Why Modern Funeral Homes Need Casket Lifting Devices

A casket lifting device is specialized equipment designed to safely raise, lower, and transport caskets and remains in funeral homes, morgues, and cemeteries. These devices eliminate the need for manual lifting and reduce workplace injuries while improving operational efficiency.

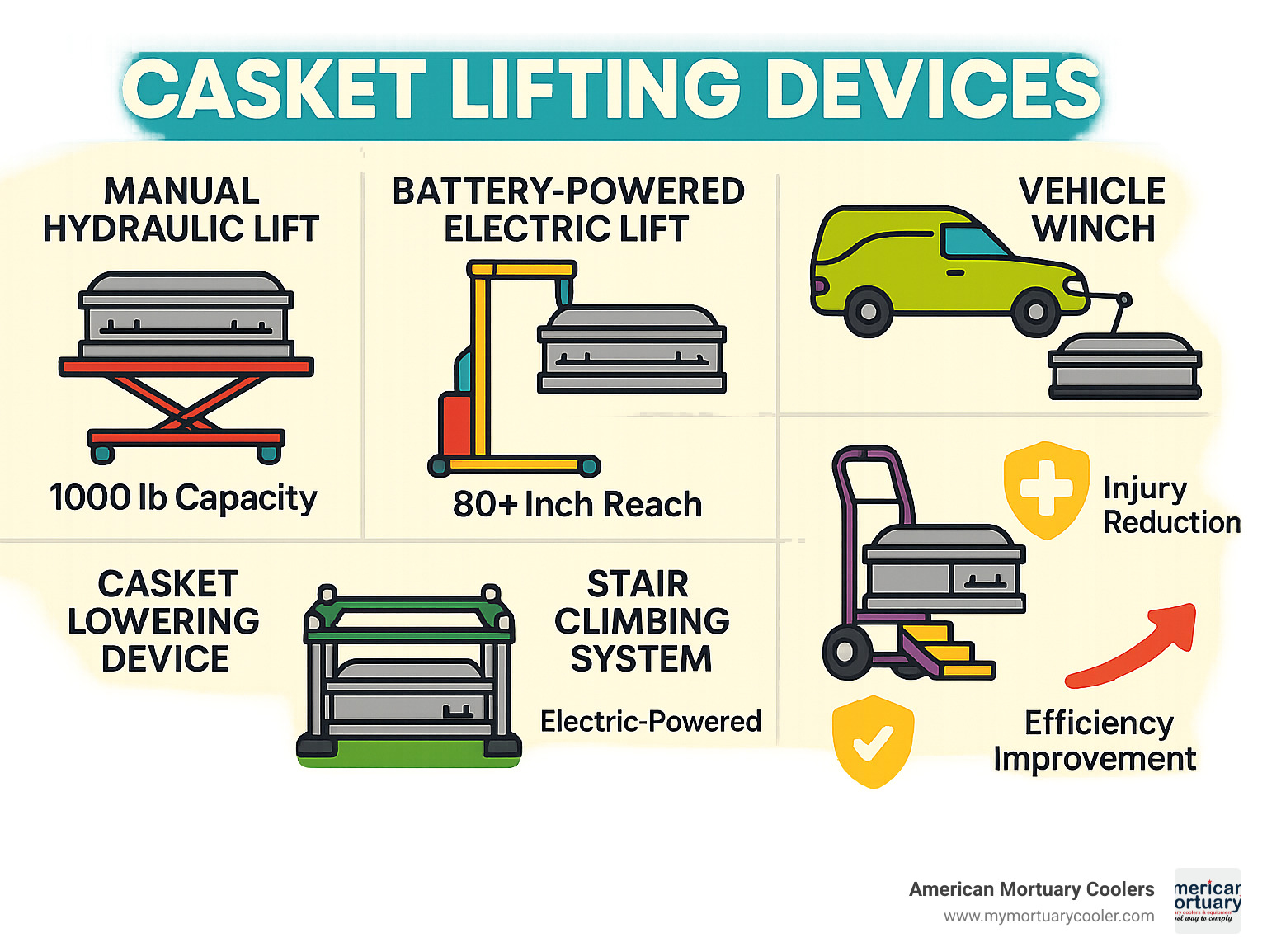

Key Types of Casket Lifting Devices:

