Why Used Walk-In Coolers Are Your Best Investment for Cold Storage

Used-walk-in-coolers-for-sale- offer substantial savings and proven reliability for businesses needing professional cold storage without the premium price tag. Whether you're expanding operations or replacing aging equipment, the used market provides tested solutions at 30-60% less than new units.

Quick Answer for Buyers:

- Cost Savings: Used units typically cost $7,500-$10,000 CAD vs. $13,000+ for new

- Where to Buy: Online marketplaces, government auctions, local dealers, specialty refrigeration companies

- Key Inspection Points: Panel integrity, door seals, compressor condition, refrigerant type

- Warranty Options: 90-day parts and labor available from reputable dealers

- Installation: Professional setup required; factor in delivery and electrical costs

The used walk-in cooler market has exploded as smart business owners find they can get commercial-grade refrigeration without breaking budgets. From restaurants upgrading kitchen storage to funeral homes needing reliable body storage, used units deliver the same temperature control as new equipment.

The reality is simple: A quality used walk-in cooler can serve your needs for decades with proper maintenance, making it an ideal choice for cost-conscious operators who refuse to compromise on reliability.

As Mortuary Cooler, a national-level mortuary cooler supplier with experience in commercial refrigeration, I've helped countless facilities find the perfect used-walk-in-coolers-for-sale- that meet their specific needs and budgets.

Used-walk-in-coolers-for-sale- terms explained:

Why This Guide Matters

Buying a used walk-in cooler shouldn't feel like navigating a minefield, but too many buyers get burned by hidden costs, regulatory headaches, and equipment failures. We've seen funeral homes pay thousands for units that failed health inspections, restaurants stuck with coolers that couldn't maintain proper temperatures, and small businesses overwhelmed by installation requirements.

The biggest pain points include:

- Budget surprises: That $8,000 cooler becomes $12,000 after delivery, installation, and electrical work

- Regulatory nightmares: Local health departments rejecting units that don't meet current codes

- Hidden damage: Panels that look fine but have compromised insulation or refrigerant leaks

This guide eliminates those headaches by giving you the insider knowledge to make smart purchases and avoid costly mistakes.

Understanding Used Walk-In Coolers: What They Are & How They Differ From New

Picture walking into a giant refrigerator - that's essentially what a walk-in cooler is. These refrigerated rooms are built from insulated panels that snap together like oversized puzzle pieces, creating a controlled environment perfect for storing everything from restaurant ingredients to funeral home needs.

The magic happens in the details. Those panels aren't just metal sheets - they're sophisticated insulation systems with R-values between R-29 and R-32, typically packed into 4-inch thick walls. This insulation keeps the cold in and the heat out, which is exactly what you want when you're paying the electricity bill.

Used-walk-in-coolers-for-sale- come from all sorts of places. Maybe a restaurant closed down, or a hospital upgraded their storage. Most units on the used market fall into that sweet spot of 8-12 years old - old enough to have proven they work reliably, but young enough to have plenty of life left.

The depreciation curve works in your favor here - that $20,000 cooler from 10 years ago might sell for $8,000 today, even though it could easily run for another 15 years with proper care.

