Why Scissor Lifts Are Essential for Professional Operations

When you need to buy scissor lift equipment, you're investing in one of the most versatile aerial work platforms available. Here's what you need to know:

Key Buying Factors:

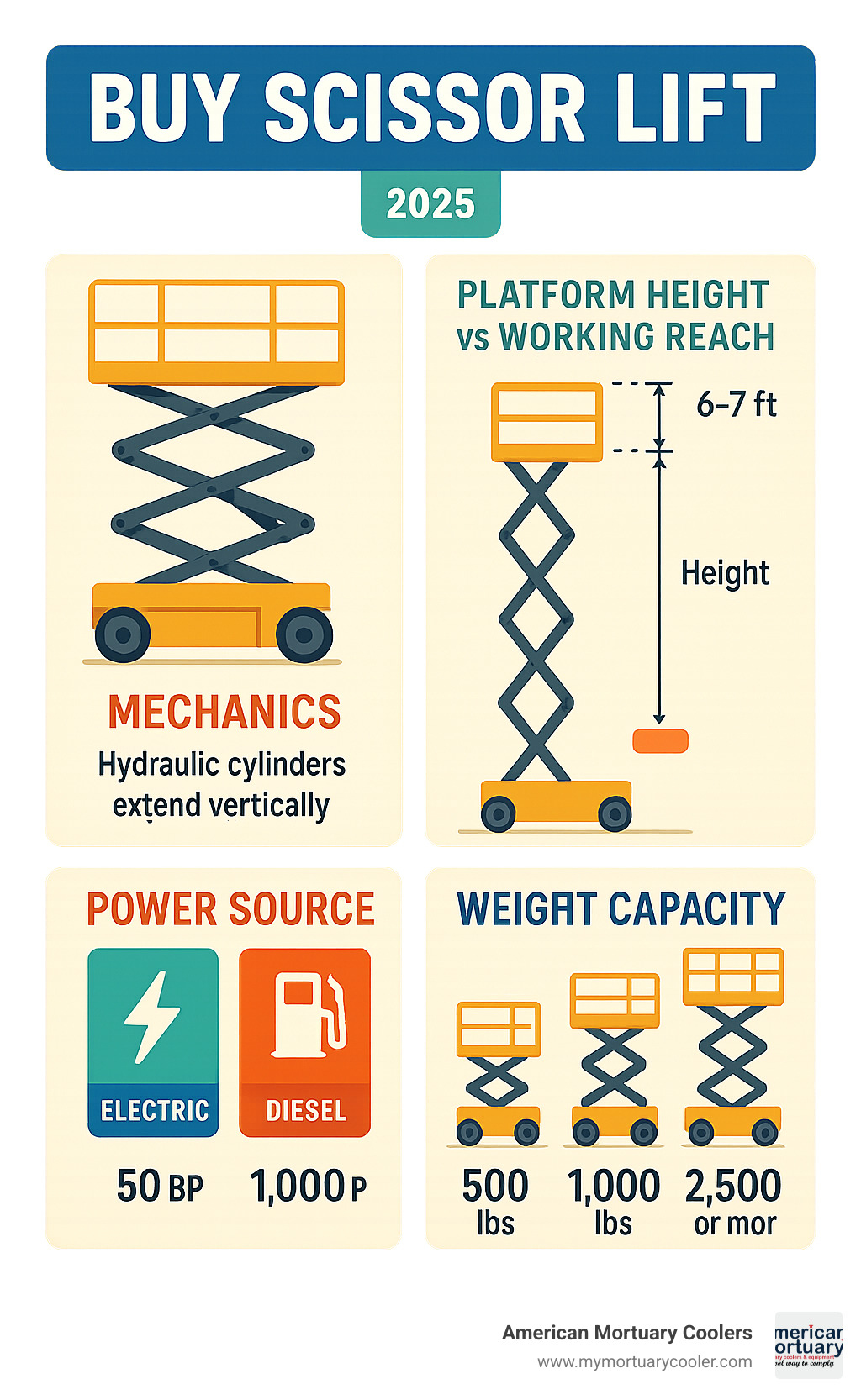

- Platform Height: 12-50+ feet (add 6-7 feet for working reach)

- Power Source: Electric (indoor, quiet) vs Diesel (outdoor, rough terrain)

- Load Capacity: 500-2,500+ lbs depending on model

- Price Range: $3,800-$40,000+ (new), significantly less used

- Where to Buy: Authorized dealers, online marketplaces, auctions

Scissor lifts use crossed hydraulic cylinders that extend vertically like scissors, providing stable access to liftd work areas. Unlike boom lifts that extend horizontally, these platforms move straight up and down, making them ideal for tasks requiring consistent overhead positioning.

