Why Cremation Racks Are Essential for Modern Funeral Operations

A cremation rack is a specialized storage system designed to safely organize and transport bodies within crematories and funeral homes. These heavy-duty racks maximize storage capacity while ensuring efficient workflow from preparation to cremation.

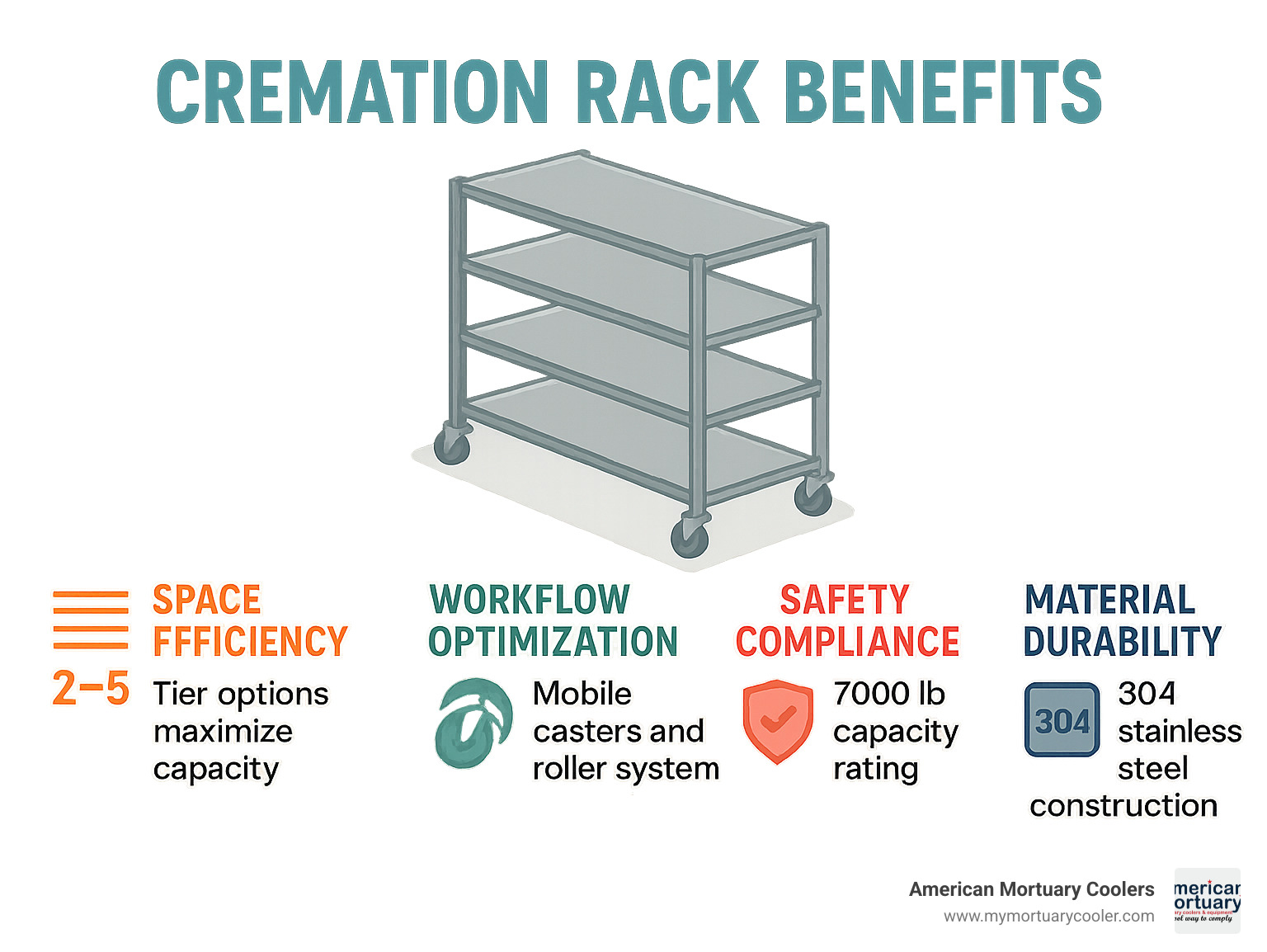

Key cremation rack types and features:

