Why Understanding Freezer Panels for Sale Is Critical for Your Facility

Freezer panels for sale come in three main categories that affect both your upfront costs and long-term performance:

- New panels: $265-$715 per panel with warranties and EISA compliance

- Used panels: Starting at $2 per square foot with potential savings of thousands

- Modular kits: DIY-friendly flat-pack solutions from $7,897 for complete systems

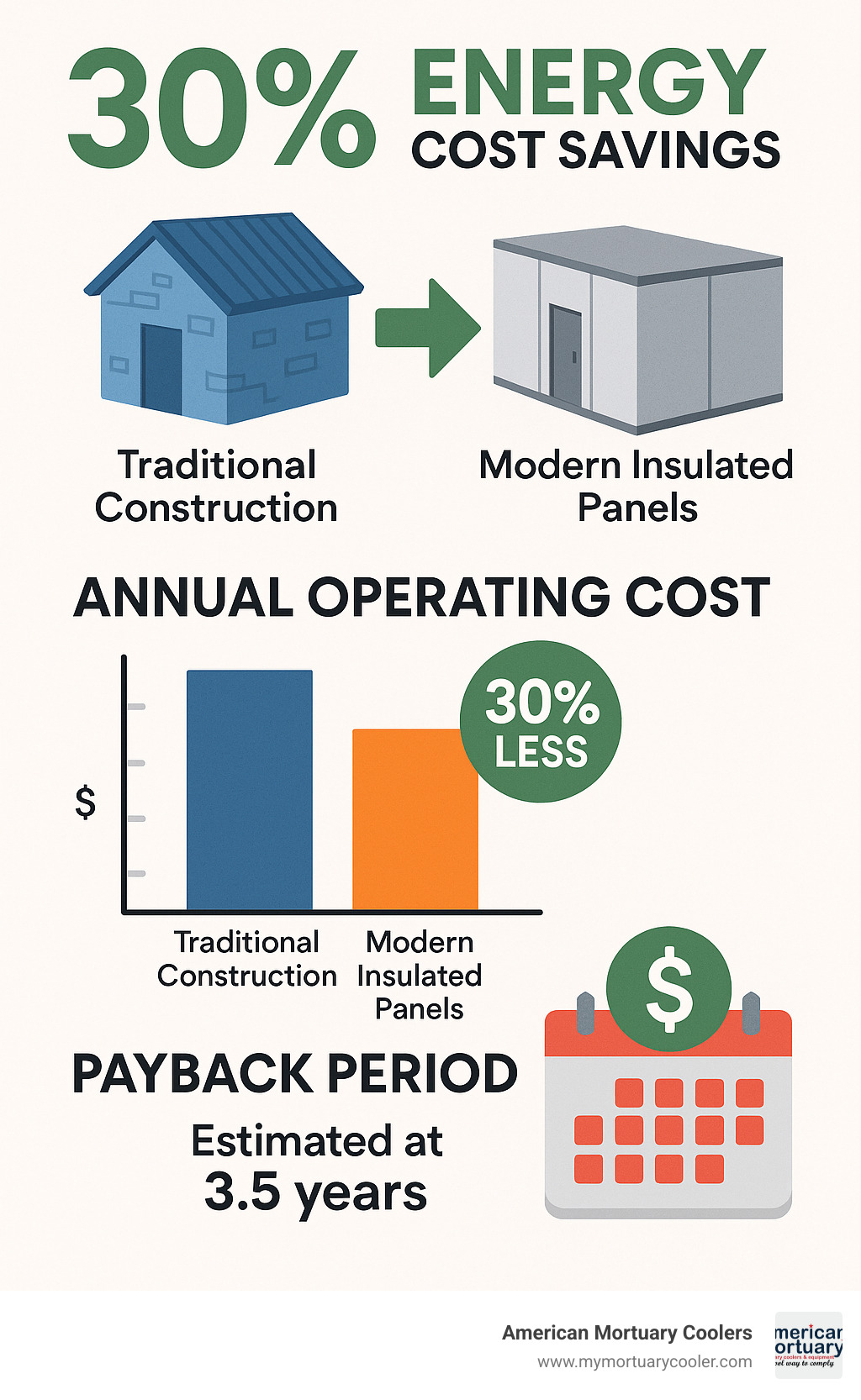

Whether you're building a new mortuary facility or upgrading existing cold storage, the right freezer panels can reduce energy costs by up to 30% compared to traditional construction methods. These insulated panels typically range from 2.5" to 4" thick, with R-values reaching 31 for maximum thermal efficiency.

