Why Autopsy Sinks Are Critical to Modern Pathology Operations

Autopsy sinks are specialized stainless steel workstations designed for post-mortem examinations in pathology labs, medical examiner offices, and funeral homes. These units integrate drainage, water controls, aspirators, and safety features to support hygienic specimen processing while protecting staff from biohazards.

Key autopsy sink components include:

- Stainless steel construction with heliarc-welded seams for easy sanitation

- Hydro-aspirators with vacuum breakers for fluid removal

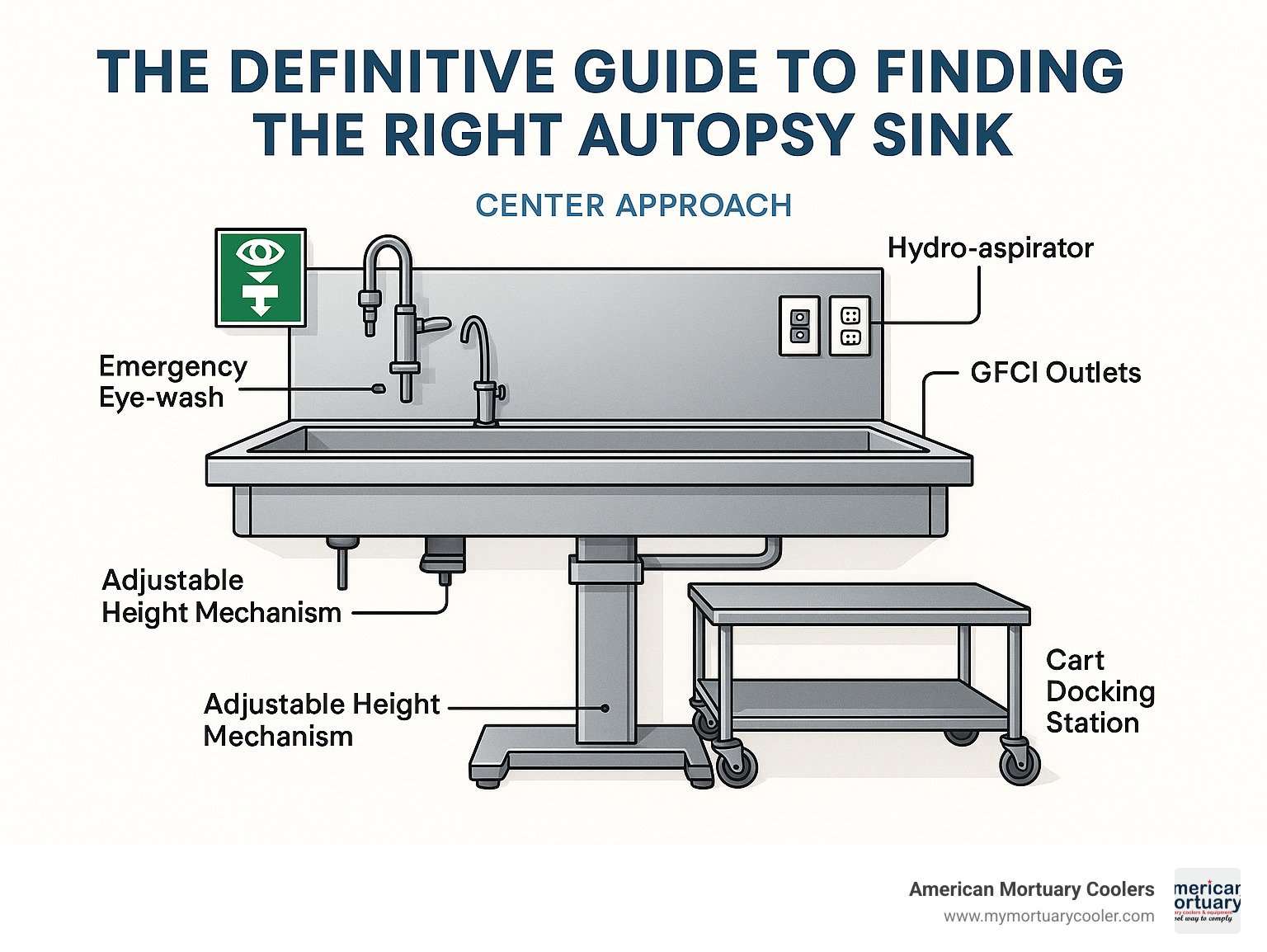

- Height-adjustable frames (typically 58-66 inches) for ergonomic workflow

- Cart-integration systems that eliminate body lifting during transfers

- Multiple configurations - wall-mounted, floor-mounted, center/left/right approach

- Safety features - GFCI outlets, emergency eye-wash stations, splash guards

Whether you're planning a new facility or upgrading existing equipment, autopsy sinks must balance functionality, safety compliance, and workflow efficiency. Modern units can be as large as 114 inches long and include features like interchangeable grid plates, instrument drawers, and integrated ventilation systems.