How a Used Unit Differs From New

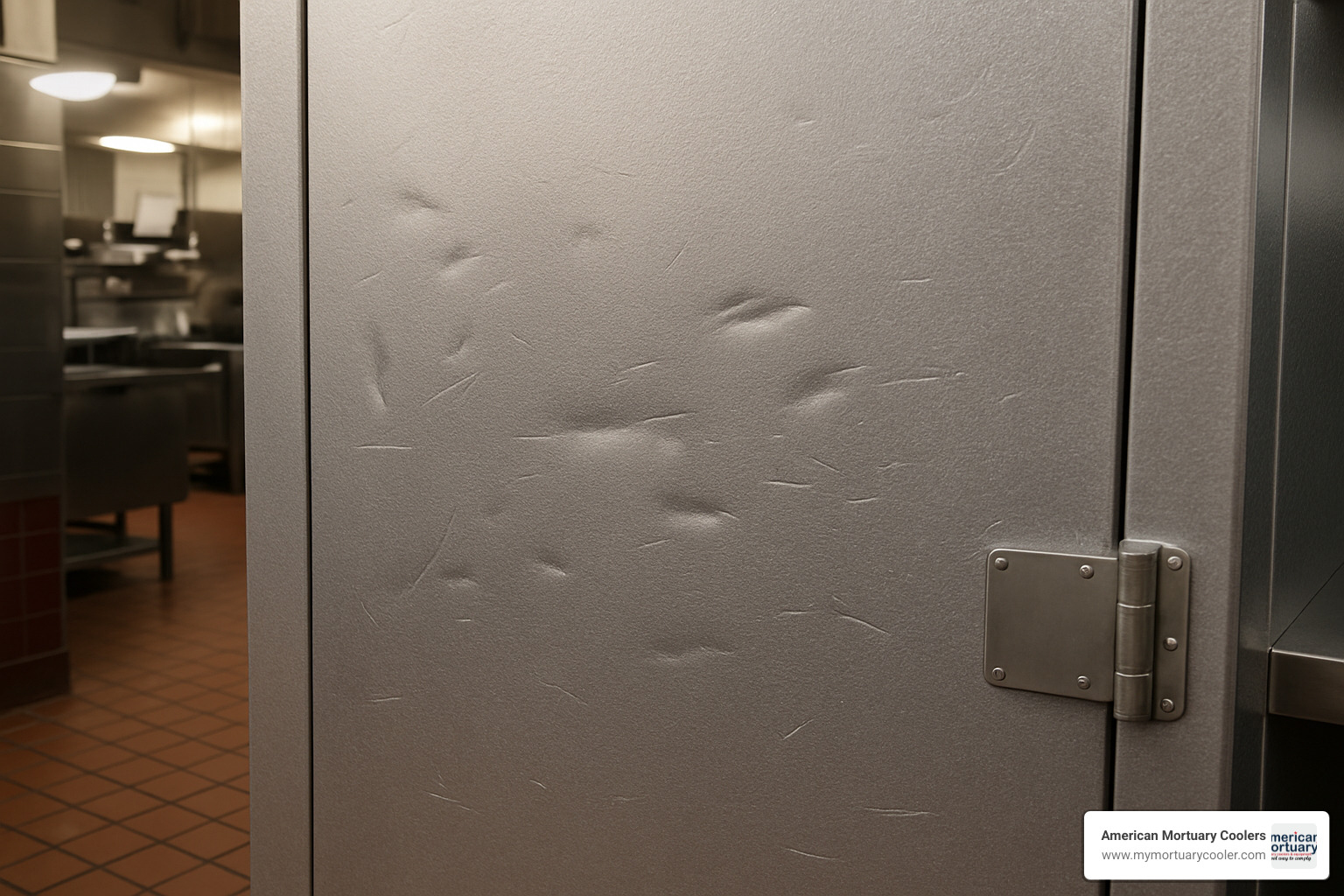

Let's be honest about what you're getting into. The most obvious difference is cosmetic wear - expect scratches on panels, scuff marks on floors, and general signs that real people used this equipment for real work. But character marks don't affect cooling performance.

The bigger considerations run deeper. Factory warranty gaps are the elephant in the room. That shiny new cooler comes with a 20-year panel warranty and 5-year compressor coverage. Your used unit? You might get 90 days from the dealer if you're lucky.

Energy efficiency deltas can add up over time. A 15-year-old unit might use 20-30% more electricity than today's models, especially if it's still running older R-22 refrigerant. But it often takes years for those energy costs to offset your upfront savings.

