Why Scissor Lift Tables Are Essential for Modern Material Handling

A scissor lift table is a mechanical device that uses interconnected folding supports (resembling scissors) to raise and lower heavy loads vertically, providing ergonomic material handling solutions across industries. These versatile platforms eliminate the need for manual lifting, reduce workplace injuries, and improve operational efficiency.

Quick Overview: Scissor Lift Table Basics

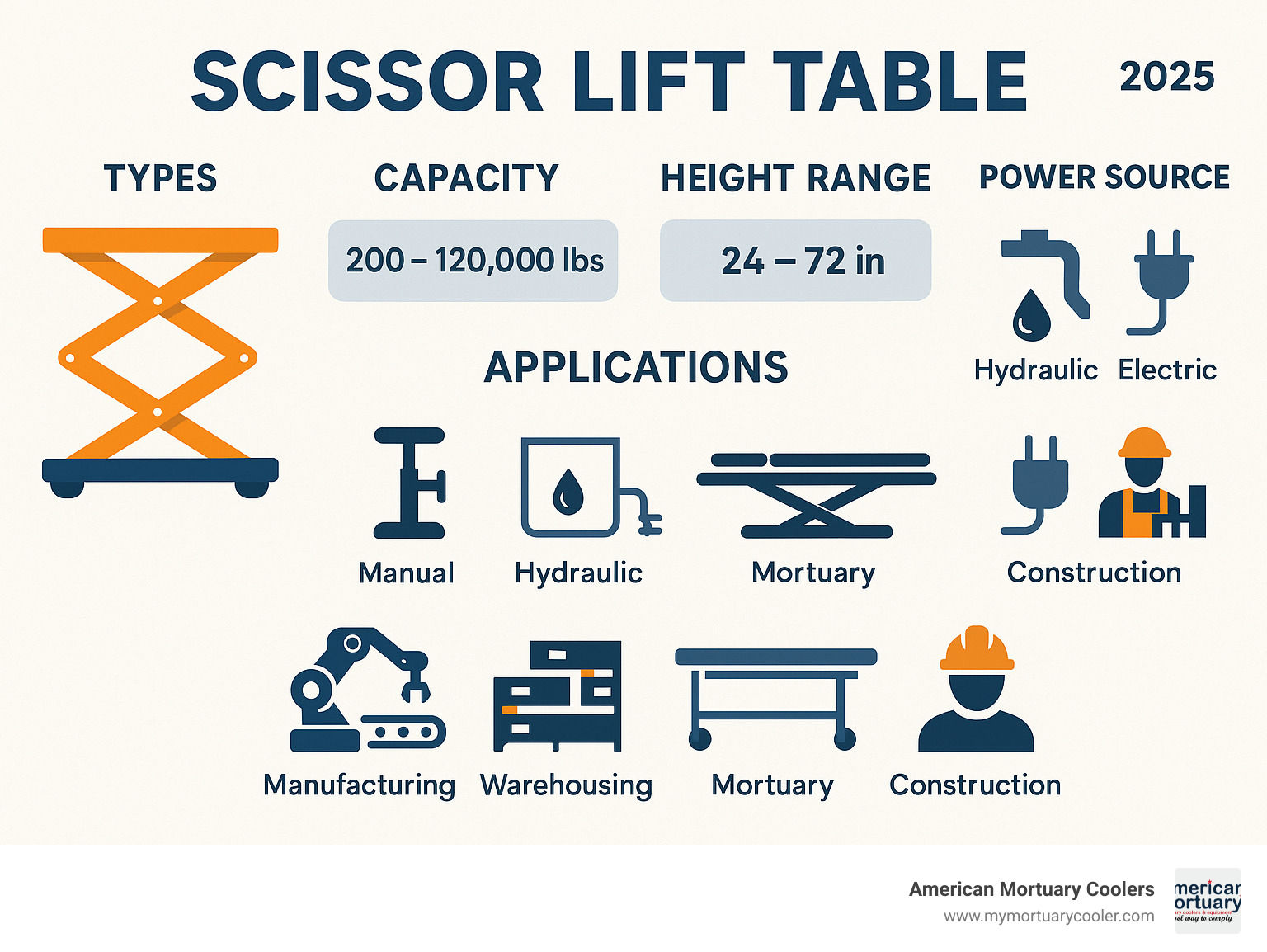

- Function: Vertical lifting of loads from 200 lbs to 120,000 lbs capacity

- Mechanism: X-shaped scissor arms powered by hydraulic, electric, or pneumatic systems

- Height Range: Typically 24" to 72" vertical travel (up to 270" for specialized models)

- Power Options: Manual foot pump, electric hydraulic, pneumatic air, or battery powered

- Applications: Manufacturing, warehousing, mortuary services, automotive, and construction

Whether you're positioning heavy materials at ergonomic heights, loading dock equipment, or handling specialized equipment in funeral homes, scissor lift tables transform how businesses approach vertical material handling. The research shows that well-maintained lift tables can last 10 to 20 years or longer, making them a smart long-term investment for any facility.