The market offers everything from individual replacement panels to complete truckloads, with standard sizes like 42" x 20' panels and customizable lengths up to 9,500mm. Key considerations include insulation type (polyisocyanurate, EPS, or PUR foam), metal skin finishes, and compliance certifications like NSF/ANSI 7 for food-grade applications.

I'm Mortuary Cooler, and as a national-level mortuary cooler supplier, I've helped facilities across the country steer the freezer panels for sale market to find cost-effective, compliant solutions. My experience sourcing both new and used panels has shown me the critical factors that separate quality investments from costly mistakes.

Freezer panels for sale vocab to learn:

Freezer Panel Fundamentals: What They Are & How They Work

Think of freezer panels for sale as the building blocks of your cold storage world. These aren't just walls – they're engineered systems that keep your facility running efficiently while protecting what matters most inside.

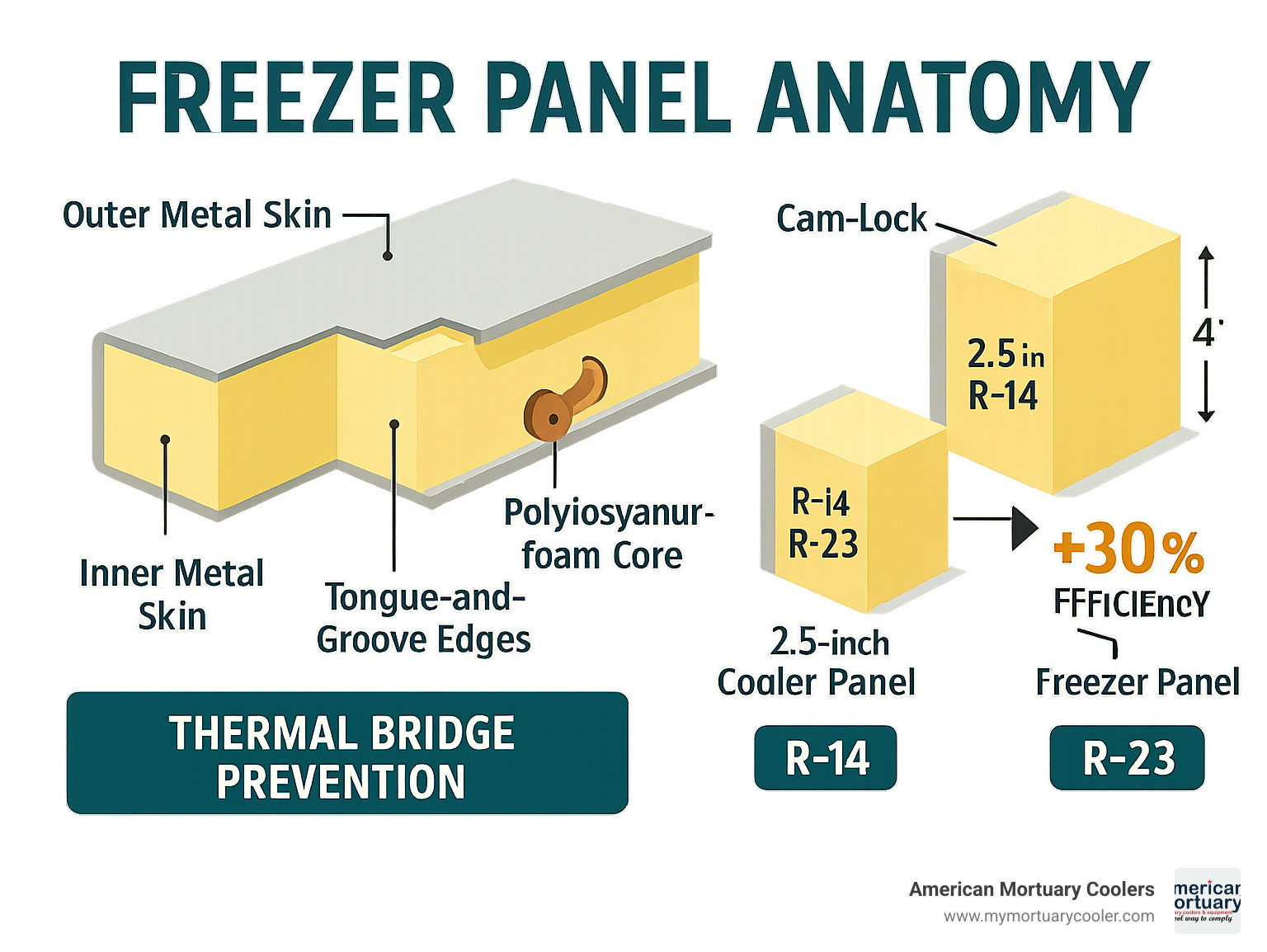

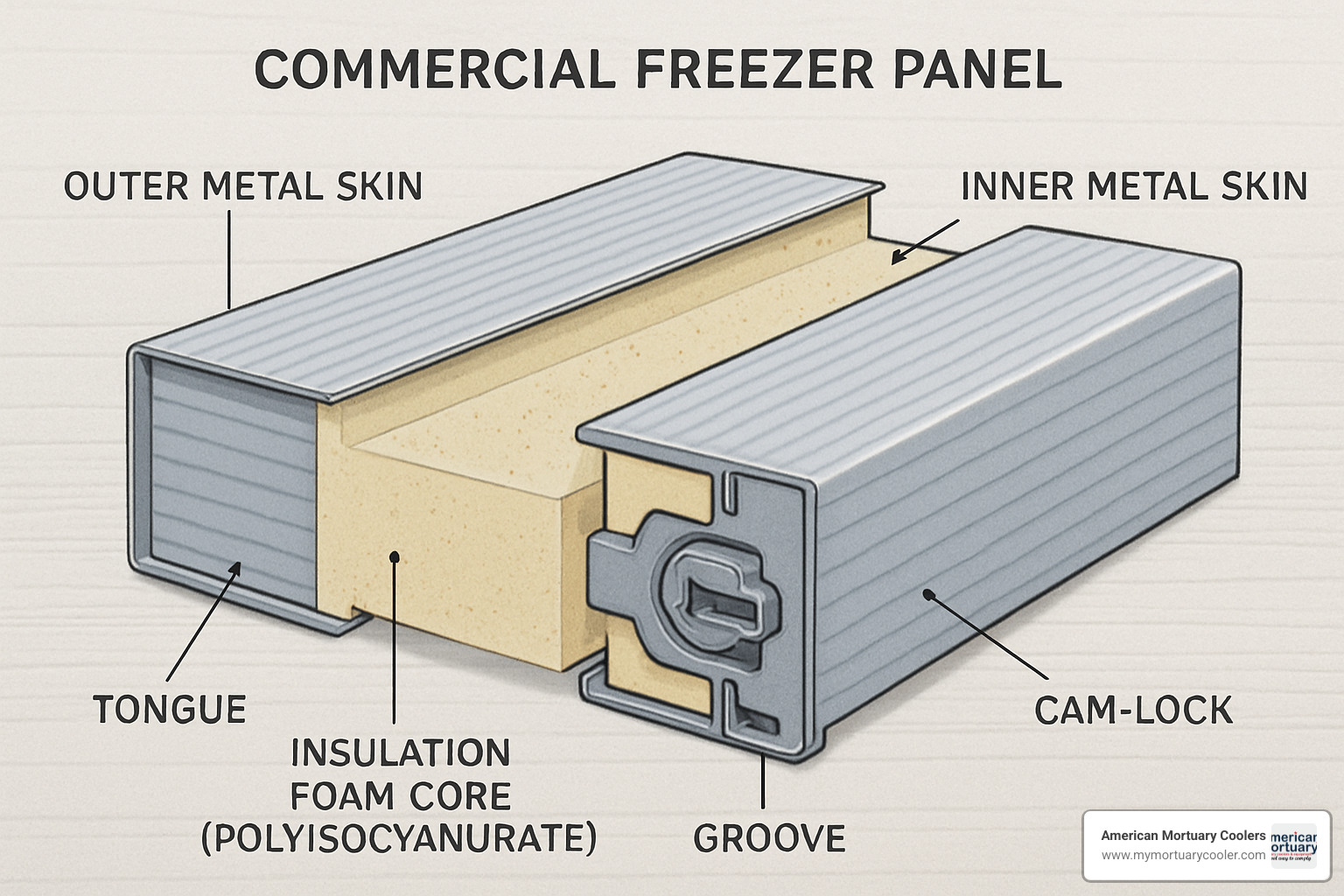

At their heart, freezer panels are surprisingly simple. Picture a sandwich: two metal "skins" on the outside with a thick layer of insulation foam in the middle. The outer skin faces the world, the inner skin faces your cold storage space, and that foam core does all the heavy lifting when it comes to keeping temperatures exactly where you need them.

What makes these panels clever is how they connect. Most use a tongue-and-groove system paired with cam-locks – think of it like a giant puzzle where each piece clicks perfectly into place. This design creates an airtight seal that stops thermal bridging, which is just a fancy way of saying "heat sneaking through where it shouldn't."