Key Components Inside Every Cooler

Understanding what makes these machines tick helps you spot a good deal from a money pit. The evaporator coil is your indoor cooling hero - it's what actually chills the air inside your cooler. Look for clean coils without excessive ice buildup or corrosion.

The condensing unit lives outside (or sometimes inside for self-contained systems) and handles the heat rejection. This is where you'll find the compressor - the heart of the whole operation. A smart buyer checks the compressor's amperage draw against the nameplate specifications. High electrical draw often signals worn components that could fail soon.

Don't overlook the door hardware. That entry door needs to close completely and seal properly every single time. Magnetic gaskets should create a tight seal all around the frame - no gaps, no compromises. Self-closing hinges and interior safety releases aren't just nice features; most building codes require them.

Finally, the digital controller manages your temperatures and keeps everything running smoothly. Modern electronic controls offer precise temperature management with built-in alarms. Older mechanical thermostats work fine but lack the precision and monitoring capabilities that can save you headaches down the road.

Pros & Cons of Buying Used Walk-In Equipment

Let's have an honest conversation about used-walk-in-coolers-for-sale-. After helping hundreds of facilities make this decision, I've seen both the incredible wins and the painful lessons learned the hard way.

Buying used equipment can be one of the smartest financial decisions you'll make - or it can turn into an expensive nightmare if you're not careful. The difference usually comes down to knowing what to look for and being realistic about the trade-offs.

Major Benefits You Shouldn't Overlook

The capital conservation alone makes most business owners sit up and take notice. We consistently see used walk-in coolers priced at 30-60% less than new units. That 8'x10' cooler that would cost you $13,000+ brand new? You can often find a quality used one for $7,500-$10,000.

Quick availability is another game-changer, especially when you're in a pinch. While ordering a new custom unit means waiting 4-8 weeks for manufacturing and delivery, used units can be in your facility within days. I've worked with funeral homes that needed emergency cooling capacity and had a used unit operational within 48 hours.

The eco-friendly angle might not be your primary motivation, but it's worth mentioning. Every used cooler that gets a second life means one less unit heading to a landfill.

Here's something many buyers don't consider: proven reliability. A 10-year-old cooler that's still humming along has already demonstrated it can handle daily use. You're not taking a gamble on how well a new design will perform over time.

Risks & How to Mitigate Them

Refrigerant leaks are probably the biggest concern I see. Older systems running R-22 refrigerant are particularly problematic since R-22 is being phased out and costs have skyrocketed. A major leak in an R-22 system can cost more to fix than the cooler is worth.

Insulation moisture is the silent killer of cooling efficiency. When panels get damaged or stored improperly, moisture seeps into the insulation and destroys its effectiveness. You might not notice the problem immediately, but your energy bills will tell the story.

Code compliance issues catch many buyers off guard. What passed inspection a decade ago might not meet today's requirements, especially in food service applications where health departments are strict.

The hidden repair costs are what really hurt. That seemingly great deal on a used cooler can quickly sour when you find it needs a new compressor ($2,000-$4,000), door replacement ($800-$1,500), or electrical upgrades to meet current codes.

Smart buyers protect themselves by always inspecting units in person before purchasing. Hire a certified refrigeration technician for a professional evaluation - it's money well spent. Budget an extra 15-20% for unexpected repairs, and verify your local code requirements before you buy anything.

The Ultimate Buying Checklist for used-walk-in-coolers-for-sale-

Smart buyers don't wing it when shopping for used-walk-in-coolers-for-sale-. After helping countless facilities avoid expensive mistakes, I've developed a proven checklist that separates the gems from the lemons.

Your journey starts with dimension planning - and this means more than just measuring your space. You need to account for delivery access, ceiling height clearances, and the fact that external dimensions are always larger than your actual storage space inside.

The box versus combo decision shapes everything else. Standalone coolers are simpler, cheaper, and more reliable. Combination cooler/freezer units offer versatility but come with complex refrigeration systems that have more failure points. Unless you absolutely need both temperatures, stick with a single-temperature unit.