- Roller racks - Use gravity-free rollers for easy loading/unloading

- Cantilever racks - Open-front design with 2-5 tier options

- Mobile units - Include locking casters for transport between areas

- Load orientations - End-load, side-load, or multi-directional access

- Materials - 304 stainless steel or powder-coated welded steel

- Capacity - Support up to 7,000 lbs per rack, 500 lbs per tray

- Standard dimensions - Fit 77.5" x 23" body trays

The cremation industry has seen dramatic growth, with rates jumping from 5% in the 1950s to over 60% today. During Covid-19, some facilities saw annual cremations surge from 150 to over 3,000 cases. This increased demand makes efficient storage and staging systems more critical than ever.

Modern cremation racks address three core challenges:

- Space efficiency - Multi-tier designs maximize cooler capacity

- Workflow optimization - Mobile units streamline body transport

- Safety compliance - Heavy-duty construction meets OSHA standards

As Mortuary Cooler with extensive experience as a national mortuary cooler supplier, I've helped countless funeral homes optimize their cremation rack setups for maximum efficiency and compliance. The right cremation rack configuration can transform your facility's workflow while ensuring respectful handling of remains.

Quick look at cremation rack:

What Is a Cremation Rack and How Does It Fit Into Modern Crematories?

A cremation rack is a specialized storage system that serves as the backbone of modern funeral operations. While families focus on memorial services, these engineered systems work behind the scenes, ensuring smooth workflow from preparation to cremation.

These racks are much more than heavy-duty shelving - they're carefully designed to handle substantial weight loads while maintaining hygiene standards in demanding crematory environments. Most accommodate standard body trays measuring 77.5 inches long and 23.125 inches wide, creating seamless integration with other funeral home equipment.

