining emergency egress routes. Staff ergonomics benefit from adjustable height systems accommodating users from 32-40 inches.

Optional accessories & emerging tech

Emergency eyewash stations provide immediate decontamination capability. Scale mounting systems integrate organ scales directly into sink setups. Hands-free controls using foot pedals reduce contamination risk.

Emerging technology includes UV sanitation systems, IoT sensors for environmental monitoring, integrated ventilation with downdraft systems, and digital documentation stations with waterproof interfaces.

Prioritize core functionality first - a well-designed basic autopsy sink that fits your workflow beats high-tech units that don't match actual needs.

More info about Prep Room Supplies that complement your autopsy sink setup.

Features, Customization & Workflow Integration

The perfect connection between your mobile autopsy cart and autopsy sink transforms facility workflow. When everything aligns properly, staff focus on important work instead of fighting equipment.

Integration with mobile autopsy carts

The autopsy sink cart integration eliminates manual specimen handling through smart design. CSI Jewett cart compatibility systems feature exclusive locking latches accessible from both sides for flexible positioning.

The overhang design extends carts directly over sink basins, creating perfect drainage alignment. Height coordination ensures seamless connections without gaps. The slide latch mechanism saves setup time - one installation reduced procedure preparation by 20 minutes per case.

Fluid containment becomes automatic with proper integration, preventing spills and cleanup headaches.

Ventilation, lighting & safety add-ons

Downdraft ventilation captures aerosols and odors at the source through 8" x 10" duct grilles with variable speed controls for different procedures.

Vapor-proof LED fixtures provide bright, even lighting designed for moisture and chemical exposure. Emergency backup systems ensure continuous operation during power outages.

GFCI protection, backflow preventers, and emergency controls provide behind-the-scenes safety protection.

Custom autopsy sink solutions

Every facility has unique challenges requiring thoughtful customization. Dimensional modifications solve space constraints - shorter sinks for tight spaces, height adjustments for low ceilings, or wider surfaces for expanded workspace.

Plumbing customization addresses building limitations through rerouted utility connections, multiple water sources (hot, cold, distilled), and improved drainage systems for high-volume operations.

ADA compliance features include accessible controls with lever handles and adjustable height systems for wheelchair users. Some facilities request branding integration for professional appearance.

Successful customization starts with proven standard configurations, modifying only where specific problems require solutions.

More info about the right autopsy sink for detailed selection guidance.