- Manual hydraulic lifts - Hand-pump operated, 1000 lb capacity

- Electric/battery-powered lifts - Remote controlled, up to 80+ inch reach

- Vehicle winches - For loading/unloading from hearses and vans

- Casket lowering devices - For graveside ceremonies, 360-999 lb capacity

- Stair climbing systems - Electric-powered for multi-level transport

The funeral industry has used these specialized lifting systems for over 50 years, with modern devices handling weights from 750 lbs to 6,000 lbs. Battery-powered models can reach heights up to 80+ inches, while the LoadAlone device allows one person to safely handle mortuary cargo weighing over 600 pounds.

Benefits include:

- Reduced staff injury risk and liability costs

- Single-operator capability for most tasks

- Improved workflow efficiency in prep rooms

- Improved dignity during burial ceremonies

As we've worked extensively with funeral home directors nationwide to specify the right casket lifting device solutions for their unique space and operational needs, our experience has shown that the right lifting equipment can transform both staff safety and service quality in mortuary operations.

Handy casket lifting device terms:

What Is a Casket Lifting Device and Why It Matters

Think of a casket lifting device as your funeral home's silent partner – the piece of equipment that transforms back-breaking work into smooth, dignified operations. These specialized machines handle the heavy lifting (literally) so your staff can focus on what matters most: caring for families during their most difficult moments.

At its heart, a casket lifting device does exactly what the name suggests: it safely lifts, lowers, and moves caskets and remains throughout your facility. Whether you're working in a prep room, moving between floors, or loading a hearse, these devices eliminate the dangerous guesswork of manual lifting.

The magic happens through vertical transport capabilities that can raise loads to optimal working heights. No more hunching over low surfaces or straining to reach awkward positions. Prep-room workflow becomes a one-person operation instead of requiring multiple staff members to coordinate every move.

For cemetery handling, these devices maintain dignity during services while protecting your team from injury. We've seen funeral directors transform their operations simply by investing in the right lifting solution – suddenly, tasks that once required careful planning and multiple people become routine, safe procedures.

Core Components of a Casket Lifting Device

Every reliable casket lifting device starts with a sturdy foundation. The mast or scissor frame forms the backbone, engineered to handle serious weight – we're talking anywhere from 750 to 6,000 pounds depending on your needs.

The platform serves as your workhorse surface, typically measuring 36" to 48" wide by 96" long. This gives you plenty of room for standard caskets and those oversized models that seem to appear more frequently these days.

Power comes from either hydraulic pumps for manual operation or electric actuators for push-button convenience. Manual systems use hand pumps – perfect when you need portability. Electric models offer remote control operation, which feels pretty futuristic until it becomes part of your daily routine.

Safety interlocks act like your equipment's conscience, preventing operation when gates aren't properly secured. Meanwhile, rollers built into the platform make moving heavy loads feel surprisingly effortless across your floors.

How a Casket Lifting Device Improves Safety & Efficiency

Here's where things get interesting – and frankly, where your workers' compensation insurance company will thank you. Reduced manual lifting isn't just about comfort; it's about protecting your team's long-term health and your business's bottom line.

Scientific research on lift safety shows dramatic reductions in back injuries when facilities switch from manual to mechanical lifting. We've worked with funeral homes across Tennessee, Georgia, and Illinois who've seen their injury claims practically disappear after installing proper lifting equipment.

OSHA compliance becomes much more straightforward when you're not asking staff to repeatedly lift hundreds of pounds manually. These devices help you meet ergonomic standards while keeping everyone safer.

The single-operator use capability might be the biggest game-changer. Tasks that once required coordinating multiple people's schedules now happen smoothly with one person. This flexibility translates to real efficiency gains and liability savings that add up quickly over time.

Your staff will notice the difference immediately, and families will appreciate the increased professionalism that comes with smooth, dignified handling throughout their service experience.