Core Functions of a Cremation Rack

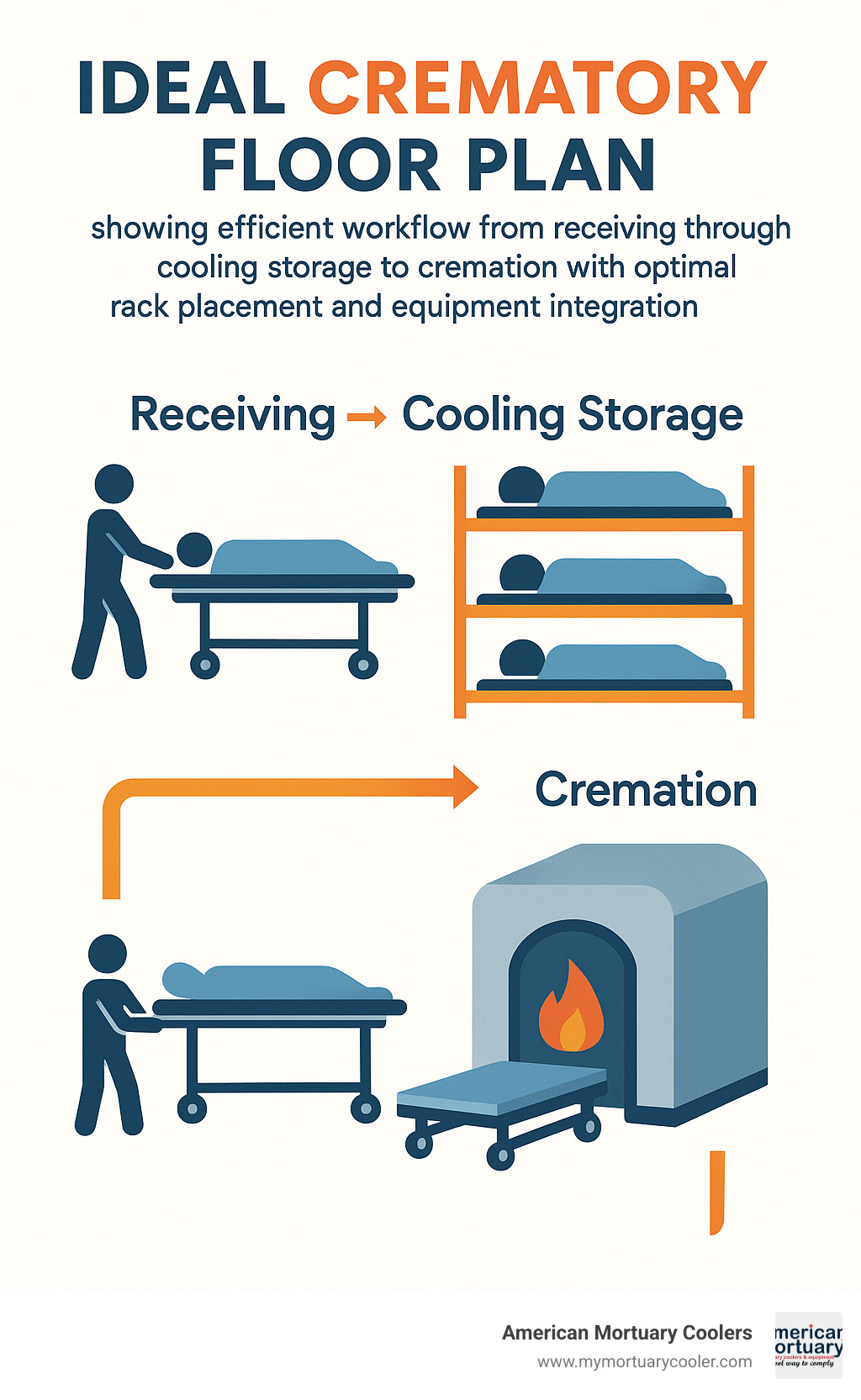

Every cremation rack serves three essential purposes: body staging, cooling zone management, and transport interface capabilities.

Body staging provides organized, respectful storage for remains awaiting cremation. Modern designs stack vertically with 2 to 5 tiers, maximizing storage without requiring additional floor space - crucial for urban funeral homes where space is premium.

Cooling zone functionality ensures racks perform reliably in refrigerated environments, handling temperature changes and humidity without deterioration. Quality racks use 304-grade stainless steel specifically for corrosion resistance in these challenging conditions.

Transport interface capabilities include mobile designs with locking casters and roller-equipped models that reduce physical strain during loading and unloading operations.

Why Cremation Racks Matter Amid Rising Cremation Rates

Cremation rates jumped from 5% in the 1950s to over 60% today, with projections showing North American rates will hit 70% soon. Covid-19 accelerated this trend dramatically - one South Carolina county saw annual cremations explode from 150 to over 3,000 during the pandemic.

These capacity challenges demonstrate why proper cremation rack selection matters. Facilities with multi-tier, high-capacity storage systems handled pandemic surges much better than those with basic setups. Modern Modern Human Cremation Chamber systems work best when paired with proper staging equipment, ensuring advanced retorts can perform at peak efficiency when families need it most.

Cremation Rack Design Types: Choosing the Right Configuration

Different facilities have different needs, and the right rack configuration can make or break your daily workflow. Like choosing the right vehicle for your needs, matching your rack design to your specific operation is crucial.

Roller-Style Cremation Rack

Roller-style cremation racks feature gravity-free rollers that make loading and unloading effortless. These systems use 1.9-inch diameter rollers with five rolling cross bars per section, reducing physical effort by about 75%.

The knock-down frame construction allows easy disassembly for cleaning or facility renovations. Heavy-duty welded steel frames handle up to 7,000 pounds per rack with anti-corrosive powder coating that protects against humidity and cleaning chemicals.