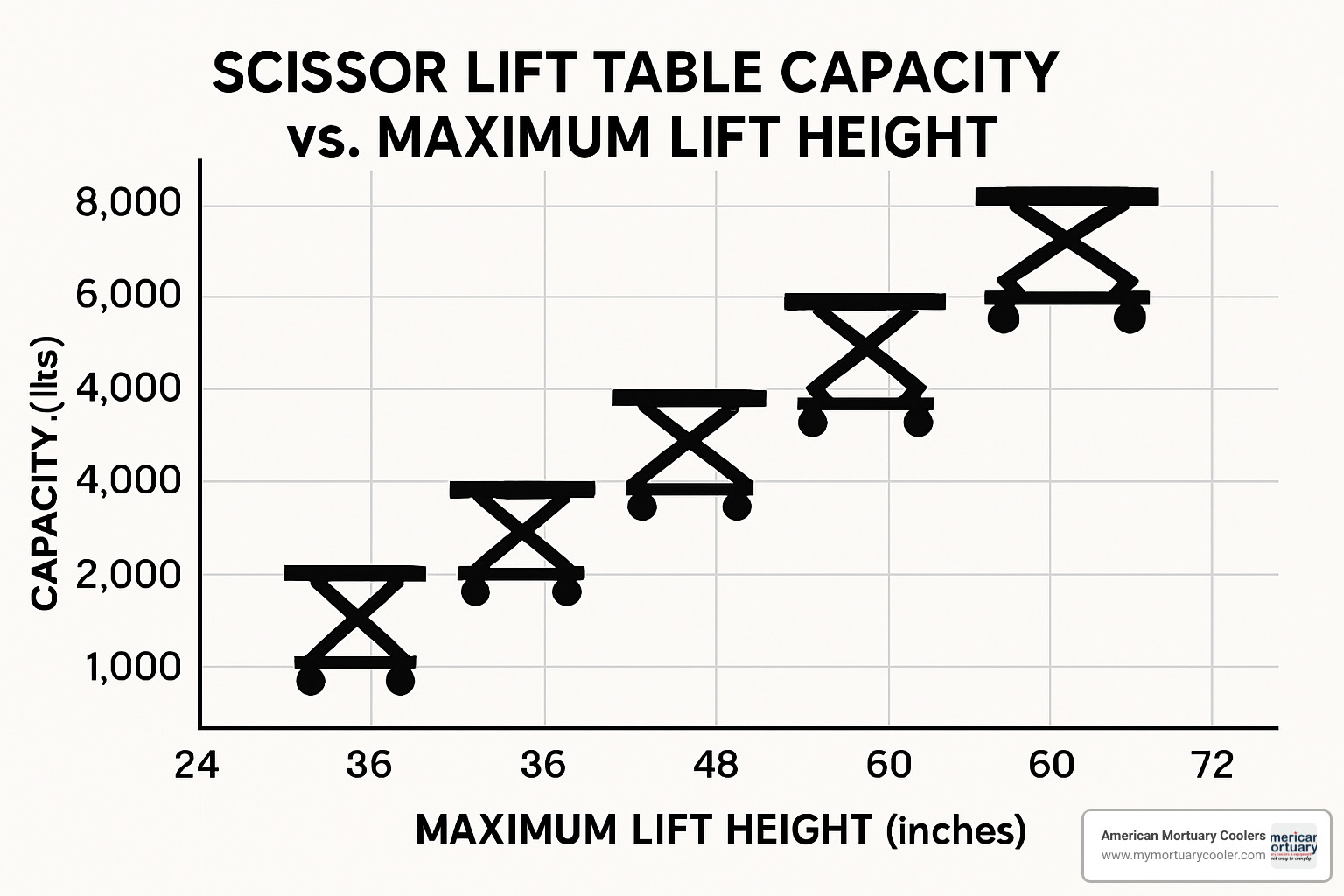

From compact 440-lb capacity units perfect for tight spaces to heavy-duty 6,000-lb industrial models, these tables come in various configurations to match specific operational needs. Standard duty models typically handle up to 6,000 lbs with 60 inches of vertical travel, while double scissor designs can reach 72 inches for higher lifting applications.

As American Mortuary Coolers, we've spent years helping funeral home directors select the right scissor lift table solutions for their facilities, focusing on durable, space-efficient equipment that meets the unique demands of mortuary operations. Our experience has shown that choosing the right scissor lift table can dramatically improve both worker safety and operational efficiency in specialized environments.

Simple scissor lift table glossary:

Understanding the Scissor Lift Table Mechanism

Ever wonder how a scissor lift table can effortlessly raise thousands of pounds with just the push of a button? The secret lies in a beautifully simple design that's been perfected over decades. Picture a giant pair of scissors lying flat—when you squeeze the handles together, the blades spread apart. That's exactly how these lifts work, just turned on their side to create vertical motion.

