Why Autopsy Sink- Selection Impacts Your Facility's Efficiency

Autopsy sink- equipped facilities require specialized drainage, infection control, and ergonomic features that standard laboratory sinks simply cannot provide. These purpose-built workstations serve as the foundation for post-mortem examinations, combining rapid fluid drainage with integrated safety systems.

Key Features of Professional Autopsy Sinks:

- Stainless steel construction - 304 or 316 grade for corrosion resistance

- Hydro-aspirator systems - Vacuum-assisted fluid removal with back-siphon protection

- Flexible spray assemblies - 8-10 foot reach for thorough rinsing

- GFCI electrical outlets - Waterproof covers for equipment safety

- Cart-locking mechanisms - Secure transport integration

- Ergonomic height - Typically 34" work surface to reduce operator fatigue

Modern autopsy facilities process thousands of cases annually, making equipment reliability critical. Research shows that approximately 25% of autopsies reveal major diagnostic errors, highlighting the importance of proper facilities and equipment that support thorough examinations.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in autopsy sink- specifications and facility design. My background includes working directly with funeral homes and medical facilities to optimize their prep room layouts for maximum efficiency and compliance.

Autopsy sink- terms to learn:

Understanding Autopsy Sink- Fundamentals

When you walk into any professional autopsy facility, the autopsy sink- serves as the central hub where precision meets practicality. These specialized workstations handle everything from routine drainage to complex fluid management, all while maintaining the ergonomic standards that keep pathologists comfortable during lengthy procedures.

The difference between a standard sink and an autopsy sink- becomes clear the moment you see one in action. While your typical laboratory sink might handle chemicals and glassware, autopsy sinks must manage biological materials, maintain strict infection control, and support the intricate dance of post-mortem examinations.

What Is an Autopsy Sink-?

An autopsy sink- is essentially a specialized command center built specifically for post-mortem examinations and preparation procedures. Unlike the sinks you'd find in a typical medical lab, these units combine multiple critical systems into one purpose-built workstation.

The key difference lies in their mission. While standard laboratory sinks focus on handling chemicals safely, autopsy sink- designs prioritize biological waste management and infection control. They're engineered to handle the unique challenges that come with post-mortem examinations while maintaining the highest hygiene standards.

Post-mortem hygiene requirements drive every design decision. These sinks must accommodate frequent rinsing, specimen handling, and fluid removal - all while keeping the workspace sterile and safe. The workflow in an autopsy suite moves fast, and the sink needs to keep up without becoming a bottleneck.

Scientific research on autopsy history shows how proper facilities directly impact examination quality. When pathologists have the right tools, they can focus on their expertise rather than fighting with inadequate equipment.