Types of Casket Lifting Devices & How They Work

Choosing the right casket lifting device feels overwhelming when you first see all the options available. But here's the good news - each type is designed for specific situations, making your decision much clearer once you understand what you actually need.

Think of it like choosing a vehicle. You wouldn't use a sports car to haul furniture, and you wouldn't pick a moving truck for a quick trip to the grocery store. Casket lifting devices work the same way - each type excels in particular situations.

From our years of helping funeral homes across the country, we've learned that most directors need one primary type for daily operations, plus maybe a specialized device for specific challenges like vehicle loading or outdoor ceremonies.

| Type | Power Source | Capacity | Best Use Case |

|---|---|---|---|

| Manual Hydraulic | Hand pump | 1000 lbs | Portable prep room use |

| Electric/Battery | 12V DC | 900-1000 lbs | Fixed installation with remote control |

| Vehicle Winch | 12V DC | 600-1000 lbs | Loading/unloading from vehicles |

| Lowering Device | Mechanical/Gravity | 360-999 lbs | Graveside ceremonies |

Manual & Hydraulic Scissor Lifts

Manual hydraulic lifts are the workhorses of the funeral industry. If you need something reliable that doesn't require electricity and can move anywhere in your facility, this is your answer.

These casket lifting devices use a simple hand pump system that makes lifting 1,000 pounds feel effortless. The double scissor design provides rock-solid stability, while the low-profile frame can squeeze into tight spaces - some models drop to just 13.5 inches high.

What makes these units special is their portability. Need to move from the prep room to the vehicle bay? No problem. The nine swivel casters roll smoothly through doorways, and you don't need to worry about finding electrical outlets or charging batteries.

The washable nylon web straps and adjustable carriages handle different casket sizes without fuss. Many funeral directors tell us these manual units become their go-to choice because they're always ready to work, regardless of power outages or electrical issues.

Electric & Battery-Powered Casket Lifting Device Options

Electric models bring convenience and precision that manual pumps simply can't match. These 12V DC systems operate quietly and smoothly, with remote control operation that lets you position caskets exactly where you need them.

The 80-inch reach capability makes these perfect for high-capacity prep rooms or facilities with liftd storage areas. Battery power means you're not tethered to wall outlets, giving you the mobility of manual units with the ease of electric operation.

More info about electric mortuary lifts shows how modern units handle over 1,000 pounds while weighing only 395 pounds themselves, thanks to marine-grade aluminum construction.

Many electric models include digital scales built right into the platform. This eliminates guesswork and provides accurate weight information for documentation and vehicle loading calculations.

The investment in electric power pays off quickly when you consider the time savings and reduced physical strain on your staff. Remote control operation means one person can handle tasks that previously required multiple team members.

Vehicle Winches and Loading Aids

Loading and unloading vehicles ranks among the most physically demanding tasks in funeral service. The LoadAlone system and similar solutions tackle this challenge head-on, enabling single-operator handling of cargo weighing over 600 pounds.

These systems work with virtually any vehicle - vans, SUVs, trucks, and traditional hearses. The wireless remote control eliminates dangerous pushing and pulling, while synthetic cables and stainless steel ramps protect both cargo and vehicle surfaces.

Casket Loading Solutions demonstrate how the patent-pending design transforms vehicle operations. What used to require careful coordination between multiple staff members now becomes a one-person job.

The Tug-Along winch integration with ramps creates a complete loading solution. Universal mounting systems mean you can move the equipment between different vehicles as needed, maximizing your investment.

Funeral homes consistently report these systems pay for themselves within the first year through reduced labor costs and decreased injury risk. The peace of mind knowing your staff won't strain their backs during vehicle operations is invaluable.

Casket Lowering Devices vs. Lifting Devices

Casket lowering devices serve a completely different purpose from the lifting equipment we've discussed. While casket lifting devices focus on prep room efficiency and vehicle loading, lowering devices are all about providing dignity during graveside ceremonies.

These mechanical marvels use centrifugal brake systems to provide smooth, controlled descent without engines or batteries. The purely mechanical operation means they work perfectly regardless of weather conditions - no worries about batteries dying during a service.