The heart of every scissor lift is its steel scissor arms—heavy-duty metal supports that form that familiar X-shape. These aren't just any pieces of metal; they're precision-engineered to handle repeated cycles under serious weight. The pivot points where these arms connect allow smooth extension and retraction while keeping everything rock-solid stable.

But what actually powers this mechanical marvel? Most systems rely on hydraulic cylinders as their muscle. These cylinders use pressurized fluid to push the scissor mechanism apart, creating the lifting force. Electric motors drive the hydraulic pumps that build this pressure, making operation as simple as flipping a switch.

For facilities where hydraulic fluid is a no-go—think food processing plants or clean rooms—pneumatic airbags step in. These systems use compressed air instead of hydraulic fluid, keeping things clean while still delivering reliable lifting power.

Don't need all that high-tech power? Foot-pump systems offer a manual alternative that's perfect for lighter loads or locations without electrical connections. These systems pair a precision foot pump with quality hydraulic components for smooth, controlled lifting that relies on good old-fashioned human power.

What is a Scissor Lift Table?

A scissor lift table is essentially a mechanical elevator for your materials. Its primary function is straightforward: lift heavy stuff up and down so your workers don't have to strain their backs doing it manually. Simple concept, massive impact on workplace safety and efficiency.

The load platform sits on top of the X-frame scissor assembly, creating a stable surface for whatever you need to move. Whether it's a 50-pound box or a 5,000-pound piece of machinery, the platform keeps everything secure during the lift cycle.

Vertical travel range varies dramatically depending on what you need. Compact units might give you just 14 to 35 inches of lift—perfect for bringing floor-level items up to comfortable working height. Double-scissor models can reach 72 inches or more, essentially creating a second-story work surface when needed.

According to ANSI/OSHA definitions, these fall squarely into the material handling equipment category. They're built specifically for lifting goods and materials, not people. That's an important distinction—these aren't personnel lifts or aerial work platforms, they're workhorses designed to move your stuff safely and efficiently.

How Does It Work?

The magic happens when hydraulic fluid pressure meets mechanical advantage. When you hit that foot pedal or push button, you're setting off a chain reaction that multiplies your small input into serious lifting power.

Electric pumps build pressure in the hydraulic system, sending fluid into cylinders that push against the scissor mechanism. The mechanical linkage does the heavy lifting here—literally. It takes that relatively small hydraulic pressure and multiplies it into enough force to raise substantial loads.

Flow-control valves act like the brakes and gas pedal of your lift system. They regulate how fast things go up and come down, ensuring smooth operation and precise positioning. No jerky movements or sudden drops—just controlled, predictable motion.

Safety isn't an afterthought in these systems. Emergency stop circuits can shut everything down instantly if something goes wrong. Limit switches prevent the mechanism from extending too far, protecting both the equipment and anyone nearby from damage or injury.

Coming back down uses gravity as a helper, with compressed air or controlled hydraulic flow managing the descent speed. Most systems include quick-release options for rapid lowering when you need to get materials down fast, but always with safety controls to prevent dangerous free-falls.

Types & Power Options of Scissor Lift Tables

When you're shopping for a scissor lift table, the variety of options might surprise you. It's like walking into an ice cream shop—there's definitely a flavor for every need and situation.

Single scissor designs are your classic workhorses, providing reliable lifting with a compact footprint that won't crowd your workspace. But when you need to reach higher, double scissor configurations are game-changers, stretching up to 72 inches of vertical travel. Think of them as the skyscrapers of the lift table world.

Tandem long scissor tables solve a different problem entirely—they're built for those awkwardly long loads that regular platforms just can't handle. If you've ever tried to balance a long piece of equipment on a short table, you'll appreciate the extra length these provide.

Ground-level or zero-lift tables are brilliant for loading operations. They can drop their platforms to within half an inch of the floor, making it easy to slide heavy items on and off without breaking your back.

For facilities that need flexibility, compact cart-style units roll wherever you need them. Rough-terrain models take this mobility outdoors with chunky treaded wheels and weather-resistant components that laugh at rain and dust.

In specialized environments, stainless-steel sanitary versions shine. Food processing plants, pharmaceutical facilities, and medical environments demand this level of cleanliness, and these tables deliver without compromise.

Battery-powered options free you from the tyranny of power cords. With capacities ranging from 100 to 500 kg, these cordless workhorses go wherever the job demands.

If you're planning to attend PROMAT 2025, you'll get a look at the latest innovations hitting the market, including smart controls and IoT integration that make these tables even more versatile.

Manual vs. Hydraulic vs. Electric vs. Pneumatic Scissor Lift Tables

Choosing the right power source for your scissor lift table is like picking the right tool for a job—each option has its sweet spot.

