Why Stretcher Wheels Are Critical for Patient Transport

A stretcher wheel is a specialized caster or transport wheel designed to facilitate the movement of patient stretchers, rescue litters, and medical gurneys across various surfaces. These wheels are engineered to handle significant loads while providing smooth, controlled movement that prioritizes both patient safety and caregiver efficiency.

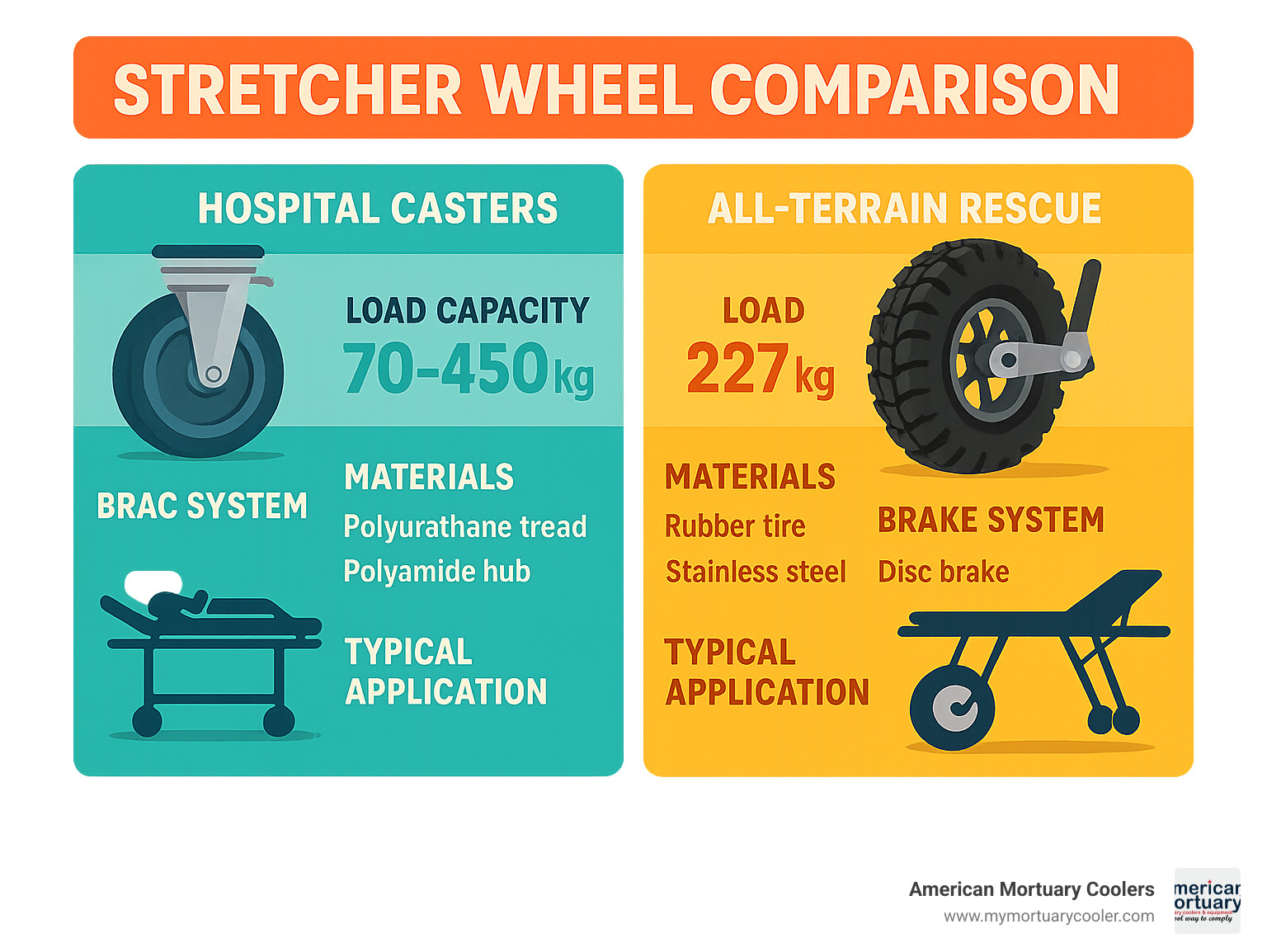

Key stretcher wheel types and specifications:

