Why Commercial Cooler Breakdowns Can Devastate Your Business Operations

Commercial cooler repair is essential maintenance that keeps refrigeration units functioning properly to prevent product spoilage, maintain food safety standards, and avoid costly business disruptions. Here's what you need to know:

Key Commercial Cooler Repair Facts:

- Response Time: Most repairs completed same-day to minimize downtime

- Common Issues: Temperature fluctuations, frost buildup, water leaks, unusual noises

- Average Lifespan: 7-15 years with proper maintenance and timely repairs

- Critical Timeline: Address issues within 4 hours to prevent food spoilage (USDA guideline)

- Most Replaced Parts: Door gaskets, thermostats, fan motors, compressors

When your commercial cooler repair needs arise, every minute counts. A malfunctioning refrigeration system can spoil thousands of dollars worth of inventory in just hours. Whether you're running a restaurant or medical facility, maintaining proper cold chain temperatures protects your reputation and bottom line.

Commercial refrigerators typically last 7-15 years with regular maintenance and prompt repairs. Most service calls involve common problems like failed door gaskets, faulty thermostats, or dirty condenser coils. Many of these issues can be prevented with proper care.

Emergency repairs are available 24/7 in most major cities, with same-day service being the industry standard. However, the key to avoiding emergencies lies in recognizing early warning signs and establishing a preventive maintenance routine.

As American Mortuary Coolers, a national-level mortuary cooler supplier with experience in commercial refrigeration systems, we've seen how proper commercial cooler repair and maintenance can extend equipment life and prevent costly failures.

Basic commercial cooler repair terms:

Commercial Coolers 101: Types, Lifespans & Business Impact

Commercial refrigeration serves as the silent guardian of your business. Whether you're preserving food, medical supplies, or serving families in their time of need, understanding your cooling equipment is essential for protecting everything you've worked to build.

What Is a Commercial Cooler?

A commercial cooler is your business's temperature guardian—a refrigeration system engineered to maintain precise cold temperatures day and night, season after season. These aren't home refrigerators scaled up; they're purpose-built machines designed to handle demanding business operations.

The cold chain keeps our world running safely. It's the unbroken sequence of temperature-controlled storage and transport that protects perishable goods from production to final destination. Break that chain, and you're looking at spoiled products, unhappy customers, and potentially serious health risks.

Most-Used Models in Business Operations

Walk-in coolers and freezers are the heavy lifters of commercial refrigeration. These room-sized units store massive quantities and typically serve businesses faithfully for 10-15 years with proper care. Their complex refrigeration systems require specialized knowledge for commercial cooler repair.

Reach-in refrigerators are the workhorses of foodservice establishments. With their front-access doors and versatile shelving, these units generally provide reliable service for 7-12 years, making them a solid investment for most businesses.

Under-counter and prep table coolers are space-savers that keep operations flowing smoothly. Their integration of workspace and cooling makes them incredibly convenient—but also more complex when repairs are needed.

Display and merchandising units walk a tightrope between visibility and temperature control. Those glass doors that let customers see products also expose the cooling system to constant temperature challenges.

How a Faulty Cooler Hurts Your Bottom Line

When commercial refrigeration fails, the damage spreads like ripples in a pond.

Inventory loss happens fast. The USDA's four-hour rule isn't a suggestion—it's a hard deadline. Leave perishable food at unsafe temperatures for more than four hours, and it needs to go in the trash. Single failures can cost businesses thousands of dollars in spoiled inventory.

Health code violations can shut you down. Health inspectors don't mess around with temperature control. Citations, fines, and closure orders can cost far more than any repair bill.

Customer trust takes years to build and minutes to destroy. Food safety incidents make headlines and social media posts that can haunt a business forever.