Manual systems with hand winches or foot pedals are the reliable workhorses that never let you down. Take a typical manual double scissor lift like the Uline H-1784—it needs 46 foot pumps to reach full height, but here's the beautiful part: zero operating costs and bulletproof reliability. No power outages, no maintenance headaches, just dependable lifting when you need it. Perfect for occasional use or remote locations where electricity is scarce.

Electric-hydraulic systems bring smooth, powerful lifting with the convenience of push-button operation. These units handle anywhere from 2,200 to 6,600 pounds with the kind of precise control that makes positioning heavy loads feel effortless. The duty cycles are impressive, making them ideal when you're lifting frequently throughout the day.

Electric systems are the speed demons of the group, offering the fastest cycle times and smart features like programmable height presets. Some models even include soft-start and stop functions that treat your loads—and your nerves—gently.

Pneumatic systems powered by compressed air are the clean freaks of the lifting world. When hydraulic fluids are absolutely forbidden—think food processing or pharmaceutical environments—these air-powered units step up to the plate. They do need a compressed air supply, and they might not lift quite as much as their hydraulic cousins, but they're spotlessly clean.

Energy efficiency and noise levels vary dramatically. Manual systems are silent and use zero power, while electric and pneumatic units consume energy only when working. Most operate at moderate noise levels that won't disturb your workspace.

Specialty Variants & Industry Examples of Scissor Lift Tables

The real magic of scissor lift tables shows up in specialized applications where standard equipment just won't cut it.

In mortuary services, we've seen how crucial the right equipment can be. Body and casket lifts handle up to 1,000 pounds with features that matter in funeral homes—marine-grade aluminum construction that resists corrosion, integrated digital scales for precise measurements, and slider transfer boards that make transfers smooth and dignified. Many include multi-directional roller systems that work beautifully in the tight spaces typical of funeral facilities.

Pallet positioners are genius in their simplicity. As workers add or remove items, these tables automatically adjust height to keep everything at the perfect picking level. No more bending, stretching, or straining—just efficient, ergonomic operation all day long.

Automotive service lifts support heavy vehicle components during maintenance, while conveyor integration models create seamless material handling systems that flow like water. Mobile trolleys combine lifting power with transport capability, featuring precision hydraulic foot pumps and quick-release systems for rapid repositioning.

Some specialized models include telescoping masts for ultra-precise positioning and reversible forks that adapt to different load types. It's this kind of versatility that makes these tables invaluable across so many industries.

If you're considering temporary solutions for a specific project, our guide on scissor lift rental covers everything you need to know about short-term options that won't break the budget.

Key Benefits & Industry Applications

When you invest in a scissor lift table, you're not just buying equipment—you're changing how your team works every single day. The benefits ripple through your entire operation, creating improvements that compound over months and years.

Think about it: how many times do your workers bend over to pick up heavy items? How often do they stretch awkwardly to reach materials stored too high or too low? Every one of those movements puts stress on their bodies and slows down your processes.

Ergonomic lifting capabilities eliminate these problems entirely. Workers can position materials at the perfect height—no more bending, reaching, or straining. This isn't just about comfort; it's about preventing the musculoskeletal injuries that cost businesses thousands in workers' compensation claims and lost productivity.

The productivity boost happens almost immediately. When materials are at the right height, everything moves faster. Workers don't get tired as quickly, they make fewer mistakes, and they can maintain their pace throughout the entire shift.

Precise positioning might sound like a small detail, but it makes a huge difference in quality-focused operations. Whether you're assembling products or preparing for a funeral service, having materials exactly where you need them improves both speed and accuracy.

Here's something that surprises many facility managers: space efficiency. A scissor lift table takes up minimal floor space when lowered, but provides all the functionality of a permanent raised platform or ramp system. You get vertical access without sacrificing valuable square footage.

The ROI calculation is straightforward. Most businesses see their equipment costs paid back within 1-2 years through reduced injuries, faster operations, and improved worker satisfaction. After that, it's pure profit.

Ergonomics & Productivity Gains

The magic happens in what ergonomics experts call the optimal reach zone—that sweet spot between waist and shoulder height where your body can work most efficiently. A scissor lift table keeps materials in this zone automatically, no matter how much you've loaded or unloaded.

Real-world studies consistently show cycle-time reductions of 15-30% when proper lifting equipment is implemented. That's not just theory—it's measurable improvement you can see on your production floor or in your service area.

Decreased fatigue is perhaps the most underestimated benefit. When workers aren't constantly bending and lifting, they maintain their energy and focus throughout the shift. This leads to fewer mistakes, better quality work, and higher job satisfaction.

The injury prevention aspect is serious business. Back injuries alone cost American businesses billions annually in workers' compensation, medical expenses, and replacement training. Scientific research on ergonomic lifts shows dramatic reductions in injury rates when mechanical lifting aids are properly deployed.

OSHA injury statistics paint a clear picture: lifting-related injuries account for a huge portion of workplace compensation claims. Every injury prevented is money saved and, more importantly, a person protected from pain and lost work time.