- Hospital casters: 5"-8" diameter, 70-450 kg capacity, precision ball bearings, electroconductive options

- All-terrain rescue wheels: Single or dual-wheel designs, ATV-style tires, 500 lb load capacity, disc brakes

- Materials: Polyurethane tread, rubber compounds, polyamide hubs, stainless steel hardware

- Features: Central locking brakes, swivel mechanisms, quick-release attachments, anti-static properties

The choice between different stretcher wheel options depends on your specific application - whether you need quiet hospital transport, rugged outdoor rescue capability, or specialized features like electroconductive properties for sensitive medical environments.

Modern stretcher wheels have evolved significantly from basic casters to sophisticated transport systems. Load capacities vary dramatically - from lightweight 70 kg hospital casters to heavy-duty rescue wheels rated for 227 kg (500 lbs).

As Mortuary Cooler, I've worked extensively with funeral homes and medical facilities to specify the right stretcher wheel solutions for their unique operational needs. My experience in the mortuary equipment industry has shown me how proper stretcher wheel selection directly impacts both staff efficiency and service quality.

Related content about stretcher wheel:

What Is a Stretcher Wheel and Why It Matters

Think of a stretcher wheel as the unsung hero of patient transport. While medical professionals focus on providing care, these specialized wheels quietly handle one of the most critical aspects of the job - moving patients safely and smoothly from point A to point B.

The magic happens in how these wheels transform what could be an exhausting, potentially dangerous lifting task into controlled, manageable movement. Whether you're navigating the polished floors of a hospital corridor or traversing rocky mountain terrain during a rescue operation, the right stretcher wheel makes all the difference.

Hospital caster wheels prioritize precision and quiet operation. Their polyurethane treads and precision ball bearings ensure that a 450 kg patient can be moved with minimal effort and virtually no noise - crucial during those late-night emergency calls.

All-terrain rescue wheels take a completely different approach. These robust systems feature ATV-style tires and disc brake systems that can handle a 500-pound load across surfaces that would stop a regular caster dead in its tracks.

What separates stretcher wheels from regular casters is their shock absorption capabilities. When you're transporting someone who's already in distress, every bump and jolt matters. Quality stretcher wheels minimize these impacts while maintaining the swivel and fixed positioning options that caregivers need for precise maneuvering.

History & Evolution of the Stretcher Wheel

The story of stretcher wheels starts on battlefields, where military litters first needed basic mobility solutions. Hospital gurneys changed the game in the mid-1900s as medical facilities grew larger and patient care became more sophisticated.

Mountain rescue operations pushed innovation in a completely different direction. When you need to evacuate someone from a cliff face or across miles of wilderness, your wheels better be tough enough to handle whatever nature throws at them.

Core Components

Every stretcher wheel is essentially a carefully engineered system where each component has a specific job. The hub serves as the foundation, the bearing system ensures smooth operation, tread compounds provide appropriate surface contact, brake systems offer control, and the axle needs to be built like a tank with precise tolerances because any wobble gets magnified when dealing with human cargo.

Major Types & Use-Case Scenarios

When you're shopping for a stretcher wheel, you'll quickly find that one size definitely doesn't fit all. The wheel that works perfectly in a quiet hospital corridor might fail completely on a muddy mountain trail, and vice versa.

The main categories break down into hospital casters, all-terrain rescue wheels, and bariatric options for heavier loads. You'll also find specialized designs like stair chair wheels and fifth-wheel assemblies that solve specific transport challenges.

Hospital Caster Stretcher Wheel

Most hospitals rely on 8-inch diameter wheels with rubber or polyurethane treads - and for good reason. These wheels are the workhorses of patient transport, designed to roll smoothly and quietly across polished floors while carrying significant weight.

The central brake system is probably the most important feature you'll use daily. One quick step locks both the wheel rotation and the swivel movement, keeping your stretcher exactly where you need it during patient transfers.