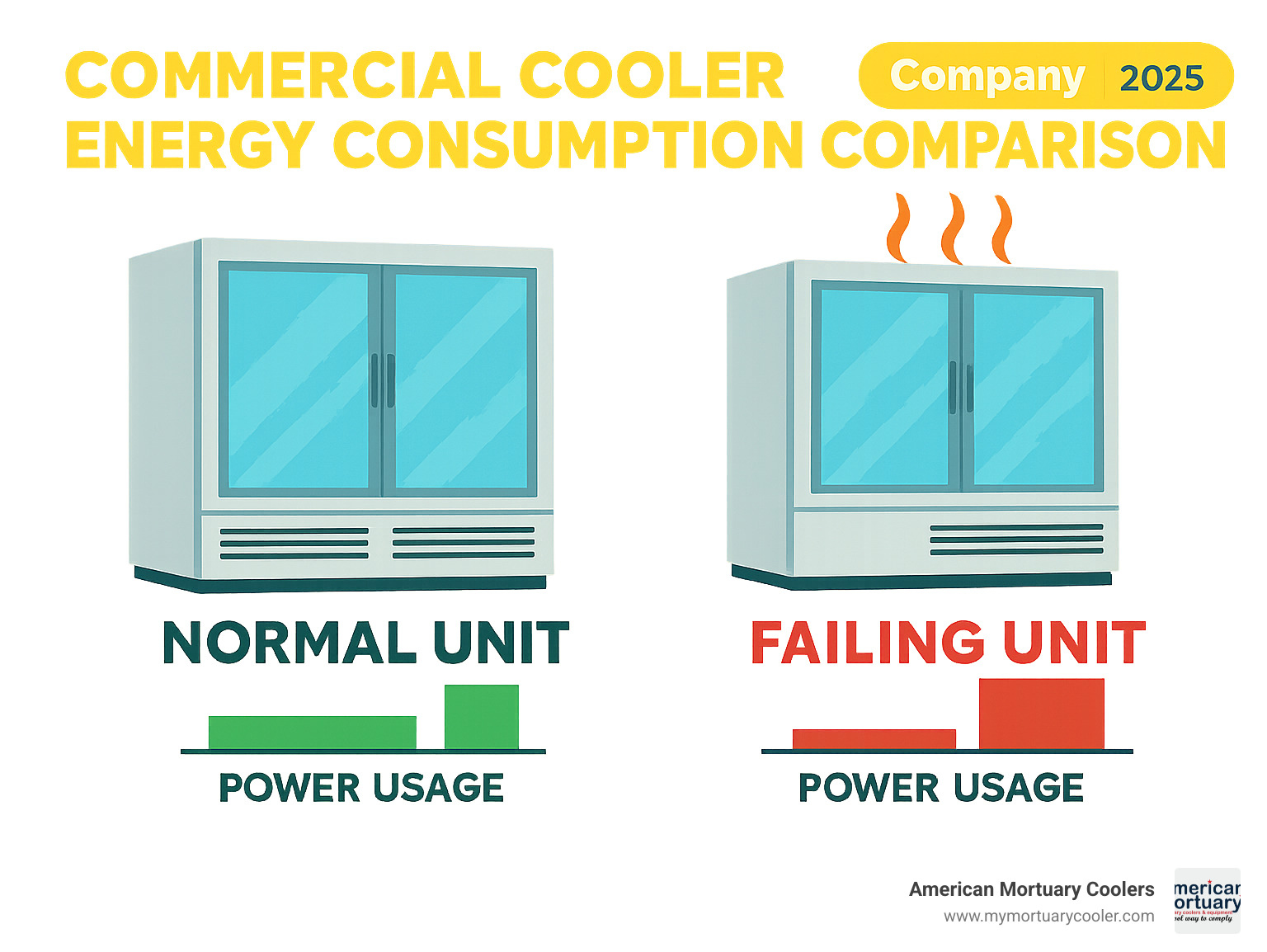

Energy costs spiral when cooling systems struggle. A dirty condenser coil can increase energy consumption by 20-30% while actually reducing cooling effectiveness.

Most of these problems are preventable with proper maintenance and prompt commercial cooler repair when issues first appear.

Early Warning Signs & Top Problems Requiring Commercial Cooler Repair

Your commercial cooler is trying to tell you something—and learning its language can save you thousands of dollars in emergency repairs and spoiled inventory. Most cooler failures don't happen overnight. Instead, they give you plenty of warning through subtle changes in performance, strange sounds, or visual clues.

Red Flags You Should Never Ignore

Temperature swings are your first red flag. Even if your cooler seems to be maintaining the right temperature overall, fluctuations of more than 2-3 degrees from your setpoint indicate system stress.