Core Components Found in Every Autopsy Sink-

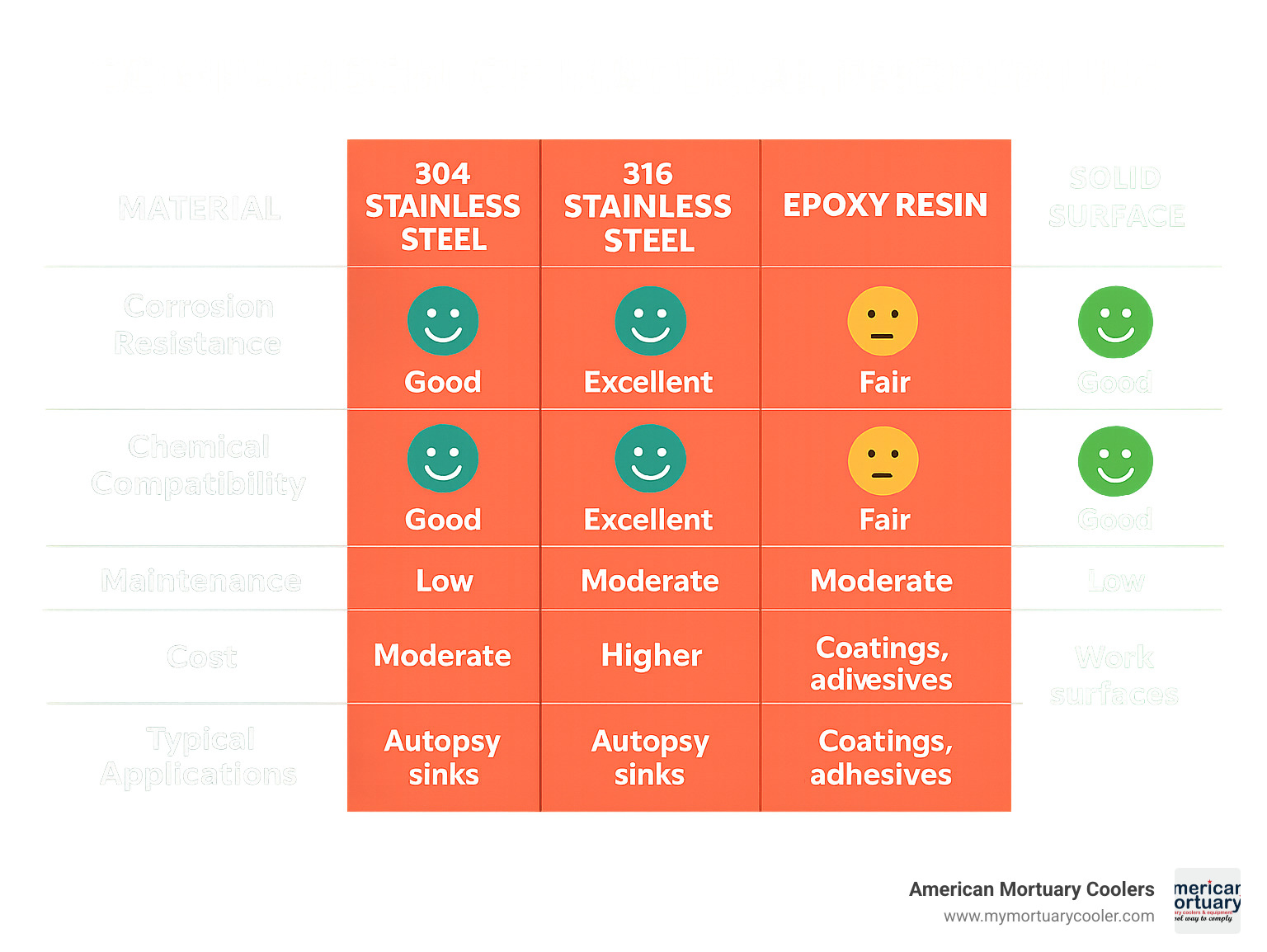

Every quality autopsy sink- includes five essential components that work together seamlessly. The stainless steel basin forms the foundation, typically using 304 or 316 grade steel that resists corrosion from biological fluids and harsh cleaning chemicals. This isn't just about durability - the smooth, non-porous surface prevents bacterial growth and makes thorough cleaning possible.

The hydro-aspirator system might sound complicated, but it's brilliantly simple. This vacuum-assisted drainage uses water pressure to create powerful suction for rapid fluid removal. Most systems include reversing-flow valves and connect to heavy-duty collection bottles that can be sterilized in an autoclave.

Flexible spray hoses extend 8-10 feet and feature precise flow controls, giving pathologists the reach they need for thorough rinsing without constantly moving equipment around.

Back-siphon protection handles a critical safety function that's required by medical and mortuary plumbing codes. These reduced-pressure assemblies prevent any possibility of contamination flowing back into the water supply.

Finally, GFCI electrical outlets provide safe power access in wet environments. These waterproof outlets include ground fault protection and spring-loaded covers that maintain water resistance even when equipment is plugged in.

Key Features, Materials & Hygiene Innovations

When you're investing in an autopsy sink-, the materials and construction quality will determine whether your equipment lasts five years or fifty. I've worked with facilities that are still using sinks from the 1980s, and others that needed replacements within a decade. The difference always comes down to the same factors: material grade, welding quality, and design details.