Quiet rolling isn't just about comfort - it's about functionality. When you're transporting patients at 3 AM, the last thing you want is wheels that sound like a freight train. Quality hospital casters use precision bearings that virtually eliminate noise, even under heavy loads.

Infection control features make these wheels practical for medical environments. The smooth polyurethane surfaces resist bacteria and clean easily with standard hospital disinfectants.

More info about Medical Stretchers 101

All-Terrain & Rescue Stretcher Wheel

Step outside the hospital, and everything changes. Rescue operations need wheels that can handle sand, snow, and mud without missing a beat. That's where all-terrain stretcher wheels prove their worth.

The ATV-style tire design gives these wheels their rugged capability. Instead of smooth polyurethane, you get aggressive tread patterns that grip loose surfaces and absorb shock from rocks and roots.

Titanium fork construction keeps weight down without sacrificing strength. Disc brake systems provide reliable stopping power on slopes where standard brakes might fail. The single-wheel frame design eliminates the sway you get with dual wheels, creating a more stable ride for injured patients over rough terrain.

Scientific research on trail wheel ergonomics

Single-Wheel vs Dual-Wheel Designs for Litters

The single-wheel versus dual-wheel debate comes down to where and how you'll use your stretcher wheel. Each design solves different problems, and understanding the trade-offs helps you make the right choice.

Single-wheel designs excel on narrow trails where every inch of width matters. The centered wheel also eliminates the rocking motion that happens when dual wheels hit obstacles at different times.

Stability is where dual-wheel systems shine. Two wheels distribute weight more evenly and provide redundancy if one wheel gets damaged. Crew fatigue considerations often tip the scales toward single-wheel designs due to less weight and easier maneuvering.

Specifications, Materials & Selection Guide

Choosing the right stretcher wheel becomes much clearer once you understand how the basic specs work together. The diameter of your wheel makes a bigger difference than you might expect. Smaller wheels around 5-6 inches are fantastic for tight hospital corridors, while 8-10 inch wheels provide better shock absorption and roll over obstacles without jarring the patient.

Load capacity is where things get serious. A basic hospital stretcher wheel might handle 70 kg, which works fine for pediatric units. But when you're dealing with bariatric patients or adding heavy medical equipment, you need wheels rated for 300-450 kg.

Sizes, Load Ratings & Application Match

The relationship between wheel size and capacity isn't just about bigger being stronger - it's about matching the right tool to the job.

| Wheel Diameter | Load Capacity | Best Use Cases | Typical Applications |

|---|---|---|---|

| 5" | 70-100 kg | Lightweight hospital casters | Pediatric stretchers, examination tables |

| 6" | 100-150 kg | Standard hospital transport | General patient gurneys, wheelchair bases |

| 8" | 150-300 kg | Heavy-duty hospital/rescue | Adult stretchers, bariatric equipment |

| 10" | 300-450 kg | Maximum capacity rescue | Bariatric rescue, multi-patient scenarios |

An 8-inch stretcher wheel hits the sweet spot for most applications. You get excellent load capacity, smooth rolling, and reasonable cost - typically between $54.95 and $87.95 depending on features.

Materials & Bearing Technologies

The tread material on your stretcher wheel determines whether you'll love it or regret the purchase. Polyurethane has become the gold standard in hospitals because it's quiet, protects floors, resists chemicals, and lasts for years.

Electroconductive polyurethane looks identical to regular polyurethane but safely channels static electricity to ground. If you're working around MRI machines or sensitive electronic equipment, this isn't just nice to have - it's essential for safety.

The bearing system separates good wheels from great ones. Precision ball bearings in both the wheel and swivel mechanism make an enormous difference in how smoothly everything operates under loads up to 450 kg.

Sealed bearing systems protect against cleaning chemicals, biological fluids, dirt, sand, and moisture. Quality stretcher wheels use temperature-proof grease and materials that perform reliably from freezing outdoor rescues to hot ambulance storage areas.

