Why Every Professional Kitchen and Prep Room Needs the Right Work Surface

A prep table is a specialized work surface designed for food preparation, featuring durable materials like stainless steel, storage options, and ergonomic design to streamline kitchen workflow and maintain food safety standards.

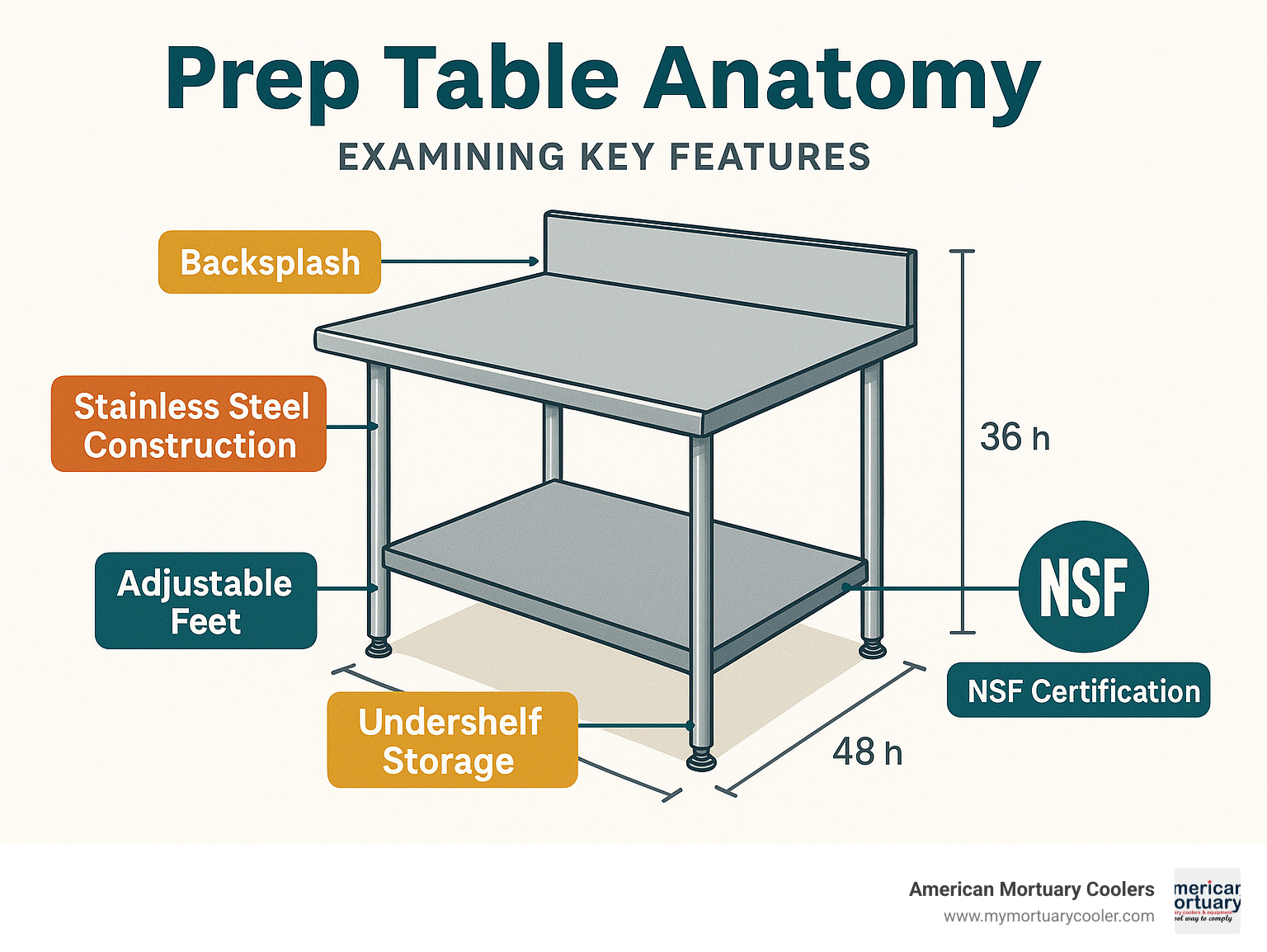

Quick Prep Table Overview:

- Primary function: Food preparation work surface

- Common materials: Stainless steel (18-gauge), wood, polyethylene

- Standard dimensions: 24-96 inches length, 30 inches depth, 36 inches height

- Key features: Undershelves, backsplashes, NSF certification

- Price range: $150-$5,000 depending on size and features

- Main types: Standard, refrigerated, mobile, with sinks/drawers

Whether you're running a busy restaurant kitchen, managing a school cafeteria, or operating a mortuary prep room, the right work surface makes all the difference. Poor prep surfaces lead to workflow bottlenecks, food safety violations, and frustrated staff. But get it right, and you'll see faster service, better organization, and improved sanitation.