The right autopsy sink configuration depends on your caseload, room layout, and specific procedural requirements. Wall-mounted units save floor space, while elevating models reduce staff injury from repetitive lifting. Custom builds typically require 6-8 weeks for production and delivery.

Glossary for autopsy sinks:

Why This Guide Matters

Pathology labs, medical examiners, and funeral homes rely on properly designed autopsy sinks to maintain infection control standards while conducting thorough post-mortem examinations. The wrong sink configuration can lead to workflow bottlenecks, staff injuries from improper lifting, and potential contamination issues that compromise both safety and examination quality.

Understanding Autopsy Sinks: Role & Function

Autopsy sinks serve as the command center of any post-mortem examination room. While drainage might seem like their main job, these specialized workstations actually juggle multiple critical functions that keep pathology operations running smoothly and safely.

When pathologists and medical examiners conduct examinations, they need everything within arm's reach - reliable water flow, efficient drainage, proper lighting, and safety equipment. That's exactly what modern autopsy sinks deliver, all wrapped up in a single, easy-to-clean stainless steel package.

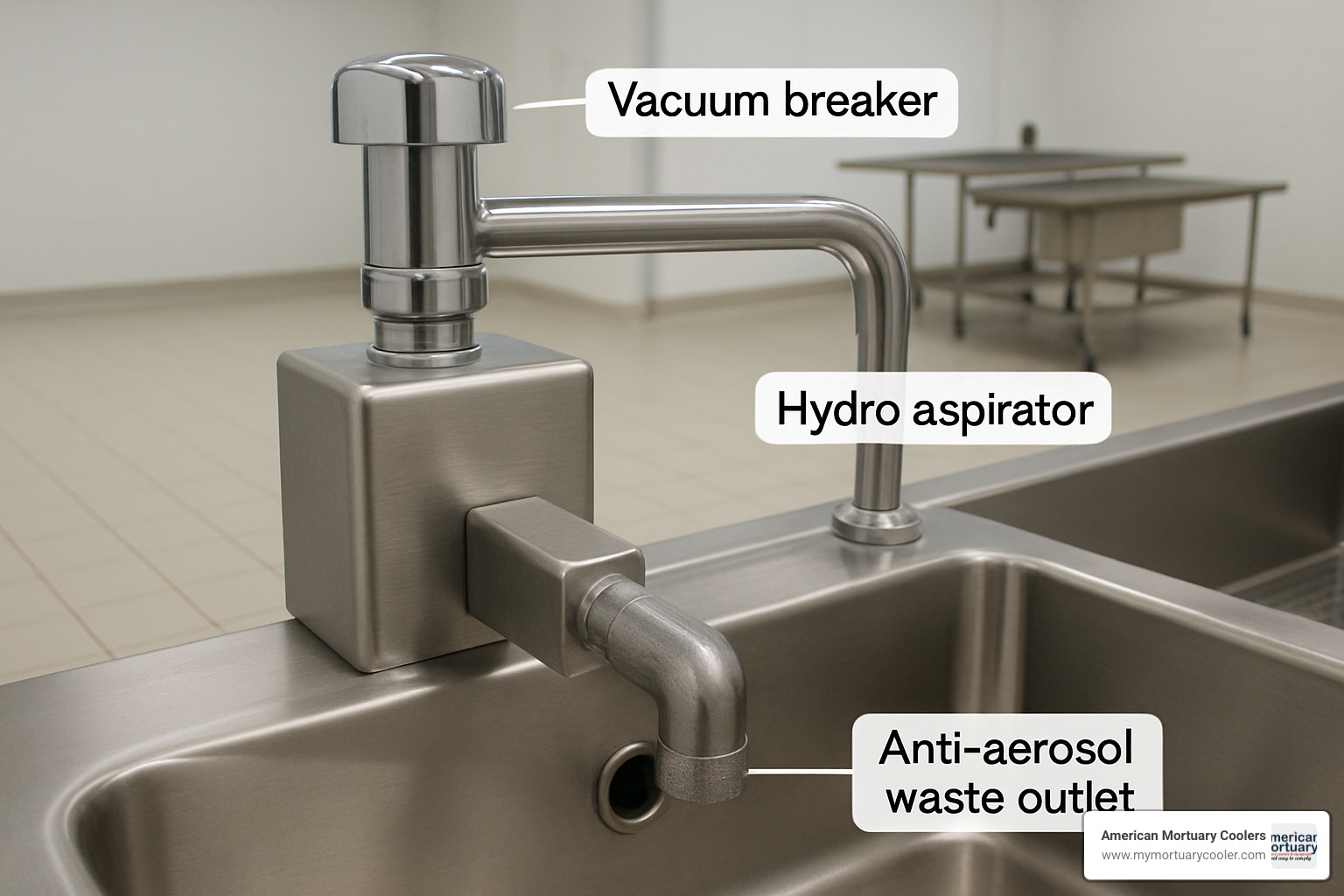

Water control and drainage systems form the backbone of every autopsy sink. The hydro-aspirator system handles fluid removal while preventing dangerous aerosols that can spread contamination. Reversing flow valves and vacuum breakers work together to manage water pressure and keep everything flowing in the right direction.

Ventilation integration keeps the air clean and safe for everyone in the room. Many sinks include built-in ventilation grilles that connect to your facility's negative pressure system. This setup contains airborne contaminants right at the source, protecting staff while maintaining specimen integrity.