Brand reputation isn't just about bragging rights - it's about parts availability and service support five years down the road. Top manufacturers like Bally, Hoshizaki, True, and American Panel maintain better long-term support than obscure brands.

Insulation thickness directly impacts your monthly electric bill. Look for 4-inch thick panels with R-29 ratings for coolers or R-32 for freezers. Thinner insulation might save money upfront but costs more to operate and may not meet current energy codes.

Key Inspection Points Before Purchase

Panel integrity requires detective work. Run your hands along surfaces feeling for soft spots that indicate water damage. Check for rust or corrosion, especially around door frames where moisture accumulates. Dents might look ugly but rarely affect performance - it's the hidden damage that kills you.

Look for proper panel alignment and tight joints. Gaps between panels waste energy and let moisture in. The vapor barriers on panel surfaces should be intact without tears or peeling.

Door gasket seals make or break efficiency. Here's my favorite test: close a dollar bill in the door and try pulling it out. You should feel resistance all around the door frame. If the bill slides out easily anywhere, budget for new gaskets immediately.

Compressor amperage draw tells the real story about mechanical condition. Use a clamp-on ammeter to measure actual electrical draw against the nameplate specifications. High amperage means worn components that will fail soon.

Refrigerant type affects both operating costs and service availability. R-404A is the current standard for commercial refrigeration. R-22 is being phased out and becoming ridiculously expensive.

Ensuring Code Compliance & Warranty Options

UL-NSF labels aren't optional suggestions for food service applications. These certifications prove electrical safety and sanitation compliance. Missing labels can trigger health department violations that shut down your operation.

DOE/EISA rules mandate minimum insulation levels for commercial refrigeration equipment. Units manufactured before 2009 might not meet current standards, creating headaches with health inspectors or energy audits.

Municipal health codes vary dramatically between jurisdictions. Some require specific door types, floor drains, or interior finishes. A quick call to your local health department before purchase can save thousands in required modifications.

90-day parts-and-labor offers from reputable dealers provide valuable peace of mind. This coverage protects you during the critical break-in period when hidden problems surface.

Budgeting for used-walk-in-coolers-for-sale-

The sticker price is just the beginning of your real costs. Purchase price for a typical 8x10 foot cooler runs $7,500-$10,000, but smart buyers budget for the complete package.

Delivery and rigging adds $500-$2,000 depending on distance and site access. Installation labor runs $1,500-$3,500 for electrical hookup, proper setup, and system startup. Don't let your brother-in-law handle this - improper installation voids warranties and creates safety hazards.

Site preparation might require concrete pads or electrical upgrades costing $200-$1,000. Permits and inspections add another $100-$500 for health department approvals.

Monthly energy bills vary based on unit efficiency and local utility rates. Older units might cost $200-$400 monthly to operate versus $150-$300 for efficient models.

Tax incentives can offset your investment. Section 179 depreciation allows immediate write-off of equipment purchases. Some utilities offer rebates for energy-efficient upgrades, so check before you buy.

Where to Find Deals & Trusted Sellers

The used-walk-in-coolers-for-sale- market spans multiple channels, each with distinct advantages and risks. We've bought from all of them and can guide you to the best options for your situation.

Online Marketplaces & Auction Platforms

eBay offers the widest selection with Walk In Cooler Unit for sale – eBay listings nationwide. Buyer protection policies provide some security, but shipping costs can be prohibitive for large units.

GovDeals specializes in government surplus equipment. We've seen excellent deals like a 16'x12'x8' cooler/freezer combo that sold for just $1,025 USD. The catch? You handle all removal and transportation, and sales are strictly as-is.

Bid-On-Equipment focuses on commercial kitchen equipment with knowledgeable staff who understand refrigeration systems. They organize listings by manufacturer (Bally, North Star, Howe, Hussman, York, American Panel) making it easier to find compatible parts later.