Type 304 stainless steel forms the backbone of most quality autopsy sinks. This grade offers excellent resistance to the biological fluids and cleaning chemicals you'll encounter daily. However, if your facility is near the coast or you regularly work with particularly harsh chemicals, 316 grade stainless steel provides superior protection against chloride corrosion.

The construction method matters just as much as the material itself. Heliarc welding creates those smooth, seamless joints that make cleaning so much easier. You won't find any crevices where bacteria can hide, and the structural integrity far exceeds what you get with mechanical fasteners or standard welding.

Radius corners might seem like a small detail, but they make a huge difference in daily use. Sharp corners are impossible to clean thoroughly, and they create stress points that can crack over time. Large-radius inside corners let you wipe down surfaces quickly while meeting the strictest sanitation requirements.

Modern rapid drainage systems incorporate sloped surfaces and oversized drains that eliminate standing water completely. This isn't just about convenience - standing water creates contamination risks and can interfere with your workflow when you need to move quickly between cases.

Antimicrobial finishes represent one of the newest innovations in autopsy sink- design. These specialized surface treatments actively inhibit bacterial growth, adding an extra layer of protection beyond what stainless steel alone provides.

Safety & Infection-Control Add-Ons

Safety features have evolved dramatically over the past decade. What used to be optional add-ons are now considered essential components of any professional autopsy sink- installation.

Emergency eye-wash stations must meet ANSI compliance standards, delivering specific flow rates within seconds of activation. These aren't just regulatory requirements - they're potentially life-saving equipment when dealing with chemical or biological exposures.

Cart-locking mechanisms prevent those heart-stopping moments when transport carts shift unexpectedly during procedures. Quality locking systems engage positively from either side of the sink and won't loosen over time.

LED task lighting has revolutionized workspace visibility. Modern LED fixtures provide shadow-free illumination with superior color rendering compared to harsh fluorescent lights. They're also more energy-efficient and last significantly longer, reducing maintenance headaches.

Negative-pressure ventilation systems require careful integration with your facility's overall air handling. The exhaust grilles must be positioned to pull airborne contaminants away from operators and toward collection points.

Smart Accessories That Boost Productivity

The right accessories can transform a basic autopsy sink- into a productivity powerhouse. These aren't luxury items - they're investments that pay for themselves through improved efficiency and reduced operator fatigue.

Scale stands with integrated mounting brackets eliminate the need for separate equipment while ensuring accurate measurements. Modern systems often include both metric and imperial capabilities.

Specimen shelving provides that crucial storage space for instruments and specimens during procedures. Twelve-inch-wide stainless steel shelves offer the perfect balance of accessibility and space efficiency.

Extended spray assemblies with 10-foot reach give you the flexibility to rinse large work areas without constantly repositioning. Quality assemblies include flow control valves and quick-disconnect fittings that make maintenance simple.

Integrated waste disposers require commercial-grade motors - typically 1/2 horsepower - to handle organic waste safely. These units need automatic water control systems and proper electrical protection, but they can significantly reduce disposal costs while improving workflow efficiency.

For facilities planning comprehensive prep room upgrades, our detailed guide on prep room tables that make mortuary work easier covers how to create the most efficient possible workspace layout.