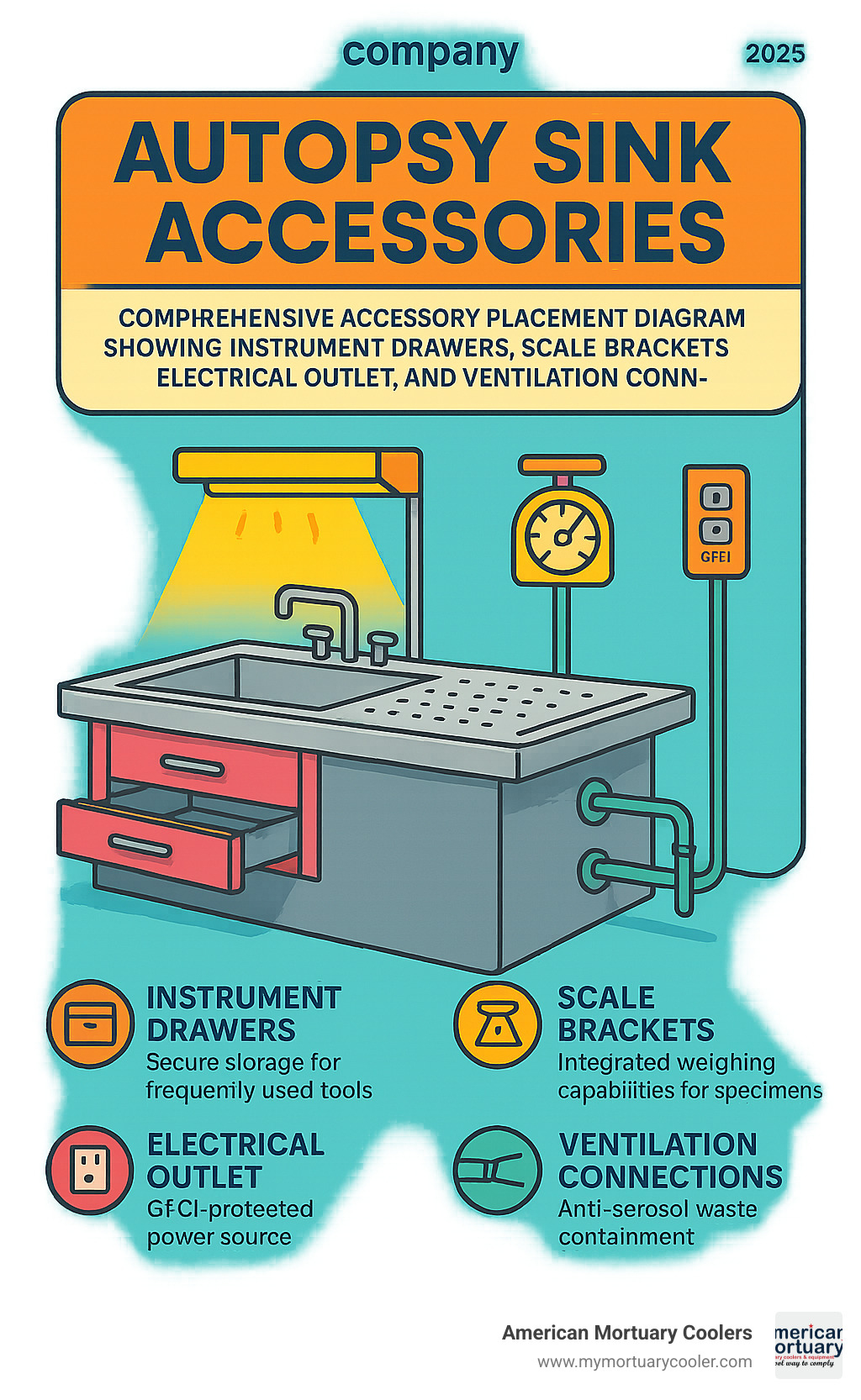

Safety features protect your team from both electrical and chemical hazards. GFCI outlets prevent electrical accidents in wet environments, while emergency eye-wash stations provide immediate response capability. Splash guards contain fluids where they belong, and anti-aerosol waste outlets prevent contamination during drainage procedures.

For comprehensive examination protocols, the Postmortem external & macroscopic examination guidelines outline the procedural standards that quality autopsy sinks must support.

How Autopsy Sinks Fit Into the Post-Mortem Process

Modern autopsy sinks have revolutionized body transfer with smart cart-integration systems that eliminate manual lifting entirely. Cadaver trolleys dock directly with the sink using specialized latching mechanisms that secure mobile tables from either side without loosening over time.

No-lift designs have been a game-changer for pathology staff who handle multiple cases daily. Cart overhangs align perfectly with sink drainage systems, ensuring proper fluid flow while reducing physical strain. Your team's backs will thank you, and workflow efficiency improves dramatically.

Autopsy Sinks and Facility Workflow

Specimen handling becomes effortless when your sink is designed with ergonomics in mind. Height-adjustable work surfaces accommodate different staff heights and various procedural requirements. Most systems offer elevating ranges from 58 to 66 inches, supported by heavy-duty frames that handle the weight of equipment and specimens.

ADA accessibility requirements don't have to complicate your facility design. Modern autopsy sinks can be configured with appropriate clearances and control positioning that meet accessibility standards while maintaining full functionality.

Types & Configurations of Autopsy Sinks