The compound effect creates substantial value. Faster cycles plus fewer injuries plus higher accuracy plus sustained performance typically pays for equipment costs faster than most business owners expect.

Industry Use Cases — Manufacturing, Warehousing, Mortuary & Beyond

Manufacturing facilities have finded that scissor lift tables solve multiple problems at once. Assembly line positioning becomes precise and adjustable, machine feeding happens at ergonomic heights, and work-in-process handling flows smoothly. The ability to adjust height precisely improves both worker comfort and product quality while cutting setup times.

Warehousing and logistics operations depend on these tables for dock leveling, order picking, and pallet handling. Ground-level models let forklifts drive directly onto platforms, while pallet positioners automatically maintain optimal picking heights as items are added or removed.

Food processing facilities benefit enormously from stainless-steel sanitary models that withstand intensive washdown procedures while maintaining strict hygienic standards. These specialized units handle the unique demands of food safety regulations without compromising lifting performance.

In logistics docks, the difference is immediately visible. Loading and unloading becomes faster and safer, with workers able to position materials at truck bed height regardless of vehicle variations.

Mortuary services represent one of our most specialized applications. Funeral homes use scissor lifts for casket positioning, body transfer, and preparation room operations. Our years of experience at American Mortuary Coolers have shown that proper lift equipment dramatically improves both worker safety and service quality in these sensitive environments. For comprehensive guidance specific to funeral homes, see our Essential Guide to American Mortuary Coolers Scissor Lifts.

Laboratories require precision positioning for equipment and sample handling, while construction sites employ rough-terrain models for material positioning in challenging outdoor environments. E-commerce fulfillment centers integrate lifts with automated systems for high-speed operations that keep pace with modern shipping demands.

Each industry brings unique requirements, but the core benefits remain consistent: safer workers, faster operations, and better results.

Choosing the Right Scissor Lift Table

Finding the perfect scissor lift table for your facility doesn't have to feel overwhelming. Think of it like buying a vehicle—you need to match the equipment's capabilities to your daily operations, budget, and future needs.

The most important question to ask yourself first: What's the heaviest load you'll ever need to lift? Your answer determines everything else. Load capacity isn't something you can fudge—exceeding the rated capacity puts your workers at risk and will destroy your equipment faster than you can say "warranty void."

Standard scissor lift tables handle loads from 2,000 to 6,000 pounds comfortably. If you're working with lighter materials, compact units starting at 440 pounds might be perfect. But if you're in heavy manufacturing or need to move massive equipment, specialized models can handle up to 120,000 pounds.

Height requirements come next. How high do you need to lift materials, and how low do they need to go? Most standard models give you 24 to 60 inches of vertical travel. Double scissor designs can reach 72 inches—great when you need that extra reach. Don't forget to measure your ceiling clearance too. There's nothing worse than ordering equipment that won't fit in your space.

Platform size matters more than most people realize. Your scissor lift table platform needs to accommodate your largest typical load with room to spare for safety. A cramped load is a dangerous load. Footprint considerations include both the platform itself and the space the scissor arms need when they extend.

Think about how often you'll use the equipment. If it's running all day, every day, you need heavy-duty construction with proper cooling systems. For occasional use, a lighter-duty model will save money without sacrificing performance.

Power availability in your facility shapes your options too. Electric systems work great if you have reliable power and need consistent performance. Battery systems give you mobility but require charging infrastructure. Pneumatic systems need compressed air but run clean—perfect for food processing or clean rooms.

Environment matters. Indoor applications have different needs than outdoor ones. If you're dealing with weather, washdown procedures, or corrosive conditions, weatherproofing and stainless steel construction become essential for long-term reliability.

Core Specs: Capacity, Height, Platform & Power

Let's break down the numbers that really matter when selecting your scissor lift table. These specifications work together like ingredients in a recipe—get the balance right, and everything works beautifully.

Capacity ranges start with compact 440 to 1,100 pound units that work perfectly for light assembly or small parts handling. The sweet spot for most facilities is the 2,000 to 6,000 pound range—these standard models handle everything from pallets to machinery components. Heavy industrial applications might need 10,000+ pound capacity units with beefed-up construction.

Height specifications include both your collapsed height (how low it goes) and maximum extension. A typical double scissor lift gives you 72 inches of vertical travel, while standard models top out around 60 inches. Remember to factor in both your highest lifting need and your lowest access requirement. Some ground-level units can get within half an inch of the floor.

Platform dimensions vary wildly based on what you're moving. Compact units might measure 20 by 30 inches—perfect for small parts or tools. Specialized long platforms can stretch to 96 by 264 inches for oversized materials. Match your platform size to your typical load dimensions, then add safety margins. A load hanging over the edges creates dangerous conditions.

Power requirements depend on your usage patterns and what's available in your facility. AC electric systems deliver consistent performance for high-duty applications. DC battery systems offer cordless mobility but need charging stations. Pneumatic systems require compressed air supply but provide the cleanest operation—no hydraulic fluids to leak or maintain.