Machinio aggregates listings from multiple sources, giving you a broader view of available inventory and pricing trends.

Working With Local Dealers & Installers

Local dealers offer the best combination of service and accountability. Companies like Foodservice Equipment Depot (FED) inspect and 24-hour test all units before sale, ensuring optimal performance. They also provide local pickup, eliminating shipping headaches.

HVAC contractors often know about units being removed from job sites. Building relationships with local technicians can lead to first access to quality equipment.

Refrigeration specialists like American Wholesale Refrigeration (28 years in business) offer both new and used units with nationwide shipping. Their experience helps match buyers with appropriate equipment.

For more detailed guidance on the buying process, check out our More info about used cooler buying resource.

Delivery, Installation & Lifetime Care

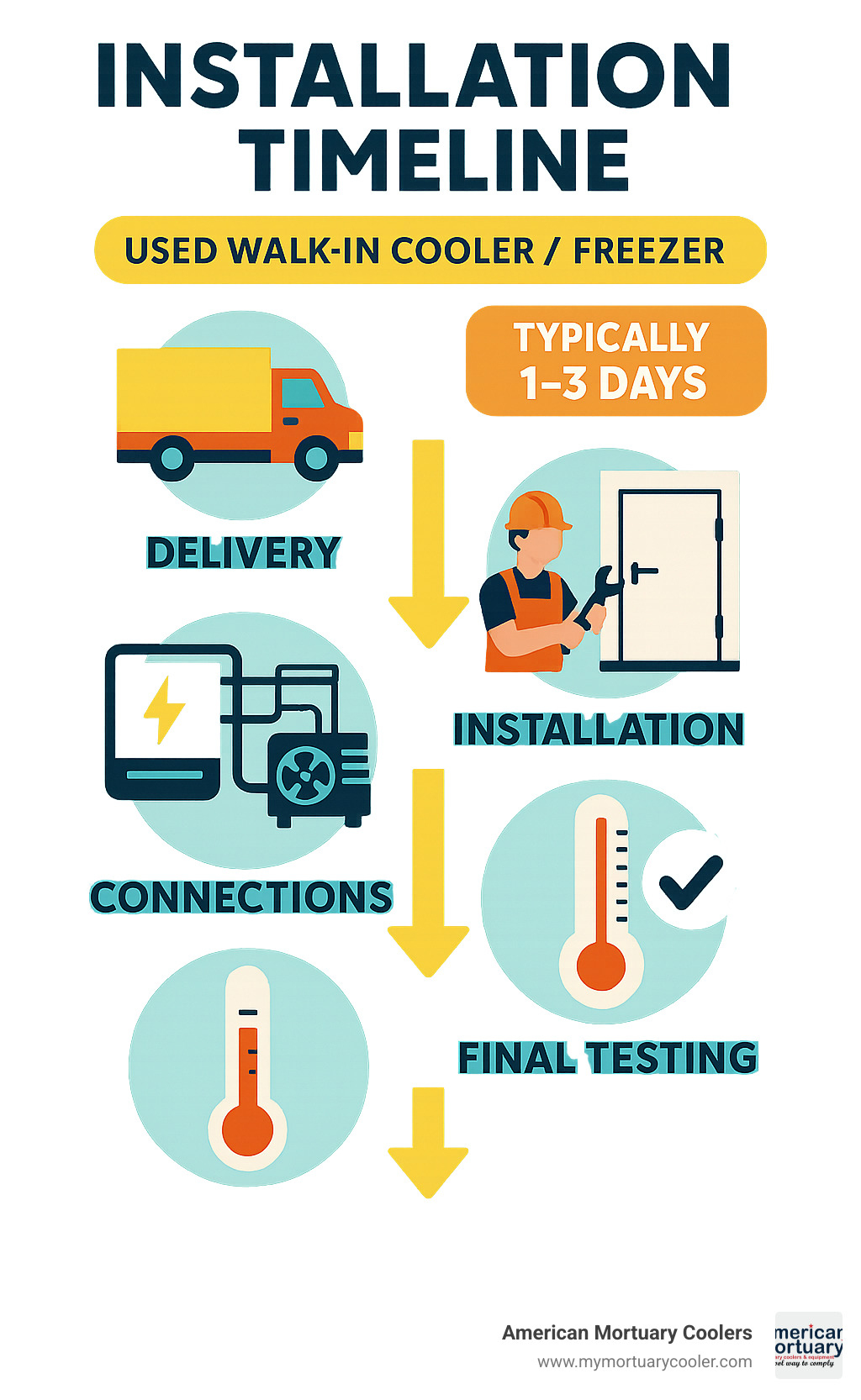

Getting your used-walk-in-coolers-for-sale- from purchase to operation involves several critical steps that can make or break your investment.

Freight considerations start with understanding that walk-in coolers ship as freight class 150, meaning they're heavy and bulky. Most residential deliveries require lift-gate service, adding $100-$300 to shipping costs. Commercial locations with loading docks avoid this fee.

Site preparation requirements include:

- Level concrete slab (within 1/4" variance per 10 feet)

- Adequate clearance for panel assembly (usually 3-4 feet on all sides)

- Electrical service sized for the refrigeration system

- Drainage for condensate removal

Electrical requirements vary by system type. Self-contained units typically need 115V or 230V single-phase power. Remote systems might require 208V three-phase for larger compressors. Always verify power requirements before delivery.

Professional installation is non-negotiable for warranty coverage and safety compliance. Licensed refrigeration contractors handle:

- Panel assembly and alignment

- Door installation and adjustment

- Refrigeration system startup and testing

- Temperature calibration and alarm setup

- Final inspection and documentation

Total Cost of Ownership Over Time

Energy consumption represents the largest ongoing cost. A typical 8'x10' cooler uses 3,000-5,000 kWh annually, costing $300-$600 in electricity. More efficient units can reduce this by 20-30%.