Commercial kitchens rely on stainless steel prep tables with NSF certification to meet health codes. These tables can support up to 800 pounds on the top shelf and 600 pounds on the undershelf. Refrigerated prep tables offer specialized cooling with up to 19.5 cubic feet of storage capacity.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right prep table solutions for their facilities.

Prep table terms explained:

Prep Table Basics: Definition & Uses

A prep table is far more than a simple work surface. These specialized tables handle everything from delicate herb chopping to heavy-duty meat processing, all while maintaining the hygiene standards that keep health inspectors happy.

Commercial kitchens depend on these surfaces for their daily operations, whether it's prepping vegetables for the evening service or assembling sandwiches during lunch rush. Mortuary facilities rely on specialized prep tables for embalming and preparation procedures, requiring even more durable and sanitary surfaces.

The key difference between a regular table and a professional prep table lies in ergonomic height (typically 36 inches), non-porous surfaces that resist bacteria, and thoughtful storage solutions that keep tools and ingredients within arm's reach.

How a Prep Table Streamlines Kitchen & Lab Workflow

Sanitation becomes second nature when you have the right prep surface. Stainless steel prep tables are non-porous and easy to sanitize, with rounded edges that eliminate hard-to-clean crevices where bacteria hide.

Speed increases dramatically with proper organization. When cutting boards have designated spots, knives are within reach, and ingredients are stored in the undershelf below, you spend more time cooking and less time hunting for supplies.

Cross-contamination prevention becomes manageable with designated prep zones. You can dedicate surfaces to raw meat, vegetables, and ready-to-eat items separately.

Primary Uses in Different Settings

Restaurant kitchens use prep tables for everything from delicate garnish work to high-volume prep. Bakeries often choose wood-top prep tables for dough work, while pizzerias invest in refrigerated prep tables with ingredient rails.

School cafeterias need heavy-duty prep tables for high-volume food service. Catering operations love mobile prep tables with casters for venue flexibility. Mortuary prep rooms require specialized tables with hydraulic height adjustment and chemical-resistant surfaces.

Types of Prep Tables (Commercial & Specialty)

The main categories break down by material, temperature control, and mobility. Understanding the differences will save you from costly mistakes.

Stainless Steel Prep Table Overview

Stainless steel prep tables are the reliable workhorses of commercial kitchens. They're built from 18-gauge steel that can handle whatever you throw at them. Type 304 stainless steel offers superior corrosion resistance compared to standard 430 grade.

Quality tables feature patented uni-lok recessed gusset design that reduces wobbling. Those rounded edges aren't just for looks - they make cleaning faster and eliminate bacteria hiding spots.

NSF certification appears on every commercial-grade table worth buying. Health departments often require it. Heavy-duty models support up to 800 pounds on the top shelf and 600 pounds on the undershelf.

For operators ready to upgrade, Prep Like a Pro with Stainless Steel Tables covers everything about selecting stainless steel surfaces.

Refrigerated Prep Table Overview

Refrigerated prep tables solve the problem of running back and forth to the walk-in cooler. These units combine work surface with cold storage below.

Storage capacity ranges from 3.4 to 19.5 cubic feet. Temperature control maintains 33-38°F in refrigerated compartments. Sandwich and salad prep becomes streamlined with refrigerated ingredient rails.

Check out Prep Tables | BK Resources for detailed specifications on different refrigerated models.

Mobile & Folding Prep Tables

Mobile prep tables with casters provide flexibility for catering or reconfiguring kitchen layouts. Caster quality makes the difference - heavy-duty 6"×2" casters roll smoothly and handle heavy loads.

Folding prep tables solve space problems. These designs fold from full-size work surfaces down to compact storage units while maintaining impressive load capacities of 600 pounds or more.

Prep Tables with Integrated Sinks & Drawers

Hand-washing stations become part of your prep area with built-in sinks. This helps meet food safety regulations requiring hand-washing facilities near food prep areas.

Storage integration through drawers maximizes every square inch of prep space. HACCP compliance becomes easier with properly designed integrated systems.

For detailed guidance, Everything You Need to Know About Choosing a Prep Table with Sink covers essential considerations.

Key Features & Buying Criteria

Choosing a prep table without understanding key features is like buying a car based solely on color. The difference between a table that serves you well for decades and one that becomes a daily frustration comes down to understanding what really matters.

Material & Construction

304 vs 430 stainless steel represents the classic quality versus cost trade-off. Type 304 stainless steel offers superior corrosion resistance in high-moisture environments or with acidic ingredients. Type 430 provides solid durability at a friendlier price point.