For outdoor applications or washdown environments, weatherproofing becomes critical. Stainless steel construction, sealed electrical components, and corrosion-resistant finishes ensure your investment lasts in challenging conditions. The upfront cost pays for itself in reduced maintenance and longer equipment life.

Customization & Integration Options for Scissor Lift Tables

Modern scissor lift tables aren't just lifting platforms—they're customizable workstations that can integrate seamlessly into your operation. The right accessories and modifications can transform a basic lift into the perfect solution for your specific needs.

Roller conveyors integrated into the platform create smooth material transfer without manual handling. Workers can slide heavy items on and off effortlessly. Turntables add 360-degree rotation capability, letting operators access loads from any angle without repositioning the entire unit.

Integrated scales provide real-time weight feedback—essential for shipping operations, batching processes, or inventory management. No more guessing about load weights or making separate trips to the scale.

Programmable height presets are game-changers for repetitive operations. Operators can store frequently used positions and return to them with the push of a button. This speeds up operations and ensures consistent positioning every time.

PLC automation takes integration to the next level. Your scissor lift table can communicate with facility management systems, conveyor controls, and safety interlocks. This connectivity supports modern manufacturing initiatives and provides valuable operational data.

Safety improvements include accordion skirting to prevent fingers or clothing from getting caught in the scissor mechanism. Light curtains create invisible barriers that stop operation if someone enters the danger zone. Warning lights keep everyone informed about operational status.

For funeral home applications, we've seen tremendous success with specialized modifications. Our Ultimate Checklist for Comparing Mortuary Lifts covers features specific to mortuary operations—from marine-grade aluminum construction to integrated transfer systems that make delicate operations safer and more dignified.

The key is thinking beyond basic lifting. What would make your operators' jobs easier? What integration points would streamline your workflow? The right customizations often pay for themselves quickly through improved efficiency and reduced labor costs.

Safety, Training & Maintenance

When it comes to scissor lift tables, safety isn't just a nice-to-have feature—it's absolutely essential. Think of it this way: you're dealing with equipment that lifts thousands of pounds, and the last thing anyone wants is a workplace accident that could have been prevented.

The foundation of scissor lift safety starts with proper equipment design. Guard rails keep personnel from accidentally stepping off liftd platforms, while toe guards protect feet during the lowering process. Velocity fuses act as a crucial backup—if hydraulic pressure drops suddenly, they prevent the platform from crashing down unexpectedly.

Overload valves serve as your equipment's built-in bodyguard, automatically preventing lifts when loads exceed safe capacity limits. Emergency stop capabilities give operators immediate shutdown control from multiple locations, and modern systems include warning alarms that alert everyone nearby when the lift is in operation.

The regulatory landscape around scissor lift tables centers on ANSI MH29.1 standards, which establish comprehensive guidelines for safe operation and maintenance. These aren't just bureaucratic requirements—they're based on decades of real-world experience and accident prevention research.