Service contracts provide predictable maintenance costs. Annual agreements typically run $500-$1,200 and include quarterly cleaning, refrigerant level checks, door adjustment, and emergency repair coverage.

Parts availability affects long-term viability. Popular brands maintain parts inventory for 15-20 years. Obscure manufacturers might leave you searching salvage yards for components.

Resale value remains surprisingly strong for quality units. Well-maintained coolers retain 40-60% of purchase price after 10 years, making them excellent investments.

Tips to Extend Service Life

Quarterly cleaning prevents most problems. Remove all products, wash interior surfaces with approved sanitizers, and clean condenser coils to maintain efficiency.

Door maintenance includes adjusting hinges, replacing worn gaskets, and lubricating hardware. A properly maintained door lasts 10-15 years versus 5-7 years with neglect.

Coil defrost schedules prevent ice buildup that reduces efficiency and damages equipment. Most modern controllers handle this automatically, but older mechanical systems need manual attention.

For comprehensive maintenance guidance, visit our More info about walk-in maintenance guide.

Frequently Asked Questions about Used Walk-In Coolers

These are the questions that keep popping up in our conversations with buyers. After helping hundreds of facilities find the right used-walk-in-coolers-for-sale-, we've learned that most concerns fall into three main categories: sizing, protection, and modifications.

What size walk-in cooler do I need?

Getting the size right feels overwhelming, but it's actually pretty straightforward once you know the basics. Start with your storage needs - restaurants typically need 1-2 cubic feet of cooler space per seat, while funeral homes have specific body storage calculations based on capacity requirements.

Don't forget about growth. We've seen too many buyers squeeze into the smallest possible unit only to outgrow it within two years. It's always cheaper to buy slightly larger now than to upgrade later.

Layout planning matters just as much as total space. You need to think about door swing clearance, interior shelving arrangements, and how your staff will move through the space. Measure your available area twice, then buy once - walk-in coolers aren't forgiving if you get the dimensions wrong.