Cantilever Cremation Rack

Cantilever cremation racks solve access problems with their open front design, eliminating front posts that obstruct loading. The cantilever design extends horizontally from central support, providing clear access from multiple angles.

Tier options range from 2 to 5 levels with adjustable heights. Leveling feet rated over 7,000 pounds each distribute weight evenly, eliminating stress points and extending equipment life.

Side-Load vs. End-Load vs. Multi-Directional

Side-load racks position access along the rack's side, requiring wider aisles but offering easier approach angles. End-load racks access from narrow ends, perfect for tight spaces but requiring more precision. Multi-directional racks combine both approaches for maximum flexibility.

| Configuration | Aisle Width Required | Loading Ease | Space Efficiency | Best Use Case |

|---|---|---|---|---|

| Side-Load | 8-10 feet | High | Medium | Wide facilities |

| End-Load | 6-8 feet | Medium | High | Narrow spaces |

| Multi-Directional | 8-10 feet | Highest | Medium-High | Variable workflow |

Mobile & Knock-Down Variants

Mobile cremation racks with industrial casters transform storage from static to dynamic. 6-inch diameter casters with locking mechanisms allow repositioning when needed, then secure locking during operations.

Break-apart design enables complete disassembly for storage or transport. These modular systems assemble in under an hour and typically reduce shipping costs by 40-60%.

Key Specifications: Materials, Tiers, Dimensions & Weight Capacity

Understanding key specifications prevents costly mistakes. The materials, tier count, dimensions, and weight capacity determine whether your rack will serve reliably for decades or need early replacement.

Material Choices and Corrosion Resistance

304-grade stainless steel is the premium option, formulated with 18-20% chromium and 8-10.5% nickel to handle humidity and cleaning chemicals. While costing 30-40% more upfront, it provides 20+ years of reliable service with minimal maintenance.

Powder-coated welded steel offers excellent value for budget-conscious facilities. Modern powder coating involves sandblasting steel, then applying electrostatically charged powder baked at high temperatures. With proper care, expect 10-15 years of reliable service.

Both materials work well with 11-gauge tubing construction, providing necessary strength while keeping weight manageable. For maximum hygiene, choose designs with smooth, welded corners that eliminate bacteria-harboring crevices.

Tier Count vs. Space Efficiency

2-tier racks work best for facilities with lower ceilings or when easy access trumps capacity. 3-tier racks hit the sweet spot for most facilities, providing 50% more capacity while maintaining comfortable access. 4-tier racks require 10+ foot ceilings but offer 33% more capacity than 3-tier systems. 5-tier racks maximize density but require high ceilings and mechanical lifting aids.

Always leave 18 inches between your top tier and ceiling for safe maneuvering.

Dimensions & Custom Sizing Options

Standard cremation rack dimensions accommodate industry-standard body trays measuring 77.5 inches long by 23.125 inches wide. Most racks measure 24-26 inches deep with 18-20 inch tier spacing.

Custom sizing handles unique situations: reduced depth for narrow coolers (minimum 22 inches), extended width for multiple bays, modified height for low ceilings, and custom tier spacing for specialized containers. Custom options typically add 2-4 weeks to delivery time with modest upcharges.

Buyer's Guide: Features, Costs, Regulations & Common Mistakes

Choosing the right cremation rack requires understanding key features, realistic budgeting, regulatory requirements, and avoiding common pitfalls that create daily operational headaches.

Must-Have Features on Any Cremation Rack

Smooth welded construction with rolled edges prevents bacteria accumulation and safety hazards. Removable rollers enable quick maintenance - individual rollers should swap out in minutes, not hours. Proper drainage through built-in ports or sloped surfaces prevents moisture buildup and bacterial growth.

Easy-clean corners with radius edges eliminate 90-degree angles where debris hides. Industrial-grade locking casters keep mobile racks positioned securely during loading operations.