When selecting autopsy sinks for your facility, you'll encounter several configuration options designed to match different room layouts and workflow requirements. The beauty of modern autopsy sink design lies in this flexibility - there's genuinely a configuration that works for every space and procedural need.

The two primary mounting approaches each offer distinct advantages. Wall-mounted units maximize floor space efficiency, making them perfect for smaller facilities or rooms where every square foot counts. Floor-mounted systems provide greater weight capacity and easier maintenance access, though they require more room to operate effectively.

Mounting Method Comparison:

| Feature | Wall-Mounted | Floor-Mounted |

|---|---|---|

| Floor Space | Minimal footprint | Larger footprint |

| Installation | Requires wall reinforcement | Independent support |

| Mobility | Fixed position | Some models adjustable |

| Capacity | Standard load limits | Higher weight capacity |

| Cost | Generally lower | Higher initial cost |

| Maintenance | Wall access needed | Full access |

Beyond mounting style, sink positioning plays a crucial role in workflow efficiency. Center approach configurations place the sink in the middle with drainboards flanking both sides - ideal for facilities handling multiple specimens simultaneously. Left or right approach designs position the sink to one side, creating a more linear workflow that many pathologists prefer for standard examinations.

Wall-Mounted Autopsy Sinks

Wall-mounted autopsy sinks represent the space-saving champions of pathology equipment. These units deliver full examination functionality while maintaining remarkably compact footprints - a game-changer for facilities working with limited square footage.

Popular wall-mounted configurations include the SR1910-30 model, measuring 114″ x 28″ x 42″ with a 30″ x 22″ sink and dual drainboards. For slightly smaller spaces, the SR1910-31 offers an 84″ x 28″ x 42″ footprint with a single drainboard configuration.