Are warranties available on used units?

Here's the reality about warranties on used equipment: manufacturer warranties don't transfer to second owners. That factory coverage you'd get on a new unit? Gone. But that doesn't mean you're buying blind.

Quality dealers offer their own protection. Companies like Canada Food Equipment provide 90-day parts and labor warranties within 60km of their warehouse. It's not the same as factory coverage, but it gives you breathing room to find any hidden problems.

Extended service plans are available from some suppliers, typically costing 8-12% of the purchase price annually. Whether this makes sense depends on the unit's age, your maintenance capabilities, and local service availability.

Always verify warranty terms before purchase. Understand exactly what's covered versus what's excluded. Some dealers cover parts but not labor. Others exclude wear items like gaskets and belts. Get everything in writing.

Can I modify a used cooler to meet local codes?

The short answer is yes, most modifications are possible. The longer answer is that they can get expensive quickly, so you need to factor these costs into your buying decision.

Panel cutting for new door openings runs $500-$1,500 depending on the complexity. Door replacement with code-compliant models costs $800-$2,000. Older units might have doors that don't meet current safety standards, especially interior release mechanisms.

Control upgrades to meet current safety standards typically run $300-$800. Digital controllers with temperature alarms are often required by health departments, and they're a smart upgrade even if not mandated.

Floor modifications for drainage or accessibility can hit $1,000-$3,000. Some locations require floor drains, while others need modifications to meet ADA requirements.

The key is getting modification quotes before purchase. Don't assume that $8,000 cooler is a bargain if it needs $4,000 in modifications to meet local codes.

We always recommend checking with your local health department or building inspector before finalizing any used cooler purchase. A quick phone call can save you thousands in unexpected modification costs.

Conclusion & Next Steps

Your journey into the used-walk-in-coolers-for-sale- market doesn't have to be overwhelming. We've walked through everything from inspection checklists to installation requirements because we know that smart buying decisions start with solid information.

The numbers speak for themselves - 30-60% savings over new equipment means more money in your pocket for other business needs. Whether you're running a busy restaurant kitchen or managing a funeral home, that kind of capital conservation makes a real difference to your bottom line.

Budget-smart buyers consistently tell us they wish they'd found the used market sooner. The reliability of a 10-year-old cooler that's been properly maintained often exceeds what you'd get from an untested new unit.

The sustainability payoff feels good too. Every time you choose a quality used unit over new manufacturing, you're extending equipment life and reducing waste. It's environmental responsibility that actually saves you money.

At American Mortuary Coolers, we've helped facilities from Tennessee to California find the perfect cold storage solutions. Our experience spans funeral homes needing reliable body storage, restaurants expanding their kitchen capacity, and medical facilities requiring precise temperature control.

Custom cold-storage solutions remain our specialty, but we've learned that used equipment often provides the fastest, most cost-effective path to getting your operation up and running. Our team knows how to evaluate used units, coordinate professional installation, and ensure everything meets your local requirements.

The process doesn't have to be complicated. We've streamlined everything to eliminate the common pitfalls that trip up first-time buyers. From helping you understand freight requirements to connecting you with certified installation teams, we handle the details so you can focus on running your business.

Contact our experts when you're ready to explore your options. We deliver directly across the contiguous 48 states, so location isn't a barrier to getting quality equipment. Our Tennessee-based team has the experience to guide you through the entire process, from initial sizing to final startup.

Need help with financing? Our comprehensive guide to walk-in cooler financing options covers everything from traditional loans to lease programs that can make your purchase even more affordable.

Next steps are simple: reach out to American Mortuary Coolers today. We'll discuss your specific needs, help you understand your options, and connect you with the right equipment at the right price. With decades of combined experience in commercial refrigeration, we're positioned to make your used-walk-in-coolers-for-sale- purchase a success story.