With over 400,000 JLG scissor lifts sold worldwide and more than 4,000 units currently available across online marketplaces, the market offers extensive options for every budget and application. Electric models dominate indoor use due to zero emissions and quiet operation, while diesel variants handle outdoor construction with 4WD capability.

The decision to buy scissor lift equipment requires careful consideration of your specific needs. Platform heights range from compact 12-foot models perfect for warehouse work to massive 50+ foot units for major construction projects. Weight capacity varies dramatically too - from 500-pound single-person lifts to heavy-duty models supporting over 2,500 pounds.

As American Mortuary Coolers with years of experience helping funeral professionals buy scissor lift equipment for specialized applications, we've seen how the right lift transforms both safety and efficiency in demanding work environments. Whether you're considering new or used options, understanding the key specifications and buying channels will save you time and money.

Find more about buy scissor lift:

How Scissor Lifts Work & the Main Types

Understanding how scissor lifts work helps you make smarter buying decisions. These machines use crossed hydraulic cylinders that look like giant scissors opening and closing. When you hit "up," hydraulic fluid pumps into these cylinders, extending them and pushing the platform straight up. Hit "down," and the fluid releases, lowering you back to ground level.

The scissor-arm design provides excellent stability. Unlike boom lifts that can sway when extended, scissor lifts provide a rock-solid platform that moves purely vertical, perfect when you need to stay positioned over the same work area for extended periods.

What powers these hydraulic pumps determines where and how you can use your lift. Electric drive systems run off rechargeable batteries and operate whisper-quiet with zero emissions. Diesel power gives you the muscle for outdoor work and rough terrain, but comes with noise and exhaust that rules out indoor use.

Platform heights typically range from compact 12-foot models perfect for warehouse maintenance up to massive 50+ foot units that can reach multiple stories.

Electric & Slab Models

When you buy scissor lift equipment for indoor work, electric models are usually your best bet. These quiet operators produce zero emissions, making them perfect for warehouses, retail spaces, hospitals, and anywhere air quality matters.

The compact width is another huge advantage. Many electric lifts squeeze through standard doorways and tight aisles - some models are just 30 inches wide. This maneuverability lets you position the lift exactly where you need it, even in cramped spaces.

Battery life varies by model size, but modern electric lifts typically run full work shifts on a single charge. Smaller 19-foot lifts might use two 12V batteries, while larger 32-foot models need four 12V batteries for adequate power. Proper battery maintenance is crucial - we've seen too many used lifts with dead battery packs that cost thousands to replace.

Platform heights on electric models typically range from 12 to 32 feet, with the sweet spot being 19-foot and 26-foot variants that handle most indoor tasks.

Diesel & Rough Terrain Models

Outdoor construction sites demand different capabilities, and that's where diesel and rough terrain models shine. These beefier lifts feature 4WD systems with pneumatic tires that can handle gravel, uneven surfaces, and moderate slopes that would stop an electric model cold.

The higher ground clearance lets these lifts steer construction debris and rough terrain without getting hung up. Platform heights typically start at 26 feet and can exceed 50 feet on the largest units - perfect for multi-story construction or industrial maintenance.

Diesel engines provide consistent power regardless of weather conditions, and you never have to worry about battery charging downtime. The trade-off is increased noise and exhaust emissions that make them unsuitable for indoor use.

Specialty Variants

The scissor lift world includes some fascinating specialty models for unique applications. Self-leveling tracked models can operate on slopes and uneven terrain while keeping the platform perfectly level - invaluable for tree maintenance and hillside work.

Low-profile models serve specialized industries like ours at American Mortuary Coolers. These lifts collapse to as little as 12.5 inches high, allowing them to fit under extremely low clearances. Some mortuary-specific models include integrated scales and marine-grade aluminum construction for easy cleaning.

Drivable at full height lifts represent the productivity champions. These models can travel while fully extended, eliminating the time-consuming cycle of lowering, moving, and raising again.

Single-man lifts fill the gap between ladders and full-size scissor lifts, typically supporting 500 pounds and reaching 12-20 feet.

Key Considerations Before You Buy

Making the right choice when you buy scissor lift equipment can feel overwhelming with so many options available. But here's the good news: focusing on a few key factors will guide you to the perfect lift for your needs. Think of it like buying a truck – you wouldn't choose a compact car to haul construction materials, and you wouldn't buy a massive semi for grocery runs.