Frost and ice buildup tells a clear story about defrost system problems. When you start seeing ice formations inside the freezer, your defrost cycle isn't working properly. This ice acts like insulation, making your system work harder.

Water puddles around your cooler aren't just slip hazards—they're crying out for attention. These leaks usually point to clogged drain lines, worn door gaskets, or defrost system malfunctions.

Unusual noises are your cooler's way of asking for help. Clicking sounds typically mean your compressor is overloading, often because dirty condenser coils are making it work too hard. Buzzing or grinding from fans suggests bearing wear or damaged blades.

Strange odors should never be ignored in refrigeration equipment. Unpleasant smells can indicate mold growth, refrigerant leaks, or electrical problems developing inside your unit.

Components That Fail Most Often

Door gaskets top the list of most frequently replaced components. Every time someone opens your cooler door, those rubber seals flex and compress. Over time, heavy use causes gasket wear that leads to air infiltration and temperature loss.

Thermostats and control systems are the brains of your operation, but they're also prone to failure. Temperature control problems can cause overcooling (wasting energy) or inadequate cooling (spoiling products).

Fan motors work tirelessly to circulate air for proper heat exchange. Your evaporator and condenser fans run almost constantly, which explains why they wear out. Quality matters here—True Refrigeration evaporator fan motors typically last 15-20 years, compared to just 3 years for some comparable models.

Compressors are the heart of your refrigeration system, and when they fail, it's usually a major repair. Commercial freezer compressors average about 10 years of service life, while walk-in cooler compressors typically last around 15 years.

For hands-on guidance when you need to tackle repairs yourself, our step-by-step guide to replacing a walk-in cooler handle walks you through the process with clear instructions.