Planning, Installation, Maintenance & Compliance

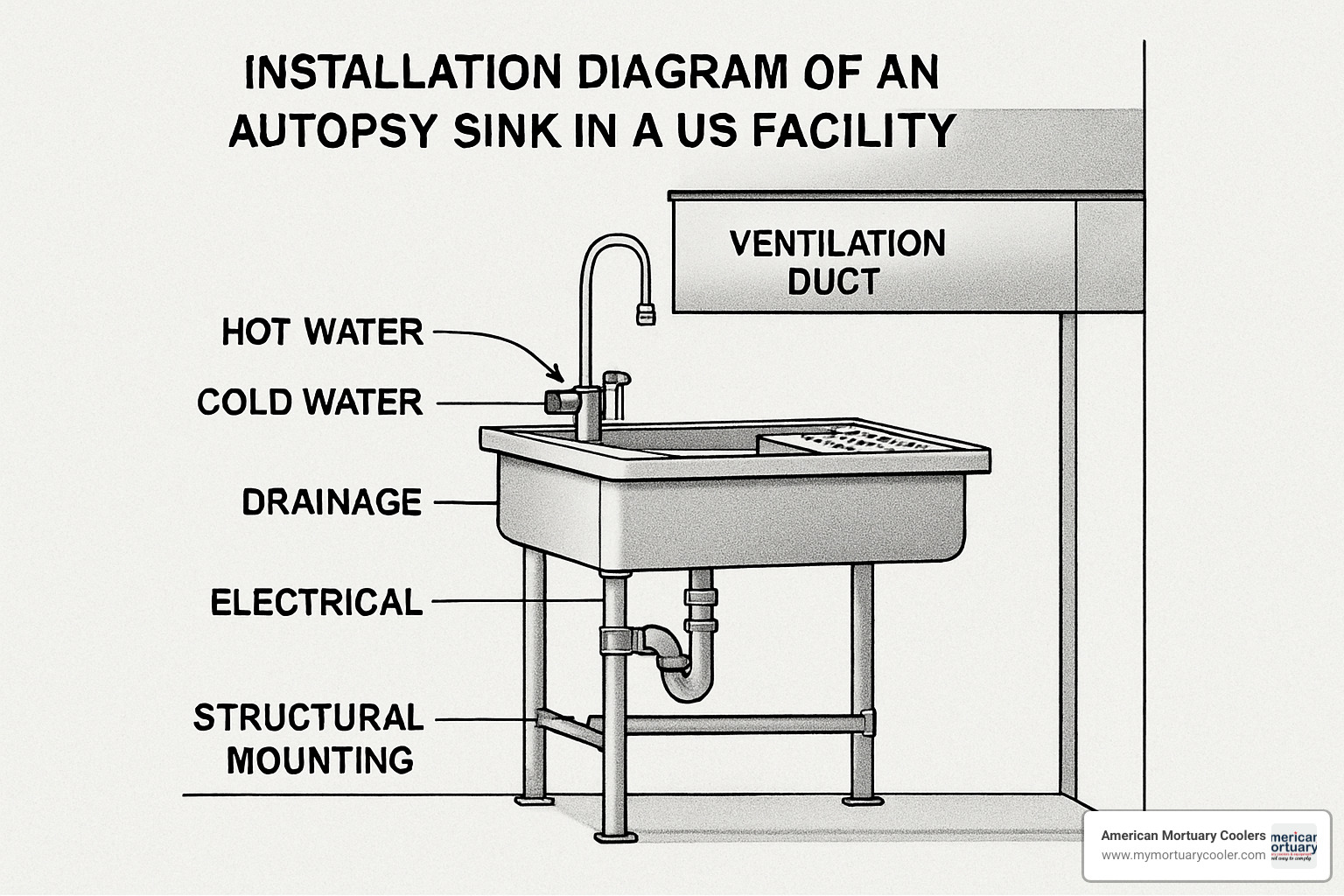

Proper autopsy sink installation requires thorough planning. Most installation problems are preventable with adequate preparation.

Installation prerequisites & best practices

Structural support is critical - wall-mounted autopsy sinks need load-bearing walls or reinforced mounting systems to handle static weight plus dynamic forces from cart docking and regular use.

Utility planning requires coordination between trades. Electrical requirements include 120V GFCI-protected circuits with waterproof covers. Water supply lines need minimum 40 PSI pressure. Drainage systems must handle volume and waste types. Ventilation connections are essential for safety and compliance.

Professional installation drawings from manufacturers show exact utility locations. Factory pre-installation of plumbing and electrical lines saves time and money while ensuring cleaner connections.

Cleaning, sanitation & infection control steps

Daily cleaning starts with removing specimens and debris, followed by initial hot water rinse before material sets. Detergent washing uses hospital-grade detergents for biological contamination, with special attention to corners.

Disinfection employs EPA-approved disinfectants following manufacturer concentration and contact time guidelines. Deep cleaning uses removable grid plates for drainage access and polypropylene components that can be autoclaved.

Hydro aspirator lines need periodic disinfectant flushing. Personal protective equipment including chemical-resistant gloves, eye protection, and fluid-resistant gowns is mandatory during cleaning.

Standards, certifications & staff training

NFPA 99 covers electrical safety, OSHA standards address bloodborne pathogens, and local codes govern plumbing and electrical requirements. UL listing for electrical components ensures safety compliance often required for insurance.

Staff training covers equipment operation, safety protocols, maintenance procedures, and regulatory compliance. Standard Operating Procedures provide consistency across shifts and staff changes.

Continuing education keeps staff current with evolving forensic pathology practices and regulatory changes.

Scientific research on infection control provides valuable insights into forensic laboratory safety protocols.

Frequently Asked Questions about Autopsy Sinks

Over the years, I've fielded countless questions from facility managers, pathologists, and funeral directors about autopsy sink selection and maintenance. These three questions come up most often, and the answers might surprise you.

What is the lifespan of a stainless-steel autopsy sink?

Here's the good news: a quality autopsy sink built from 14 or 16 gauge Type 304 stainless steel will likely outlast your mortgage. We're talking 20-30 years of reliable service with proper care, and I've seen units from the 1980s still going strong today.

The secret lies in that heliarc-welded construction and corrosion-resistant materials. Unlike cheaper alternatives that might rust or crack under pressure, these sinks are built to handle whatever forensic work throws at them.

Several factors influence how long your investment will last. High-volume facilities that process dozens of cases weekly might see slightly shorter lifespans, but we're still talking decades, not years. Water quality plays a bigger role than most people realize - hard water or unusual chemical exposure can accelerate wear on moving parts.