Configurations & Types to Match Your Workflow

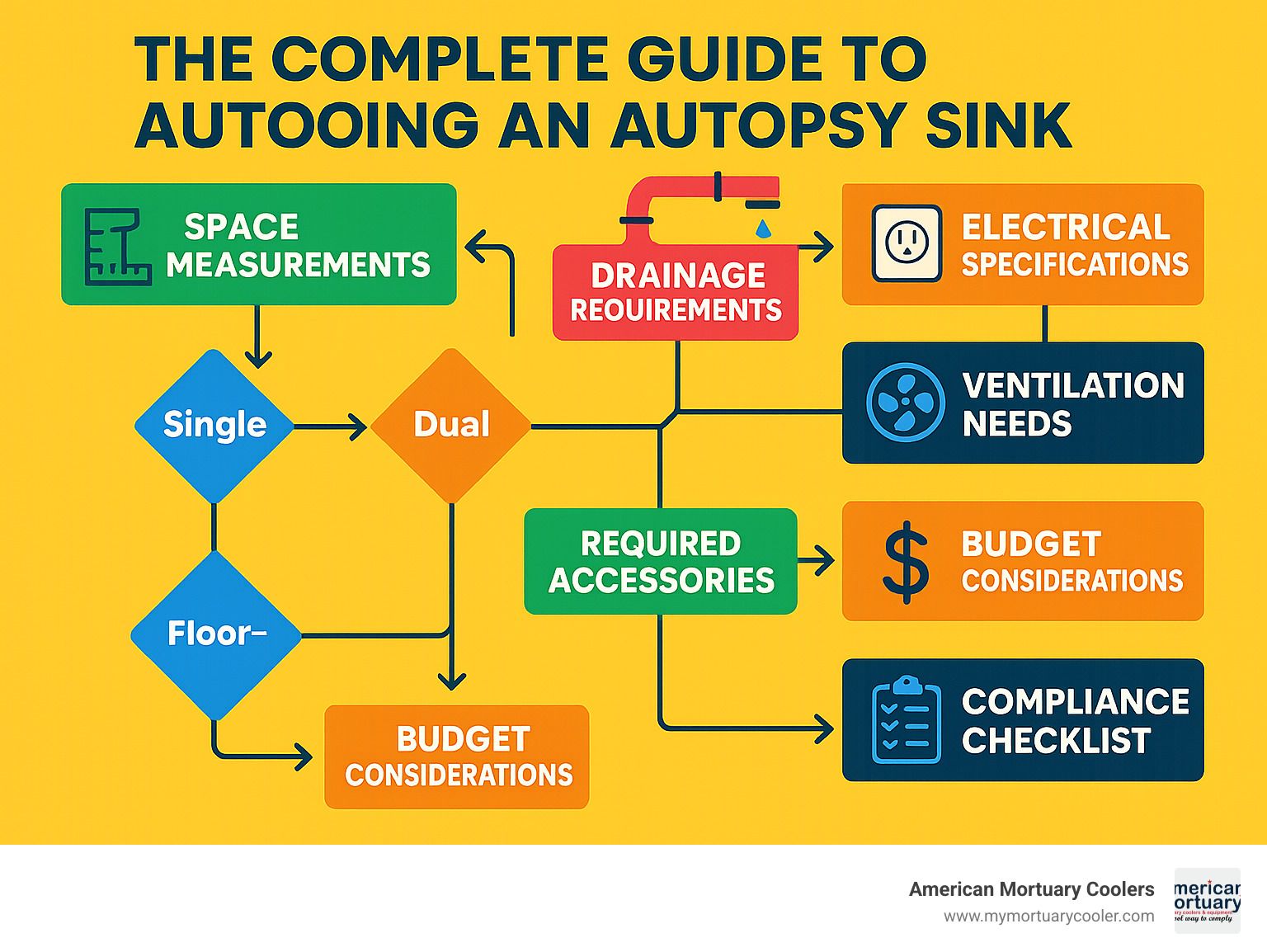

Finding the right autopsy sink- configuration feels a bit like solving a puzzle - you need all the pieces to fit together perfectly. Your facility's layout, workflow patterns, and staffing levels all play crucial roles in determining which setup will serve you best.

Wall-mounted systems offer a neat solution when floor space is precious. These streamlined units attach directly to reinforced walls, freeing up valuable room for other equipment. They're particularly popular in smaller funeral homes where every square foot counts.

Floor-mounted stations give you flexibility that wall units simply can't match. These freestanding workhorses can be repositioned if your facility needs change, and they often include built-in storage that keeps essential supplies within arm's reach.

The sink positioning - whether center, left, or right - might seem like a minor detail, but it dramatically affects daily operations. Center-sink designs create equal access from both sides, perfect for facilities where technicians approach from different directions. Left or right positioning works beautifully in linear room layouts where workflow follows a predictable path.