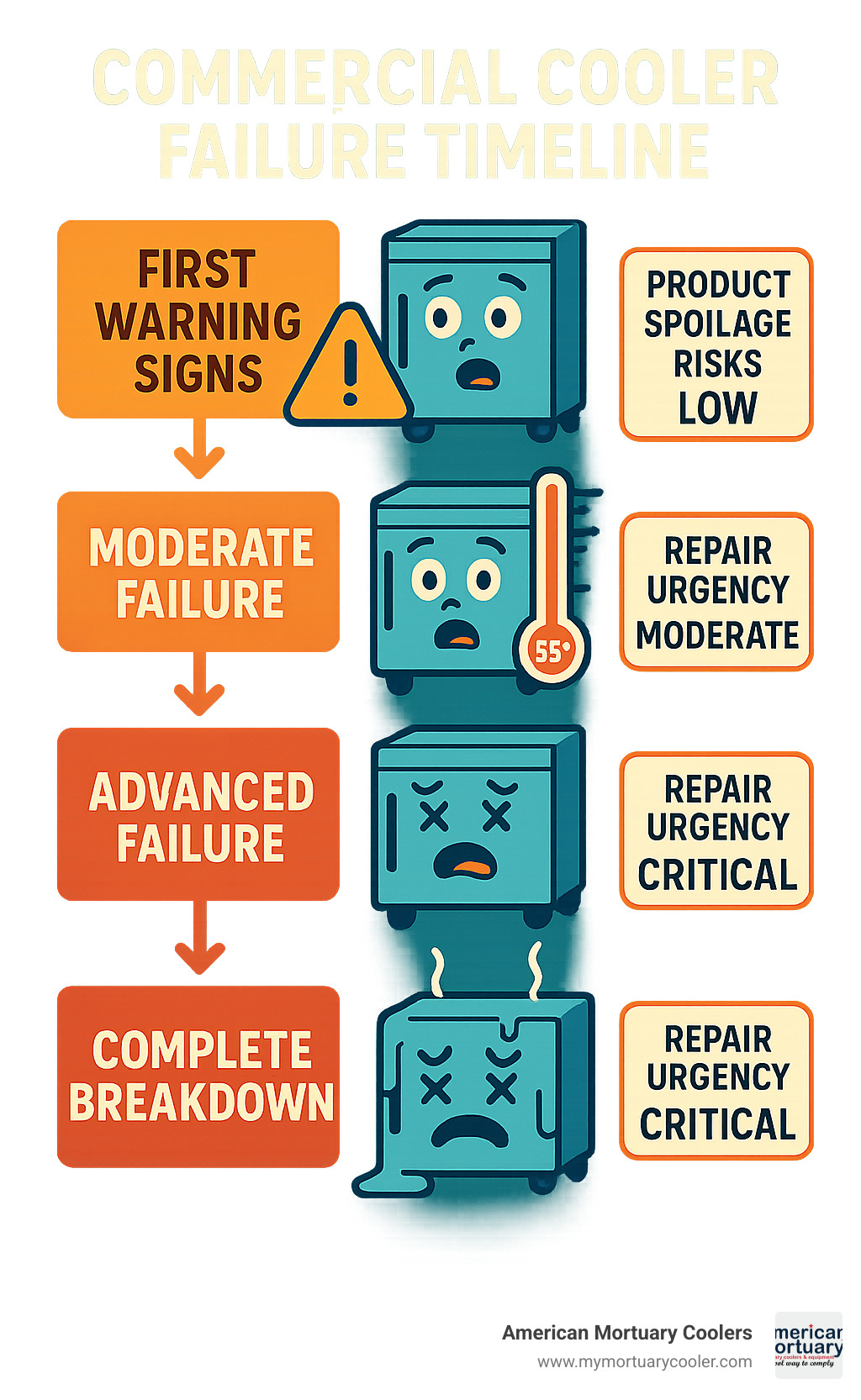

Consequences of Delayed Repairs

Putting off commercial cooler repair might seem like a money-saving strategy, but it usually backfires in expensive ways.

Bacterial growth becomes a serious concern when temperatures creep above 40°F. The "danger zone" between 40-140°F creates ideal conditions for harmful bacteria to multiply rapidly.

Equipment wear accelerates when one component starts failing. A struggling compressor generates excess heat and puts stress on every other part of your system. This domino effect often transforms what could have been a simple repair into a major overhaul.

Regulatory compliance becomes an issue when health departments find temperature violations during inspections. These agencies take food safety seriously, and repeat violations can result in fines or shutdown orders.

Those early warning signs aren't suggestions—they're urgent requests for attention that can save your business from much bigger problems down the road.

The Commercial Cooler Repair Process Step-by-Step

When your commercial cooler repair needs arise, understanding the process helps you know what to expect. Professional technicians follow a proven system that gets your equipment running reliably again.

The repair process starts the moment you call for service. Most reputable companies offer same-day service for urgent issues, especially when food safety is at risk.

Commercial Cooler Repair: Diagnostic Checklist

A skilled technician begins every repair with thorough diagnostics.

The first step involves accurate thermometer readings throughout your cooler. Hot spots or temperature variations tell the story of what's going wrong.

Coil inspection comes next. Dirty condenser coils are behind many cooling problems, while frosted evaporator coils signal defrost system failures.

Electrical testing reveals hidden problems that visual inspection might miss. Loose connections, failing motors, or control board issues often cause intermittent problems.

Refrigerant pressure testing completes the diagnostic picture. Low pressure might indicate leaks, while high pressure could mean restricted airflow or overcharging.