Maximum capacities range from 360 kg (793 lbs) to 453 kg (999 lbs), with standard lowering times of approximately one minute. The modular construction allows quick setup and breakdown for transport between cemetery locations.

The acid-proof steel bases and cast aluminum heads resist corrosion from outdoor exposure, while adjustable dimensions accommodate oversized caskets when necessary. These devices replace manual lowering methods with dignified mechanical operation that families appreciate during difficult times.

The psychological comfort provided to families often justifies the investment beyond operational considerations. There's something respectful and ceremonial about the smooth, controlled descent that manual methods simply can't match.

Key Features, Specifications, and Selection Checklist

Choosing the perfect casket lifting device for your funeral home isn't just about picking the biggest or most expensive model. It's about finding equipment that fits your space, handles your workload, and grows with your business over time.

The specifications can feel overwhelming at first glance. Capacity ratings range from modest 750-pound units perfect for smaller operations to heavy-duty systems that handle up to 6,000 pounds. Platform sizes typically measure between 36" to 48" wide by 96" long, though we've built custom dimensions for unique situations.

Travel height makes a huge difference in daily operations. Some compact models keep a low profile at just 12 inches, while others reach impressive heights of 80+ inches for multi-level facilities. The sweet spot depends on your prep room layout and ceiling height.

Power requirements vary significantly between models. Electric systems typically need 240 VAC, 60 Hz, single phase power, while portable battery units run on convenient 12V DC systems. Speed ratings usually fall between 10 to 25 feet per minute - fast enough for efficiency but smooth enough for dignity.

More info about mortuary lifting equipment breaks down the technical details that matter most when comparing different manufacturers.

Size & Weight Capacity of a Casket Lifting Device

Here's what most funeral directors don't realize when they first shop for lifting equipment: standard caskets with remains typically weigh 400-800 pounds, but that's just the starting point. Bariatric cases easily exceed 1,000 pounds, and oversized caskets add both weight and handling challenges.

We always recommend selecting systems with at least 25% capacity margin above your anticipated maximum loads. This safety buffer protects your equipment and staff while handling those unexpected situations that inevitably arise.

Bariatric readiness isn't just about weight capacity anymore. Modern funeral homes are seeing more oversized caskets that require wider platforms and stronger lifting mechanisms. A 48" wide platform provides significantly more versatility than 36" models, though space constraints sometimes dictate the smaller size.

Future-proofing your specifications prevents costly upgrades down the road. The trend toward larger caskets and increased service volume makes higher-capacity systems a smart long-term investment. We've seen too many funeral homes outgrow their equipment within just a few years.

Accessories That Improve a Casket Lifting Device

The right accessories can transform a basic casket lifting device into a comprehensive workflow solution. Roller tops reduce friction during loading and positioning, making one-person operation genuinely effortless. Digital scales eliminate the guesswork in weight management - no more wondering if you're approaching capacity limits.

Entry and exit ramps solve those annoying platform lip clearance issues, especially important for low-profile installations. Platform lighting improves visibility during detailed positioning work, while custom color options help equipment blend seamlessly with your facility's aesthetics.

Track and gantry systems represent the ultimate in prep room versatility. VIEW TRACK AND GANTRY options provide incredible flexibility compared to standard stationary mounts. These customized track systems allow caskets to be positioned anywhere along the track length, maximizing your prep room efficiency.

Draping systems maintain dignity during transport while protecting caskets from environmental exposure. Marine-grade materials ensure longevity in mortuary environments, while non-skid surfaces improve safety during wet conditions.

We've found that funeral homes often underestimate how much these accessories improve daily operations. The initial investment pays dividends in reduced staff fatigue and improved service quality.

Safety, Compliance, Installation, and Maintenance

When it comes to casket lifting device safety, there's no room for shortcuts. These powerful machines require proper attention to regulatory compliance, installation standards, and ongoing maintenance to protect both your staff and your investment.

The good news is that modern lifting devices are designed with safety as the top priority. Understanding the requirements upfront helps avoid costly mistakes and ensures smooth operation for years to come.