The most important decision starts with understanding exactly what you need to accomplish. Are you working indoors or outdoors? How high do you need to reach? What's the total weight you'll be lifting? These fundamental questions will narrow your choices significantly and prevent expensive mistakes.

Calculating the Right Specifications

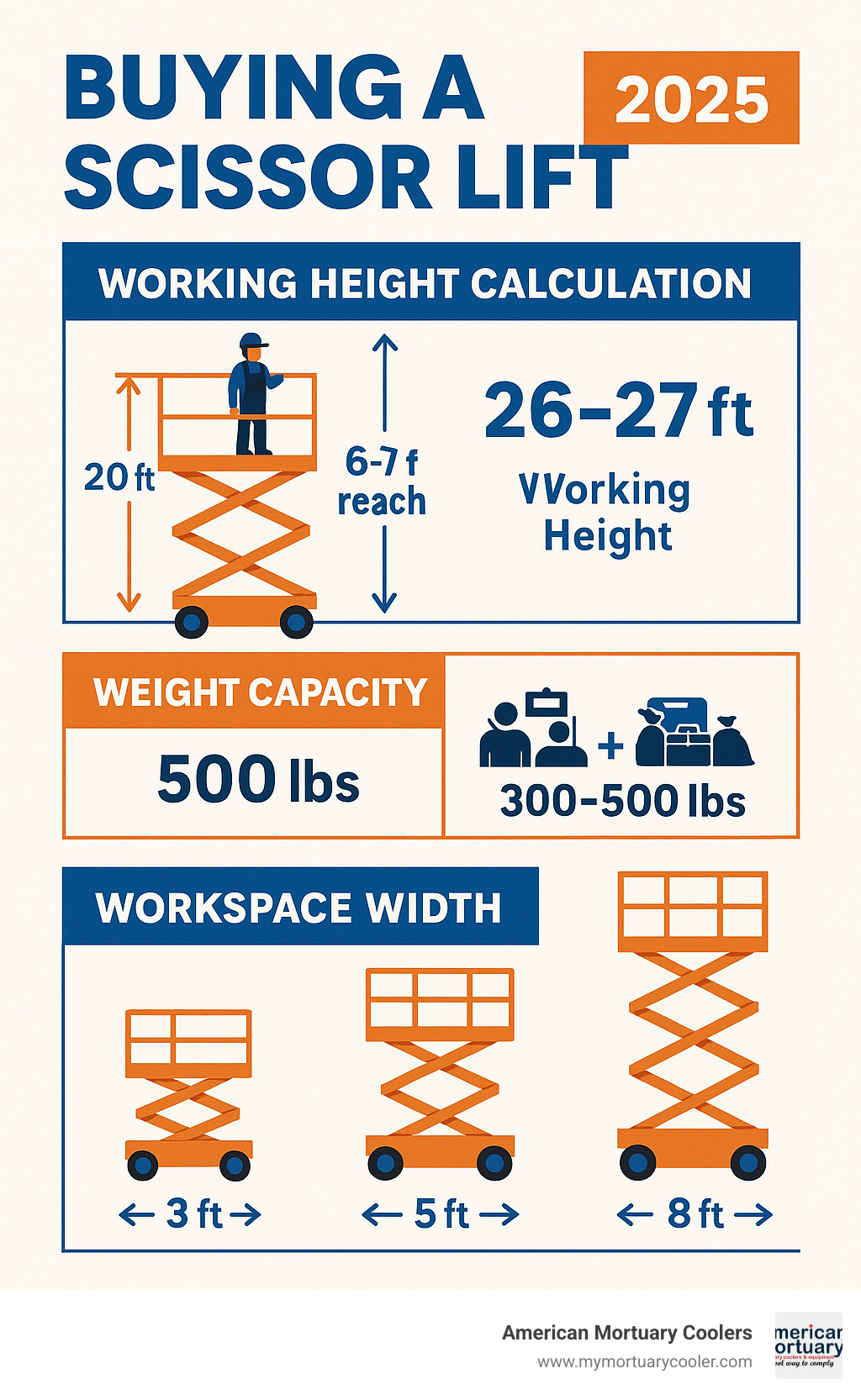

Here's where many buyers get tripped up: platform height isn't the same as working height. If you need to reach 25 feet, don't buy a 25-foot scissor lift – you'll come up short every time.