Emergency vs. Routine Commercial Cooler Repair

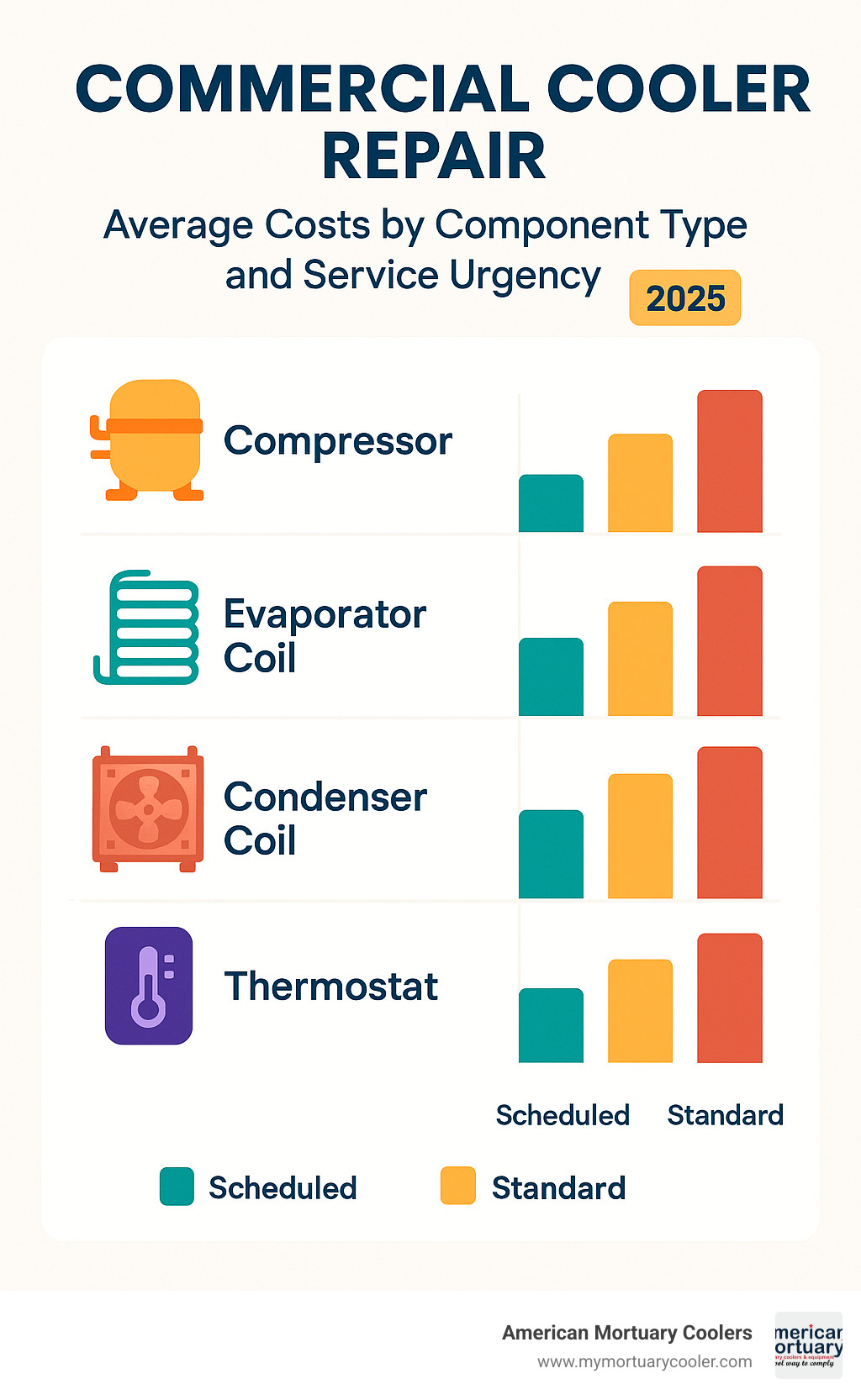

| Aspect | Emergency Repair | Routine Maintenance |

|---|---|---|

| Response Time | 24/7, same-day | Scheduled, flexible |

| Cost Premium | 50-100% higher | Standard rates |

| Scope | Crisis resolution | Preventive care |

| Planning Time | Immediate | Advance scheduling |

| Parts Availability | Limited to stock | Full selection |

Emergency repairs happen when your cooler fails completely or temperatures climb into the danger zone. These after-hours calls cost significantly more but prevent massive inventory losses.

Routine maintenance lets you plan ahead with flexible scheduling and standard pricing. You get access to the full parts selection and can address multiple issues during a single visit.

Certifications & Choosing a Technician

Not all refrigeration technicians are created equal. The right certifications make the difference between a quick fix and a lasting solution.

EPA 608 certification isn't optional—it's legally required for anyone handling refrigerants. Never work with uncertified technicians, as this can create legal liability for your business.

Manufacturer training becomes crucial for complex equipment. Technicians trained on your specific brand understand the quirks and common issues that generic repair services might miss.

Insurance and bonding protect your business if something goes wrong during repairs. Always verify that your service provider carries adequate liability coverage.

Google reviews offer real insight into service quality. Look for providers with consistently high ratings and substantial review counts.

For Calgary businesses, reliable, professional and timely fridge repair service providers maintain these high standards while offering transparent pricing and guaranteed work.