The biggest factor? Maintenance quality. Facilities that follow our recommended cleaning protocols consistently hit that 30-year mark, while those that skip regular care might need replacements closer to the 20-year range.

From our experience with American Mortuary Coolers installations across the country, the units that get proper daily cleaning and annual professional service are the ones still running perfectly after three decades of use.

Can an autopsy sink be retrofitted into a small prep room?

Absolutely, and I've helped dozens of facilities make this work. The key is choosing the right configuration and being realistic about what modifications you'll need.

Compact models measuring 84 inches work beautifully in spaces where the standard 114-inch units won't fit. We've successfully installed these in prep rooms that seemed impossibly small at first glance.

The biggest challenge isn't space - it's usually the infrastructure. Wall reinforcement becomes necessary for wall-mounted units because existing prep rooms weren't designed to support these loads. Floor-mounted units often solve this problem neatly since they don't stress the walls.

Utility modifications are almost always required. Your existing electrical, plumbing, and ventilation systems probably weren't designed for autopsy sink requirements. The good news is that these upgrades often improve the entire prep room's functionality.

Space planning matters more in retrofits than new construction. You need those minimum 36-inch clearances for cart maneuvering, and there's no negotiating with physics. Adjustable height models provide extra flexibility when you're working within tight constraints.

One thing to watch for: retrofits sometimes trigger additional code compliance requirements that can add unexpected costs. Check with your local authorities before finalizing plans.

How often should the hydro aspirator and waste disposer be serviced?

Think of these components like the engine in your car - regular maintenance prevents expensive breakdowns and keeps everything running smoothly.

For the hydro aspirator, I recommend a simple monthly inspection of the hoses for wear or blockages. It takes five minutes and can save you from major headaches later. Quarterly cleaning of the vacuum breaker keeps the system operating efficiently, and an annual professional inspection catches problems before they become emergencies.

The waste disposer needs more attention because it works harder. Weekly cleaning with cold water and ice keeps the blades sharp and removes buildup. This old trick works better than any commercial cleaner I've tried.

Monthly inspections for leaks or unusual noise help you catch problems early. That grinding sound isn't normal, and addressing it quickly usually means a simple repair instead of complete replacement.

Annual professional service including blade sharpening extends the life significantly. Most facilities skip this step and end up replacing disposers every 3-4 years instead of the 5-7 years they should last.

The standard 1/2 HP disposers typically need replacement every 5-7 years under normal use. If you upgrade to 1 HP or 2 HP units, they last longer but require more frequent professional attention due to their complexity.

Here's what I tell all my clients: regular maintenance prevents emergency repairs. That middle-of-the-night service call costs ten times more than scheduled maintenance, and it always happens at the worst possible moment.

Conclusion & Next Steps

Choosing the right autopsy sink means investing in your facility's future. The decision you make today impacts operations for the next 20-30 years, making understanding fundamentals crucial.

What makes the difference? Three critical factors: proper sizing for your space and workflow, quality construction that withstands daily use, and professional installation ensuring everything works as designed. The 84-114 inch length options accommodate most facilities, while 14-16 gauge stainless steel construction provides necessary durability.

Your facility is unique, and your autopsy sink should reflect that. Custom solutions address challenges standard equipment can't handle. Cart docking systems eliminate manual transfers, while proper ventilation integration keeps staff safe.

At American Mortuary Coolers, we understand these challenges. Based in Tennessee with delivery across all 48 contiguous states, we've helped facilities from small rural funeral homes to major metropolitan morgues find perfect solutions. Our focus on durable, custom equipment means you get exactly what you need.

Ready to move forward? Start by assessing current workflow challenges. Are staff struggling with manual lifting? Is cleaning taking too long? These frustrations point to features that matter most for your situation.

The planning phase is crucial. Work with professionals who understand technical requirements and day-to-day forensic pathology realities. Proper utility planning, structural considerations, and code compliance determine installation success.

Integration matters. Your autopsy sink works alongside existing equipment and workflows. Consider connections with mobile carts, ventilation systems, and overall facility design. The best installations feel seamless because components work together.

Don't rush this decision. Visit other facilities, talk to daily users, and ask detailed maintenance questions. Extra evaluation time pays dividends for decades.

More info about operating tables that complement your autopsy sink installation.

Your investment in quality mortuary equipment reflects commitment to professional excellence. The right autopsy sink supports staff, improves efficiency, and maintains highest safety standards. Choose thoughtfully with experienced professionals - you're investing in long-term success.