The magic number is 6-7 feet of additional reach above the platform height. That's how high an average person can comfortably work with arms extended. So a 19-foot platform gives you about 25-26 feet of actual working height. Always measure your target work areas and add a safety buffer rather than cutting it close.

Weight calculations require honest math. Two workers typically weigh 300-400 pounds combined. Add tools, materials, and equipment, and you're easily looking at 750-1,000 pounds or more. Don't forget about those heavy pipe sections, panels, or supply boxes that seem to multiply on the platform.

Platform size matters more than you might think initially. A cramped platform makes work inefficient and potentially dangerous. Consider not just today's needs but future projects. That extra space might seem unnecessary now, but it becomes invaluable when you're juggling multiple tools and materials 30 feet in the air.

Safety & Ergonomic Features to Demand

When you buy scissor lift equipment, certain safety features should be absolutely non-negotiable. These aren't luxury add-ons – they're the difference between a productive workday and a potential disaster.

Pothole protection automatically stops the lift when it hits an obstacle or depression that could cause tipping. This feature has literally saved lives on construction sites where debris and uneven surfaces are constant hazards. Tilt sensors work similarly, preventing operation if the unit isn't properly level.

Modern lifts include descent alarms that warn nearby workers when the platform is coming down. It sounds simple, but this feature prevents countless accidents. Emergency lowering systems ensure you can get down safely even if the primary power fails – nobody wants to be stranded 30 feet up with a dead battery.

Look for fold-down guardrails and intuitive controls that make daily operation smoother. Platform surfaces should provide solid traction, and control panels need protection from weather and impacts. The joystick operation should feel smooth and responsive, not jerky or unpredictable.

At American Mortuary Coolers, we've seen how the right safety features make all the difference in specialized applications. Whether you're working in a funeral home's tight spaces or on an outdoor construction site, these features transform a potentially dangerous task into a routine, safe operation. OSHA and ANSI compliance isn't just paperwork – it's your assurance that the lift meets rigorous safety standards developed from decades of real-world experience.