Both systems include 8-foot stainless steel spray hoses and 10-foot PVC aspirator hoses, providing the reach and flexibility needed for thorough specimen handling. Installation does require proper wall reinforcement to handle the combined weight of the sink, fluids, and specimens.

Elevating Autopsy Sinks for Ergonomics

Elevating autopsy sinks tackle one of pathology's most persistent challenges - protecting staff from repetitive strain injuries caused by improper working heights. These systems transform the examination environment by providing height adjustment from 58 to 66 inches, accommodating different staff heights and varying procedural requirements.

The no-lift transfer capability represents perhaps the most significant advancement in pathology workflow efficiency. Elevating sinks coordinate perfectly with cadaver trolley heights, eliminating the manual lifting that once defined body transfers. The cart overhang design ensures proper fluid drainage while maintaining optimal ergonomic positioning throughout examination procedures.

Combination Autopsy/Embalming Stations

Combination autopsy/embalming stations serve facilities that need maximum versatility from their equipment investment. These comprehensive units merge autopsy sink functionality with embalming-specific features, creating a single workstation capable of handling diverse post-mortem procedures.

The MOBI Autopsy/Embalming Station exemplifies this dual-purpose approach. Constructed with 304 stainless steel and heliarc welding, these built-to-order units allow complete customization for specific prep room layouts. The 6-8 week production timeline reflects the detailed engineering required to integrate multiple systems seamlessly.

For facilities evaluating different station configurations, More info about comparing stations provides detailed analysis of the various options available and their respective advantages.

Key Features & Modern Innovations

Today's autopsy sinks have evolved from simple drainage basins into sophisticated workstations that integrate cutting-edge materials, safety systems, and workflow innovations that make post-mortem examinations safer and more efficient for pathology staff.

304 stainless steel construction forms the backbone of quality autopsy sinks, providing exceptional resistance to harsh chemicals and biological materials encountered daily. Heliarc welding creates smooth, seamless joints that make thorough sanitation possible between cases.

Advanced hydro-aspirators now feature reverse-flow capability with built-in vacuum breakers, while anti-aerosol outlets prevent contamination during waste removal. GFCI outlets provide essential electrical protection in wet environments, and emergency eye-wash stations offer immediate decontamination when staff need it most.

Modern workflow features include interchangeable grid plates (up to four removable sections), LED lighting systems for energy-efficient illumination, and integrated ventilation plenums that coordinate with facility air handling systems.

Materials & Construction Essentials

The difference between a good autopsy sink and a great one often comes down to construction quality. 304 stainless steel has become the gold standard because it stands up to daily exposure to formaldehyde, bleach solutions, and other aggressive cleaning agents without corroding or staining.

Heliarc welding creates perfectly smooth seams with no gaps, no crevices, no places for bacteria to hide. The polished finish prevents bacterial accumulation and makes daily cleaning much more effective. Reinforced framework supports not just the sink itself, but all the equipment and specimens you'll use during procedures.

Safety & Compliance Upgrades

Safety regulations have driven important innovations in autopsy sinks. Vacuum breakers prevent backflow contamination - a critical feature when dealing with potentially infectious materials. Anti-aerosol drain systems contain hazardous particles during fluid removal, protecting both immediate staff and facility air quality.

OSHA compliance requires GFCI protection for all electrical connections in wet environments. Emergency eye-wash stations provide immediate decontamination capability when staff are exposed to chemicals or biological materials during procedures.

Smart Accessories & Tech Add-Ons

Contemporary autopsy sinks can be equipped with accessories that genuinely improve daily workflow. Instrument drawers keep frequently used tools organized and immediately accessible during procedures. Scale brackets enable integrated specimen weighing without requiring separate equipment or additional workspace.

Waste disposers handle organic materials safely and efficiently, reducing manual waste handling and associated contamination risks. Advanced ventilation integration includes plenums and ductwork connections that coordinate seamlessly with facility HVAC systems.

Selecting the Right Autopsy Sink for Your Facility

Choosing the right autopsy sinks for your facility comes down to asking the right questions upfront. Your room size sets the foundation for everything else. A cramped space might force you toward wall-mounted units, while a spacious facility opens up possibilities for elevating systems with full cart integration.