When you're shopping for panels, you'll hear a lot about R-values. Don't let the technical term intimidate you – it's simply a measure of how well something resists heat flow. Higher R-values mean better insulation, and panels with R-values around 31 can dramatically outperform traditional construction methods in walk-in coolers and cold storage applications.

Core Materials & Insulation Science

The foam core is where the real science happens, and you've got three main players in this game. Each has its own personality and strengths.

Polyisocyanurate (we'll call it polyiso to keep things friendly) is the overachiever of the group. It packs the highest R-value per inch, making it perfect when you need maximum insulation but don't have much space to work with. Modern non-CFC polyiso foam meets environmental standards while delivering exceptional thermal performance.

Expanded Polystyrene or EPS is the reliable workhorse. It costs less than polyiso but still delivers solid performance day after day. EPS resists moisture beautifully and maintains consistent insulation values over time. Many facilities love EPS panels because they're straightforward to install and maintain their performance for years.

Polyurethane (PUR) foam brings something special to the table – it bonds incredibly well with the metal skins, creating a strong, unified panel. You'll often find PUR in flat-pack kits because it holds up well during shipping and handling.

Here's something important: fire ratings vary significantly between these materials. Different panels carry different fire safety certifications, so make sure you verify compliance with your local codes before installation. Quality panels typically meet ASTM E-84 standards with controlled flame spread and smoke ratings.

Standard Sizes & Thickness Options

The industry has settled on some standard sizes that make everyone's life easier. Most freezer panels for sale come in 36" or 42" widths, with 36" being particularly popular because it speeds up construction time and works well for food service, healthcare, and industrial facilities.

Panel thickness tells the story of what temperature range you're planning to handle. 2.5" panels work great for cooler applications above freezing. 4" panels have become the industry standard for freezer work, delivering R-values around 31. When you need to go really cold or deal with extreme conditions, 6" panels step up to handle ultra-low temperatures.

The beauty of modern manufacturing is flexibility. Some suppliers can create custom panels up to 9,500mm (over 31 feet) long, perfect for those oddly-shaped spaces that seem to exist in every facility. The 42" × 20' configuration has become increasingly popular for long, narrow storage areas where you want minimal seams and maximum efficiency.

At American Mortuary Coolers, we've seen how the right panel thickness and configuration can make or break a project. That 4" industry standard thickness exists for good reason – it hits the sweet spot between performance, cost, and practicality for most applications.