Budgeting & Price Drivers

Material choice creates the biggest price difference. Powder-coated steel racks run $1,500 to $4,000 for standard configurations. 304 stainless steel costs $3,000 to $8,000 but provides decades of corrosion-free service.

Tier count affects pricing with each additional tier adding 20-25% to base cost, though cost per storage position actually decreases. Custom features add 15-40% depending on complexity. Freight costs typically add $200-$600 for standard shipping.

Remember - this is a 15-25 year investment. Even an $8,000 rack costs less than $30 per month over its lifespan.

Regulatory & Industry Standards

OSHA load limits require proper engineering documentation for multi-tier installations supporting over 500 pounds per tier. State mortuary codes vary significantly - some require stainless steel construction while others focus on cleaning protocols. NFDA guidelines provide industry best practices that exceed regulatory minimums.

Pitfalls to Avoid When Purchasing

Ceiling height miscalculations create safety hazards. Measure twice and account for tray height plus maneuvering space. Tray compatibility issues cause immediate problems - verify compatibility with existing trays. Undersized casters fail under load - choose casters rated for full loaded weight. Inadequate aisle spacing creates daily obstacles - plan with fully extended trays in mind.

Maintenance, Workflow Efficiency & Safety Best Practices

Proper cremation rack maintenance keeps staff safe and operations running smoothly. Well-maintained systems work reliably for decades, while neglected ones cause headaches and safety concerns.

Cleaning & Disinfection Routine for a Cremation Rack

Daily routine requires thorough wipe-down using EPA-approved disinfectants designed for mortuary use. Quaternary ammonium compounds provide broad-spectrum protection without damaging metal surfaces. Avoid chlorine bleach completely - it causes pitting and corrosion even on stainless steel.

Weekly application of specialized stainless steel polish keeps surfaces professional while providing additional protection. Monthly attention to roller mechanisms prevents debris accumulation and ensures smooth operation with food-grade lubricant.

Quarterly deep cleaning sessions involve disassembling removable components for thorough sanitization, catching areas daily procedures might miss.

Extending Lifespan Through Preventive Maintenance

Roller replacement should happen on schedule - most provide 5-7 years of service. Keep spare rollers in inventory to prevent downtime. Test caster brakes monthly and replace any showing wear immediately.

Schedule annual weld inspections to catch fatigue cracks early. Lubrication schedules depend on environment - mobile racks in high-humidity areas need monthly attention while climate-controlled installations might go quarterly.

Maintain detailed maintenance records for compliance documentation and pattern identification.

Integrating Racks for Seamless Workflow

Optimal cooler-to-retort paths should be direct with adequate maneuvering space. Coordinate rack heights with lift table heights for ergonomic transfers. Design traffic flow patterns to separate incoming and outgoing remains when possible.

Accessories That Boost Productivity

Body trays measuring 77.5" × 23.125" × 2.75" provide the critical interface between racks and remains. Transfer boards and slider systems reduce physical effort for moving remains. Cooling racks for cremation pans provide safe post-cremation staging.

Cremation Systems: The Heart of Modern Farewells demonstrates how coordinated equipment selection amplifies efficiency gains throughout your facility.

Frequently Asked Questions about Cremation Racks

When helping funeral homes across the country select the right storage solutions, we hear the same questions repeatedly. Here are the answers to the three most common concerns about cremation rack systems.

How much weight can a standard cremation rack hold?

This is probably the first question every funeral director asks - and for good reason. You need equipment that can handle real-world demands safely.

Standard cremation racks are built like tanks. Individual body trays typically support 500 pounds each, which accommodates virtually every adult case you'll encounter. The complete rack assembly handles up to 7,000 pounds total - that's enough for multiple cases simultaneously without breaking a sweat.

Here's what makes these numbers reliable: cantilever rack leveling feet are individually rated for over 7,000 pounds each. That means even a fully loaded 5-tier rack has exceptional stability. The engineering goes far beyond minimum requirements because manufacturers understand the consequences of failure in mortuary environments.