Regulatory compliance centers around vertical reciprocating conveyor (VRC) regulations. Your casket lifting device must have full enclosures at both upper and lower landings - think of these as protective barriers that prevent accidents. One critical rule: these systems are never rated for passengers or riders, only for caskets and equipment.

Installation planning makes a huge difference in long-term satisfaction. You'll choose between single-mast and telescoping mast designs based on your space and workflow needs. Hatch cover systems rise with the platform and seal flush with the upper floor when lowered, while hatch door systems use mechanical arms to push open built-in floor doors.

The pit versus ramp decision affects daily operations significantly. Pit installations eliminate platform lips entirely, creating seamless loading conditions that reduce strain and improve efficiency. However, structural requirements sometimes make ramp alternatives more practical for existing buildings.

Operating a Casket Lifting Device Safely

Safe operation starts with proper training - and we can't stress this enough. Every staff member who operates your casket lifting device needs comprehensive instruction on procedures, safety protocols, and emergency responses.

Pre-use checklists become second nature with practice. Before each operation, verify that the platform is properly positioned, interlock gates function correctly, and the load is secure. These simple steps prevent most accidents before they happen.

Lockout/tagout procedures protect staff during maintenance and cleaning. Never skip these steps - accidental activation during service can cause serious injury. Personal protective equipment requirements typically include non-slip footwear and proper body mechanics training for casket positioning.

Interlock gates serve as your primary safety feature, preventing lift movement when entry or exit points aren't properly secured. Test these systems regularly and never bypass or disable them, even temporarily. More info about safe lift systems provides detailed safety protocols that can help establish your training program.

Load distribution matters more than many people realize. Always center caskets on platforms with weight evenly distributed. Off-center loading creates dangerous tilting forces that can damage equipment or cause accidents. When in doubt, take the extra moment to reposition properly.

Maintenance & Durability Best Practices

Regular maintenance isn't just about preventing breakdowns - it's about ensuring safe operation day after day. The marine-grade aluminum and stainless steel construction in quality lifting devices provides excellent corrosion resistance, but regular cleaning prevents buildup of embalming chemicals and other contaminants that can cause problems over time.

Hydraulic systems need periodic attention to fluid levels and quality. Check according to manufacturer schedules and replace fluids when recommended. Battery-powered units require consistent charging cycles and eventual battery replacement, typically every 3-5 years depending on usage patterns.

Monthly lubrication of pivot points and moving components keeps everything operating smoothly. Use only manufacturer-recommended lubricants to prevent premature wear and maintain warranty coverage.

Professional service intervals typically include annual inspections to verify safety systems and mechanical components. Many manufacturers offer five-year limited parts warranties with one-year operational parts coverage, making professional service a smart investment rather than an expense.

Replacement parts availability becomes crucial as equipment ages. Established manufacturers maintain parts inventory even for discontinued models, while newer companies may not provide long-term support. This factor alone can influence your initial purchase decision significantly.

At American Mortuary Coolers, we've seen how proper maintenance extends equipment life well beyond warranty periods. Our Tennessee-based team works with funeral homes across the contiguous 48 states to establish maintenance programs that protect both safety and investment value.

Frequently Asked Questions about Casket Lifting Devices

When funeral directors call us about casket lifting devices, they usually have three main questions. After helping hundreds of funeral homes across Tennessee, Georgia, Illinois, and beyond, we've noticed these same concerns come up again and again.

Let's tackle the big questions that keep coming up in our conversations with funeral professionals.

What weight capacity should I choose for my casket lifting device?

Here's the honest truth - most funeral directors underestimate the capacity they'll actually need. We always recommend starting with at least 1,000-pound capacity for standard funeral home operations, even if you think you'll never need it.

Standard caskets with remains typically weigh between 400-800 pounds. That sounds manageable, right? But then you get that one bariatric case that pushes well over 1,000 pounds, and suddenly your 750-pound lift isn't cutting it.

Think about your service area too. Are you seeing larger caskets becoming more common? Many of our clients have told us they wish they'd gone with higher capacity from the start. The difference in cost between a 1,000-pound system and a 1,500-pound system is usually much less than having to upgrade later.