Freezer Panels for Sale: Types, Configurations & Market Options

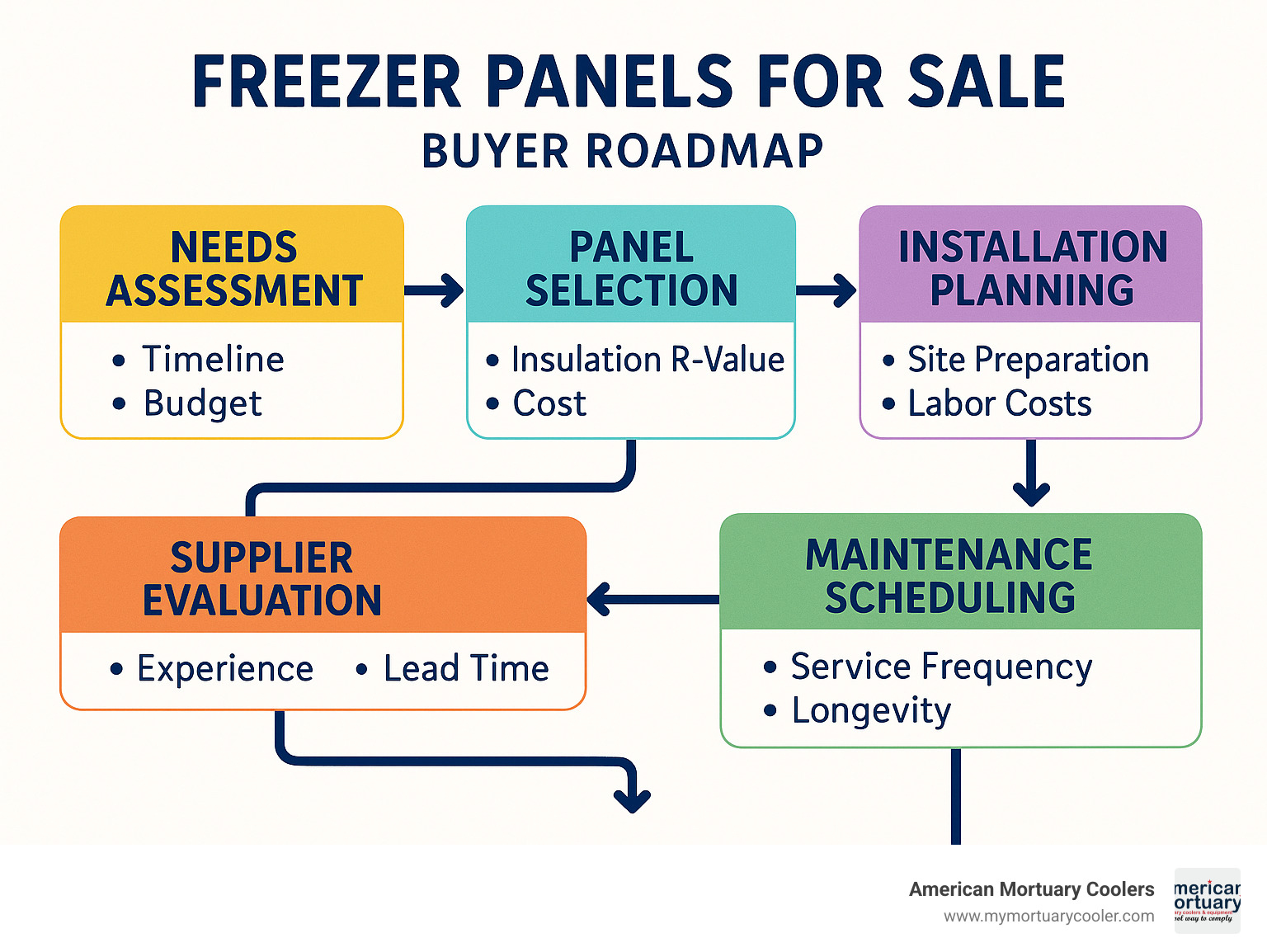

Shopping for freezer panels for sale can feel overwhelming when you first see the options available. The good news? The market breaks down into three main categories that make decision-making much simpler once you know what to look for.

Most suppliers keep over 1,000 panels in stock at any given time, so availability usually isn't an issue. The real question is finding the sweet spot between your budget, timeline, and performance needs. Let me walk you through each option so you can make the best choice for your facility.

| Option | Cost per ft² | Warranty | Best For |

|---|---|---|---|

| New Panels | $6-12 | Full warranty | Long-term installations |

| Used Panels | $2-4 | Limited/none | Budget-conscious projects |

| Modular Kits | $4-8 | Varies | DIY installations |

New Freezer Panels for Sale: Factory-Fresh Advantages

When you buy new panels, you're getting the latest technology and peace of mind. These panels come with full warranties and meet all current regulations right out of the box. No guesswork, no surprises.

R-32 compliance is automatic with new panels. Since 2009, federal law requires this minimum insulation rating, and manufacturers have responded by making even better panels than the law requires. You'll often find R-values reaching 31 or higher.