More info about EMT stretcher buying

Key Features, Leading Brands & Pricing Insights

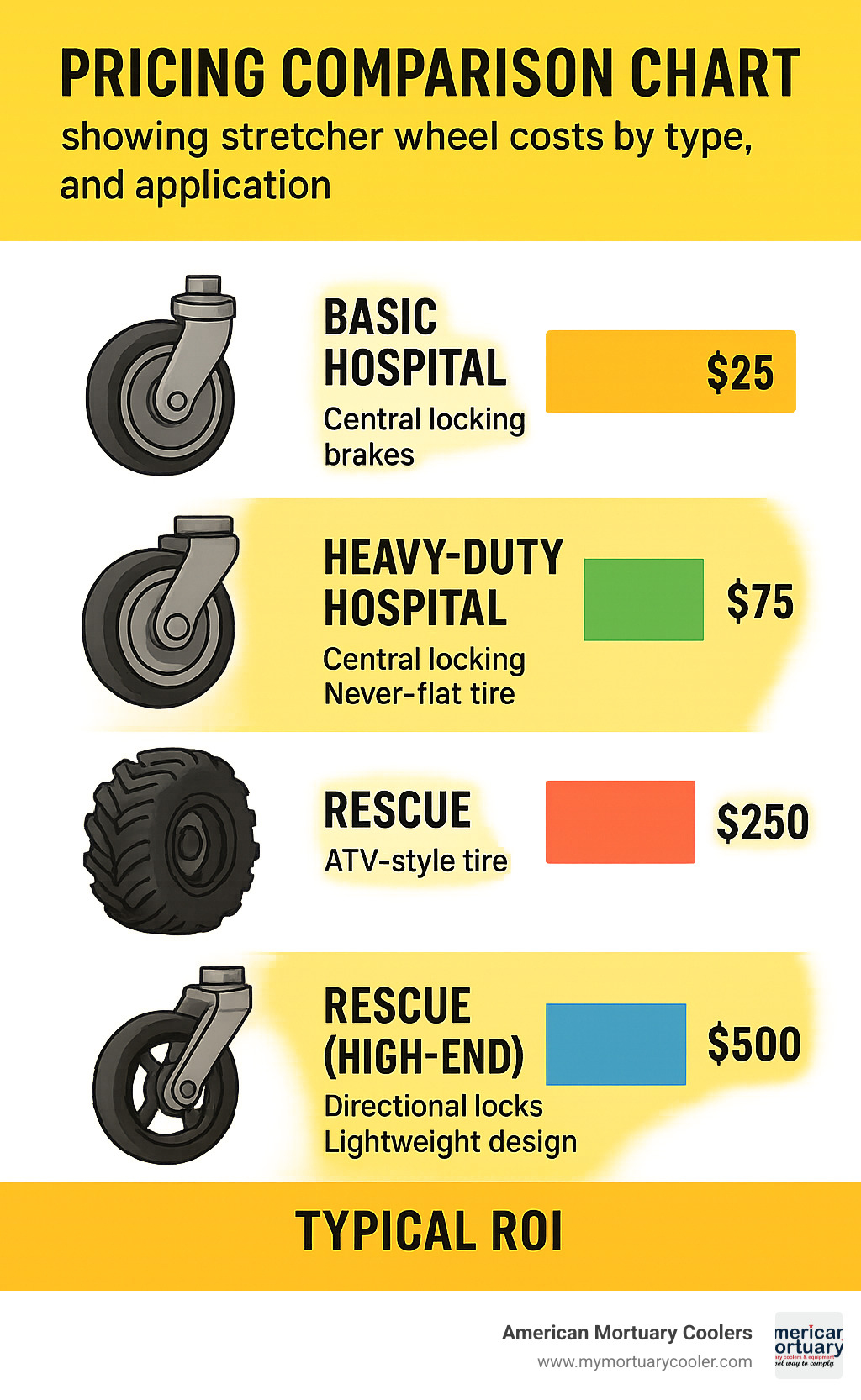

When you're shopping for a stretcher wheel, prices can range dramatically - from basic hospital casters at $22.95 to sophisticated rescue systems that cost $370.95 or more. Understanding what drives these price differences will help you make the right choice.