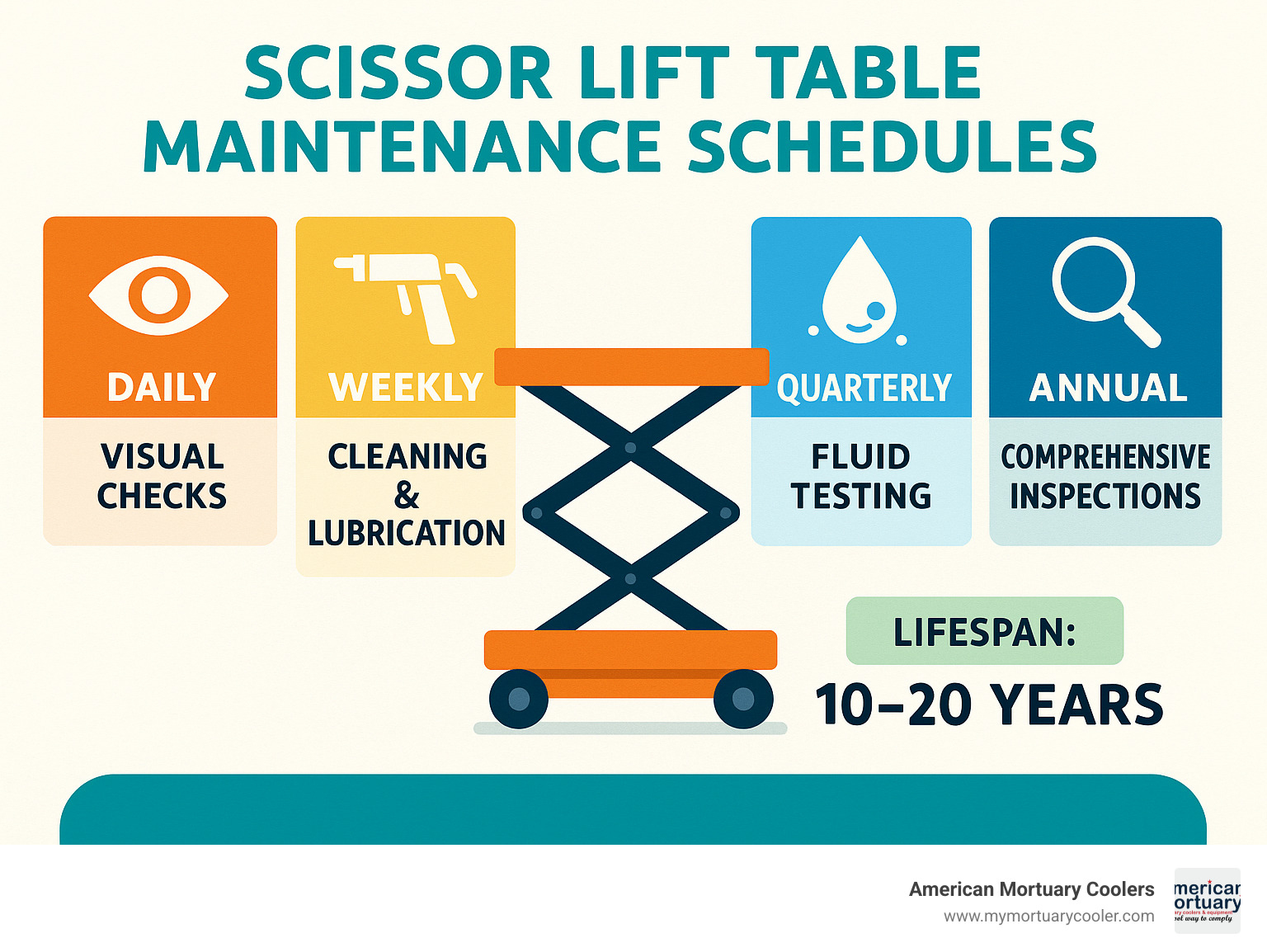

Proper maintenance isn't just about keeping your equipment running; it's about ensuring it operates safely for its entire 10-20 year lifespan. Regular inspections catch potential problems before they become dangerous situations, and a well-maintained lift table will serve your facility reliably for decades.

Essential Safety Features & Regulatory Standards for Scissor Lift Tables

The safety features on modern scissor lift tables have evolved significantly over the years, and for good reason. Lock-out/tag-out procedures ensure that nobody can accidentally activate equipment while someone else is performing maintenance—a simple concept that prevents serious injuries.

Interlock gates take this protection further by physically preventing operation when safety barriers are open. It's like having a built-in safety supervisor that won't let the equipment run unless everything is properly secured.

Warning systems have become increasingly sophisticated, with both audible alarms and visual indicators that show operational status. In busy facilities where ambient noise can mask equipment sounds, these systems provide crucial awareness for everyone in the area.

Certification requirements vary depending on your location and specific application, but CE marking for European markets and UL listing for North American applications demonstrate that equipment meets rigorous independent testing standards. These aren't just stickers—they represent comprehensive safety evaluations.

Training typically requires 2-4 hours of initial instruction covering equipment operation, safety procedures, and emergency response protocols. Most facilities find that refresher training every 1-3 years keeps operators sharp and addresses any procedural updates or lessons learned from industry experience.

Documentation plays a bigger role than many people realize. Operator certifications, maintenance records, and inspection logs don't just demonstrate compliance—they provide valuable data for optimizing maintenance schedules and identifying potential issues before they become problems.

Maintenance Checklist & Expected Lifespan

A well-maintained scissor lift table is like a reliable old friend—it'll serve you faithfully for decades if you treat it right. The key is establishing consistent maintenance routines that become second nature for your team.

Daily visual inspections should become as routine as checking your mirrors before driving. Look for fluid leaks, damaged components, and verify that safety systems are working properly. Test the emergency stop function and listen for unusual noises or vibrations that might indicate developing problems.

Weekly maintenance involves keeping the equipment clean and properly lubricated. Debris in scissor mechanisms can cause premature wear, while proper lubrication of pivot points ensures smooth operation and extends component life. Check fluid levels and test all controls to catch issues early.

Quarterly hydraulic fluid testing might seem like overkill, but contaminated fluid is one of the fastest ways to destroy expensive hydraulic components. Fluid changes at recommended intervals maintain optimal performance and prevent the kind of catastrophic failures that result in costly downtime.

Annual comprehensive inspections should include cylinder rebuilds or professional service evaluations. This is also the time for caster replacement, seal renewal, and thorough safety system testing. Think of it as an annual physical for your equipment.

The 10-20 year lifespan typical of quality scissor lifts makes proper maintenance a smart financial decision. Parts availability and service support become crucial factors over this extended timeframe, which is why choosing established manufacturers pays dividends in the long run.

For systematic troubleshooting guidance when issues do arise, manufacturer resources like troubleshooting lift manuals provide step-by-step approaches to resolving common problems efficiently.