The real key is matching your specific needs to manufacturer ratings. If your facility occasionally handles unusually large cases, mention this when ordering. Most suppliers can recommend heavy-duty configurations that provide extra capacity where needed.

Can I order a custom-sized rack for an odd-shaped cooler?

Absolutely! Custom cremation racks are more common than you might think. We've designed storage solutions for some pretty challenging spaces over the years.

Funeral homes rarely have perfect rectangular coolers with ideal dimensions. That's why manufacturers regularly create custom configurations for reduced-depth units (as narrow as 22 inches), modified heights for low ceilings, and adjusted widths for specific bay layouts.

We've successfully fitted racks into spaces that seemed impossible - including a 6-foot-wide cooler with a 7-foot ceiling. The key is working with experienced suppliers who understand both the engineering constraints and your operational needs.

Custom colors are another popular option. Some facilities want racks that match their décor, while others use color coding for organizational purposes. Most powder coating shops can match specific colors for a modest upcharge.

The important thing is identifying custom requirements before you order. Changes after manufacturing begins can delay delivery by weeks and significantly increase costs. Measure twice, order once - it'll save you headaches and money.

What maintenance schedule keeps racks compliant with health codes?

Smart maintenance prevents problems and keeps inspectors happy. The good news is that quality cremation racks don't require complicated maintenance procedures.

Daily cleaning forms the foundation of any good maintenance program. Use EPA-approved disinfectants designed for mortuary use - they provide broad-spectrum protection without damaging metal surfaces. Avoid chlorine bleach completely, as it can cause pitting even on stainless steel.

Weekly inspections should cover roller mechanisms, caster function, and overall structural condition. This takes about 10 minutes but catches small problems before they become big headaches. Look for debris in roller channels and test caster brakes to ensure they lock properly.

Monthly tasks include lubricating moving parts with food-grade lubricants and performing more detailed brake testing on mobile units. Keep spare rollers in inventory - they typically last 5-7 years but having replacements on hand minimizes downtime.

Quarterly deep cleaning involves disassembling removable components for thorough sanitization. This intensive procedure addresses areas that daily cleaning might miss and provides opportunity for detailed wear inspection.

Document everything. Digital maintenance logs make compliance reporting easier and help identify patterns that predict future maintenance needs. Most health departments appreciate facilities that can demonstrate systematic maintenance procedures during inspections.

Conclusion

Choosing the right cremation rack system transforms how your facility operates during challenging times. With cremation rates soaring from 5% in the 1950s to over 60% today, quality storage infrastructure has become essential, not optional.

The specifications we've covered - 304 stainless steel construction, multi-tier configurations, and mobile capabilities - are building blocks of systems that serve facilities reliably for 15-25 years while adapting to changing demands.

Covid-19 demonstrated this clearly. Facilities with proper cremation rack systems weathered the storm, while others scrambled for emergency solutions. The difference came from investing in quality infrastructure before crisis hit.

Every facility faces three core challenges: maximizing cooler space, maintaining smooth workflow during peak periods, and ensuring safety standards under pressure. The right rack configuration addresses all three simultaneously.

At American Mortuary Coolers, we've learned from our work across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania that no two facilities are identical. What works for high-volume urban crematories might be wrong for small-town funeral homes with space constraints.

That's why we focus on custom solutions custom to your specific needs. Whether dealing with low ceilings, narrow coolers, or unique workflow patterns, the right cremation rack system exists - it might just need custom design.

Quality rack systems pay for themselves through reduced staff fatigue, improved workflow efficiency, and peace of mind knowing your facility can handle any volume. With 20+ year service life, monthly costs often work out to less than a tank of gas.

Ready to optimize your facility's cremation workflow? Visit our website to explore custom mortuary cooler and rack solutions designed specifically for your needs. Our team delivers directly across the contiguous 48 states, bringing decades of experience right to your door.