Dual-approach models represent the premium option for high-volume facilities. These impressive units stretch 150 inches compared to the standard 84-114 inches, allowing two technicians to work simultaneously without getting in each other's way.

Elevating models address one of the most common complaints we hear - operator fatigue from poor ergonomics. These height-adjustable systems accommodate different body types and can be optimized for specific procedures.

Choosing Between Single-Side and Dual-Side Stations

The single-side versus dual-side decision often comes down to honest assessment of your actual needs versus your aspirations. We've seen facilities invest in massive dual-side stations only to use half the capacity most of the time.

Space requirements tell the story immediately. That dual-side autopsy sink- needs 150 inches of length - that's over 12 feet. Add in clearances for cart movement and operator access, and you're looking at substantial floor space commitment.

Staffing patterns provide the clearest guidance. If you regularly have two technicians working simultaneously, dual-approach systems pay for themselves in efficiency gains. But if you're typically a one-person operation with occasional busy periods, the single-side configuration often proves more practical.

Budget reality brings everything into focus. Dual-approach systems typically cost 40-60% more than comparable single-side units. That's not just the initial purchase - it's also installation, ventilation, and ongoing maintenance costs.

Mobile Carts vs Fixed Autopsy Sinks

The relationship between transport carts and your autopsy sink- affects every single procedure. Get this integration right, and workflows feel effortless. Get it wrong, and daily operations become frustrating.

Transport safety starts with proper cart-to-sink connections. Quality latching systems operate smoothly from either side and maintain secure engagement throughout procedures. Mechanical locks consistently outperform friction-based systems.

Height adjustability in mobile carts transforms ergonomics for facilities with varying staff heights. This flexibility becomes particularly valuable during lengthy procedures where operator comfort directly impacts quality and safety.

Cart docking systems represent the pinnacle of autopsy sink- integration. Modern designs include specialized mechanisms that align carts perfectly with work surfaces while eliminating gaps where fluids could spill.

The best docking systems eliminate the wobble and instability that can compromise both safety and precision during procedures. When everything locks together properly, technicians can focus entirely on their work rather than worrying about equipment stability.

Installation, Maintenance & Compliance Checklist

Getting your autopsy sink- properly installed isn't just about connecting pipes and plugging it in. We've helped facilities across the country avoid costly mistakes by understanding the full scope of requirements upfront.

The plumbing work alone involves multiple systems that standard contractors might not expect. Your autopsy sink- needs hot water, cold water, and tempered water connections - plus separate drainage for both the main sink and the hydro-aspirator system. That aspirator requires its own water supply line to create the vacuum effect, along with a dedicated drain connection.

Seismic anchoring becomes critical if you're located anywhere with earthquake activity. Most autopsy sink- models come with seismic anchor kits available, but you need to specify this when ordering - not after delivery.

The RPZ valves (reduced-pressure zone valves) aren't optional in most areas. These prevent contaminated water from backing up into the clean water supply. They require annual testing by certified professionals, so factor that ongoing cost into your budget.

OSHA and CDC guidelines cover everything from ventilation requirements to how your staff handles personal protective equipment. Daily cleaning protocols need to be written down, not just understood - specify which cleaning agents to use and how long they need to stay in contact with surfaces for effective disinfection.

Routine Care to Extend Service Life

Taking care of your autopsy sink- doesn't require a maintenance degree, but it does need consistent attention to the right details.

Neutral detergents are your friend when it comes to cleaning stainless steel surfaces. We've seen facilities accidentally damage expensive equipment by using chloride-based cleaners that cause pitting and corrosion. Stick with pH-neutral products and your stainless steel will maintain that professional appearance for years.

The hydro-aspirator system deserves monthly attention. Check those collection bottles, inspect the hoses for wear, and make sure the vacuum-breaker valves are operating properly. It's much easier to replace a worn component during scheduled maintenance than to deal with system failure in the middle of a procedure.

If your autopsy sink- includes a waste disposer, those cutting blades need quarterly inspection. Dull blades make the motor work harder and can lead to premature failure.

Don't forget about silicone seal maintenance around faucets, spray assemblies, and electrical connections. These seals prevent water intrusion and contamination, but they degrade over time. Annual replacement keeps everything watertight and functioning properly.