The USDA white finish comes standard on quality new panels. This isn't just about looks - it's about meeting health department requirements for mortuary facilities. The white stucco coating on both sides creates a clean, professional appearance that inspectors expect to see.

QUICKSHIP programs make new panels surprisingly fast to get. Standard sizes typically arrive within 3-5 business days, while custom configurations usually ship within three weeks. When you're under pressure to get a facility operational, this speed can be worth the extra cost.

Warranties provide real protection for your investment. Most manufacturers back their panels with comprehensive coverage against defects in materials and workmanship. Given that quality panels can last decades, this protection offers significant value.

Expect to pay $265 to $715 per panel for new units, depending on size and specifications. While that's a substantial upfront investment, the combination of warranty coverage, compliance certainty, and maximum service life often makes new panels the most cost-effective long-term choice.

Used Freezer Panels for Sale: Budget Wins & Inspection Tips

The used market offers incredible savings for buyers who know what to look for. You can find quality used panels starting at $2 per square foot - sometimes less than half the cost of new panels.

Discount pricing makes used panels attractive for budget-conscious projects. American Wholesale and similar suppliers regularly clear out inventory at blowout prices, especially when they have complete sets from decommissioned facilities.

Refurb quality varies dramatically, so inspection becomes critical. Look for foam core integrity first - any compression or moisture damage means trouble. Check the metal skins for dents, rust, or corrosion that could compromise performance. Make sure the tongue-and-groove edges are intact and the gaskets remain flexible.

You'll find used panels on Craigslist, Kijiji, and specialized industrial equipment sites. Some sellers even reference eBay's condition definitions to help buyers understand what they're getting. This transparency helps, but nothing beats seeing the panels in person before buying.

The biggest savings come from buying complete truckloads when someone's dismantling an entire facility. These bulk purchases require careful logistics planning, but the per-panel savings can be substantial for larger projects.

Modular & DIY Kits: Flat-Pack Convenience

DIY kits offer a middle ground between buying individual panels and hiring professional installation. These flat-pack systems include everything needed for assembly, making cold storage accessible to smaller facilities.

Self-install capabilities make these kits popular with hands-on facility managers. A typical 1.5 hp kit for a 2.0 x 2.0 x 2.4 meter walk-in freezer runs about $7,897 complete with refrigeration equipment. That's remarkably affordable for a complete cold storage solution.

Brew caves and grow rooms represent growing markets for modular systems. Craft breweries need precise temperature control for fermentation, while cannabis cultivators require consistent conditions for optimal plant growth. The flexibility of modular panels makes both applications practical.

The flat-pack approach works well for remote locations where professional installation would be expensive, seasonal applications, or facilities that might need to relocate their cold storage. Just remember that while these kits are designed for DIY installation, you'll still need basic construction skills and may want professional help with electrical connections.

How to Choose: Performance, Compliance & Eco Factors

Picking the right freezer panels for sale feels like solving a puzzle with three moving pieces: keeping your energy bills reasonable, staying on the right side of regulations, and doing right by the environment. After helping facilities nationwide steer these choices, I've learned that panels meeting higher standards often save money in the long run, even when they cost more upfront.

Here's something that might surprise you: energy efficiency represents your biggest long-term cost factor. Quality insulated freezer panels can slash energy costs by up to 30% compared to traditional construction methods. That's real money staying in your pocket month after month, year after year.

The magic happens through superior thermal performance and dramatically reduced air infiltration. Think of it like upgrading from a leaky old window to a modern double-pane - the difference shows up immediately on your utility bill.

Regulatory compliance isn't optional, and the alphabet soup of certifications can feel overwhelming. The key standards you'll encounter include NSF/ANSI 7 for food-grade applications, UL 471 for fire safety certification, ASTM E84 for flame spread and smoke development ratings, and EISA for federal energy efficiency requirements. Each serves a specific purpose in keeping your facility safe and compliant.

Don't overlook acoustic control - it's often the forgotten factor that becomes critical later. Panels with good noise isolation properties minimize sound transmission, which proves invaluable if your facility sits near workstations or public areas. Nobody wants to explain why the freezer sounds like a freight train at 2 AM.