How to Buy Scissor Lift: Pricing, New vs Used & Where to Shop

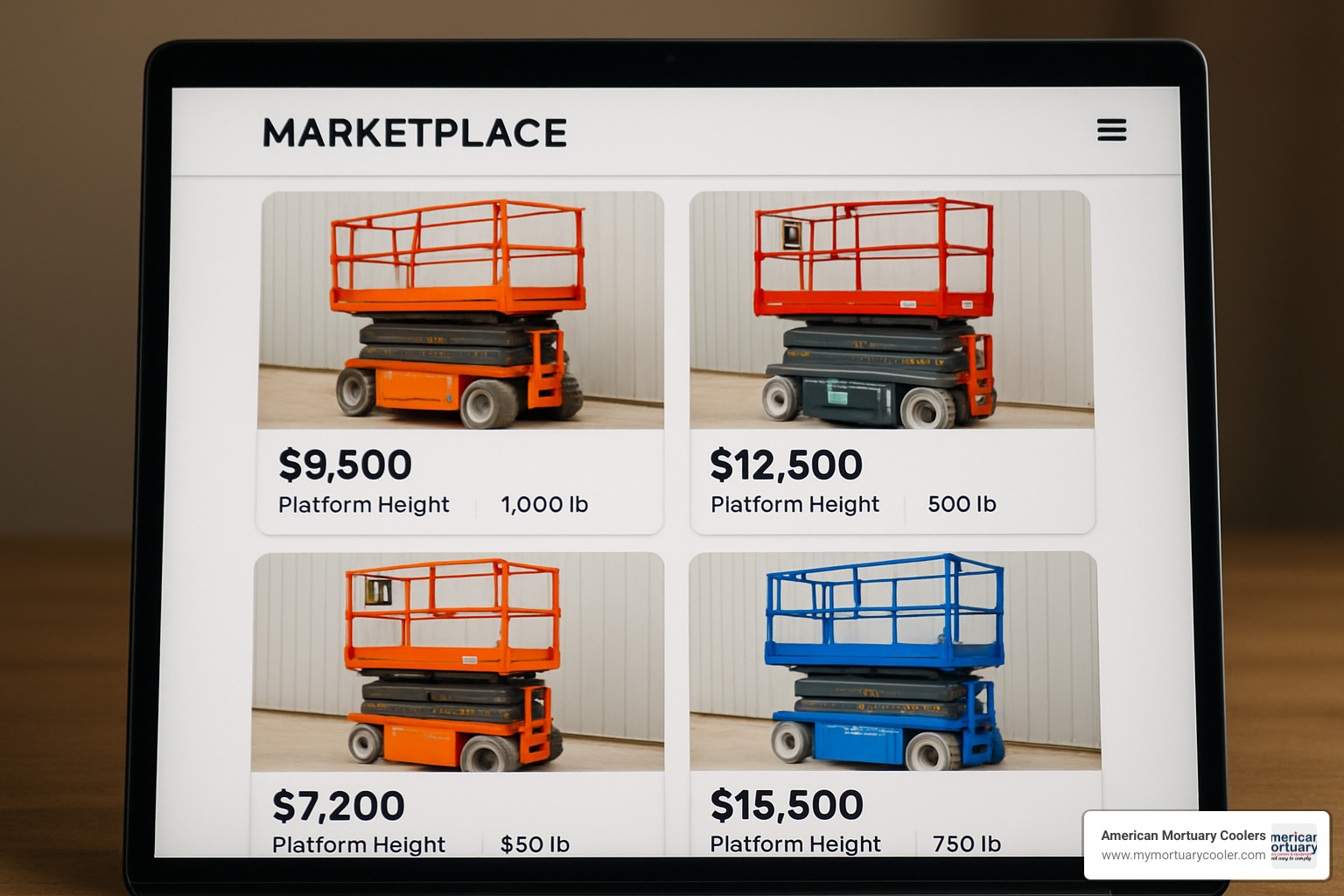

Let's talk money - because when you're ready to buy scissor lift equipment, understanding the market helps you make smart decisions. The pricing landscape varies dramatically based on what you need and how much wear and tear you can accept.

New electric scissor lifts start around $3,800 for compact 19-foot models, which is actually pretty reasonable for professional-grade equipment. If you need something bigger, expect to pay $8,000-$15,000 for mid-range 26-foot electric units. The heavy-duty rough terrain models? Those can hit $15,000-$40,000 depending on features and platform height.

The used market tells a different story entirely. We've seen auction listings start as low as $25 for units that need serious work (probably more headache than they're worth). Realistically, good condition used lifts typically run $2,000-$8,000 for electric models and $5,000-$20,000 for diesel units, depending on age, operating hours, and how well they've been maintained.

Should You Buy Scissor Lift New or Used?

This is where things get interesting. When you buy scissor lift equipment new, you're getting full manufacturer warranties (usually 1-2 years), the latest safety features, and that peace of mind knowing every component is fresh. No surprises, no wondering what the previous owner put it through.

Used lifts can save you 40-60% off new prices, which is hard to ignore if you're watching your budget. A well-maintained 5-year-old electric scissor lift might give you years of reliable service at a fraction of new cost. The trick is knowing what to look for and not getting burned by someone else's problems.

Here's what we've learned from years in the equipment business: total cost of ownership matters more than sticker price. A slightly more expensive used lift with recent maintenance records often costs less long-term than a "bargain" unit that needs immediate repairs. Factor in parts availability, service support, and realistic remaining life.

Manufacturer refurbishment programs offer a sweet spot between new and used. These programs take trade-ins, rebuild them to near-new condition, and offer limited warranties at prices that split the difference. It's worth asking dealers about refurb options.

Where to Buy Scissor Lift Online and Offline

Authorized dealers remain the gold standard when you buy scissor lift equipment. They provide comprehensive service including financing, warranties, parts support, and often delivery and setup. If you need an ongoing relationship for service and support, dealers are invaluable.

Online marketplaces have exploded in recent years. eBay currently shows over 425 scissor lift listings with extensive selection and competitive pricing. Auction sites like IronPlanet feature 1,826 total listings with detailed specifications and condition reports. These work great if you know exactly what you want and can evaluate equipment from photos and descriptions.

Used Scissor Lifts for sale Browse Ritchie List provides another excellent resource for quality used equipment with detailed specs and direct seller contact information.

Rental fleet retirements offer some of the best opportunities for well-maintained equipment. Rental companies maintain their fleets carefully and retire units while still in good condition to protect their service reputation. These lifts often have higher hours but consistent maintenance records.

Before you buy, consider whether rental might work better for your needs. More info about lift rentals can help you evaluate rental versus purchase options.

Financing, Leasing & Tax Incentives

Here's some good news: most scissor lift purchases qualify for Section 179 tax deductions, letting you deduct the full purchase price in the year you buy rather than depreciating it over several years. For profitable businesses, this can provide substantial tax savings that effectively reduce your real cost.

Equipment financing is widely available with terms from 2-7 years. Interest rates depend on your creditworthiness and loan terms, but competitive rates are available for qualified buyers. Many dealers offer financing programs that streamline everything into one transaction.