For facilities looking to optimize their entire setup, our comprehensive guide on morgue equipment options covers maintenance procedures for all your essential equipment.

Passing Health & Safety Inspections

Nobody enjoys inspection day, but proper preparation makes the process straightforward rather than stressful.

Documentation forms the backbone of any successful inspection. Keep detailed records of maintenance activities, water quality testing, and equipment calibrations. Inspectors appreciate organized facilities that can quickly produce the records they need to verify compliance.

Staff training records need annual updates and should cover proper use of personal protective equipment plus emergency procedures.

Water temperature monitoring might seem tedious, but it's required for safety compliance. Log temperatures at all fixtures to ensure your tempered water systems maintain consistent, safe temperatures within specified ranges.

Air exchange verification requires regular measurement of ventilation system performance. Document air flow rates, filter replacement dates, and verify that negative pressure is maintained in autopsy areas.

The importance of proper facilities becomes clear when you consider research showing that diagnostic errors can be reduced through better equipment and procedures. Your autopsy sink- installation plays a vital role in supporting accurate, thorough examinations.

How to Choose the Right Autopsy Sink- for Your Facility

Choosing the perfect autopsy sink- feels overwhelming at first, but breaking it down into key factors makes the decision much clearer. After helping countless facilities upgrade their equipment, I've learned that the right choice depends on understanding your specific needs rather than just picking the fanciest model.

Your case load tells the whole story. If you're processing dozens of cases monthly, that dual-approach system starts making real sense. But smaller facilities often find single-side units handle their workload perfectly while saving significant money and space. Document your current volumes and honestly project where you'll be in five years.

Modern body sizes demand modern solutions. The uncomfortable truth is that standard autopsy tables from decades past simply don't accommodate today's population. Your autopsy sink- needs adequate workspace for the full range of cases you'll encounter.

Space planning prevents expensive surprises. We've seen facilities fall in love with a particular autopsy sink- configuration only to find it won't fit through their doorway. Measure everything twice - door widths, corridor turns, elevator dimensions, and final placement area.

Future-proofing saves money long-term. Technology keeps advancing, and your autopsy sink- should accommodate upgrades without complete replacement. Modular designs with expandable electrical and plumbing connections let you add digital imaging, improved ventilation, or other innovations as they become available.

Quick Buyer's Checklist

Measure those doorways first. Standard autopsy sink- units range from 84 to 150 inches long, and getting one stuck in a hallway creates expensive problems. Check every doorway, corridor width, and elevator dimension between your loading dock and final installation location.

Verify your electrical service capacity. Most installations need dedicated 20-amp circuits for GFCI outlets, LED lighting, and waste disposers. Older buildings sometimes require electrical upgrades that add unexpected costs to your project.

Request detailed CAD drawings showing all dimensions, plumbing connections, and electrical requirements. These technical drawings help your contractors bid accurately and prevent installation surprises.

Plan for 6-8 week lead times on custom autopsy sink- systems. Domestic manufacturing takes time, but the quality and support make it worthwhile.

For detailed specifications and selection guidance, our team has created The Definitive Guide to Finding the Right Autopsy Sink that covers every technical detail you'll need.

Budgeting & Funding Strategies

Capital budgets work best for major equipment purchases. Most facilities plan autopsy sink- investments as part of their annual capital budget cycle, often coordinating with other facility improvements. This approach maximizes efficiency and minimizes operational disruption.

Grant opportunities exist for qualifying facilities. Federal and state programs sometimes support facility improvements for medical examiner offices and forensic laboratories. Research available grants early in your planning process, as applications often require months of lead time.

Phased upgrades maintain operational capacity while modernizing your facility. Large operations can replace one autopsy sink- at a time, keeping other stations operational during installation. This strategy spreads costs over multiple budget cycles while ensuring continuous service.

Frequently Asked Questions about Autopsy Sinks

Do I need a center, left, or right sink layout?