More info about walk-in cooler features

Matching Panel Thickness to Temperature Range

Panel thickness isn't a "one size fits all" decision. Your specific temperature requirements and operating conditions should drive this choice. Thicker panels provide better thermal retention but demand more upfront investment and additional structural support.

2.5" panels handle cooler applications maintaining temperatures above 32°F beautifully. These work perfectly for produce storage, floral coolers, and pharmaceutical storage requiring moderate temperature control. They're the practical choice when you need consistent cooling without the expense of freezer-grade insulation.

4" panels earn their reputation as the industry standard for freezer applications. With R-values around 31, these panels effectively maintain sub-freezing temperatures while delivering excellent cost-performance balance. Most mortuary applications benefit from 4" thickness - it's the sweet spot between performance and practicality.

6" to 8" panels enter specialized territory, reserved for ultra-low temperature applications or extreme climate conditions. You'll need these for laboratory storage or facilities in harsh climates where outdoor temperature swings test your system's limits. They're overkill for most applications, but essential when nothing else will do the job.

Environmental & Health Considerations

The freezer panels for sale market has acceptd environmental responsibility in ways that benefit both your facility and the planet. Zero-ODP (Ozone Depletion Potential) foams have become standard, replacing older CFC-based insulation materials that damaged the ozone layer.

LEED credits represent more than environmental bragging rights. High-performance panels contribute to LEED certification through improved energy efficiency and use of recycled materials. This consideration becomes crucial for facilities pursuing green building certification or working with environmentally conscious clients.

Low-VOC finishes improve indoor air quality while meeting increasingly strict health regulations. These interior finishes with minimal volatile organic compound emissions create healthier work environments and reduce long-term health risks for staff.

Recyclability adds practical value at the end of your panels' service life. Metal skins from quality panels retain material recovery value, providing some return on investment while keeping materials out of landfills. As disposal costs rise and environmental regulations tighten, this factor becomes increasingly important for long-term facility planning.

Installation, Pricing & Where to Buy

Getting your freezer panels for sale from purchase to working cold storage involves more moving parts than you might expect. The good news? The modular tongue-and-groove design with cam-locks makes assembly surprisingly straightforward once you understand the process.

The cam-lock system shown above is where the magic happens. These mechanical fasteners pull panels together tightly, creating the airtight seal that keeps your temperatures stable. Think of it like a giant puzzle where each piece clicks into place - except this puzzle keeps your facility running smoothly for decades.

Professional installation versus DIY comes down to your comfort level and local requirements. While manufacturers love to say their panels are "easy to install," there's a difference between possible and practical. Professional installers bring expertise in proper sealing techniques, electrical connections for heated doors and lighting, and knowledge of local building codes. They also ensure your warranty stays intact - some manufacturers require professional installation to honor their guarantees.

Beyond the panels themselves, you'll need supporting components that add to both cost and complexity. Insulated doors with proper gaskets and hardware can run $800 to $2,500 each. Installation trim and finishing materials help everything look professional. Your refrigeration equipment needs to be properly sized for the enclosure - too small and you'll struggle to maintain temperature, too large and you'll waste energy. Don't forget electrical connections for lighting and door heaters, which prevent ice buildup in freezer applications.

Freight logistics deserve special attention because panels are both large and surprisingly delicate. Most suppliers provide freight quotes separately from panel pricing. Delivery trucks need adequate access, and you'll need equipment for offloading - these aren't packages you can hand-carry. Plan for covered storage space and weather protection during installation, especially if you're doing the work yourself over several days.

More info about walk-in cooler pricing

Cost Breakdown & Budgeting

Here's where reality meets your initial budget estimates. Panel costs represent just the starting point for your total investment, not the finish line.

Used panels at $2 to $5 per square foot look attractive until you factor in potential refurbishment costs and missing components. New standard panels typically run $265 to $349 per panel, while premium or custom panels can reach $495 to $715 per panel. The price jump reflects better insulation, upgraded finishes, or custom sizing.

The supporting cast of components adds up quickly. Doors and hardware range from $800 to $2,500 per door depending on size and features. Refrigeration equipment varies dramatically - a simple system might cost $2,000 while larger or specialized units reach $8,000 or more. Installation labor runs $50 to $100 per hour, and electrical connections typically add $500 to $1,500 to your project.