The most significant feature upgrade you'll encounter is advanced brake systems. Central locking brakes that secure both wheel rotation and swivel movement with a single action provide far superior control compared to basic wheel-only brakes.

Never-flat tire technology eliminates the risk of punctures in critical situations. These systems use solid polyurethane construction that maintains performance even after sustaining damage that would disable traditional pneumatic tires.

Top Manufacturers & Distinguishing Features

Stryker has established itself as the gold standard in hospital stretcher wheels, with their 8-inch electroconductive wheels featuring polyurethane treads and precision ball bearings. Their electrostatic control features make them particularly valuable in sensitive areas like MRI suites.

The Ferno Mule II system revolutionized rescue transport with its rugged all-terrain approach. Its ATV-style tire provides excellent shock absorption while the eight-position adjustable handles significantly reduce crew fatigue during long evacuations.

Cascade Rescue's Terra Tamer pushes the boundaries with lightweight construction. At just 15.40 lbs, it's the lightest all-purpose patient transport wheel on the market, thanks to its pure titanium framework. Despite this minimal weight, it maintains robust load capacity.

Specialized manufacturers like ALCO and MedCaster focus on specific market segments, offering precision-engineered solutions for unique applications with innovative mounting systems and specialized materials.

Pricing, Warranties & Recent Innovations

Stretcher wheel pricing directly reflects the complexity and specialization required. Basic hospital casters start around $22.95, mid-range options with precision ball bearings fall between $54.95 and $87.95, while high-end rescue wheels command premium prices due to specialized construction.

The stretcher wheel industry continues to innovate with smart sensors that monitor wheel condition, advanced brake systems with electronic controls, modular designs for quick reconfiguration, and improved electroconductive materials for better static dissipation.

Warranty coverage varies significantly, with hospital-grade wheels typically offering 1-2 year warranties while specialized rescue equipment may include longer coverage periods.

Installation, Maintenance & Safety Best Practices

Getting your stretcher wheel system properly installed and maintained isn't just about following instructions - it's about ensuring that when someone's life depends on your equipment, everything works exactly as it should.

Most stretcher wheel systems are designed with real-world use in mind. Hospital casters typically bolt directly to stretcher frames, while rescue wheels often feature quick-release systems for rapid deployment.

The forces involved are much higher than most people expect. Ratchet mechanisms on rescue wheels can generate over 3,500 pounds of force - enough to damage equipment if you're not careful.

Attaching a Stretcher Wheel Assembly Correctly

When installing a quick-release stretcher wheel system, sequence matters. Start by removing the litter saddle from the fork assembly completely, position it forward of where the litter splits, then carefully thread the hooks between the shell and top rail.

The key is removing slack by pulling parallel to the litter bottom rather than straight up vertically. This distributes forces properly and prevents damage.

Universal clamp systems have made life easier for rescue operations. The Terra Tamer's universal brake clamp fits litter rails from 5/8" to 1" diameter, but needs unwrapped metal rails to work properly.

The biggest mistake? Over-tightening. That 3,500-pound force capability means you need restraint and must follow manufacturer tension guidelines.

Preventive Maintenance Checklist

Daily inspections should include visual checks for obvious damage - cracks in the wheel, bent mounting hardware, or unusual wear patterns.

For pneumatic rescue wheels, tire pressure should stay at or below 10 psi. This might seem low, but it's crucial for proper shock absorption and terrain conformance.

Bearing lubrication schedules depend heavily on environment. Hospital wheels in clean settings might only need annual service, while rescue wheels need attention much more frequently. Even sealed bearing systems require periodic service.

Don't forget brake system calibration, especially for rescue applications where you need precise speed control on slopes.

Safety & Ergonomic Considerations

Patient stability starts with smooth stretcher wheel operation. Quality wheels with precision bearings create less vibration transmitted to patients - particularly important for trauma cases.

Your staff will notice the difference quality wheels make. Smooth-rolling wheels mean less effort to maneuver stretchers, while properly functioning swivel mechanisms give precise control.

Anti-static compliance isn't optional in certain hospital areas. Electroconductive stretcher wheels prevent static buildup that could interfere with sensitive equipment, but they must be properly grounded to function effectively.