Maintenance & Prevention Strategies That Extend Cooler Life

Think of commercial cooler repair like car maintenance—you can either pay a little now or pay a lot later. Consistent care can double equipment life and prevent those dreaded middle-of-the-night emergency calls.

Creating a Preventive Maintenance Schedule

Monthly check-ups should become as routine as taking inventory. Start by cleaning condenser coils with a soft brush—dirty coils are the leading cause of compressor failure. Next, inspect door gaskets for cracks or tears that let warm air sneak in. Don't forget to check drain lines for clogs and verify your temperatures are holding steady.

Every three months, dig a little deeper. Tighten electrical connections that vibration has loosened, and inspect refrigerant lines for signs of wear. This is also when you should calibrate temperature controls to ensure accuracy.

Twice a year, bring in the professionals. A trained technician can perform comprehensive system testing, analyze refrigerant pressures, and spot problems you might miss.

Annual evaluations are your chance to think bigger picture. This is when you assess overall system efficiency, consider component upgrades, and plan for future needs.

DIY Tasks vs. Pro Services

You don't need to be a refrigeration expert to keep your cooler healthy. Visual inspections can catch obvious problems like ice buildup or water leaks. Basic cleaning of accessible surfaces prevents dirt accumulation, and temperature monitoring helps you spot trends before they become emergencies.

However, some tasks require professional expertise. Refrigerant work needs EPA certification—it's not just recommended, it's the law. Electrical repairs can be dangerous without proper training, and compressor service requires specialized tools and knowledge.

For specific cleaning guidance, check out our detailed guide on how to get rid of mold in a walk-in fridge forever.

Upgrades for Efficiency & Longevity

Modern technology can breathe new life into older equipment. EC fans use up to 70% less energy than traditional motors while running quieter and lasting longer. LED lighting not only cuts electricity costs but also reduces heat load inside your cooler.

Smart monitoring systems are game-changers for busy operations. They can alert you to temperature fluctuations via text message, track energy usage, and even predict when components might fail.

The best upgrades pay for themselves through energy savings and reduced maintenance costs. Start with the most cost-effective improvements like LED lighting and EC fans, then consider more advanced systems as your budget allows.

Budgeting, Service Selection & Downtime Minimization

Understanding commercial cooler repair costs helps you make smart decisions when your equipment starts acting up. In Calgary and most major cities, you can expect to pay anywhere from $200 to $900 for typical commercial cooler repairs. Simple fixes like replacing door gaskets might hit the lower end, while compressor replacements definitely lean toward the higher range.

Service agreements can cut your repair costs by 30-40% while giving you priority scheduling. Think of it as insurance for your peace of mind.

How to Choose the Right Commercial Cooler Repair Provider

Finding the right repair team requires careful consideration. Response time should be your first consideration. The best providers guarantee same-day service and actually mean it.

Look for transparent pricing that doesn't hit you with surprise fees. Quality technicians will give you a detailed estimate before touching your equipment.

Certifications matter more than you might think. EPA 608 certification isn't just a nice-to-have—it's legally required for anyone handling refrigerants. Electrical licenses and manufacturer training separate the pros from the wannabes.

Check those Google reviews, but read between the lines. Look for patterns in feedback about punctuality, pricing, and problem-solving skills.

Insurance coverage protects both you and the repair team. Don't work with anyone who can't provide proof of comprehensive liability coverage.

When Repair Isn't Viable—Planning for Replacement

Sometimes you have to know when to fold. If your cooler is over 10 years old and facing its third major repair, it might be time for replacement. The general rule is simple: when repair costs hit 50% of replacement cost, start shopping for new equipment.

Energy bills tell a story too. Older units can consume 40-50% more electricity than modern equivalents. Those monthly savings often pay for new equipment within 3-5 years.

Don't forget about rebate programs—many utilities offer substantial incentives for energy-efficient commercial refrigeration. These rebates can cover 20-40% of your upgrade costs.

Keeping Operations Running During Repairs

Nobody wants to shut down operations, but sometimes repairs take time. Smart planning keeps your business running smoothly even when your main cooler is out of commission.

Temporary solutions can save the day. Ice delivery services work great for short repairs, while rental coolers handle extended downtime.

Inventory management becomes crucial during repairs. Move your most perishable items to backup cooling first. Consider reducing orders before scheduled maintenance to minimize risk.