Wood-top prep tables serve specific purposes stainless steel can't match. Bakeries love the laminated wood surface for dough work because it doesn't conduct heat like metal. However, wood demands more maintenance and isn't suitable for all food prep applications.

Load ratings separate heavy-duty champions from lightweight pretenders. Commercial-grade prep tables typically support 800 pounds on the top shelf and 600 pounds on the undershelf.

Size, Dimensions & Ergonomics

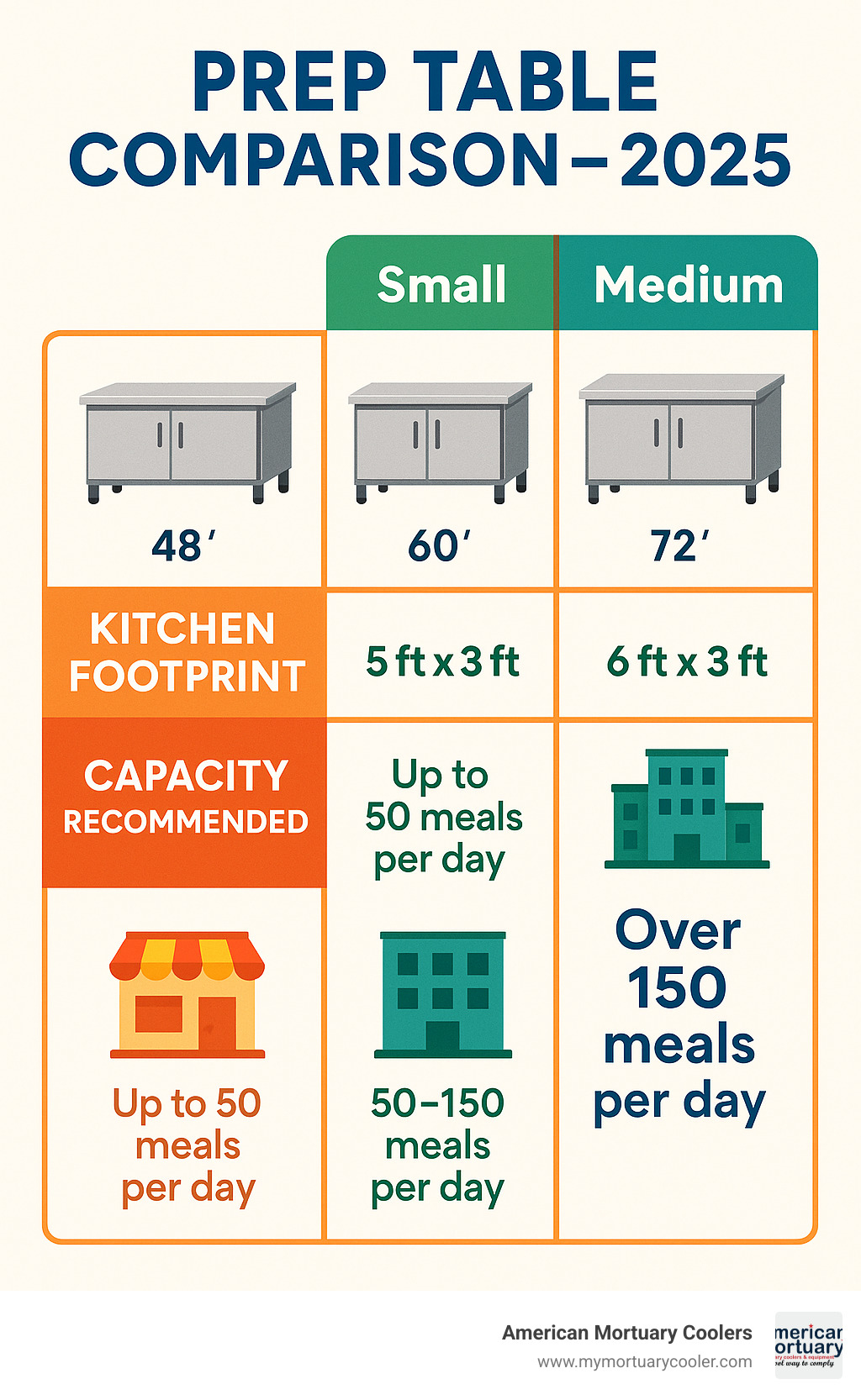

Length options run from compact 24-inch models to expansive 96-inch tables. The sweet spot for most operations falls between 48", 60", and 72" lengths. Depth standards typically measure 30 inches. Working height standardizes at 36 inches for ergonomic reasons.

Accessories & Add-Ons

Cutting boards designed specifically for your prep table ensure proper fit and food safety compliance. Over-shelves double your storage capacity without stealing floor space. Drawers keep essential tools within arm's reach. Casters transform any table into a mobile workstation.