Frequently Asked Questions about Stretcher Wheels

Let me address the most common questions I hear from funeral directors, hospital administrators, and rescue teams when selecting stretcher wheel systems.

What size stretcher wheel should I choose for my application?

For most hospital and mortuary applications, 8-inch wheels hit the sweet spot perfectly. They handle loads up to 300 kg while rolling quietly across smooth floors - exactly what you need for professional patient transport.

Larger wheels roll easier but make transfers more challenging because they raise stretcher height. If you're primarily working on smooth surfaces like hospital corridors or funeral home floors, that 8-inch diameter gives you the best balance.

Rescue teams face different challenges. When dealing with rough terrain, larger 10-inch wheels make sense for maximum load capacity. But don't overlook specialized designs like the Terra Tamer's 4.25" wide tire - sometimes width matters more than diameter.

How often should stretcher wheel bearings be serviced?

Bearing maintenance depends entirely on your operating environment. For stretcher wheels in clean hospital or funeral home environments, precision ball bearings typically need annual inspection with lubrication every 2-3 years under normal usage.

Rescue operations are completely different. Those wheels face dirt, moisture, extreme loads, and temperature swings. Rescue wheel bearings may need service every 6-12 months depending on deployment frequency and conditions.

Warning signs include increased rolling resistance, unusual noise, or any play in the wheel assembly. Don't wait for complete failure - degraded bearings compromise both performance and safety.

Are electroconductive stretcher wheels necessary in every hospital area?

The answer is definitely not universal. Electroconductive stretcher wheels serve a specific safety purpose, but they're overkill for many hospital areas.

You absolutely need electroconductive wheels in MRI suites, areas with sensitive electronic monitoring equipment, and anywhere static electricity could create ignition risks - particularly oxygen-rich environments.

For most general hospital corridors and patient rooms, regular polyurethane wheels work perfectly fine. The critical point many miss: electroconductive wheels only work with proper grounding. Without that connection, you're paying extra for no benefit.

Work with your facility's electrical team to identify which areas truly require electroconductive wheels, then use standard wheels everywhere else.

Conclusion

Choosing the right stretcher wheel comes down to understanding your specific needs and matching them with the right features. Whether you're moving patients through quiet hospital corridors or navigating rocky mountain trails, the wheel system you select directly impacts both safety and efficiency.

Single-wheel designs shine when you need maximum maneuverability on narrow trails and want to reduce crew fatigue during long rescues. The stability they provide over rough terrain makes them the go-to choice for wilderness rescue teams. Dual-wheel systems, on the other hand, give you that rock-solid stability for longer transports on smoother surfaces - perfect when you're covering distance rather than navigating obstacles.

Hospital environments have their own unique demands. Your stretcher wheel needs to roll quietly during those late-night patient transfers, lock securely during procedures, and resist the harsh cleaning chemicals that keep facilities safe. The precision ball bearings and specialized polyurethane treads in quality hospital casters aren't just nice-to-have features - they're essential for daily operations.

Regular maintenance makes all the difference in wheel performance and longevity. A simple daily visual check and periodic bearing service can prevent failures when you need your equipment most. The investment in quality wheels pays for itself through reduced downtime and improved reliability.

At American Mortuary Coolers, we've seen how the right stretcher wheel selection transforms daily operations. Our Tennessee-based team has worked with funeral homes and medical facilities across the contiguous 48 states, and we understand that every situation has unique challenges. Sometimes you need the whisper-quiet operation of hospital casters, other times you need the rugged reliability of all-terrain rescue wheels.

More info about Explore the Benefits of Ambulance Stretchers

Your patients and staff deserve equipment that works reliably every single time. Whether you're transporting a patient through a busy emergency department or moving someone across challenging terrain, the right stretcher wheel system ensures smooth, safe transport when it matters most.

For custom stretcher solutions and expert guidance on wheel selection, American Mortuary Coolers delivers durable, custom equipment directly to your location. Our experience in the medical and mortuary industries means we understand the demanding requirements your equipment faces every day - and we're here to help you find the perfect solution.