Frequently Asked Questions about Scissor Lift Tables

We get a lot of questions about scissor lift tables from our customers, especially those in the funeral industry who need reliable equipment for their daily operations. Here are the most common concerns we hear and the straight answers you need.

Are scissor lift tables safe to use outdoors?

Absolutely, but you need the right equipment for the job. Standard scissor lift tables designed for indoor use won't hold up to rain, snow, and temperature swings. However, weather-resistant models are specifically built to handle outdoor conditions.

These outdoor-rated units come with sealed electrical components that keep moisture out of critical systems. The hydraulic cylinders and pumps are protected with corrosion-resistant finishes, and drainage systems prevent water from pooling in areas where it could cause damage.

For rough terrain applications, manufacturers offer models with large treaded wheels and improved stability features. These handle uneven surfaces much better than standard casters designed for smooth warehouse floors.

That said, common sense still applies. Don't operate any lift table in extreme weather conditions like high winds, ice storms, or severe thunderstorms. Even the most robust equipment has its limits.

Temperature is another consideration. Hydraulic fluid can thicken in extreme cold, affecting performance. In very hot climates, systems might need additional cooling. Always check the manufacturer's operating temperature range before installation.

What operator training is required?

The training requirements depend on where you're located and how you're using the equipment, but most scissor lift table operators need some form of certification. Don't worry—it's not as complicated as getting a forklift license.

Basic training typically takes 2-4 hours and covers the essential topics. You'll learn how to operate the controls safely, understand weight capacity limits, and practice proper load positioning. Emergency procedures are a big part of the training too—everyone needs to know how to shut down the system quickly if something goes wrong.

The hands-on portion is crucial. Reading a manual is one thing, but actually operating the equipment under supervision builds real confidence. Most training programs require demonstrated competency before they'll certify an operator.

Refresher training usually happens every 1-3 years, depending on your local regulations and company policies. This keeps skills sharp and covers any updates to safety procedures or equipment changes.

Documentation matters too. Keep records of who's been trained and when. Your insurance company and safety inspectors will want to see these records, and they're important for liability protection.

How do scissor lift tables compare to vertical mast lifts?

This is like comparing a pickup truck to a ladder—both lift things up, but they're designed for completely different jobs. Understanding the differences helps you choose the right tool.

Scissor lift tables excel at handling heavy loads at moderate heights. They provide rock-solid stability and can handle thousands of pounds without breaking a sweat. The platform stays level throughout the lifting range, making them perfect for positioning heavy equipment or materials.

Vertical mast lifts are the opposite—they reach much higher (often 10+ feet) but can't handle nearly as much weight. They're ideal when you need to access high shelving or position lighter items at significant heights.

Cost-wise, scissor lifts usually win for heavy-duty applications. They're built like tanks and last for decades with proper maintenance. Mast lifts can be more economical if you need height more than lifting capacity.

For funeral homes, we almost always recommend scissor lift tables because they're better suited for the heavy, precise work involved in mortuary operations. The stability and weight capacity make them much safer for handling caskets and other funeral equipment.

The choice really comes down to your specific needs. If you're moving heavy items at moderate heights, scissor lifts are your best bet. If you need to reach high places with lighter loads, consider a mast lift instead.

Conclusion

When it comes to material handling, the right scissor lift table isn't just equipment—it's a game-changer that transforms how your team works every day. Whether you're dealing with a compact 440-lb unit for delicate assembly work or a powerhouse 6,000-lb industrial model for heavy-duty operations, there's a perfect match waiting for your specific needs.

The beauty of these machines lies in their versatility. Load capacity, height requirements, platform dimensions, power source, and environmental conditions all play crucial roles in finding your ideal solution. But here's what really matters: when you get the selection right, you're not just buying equipment—you're investing in safer workplaces, happier employees, and smoother operations.

Safety features, proper operator training, and solid maintenance programs ensure your investment keeps paying dividends for the long haul. With typical lifespans of 10-20 years when properly maintained, a quality scissor lift table more than earns its keep through reduced injuries, improved efficiency, and improved operational capabilities.

At American Mortuary Coolers, we've seen how the right equipment transforms specialized operations. Our experience serving funeral homes across Tennessee, Atlanta, Chicago, and beyond has taught us that proper equipment selection makes all the difference—not just in day-to-day operations, but in the dignity and professionalism you bring to your important work.

Whether you're streamlining warehouse operations, upgrading mortuary equipment, or improving industrial manufacturing processes, the right scissor lift table delivers measurable improvements that your team will notice from day one. The upfront investment quickly pays for itself through fewer workplace injuries, faster cycle times, and improved operational flow.

Ready to find the perfect fit for your facility? Our Detailed Guide to Finding the Best Mortuary Lift Table walks you through every consideration for mortuary-specific applications. With custom solutions and direct delivery across all 48 contiguous states, we make sure you get exactly what you need, delivered right to your door.