Your room's shape and workflow patterns will guide this decision more than any other factor. Center-sink configurations shine in square rooms where you need easy access from all sides - think of it as creating a workspace that flows naturally around the entire perimeter.

Left or right positioning works beautifully in narrow or rectangular rooms where you're dealing with linear workflows. If your carts typically approach from one direction, or if you have doors positioned on specific walls, positioning your autopsy sink- to match that natural traffic flow will save steps and reduce congestion.

I always tell facilities to walk through their typical procedures mentally. Where do carts come from? How do staff members move around the space? The sink position should feel intuitive, not force awkward movements or create bottlenecks.

How is bio-waste collected and disposed of safely?

Modern autopsy sink- systems handle waste through multiple integrated pathways, each designed for specific types of materials. Solid biological waste goes directly into designated biohazard containers that mount securely near the work area - you'll want these easily accessible but out of the way of normal workflow.

Liquid waste management happens through the sophisticated drainage system that connects to approved treatment facilities. The hydro-aspirator system handles rapid fluid removal using vacuum suction, while the main drainage carries rinse water and other liquids away from the work surface.

Many facilities appreciate integrated waste disposers for processing certain organic materials on-site. These commercial-grade units reduce disposal volume and costs, though they require proper water flow and electrical protection to operate safely.

The key is following your local regulations religiously - biohazard waste disposal requirements vary significantly between jurisdictions, and compliance isn't optional. Work with your waste management company to establish clear protocols that your staff can follow consistently.

What maintenance does the hydro-aspirator require?

The hydro-aspirator system needs attention more frequently than other autopsy sink- components, but the maintenance tasks are straightforward. Monthly inspections should cover the collection bottles, vacuum hoses, and that critical vacuum-breaker valve that prevents contamination.

Collection bottles need emptying and sterilization regularly - typically after each use in high-volume facilities, or at least daily in smaller operations. These bottles are designed for autoclaving, making sterilization simple and reliable.

The vacuum-breaker valve deserves special attention because it protects your water supply from contamination. Test this component quarterly to ensure it's operating correctly - a failed vacuum-breaker can create serious compliance issues and safety hazards.

Hose replacement shouldn't wait until failure occurs. Worn vacuum hoses reduce system efficiency and can fail suddenly during procedures. Replace them at the first sign of cracking, stiffening, or reduced suction performance.

Most facilities find that keeping spare collection bottles and hoses on hand prevents unexpected downtime. The aspirator system is too critical to your workflow to risk being without it while waiting for parts.

Conclusion

Choosing the right autopsy sink- isn't just about buying equipment – it's about investing in your facility's future success. After working with hundreds of facilities across the country, I've seen how the right sink transforms daily operations while the wrong choice creates years of frustration.

Every facility we work with has its own personality. Some handle dozens of cases weekly, others focus on specialized forensic work. Some operate in cramped spaces, others have room to spare. That's why American Mortuary Coolers doesn't believe in one-size-fits-all solutions.

Our custom stainless-steel autopsy sink- systems are built right here in Tennessee, where we can control every aspect of quality and craftsmanship. We've been perfecting these systems for years, learning from real-world feedback and constantly improving our designs.

What sets us apart is simple: We deliver directly to all 48 contiguous states, and we stand behind our work with a durability guarantee that means something. When you're dealing with critical infrastructure that operates around the clock, you need a partner who understands the stakes.

The investment you make in quality autopsy sink- equipment pays for itself quickly. Better workflow efficiency means faster case processing. Superior safety features protect your staff. Reliable operation means fewer emergency repairs and less downtime. Most importantly, proper equipment supports the important work you do every day.

Whether you're building a new facility from the ground up or finally replacing that troublesome old sink that's been causing headaches, we're here to help. Our team knows the questions to ask and the details that matter.

Planning your entire morgue setup? Our comprehensive guide Behind Closed Doors: A Guide to Morgue Equipment covers everything you need to know about creating an efficient, compliant facility.

Ready to talk about your specific needs? Contact our team today. We'll walk through your requirements, discuss your options, and show you exactly how our autopsy sink- solutions can make your facility work better for years to come.