Don't forget the paperwork costs. Permits and inspections usually run $200 to $800, depending on your location and project complexity. These aren't optional - they're required for legal operation and insurance coverage.

Financing options help spread these costs over time while preserving your working capital. Many suppliers offer qualified buyers financing programs that make sense for larger projects. Bulk discounts become significant when purchasing complete systems or large quantities. Some suppliers offer substantial savings for truckload quantities, though this requires careful logistics planning.

Shipping, Delivery & Storage Best Practices

Getting your freezer panels for sale from the supplier to your facility safely requires more planning than ordering office supplies. These panels are large, heavy, and surprisingly vulnerable to damage if handled carelessly.

Flatbed trucks work best for large panels and bulk orders, giving easy access for loading and unloading. Box trucks provide weather protection for smaller quantities but limit panel sizes. LTL (Less Than Truckload) shipping works for individual panels but costs more per unit and involves more handling.

Before delivery day arrives, confirm your facility has adequate access for delivery trucks. Many suppliers use large trucks that need room to maneuver. Arrange for unloading equipment - a forklift or crane makes the job much easier and safer. Prepare a covered storage area protected from moisture, because wet panels can develop serious problems. Schedule delivery to coordinate with your installation timeline rather than accepting whatever date the shipper suggests.

Proper storage prevents expensive damage and installation headaches. Store panels vertically to prevent warping - laying them flat can cause permanent bowing. Protect them from moisture with vapor barriers or tarps. Maintain stable temperatures to prevent condensation, which can damage both the foam core and metal skins. Secure panels properly to prevent shifting or falling, which can cause edge damage that makes installation difficult.

Frequently Asked Questions About Freezer Panels for Sale

Understanding R-value versus panel thickness confuses many buyers. R-value measures insulation effectiveness, not just thickness. A 4-inch panel with R-31 insulation outperforms a 6-inch panel with lower R-value per inch. Focus on total R-value rather than just thickness when comparing options.

Panel relocation is possible with quality cam-lock connections. Panels can be disassembled and moved to new locations, making them valuable for temporary installations or facilities that might need to relocate. This flexibility adds value compared to permanent construction.

Insulated floors depend on your specific installation and application. Ground-level installations over concrete typically don't require insulated floors. However, installations over heated spaces or in extreme climates benefit significantly from floor insulation to prevent heat transfer from below.

Cooler versus freezer panels differ primarily in insulation thickness and R-value. Cooler panels (2.5 to 3 inches thick) handle temperatures above 32°F effectively. Freezer panels (4 inches or thicker) provide the extra insulation needed for sub-freezing temperatures.

Panel lifespan with proper installation and maintenance typically reaches 15 to 20 years. Factors affecting longevity include installation quality, operating conditions, and maintenance practices. Quality panels represent a long-term investment rather than a short-term expense.

Conclusion & Next Steps

Navigating the freezer panels for sale market successfully requires understanding the interplay between performance, compliance, and cost factors. Whether you choose new panels with full warranties, used panels for budget savings, or modular kits for DIY installation, the key lies in matching panel specifications to your specific requirements.

At American Mortuary Coolers, we've helped facilities across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania find the right cold storage solutions. Our experience sourcing panels for mortuary applications has taught us that the lowest initial price rarely represents the best long-term value.

Project Planning Checklist:

- [ ] Determine required temperature range and R-value

- [ ] Verify compliance requirements (NSF, UL, ASTM, EISA)

- [ ] Calculate total project costs including installation and accessories

- [ ] Confirm delivery logistics and storage requirements

- [ ] Plan electrical connections and refrigeration equipment

- [ ] Obtain necessary permits and schedule inspections

The 30% energy savings potential of quality insulated panels often justifies higher upfront costs through reduced operating expenses. When combined with proper installation and maintenance, the right panels provide decades of reliable service.

Ready to move forward with your cold storage project? We deliver custom, energy-efficient panel solutions nationwide with direct delivery across the contiguous 48 states. Our team can help you steer the options and find the most cost-effective solution for your specific requirements.

More info about our mortuary coolers

Contact us today for a custom quote and let our expertise guide you to the right freezer panels for sale for your facility's unique needs.