Your case volume matters just as much. A facility handling three cases per week has very different needs than one processing twenty. The regulatory landscape adds another layer of complexity. Custom builds offer the perfect solution when standard configurations fall short, but they require patience. Most custom autopsy sinks need 6-8 weeks for production, plus shipping time.

For facilities also considering autopsy tables, our Autopsy Tables: In-Depth Analysis of Design and Functionality in Forensic Pathology guide provides comprehensive comparisons to help coordinate your equipment selection.

Space Planning & Layout

Your facility's mechanical systems will largely dictate where your autopsy sinks can go. Plumbing connections, electrical supply, and ventilation requirements aren't flexible - they're facts you'll need to work around. The smart approach starts with mapping these constraints before falling in love with a particular sink configuration.

Clearance requirements matter more than most people realize. You need at least 36 inches of open space around your sink for staff movement and cart maneuvering. Tight spaces create bottlenecks that slow down procedures and increase accident risk.

Compliance Checklist Before You Buy

Regulatory compliance for autopsy sinks involves multiple agencies with overlapping requirements. The CDC provides infection control guidelines that form the foundation of safe autopsy practices. OSHA adds workplace safety requirements that affect everything from electrical systems to emergency equipment.

State and local codes often impose the most restrictive requirements. International guidelines like the WHO Recommendations for conducting an external inspection of a body and filling in the Medical Certificate of Cause of Death provide additional context for facilities handling diverse cases.

Budgeting for Custom Builds & Lead Times

Custom autopsy sinks offer the perfect solution when standard configurations don't meet your needs, but they require careful financial planning. Base unit costs vary significantly based on size, configuration, and included features. Customization fees apply to any non-standard specifications.

The 6-8 week production timeline for custom builds means you'll need to plan ahead. Installation requires professional expertise to ensure proper connections to plumbing, electrical, and ventilation systems. The investment in quality autopsy sinks pays dividends over time through improved workflow efficiency, reduced maintenance costs, and improved staff safety.

Cleaning, Maintenance & Infection Control

Keeping your autopsy sinks clean and well-maintained isn't just about following rules - it's about protecting your staff and ensuring every examination meets the highest standards. Daily decontamination goes beyond basic cleaning. Enzymatic cleaners work differently than regular detergents, actually breaking down proteins and organic materials that stick to surfaces.

Modern autopsy sinks make this easier with built-in flush systems. The cold-water flush under dissecting trays lets you wash away debris immediately, preventing buildup that becomes harder to remove later.

For broader facility planning that supports infection control, check out A Comprehensive Guide to Mortuary Prep Rooms.

Step-by-Step Cleaning Protocol

The key to effective cleaning is consistency and thoroughness. Daily cleaning starts with a cold water rinse to remove gross debris. Hot water can actually set proteins, making them harder to remove later. Follow with enzymatic cleaner, allowing proper contact time.

Scrubbing requires the right tools for stainless steel surfaces. Avoid abrasive materials that can scratch and create hiding places for bacteria. After thorough scrubbing, apply EPA-approved disinfectant according to manufacturer instructions.

Final rinsing removes all cleaning residues, which is crucial because some disinfectants can leave films that interfere with future cleaning. Documentation helps identify patterns or problems. Record cleaning procedures, any maintenance issues, and unusual observations.

Preventive Maintenance to Extend Lifespan

Regular maintenance prevents expensive repairs and downtime that can disrupt your operations. Monthly maintenance tasks include checking all seals for wear, cracking, or displacement. Hose examinations should look for cracks, bulges, or deterioration that could lead to sudden failures.

Electrical safety checks are critical in wet environments. Verify GFCI function monthly and inspect outlets for any signs of corrosion or damage. Professional service contracts provide access to qualified technicians who understand the specific requirements of autopsy sinks.

Infection-Control Best Practices Around Autopsy Sinks

Negative pressure room systems work hand-in-hand with your autopsy sink to contain airborne contaminants. The sink's ventilation features should coordinate with room air circulation to draw contaminated air away from staff breathing zones.

Staff training ensures everyone understands how to use sink safety features properly. Personal protective equipment must be appropriate for all procedures, not just examinations. Surface decontamination should happen immediately after spills or splashes.

Frequently Asked Questions about Autopsy Sinks

When helping facilities choose the right autopsy sinks, we hear the same questions repeatedly. These are the three most important ones that can make or break your decision.

What size autopsy sink do I need for my caseload?