Industry Standards & Certifications

NSF certification ensures compliance with public health standards and is often required by health departments. UL listing addresses electrical safety for refrigerated tables. Always check with your local health department for specific requirements in your area.

Cost, Shipping & Installation Considerations

Prep table prices range from budget-friendly $150 models to premium $5,000+ units. Understanding what drives these price differences helps you avoid paying for features you don't need.

Factors that Influence Price

Material grade acts like the foundation of your investment. Basic 430 stainless steel keeps costs down, while 304 stainless steel costs more but offers better corrosion resistance. Refrigeration transforms a simple table into complex equipment costing thousands more. Custom fabrication opens possibilities but opens your wallet too.

Shipping, Assembly & Common Mistakes

Pallet delivery is standard because most prep tables weigh around 480 pounds. Liftgate service becomes essential without loading dock facilities. Assembly requirements vary wildly between manufacturers.

Common mistakes include not measuring doorways and missing hardware checks. Double-check your delivery path, verify electrical specifications for refrigerated units, and ensure your floor can handle the weight. Lead times typically run 2-4 weeks for standard models.

Maintenance, Safety & Longevity

Your prep table investment can serve you faithfully for decades or become a costly headache within years. The secret is understanding how to care for what you have.

Cleaning Protocols for Stainless & Wood Tops

Stainless steel surfaces have a grain direction - always wipe with the grain using mild detergent and soft cloths. Chloride-based cleaners are stainless steel's worst enemy - they cause pitting and corrosion. Stick with pH-neutral cleaners specifically designed for stainless steel.

Wood top maintenance requires regular oiling with food-grade mineral oil to prevent cracking and warping. Sand and refinish periodically to maintain that smooth, sanitary surface.

How Prep Tables Improve Food Safety & Efficiency

Cross-contamination prevention starts with having dedicated surfaces. Organized stations transform chaotic kitchens into smooth operations. When every tool and ingredient has its designated spot, staff works faster and makes fewer mistakes.

For systematic organization templates, the Prep Sheets guide provides practical tools for maintaining consistent prep station organization.

Frequently Asked Questions about Prep Tables

What size prep table do I need for my kitchen?

Kitchen size sets your upper limit, but don't choose a table that's too small. For small operations, a 48-inch prep table provides enough workspace for one person. Busy restaurants with multiple staff need 72-96 inch tables or multiple prep stations.

Plan for at least 24 inches of working space per person, plus room for tools and ingredients. Available space around the table matters - plan for at least 3 feet of clearance on working sides.

Is NSF certification mandatory for commercial prep tables?

Most health departments require NSF-certified equipment for commercial food service. This isn't just red tape - NSF certification means your prep table meets strict standards for materials, construction, and cleanability.

Your insurance company might also require certified equipment. Some commercial policies specifically mandate NSF certification, so skipping it could void coverage.

When is a refrigerated prep table necessary over a standard model?

If you're constantly walking to your walk-in cooler during prep, a refrigerated prep table will change your life. Cold ingredient operations like sandwich shops and pizza places benefit most. High-volume operations see immediate returns on investment through time savings alone.

Conclusion

Finding the perfect prep table is like finding the missing piece of a puzzle - suddenly everything clicks into place. Whether you're managing a busy restaurant kitchen, overseeing a school cafeteria, or running a mortuary facility, the right work surface becomes the quiet hero that makes everything else possible.

The journey through materials, sizes, and features might seem overwhelming at first, but it all comes down to understanding your specific needs. Stainless steel prep tables with NSF certification deliver the reliability most operations demand, while specialized refrigerated or mobile units solve those unique challenges that keep you up at night.

Quality matters more than you might expect. A well-built prep table doesn't just survive the daily grind - it thrives in it. The difference between 18-gauge and 20-gauge steel, between 304 and 430 stainless, between proper welds and shortcuts - these details determine whether your table serves you faithfully for decades or disappoints you within months.

Here at American Mortuary Coolers, we've learned something important from our years in Tennessee crafting custom solutions: every facility tells a different story. A high-volume restaurant needs different prep solutions than a small-town funeral home. That's why we focus on understanding your specific requirements before recommending equipment.

The investment pays for itself in ways you might not expect. Faster prep times, fewer food safety concerns, happier staff, and that peace of mind that comes from knowing your equipment won't let you down during the busiest moments. It's the difference between fighting your workspace and having it work with you.

We deliver across all 48 contiguous states because we believe distance shouldn't determine access to quality equipment. Whether you're in downtown Nashville or rural Montana, the right prep table should be within reach.

Your operation deserves better than "good enough." It deserves a prep surface that understands the demands you face and rises to meet them, day after day, year after year.

Ready to find your perfect prep solution? Explore our stainless prep table lineup and find how American Mortuary Coolers can craft the custom solution your operation needs, delivered straight to your door.