Staff training makes all the difference. Everyone should know emergency procedures and have repair service contact information handy.

For detailed food safety guidelines during equipment failures, check out the latest research on power-outage food safety from the FDA.

Frequently Asked Questions about Commercial Cooler Repair

When your commercial cooler repair needs arise, you probably have urgent questions that need immediate answers.

How quickly should commercial cooler repairs be addressed?

The short answer? Immediately. When it comes to commercial refrigeration, time isn't just money—it's everything.

The USDA's 4-hour rule means you must discard perishable items if they've been at unsafe temperatures beyond that timeframe. That's not a suggestion—it's a food safety requirement that protects your customers and your business from liability.

Most reputable service providers offer same-day repairs for this exact reason. In major metropolitan areas, you can typically expect 24/7 emergency service availability.

Critical issues like complete temperature loss, refrigerant leaks, or electrical hazards need immediate attention—call now, not tomorrow. Urgent problems like partial cooling loss or unusual noises should be addressed within hours, not days.

Which parts get replaced most often, and why?

Door gaskets top the list. These rubber seals get slammed, stretched, and stressed hundreds of times daily in busy commercial kitchens.

Fan motors and blades come in second. These components run continuously in harsh conditions, dealing with temperature extremes, humidity, and kitchen debris. While some fans last only 3 years, premium models like True Refrigeration fans can keep running for 15-20 years.

Thermostats and controls fail frequently because they're constantly working. Every temperature cycle creates electrical stress, and over time, these components wear out.

Defrost components round out the most-replaced parts list. These elements cycle between freezing and heating regularly, and that extreme temperature swing takes its toll.

What's the difference between emergency service and routine maintenance?

Emergency service is the ambulance of the refrigeration world—it's available 24/7, costs significantly more, and focuses on getting you back up and running as quickly as possible.

Emergency calls typically cost 50-100% more than standard rates. Technicians are working nights, weekends, and holidays with limited parts inventory.

Routine maintenance is like your annual physical—it's scheduled at your convenience, costs standard rates, and takes a comprehensive approach to keeping everything healthy.

Businesses that invest in routine maintenance reduce their emergency calls by 60-80%. A $200 preventive service call can easily prevent an $800 emergency repair.

Commercial cooler repair isn't just about fixing what's broken—it's about protecting your business, your customers, and your reputation.

Conclusion

When your commercial cooler repair needs arise, you're not just dealing with a broken appliance—you're facing a potential business crisis. But with the right approach, you can turn refrigeration maintenance from a constant worry into a manageable part of your operations.

Spending a few hundred dollars on preventive maintenance beats spending thousands on emergency repairs every single time. The businesses that thrive are the ones that treat their coolers like the critical equipment they are.

The smart money is on prevention. Those temperature fluctuations you've been ignoring? That slight frost buildup that "doesn't seem too bad"? These are your cooler's way of asking for help before it breaks down completely. Listen to these early warnings, and you'll save yourself from those heart-stopping moments when you walk in to find everything warm.

At American Mortuary Coolers, we've seen what happens when refrigeration fails at the worst possible moment. In our industry, temperature control isn't just about preserving products—it's about preserving dignity during families' most difficult times. That's why we build our custom mortuary coolers to last, but more importantly, we understand that even the best equipment needs professional care.

Your refrigeration system is only as reliable as your maintenance program. Start with the basics: find certified technicians with EPA 608 credentials, establish a regular cleaning schedule, and don't try to DIY repairs involving refrigerant.

Commercial cooler repair isn't something you want to learn about during an emergency. Build relationships with qualified service providers now, while your equipment is running well. Get those phone numbers in your contacts, understand your warranty coverage, and have a backup plan ready.

The businesses that succeed long-term are the ones that plan ahead. They know their equipment's age, they schedule maintenance during slow periods, and they budget for repairs before they're needed. Most importantly, they understand that reliable refrigeration is an investment in their reputation.

Ready to take control of your refrigeration maintenance? Start with a professional assessment of your current equipment. For more guidance on finding reliable repair services, check out our walk-in cooler service guide.

Your coolers work hard for you every single day. Give them the professional attention they deserve, and they'll keep your business running cold for years to come.