This is hands-down the most common question we get, and honestly, it's the most important one to get right. Nothing's worse than installing a sink that's too small and realizing you need more space when you're swamped with cases.

Start with your peak volume, not your average. If you typically handle 2-3 cases daily but sometimes get hit with 5-6 during busy periods, plan for those busy days. A cramped workspace during peak times creates stress and safety issues that nobody wants to deal with.

For facilities processing 1-3 cases daily, an 84-inch unit usually provides enough workspace without overwhelming smaller prep rooms. But if you're regularly handling 5+ cases daily or need space for multiple simultaneous procedures, you'll want to consider the 114-inch units or even multiple sink installations.

Room size ultimately makes the final call, though. Remember to leave at least 36 inches of clearance around your autopsy sinks for cart movement and staff access. We've seen too many facilities squeeze in oversized units only to create workflow nightmares.

How often should the hydro-aspirator be serviced?

The hydro-aspirator is the workhorse of your autopsy sink system, so keeping it running smoothly is crucial. Monthly visual inspections should be part of your routine - check for proper suction, listen for unusual noises, and examine hose condition.

Any drop in suction power or strange sounds means it's time for immediate attention. Don't wait until it fails completely during a procedure.

Professional service every six months keeps everything running at peak performance. This includes checking the vacuum breaker operation, cleaning internal passages, and replacing worn seals before they start leaking. It's much cheaper than emergency repairs when something breaks down unexpectedly.

Daily cleaning of the external components and hoses prevents organic buildup that can reduce efficiency and create contamination risks. Use only manufacturer-approved cleaning agents - some chemicals can damage internal components and void your warranty.

Can autopsy sinks be retrofitted with eye-wash stations?

The short answer is usually yes, but it depends on your specific sink design and existing plumbing setup. Most modern autopsy sinks can accommodate emergency eye-wash stations with the right modifications.

Wall-mounted sinks typically require more extensive plumbing work since you'll need to run additional water lines and ensure proper drainage. Floor-mounted units offer more flexibility because there's usually better access to plumbing connections.

Here's the important part: any eye-wash station must meet ANSI Z358.1 standards for flow rate, temperature, and accessibility. This isn't optional - it's a safety requirement that could save someone's vision.

Professional installation is non-negotiable for retrofit eye-wash stations. The water pressure, temperature mixing, and drainage all need to work perfectly without interfering with your existing sink functions. Some older sink designs might need significant modifications to meet modern safety standards.

We always recommend having a qualified professional evaluate your current setup before committing to a retrofit. Sometimes it makes more sense to upgrade to a new unit with integrated safety features rather than modifying an older system.

Conclusion

Choosing the right autopsy sinks might seem overwhelming at first, but it really comes down to understanding your facility's specific needs and planning ahead. The good news is that a quality sink isn't just an expense—it's an investment that transforms how your team works every single day.

We've seen countless facilities struggle with outdated equipment that slows down procedures and puts staff at risk. But when you get the right autopsy sinks in place, everything changes. Your team moves more efficiently, safety improves dramatically, and the whole workflow just flows better.

Modern autopsy sinks have come a long way from basic drainage systems. Today's units are like command centers that handle everything from fluid management to specimen processing, all while keeping your staff safe and comfortable. Whether you need a compact wall-mounted unit to maximize floor space or a full elevating system to protect your team's backs, there's a configuration that fits your exact situation.

Yes, custom builds take 6-8 weeks to complete, which means you need to plan ahead. But here's the thing—that wait time is worth it when you get equipment that's built specifically for how your facility operates. Standard units might seem faster, but they often leave you working around limitations instead of working efficiently.

The installation process matters just as much as the equipment itself. Professional installation ensures everything connects properly to your plumbing, electrical, and ventilation systems. More importantly, it protects your warranty and gives you confidence that everything will work as intended from day one.

At American Mortuary Coolers, we've helped facilities across Tennessee and throughout the contiguous 48 states find their perfect autopsy sink solution. Every facility is different, and we've learned that taking time to understand your specific workflow, space constraints, and future plans leads to much better outcomes than rushing into a quick decision.

The right autopsy sink doesn't just improve your current operations—it positions your facility for future growth and changing regulations. When you invest in quality equipment now, you're setting up your team for success for years to come.

Ready to explore how the right mortuary equipment can transform your entire facility? Check out our More info about mortuary cooler solutions to see how integrated design can optimize every aspect of your operation.