For facilities serving larger populations or offering specialized bariatric services, systems up to 6,000 pounds might make sense. It's better to have the capacity and not need it than to need it and not have it.

Do I need a pit or can I use a ramp during installation?

This question usually comes down to your building's reality versus the ideal setup. Pit installations are absolutely the gold standard - they eliminate those awkward platform lips that require lifting caskets up and over edges. Your staff will thank you every single day for that smooth, level loading.

But here's the thing - not every building can handle a pit. We've seen funeral homes where basement utilities, structural limitations, or concrete slab foundations make pits either impossible or incredibly expensive.

Ramp installations offer a solid alternative when pits aren't feasible. Yes, there's still some lifting involved, but entry and exit ramps minimize the effort significantly. We've installed plenty of ramp systems that work beautifully for decades.

The choice often comes down to your renovation budget and what your building can support. Don't let the perfect be the enemy of the good - a casket lifting device with ramps is infinitely better than no lifting device at all.

How often should a casket lifting device be serviced?

Think of your lifting equipment like the hearse in your fleet - regular maintenance prevents those emergency breakdowns that always seem to happen at the worst possible time.

Professional service should happen annually at minimum. For high-usage installations, you might want to bump that up to twice a year. We've seen too many funeral homes skip annual service only to have equipment fail during a busy period.

Your staff can handle the monthly basics - lubrication, cleaning, and basic safety checks. It's not complicated, but it needs to happen consistently.

Battery-powered systems need extra attention. Those batteries need regular charging cycles and replacement every 3-5 years, depending on how much you use them. Hydraulic systems need periodic fluid changes and seal inspections to prevent leaks.

The bottom line? A little preventive maintenance costs a lot less than emergency repairs or equipment replacement. Plus, well-maintained equipment keeps your staff safe and your operations running smoothly.

Conclusion & Next Steps

Choosing the right casket lifting device isn't just about buying equipment—it's about changing how your funeral home operates every single day. When we talk with funeral directors across Tennessee, Georgia, Illinois, and beyond, the stories are remarkably similar: reduced back injuries, smoother workflows, and staff who actually look forward to handling transfers instead of dreading them.

The numbers speak for themselves. Most funeral homes see their lifting equipment pay for itself within 18 months through reduced workers' compensation costs alone. Add in the productivity gains from single-operator capability and the improved service quality families notice, and the ROI becomes compelling.

At American Mortuary Coolers, we've learned that cookie-cutter solutions rarely work in the funeral industry. Your 1920s building has different challenges than a modern facility. Your service volume and client demographics create unique requirements that deserve custom attention.

That's why we take time to understand your specific situation before recommending equipment. Facility layout, service volume, and operational preferences all factor into finding the perfect match. Sometimes a simple manual hydraulic lift solves everything. Other times, you need a full track and gantry system with digital scales and remote controls.

The investment extends far beyond equipment costs. We're talking about improved staff morale when your team isn't afraid of back injuries. We're talking about the professional confidence that comes from handling every transfer with mechanical precision. Families notice when their loved ones are moved with dignity rather than struggle.

More info about top mortuary lift company offerings provides detailed comparisons if you want to dive deeper into specifications and manufacturer differences.

We encourage you to talk with lifting equipment specialists before making final decisions. The complexity of installation requirements, regulatory compliance, and long-term maintenance makes professional guidance valuable for avoiding expensive mistakes down the road.

Our custom solutions approach means we can specify equipment that perfectly matches your needs, space constraints, and budget. Whether you need a simple 1,000-pound manual lift or a sophisticated electric system reaching 80+ inches, we'll help you find the right fit.

The funeral industry keeps moving toward higher safety standards and operational efficiency. The right casket lifting device positions your facility for long-term success while showing real commitment to both staff welfare and service quality.

Ready to see how lifting equipment can transform your operations? Contact our team to discuss your specific needs. We're here to help you protect your most valuable asset—your dedicated staff—while elevating the professional service families deserve during their most difficult times.