Leasing options include both operating and capital leases. Operating leases often feature lower monthly payments and may include maintenance packages - nice if you want predictable costs. Capital leases build equity and often include purchase options at lease end. Zero-down leases are available for qualified buyers, preserving cash flow for other business needs.

At American Mortuary Coolers, we understand equipment investments. Whether you're expanding capabilities or replacing aging equipment, the right financing can make quality equipment accessible without straining your cash flow.

Ownership Essentials: Inspection, Maintenance, Accessories & Legalities

Once you buy scissor lift equipment, you're taking on responsibilities that go well beyond writing the check. Proper care isn't rocket science, and it'll keep your investment running smoothly for years.

Daily pre-start inspections are your first line of defense and they're required by OSHA anyway. Before anyone steps on that platform, take a quick walk around and check the basics: hydraulic fluid levels, battery charge, tire condition, and all safety systems. It takes maybe five minutes, but catching a small problem early beats dealing with a breakdown later.

ANSI 92.24 training isn't optional - it's the law. Every operator needs to understand proper operation, how to spot hazards, and what to do in emergencies. The training covers everything from basic controls to emergency procedures, and you'll need to document it and renew it periodically.

Scheduled service intervals vary by manufacturer and usage intensity, but they're not suggestions. Battery care is especially critical for electric models - keep terminals clean, check water levels in flooded batteries, and follow proper charging procedures.

Inspecting a Used Lift Before Purchase

When you're looking at used equipment, that hour meter tells a story. Electric lifts with under 500 hours are barely broken in, while units over 2,000 hours have definitely been around the block. But a well-maintained high-hour lift often beats a neglected low-hour one.

Hydraulic leaks are like that dripping faucet - they start small but get worse over time. Look carefully at all cylinders, hoses, and fittings. A tiny bit of seepage might be normal on older equipment, but if you see active puddles or wet spots, budget for repairs.

Weld integrity is serious business since these are the joints holding everything together. Check the scissor arms, platform mounting points, and base frame for any cracks, previous repairs, or excessive wear.

Don't forget to test every joystick function - raise, lower, drive, and steer should all respond smoothly without sticking or excessive play.

Must-Have Accessories & Attachments

The right accessories can transform your scissor lift from basic transportation into a productivity powerhouse. Pipe racks are game-changers if you work with conduit, lumber, or any long materials - they keep everything secure and organized instead of juggling armloads of supplies on the platform.

Panel cradles make handling drywall, glass, or other flat materials so much easier and safer. Lighting kits extend your working day and improve visibility in dark spaces. Modern LED work lights are incredibly efficient and won't drain your battery quickly.

Pothole guards might sound boring, but they're lifesavers if you move between job sites. They protect the scissor mechanism from damage when crossing rough terrain or construction debris.

See Parts & Accessories On OnlineExpress offers manufacturer-approved accessories that you know will fit properly and maintain your warranty coverage.

Certifications, Licenses & Insurance

OSHA regulation 1910.29 isn't just paperwork - it's the framework that keeps everyone safe. As an employer, you're responsible for ensuring operators are properly trained, equipment is regularly inspected, and maintenance records are kept.

ANSI A92.6 provides the technical backbone for how scissor lifts should be designed, tested, and operated. Understanding these standards helps you select compliant equipment and maintain proper procedures.

Site-specific permits can catch you off guard if you're not prepared. Working on public property, near utilities, or in regulated environments often requires additional permits. Check local requirements before starting work.

Operator certification cards are proof that your people know what they're doing. Keep them current and make sure operators carry them on job sites. Many insurance companies offer premium discounts for properly trained operators.

At American Mortuary Coolers, we've seen how proper maintenance and compliance protect both equipment investments and the people who depend on them.

Frequently Asked Questions About Buying a Scissor Lift

Getting ready to buy scissor lift equipment often brings up the same questions we hear from customers every day. Here are the answers to the most common concerns that come up during the buying process.

How much does a typical scissor lift cost?

The price to buy scissor lift equipment varies dramatically based on size, power source, and whether you choose new or used. New electric scissor lifts start around $3,800 for basic 19-foot models - perfect for most warehouse and maintenance work. Mid-range units with 26-foot platforms typically run $8,000 to $15,000, while the big rough terrain diesel models can push over $40,000 for the largest units.

Used equipment offers much better value for budget-conscious buyers. You can find good condition electric lifts for $2,000 to $8,000 depending on age and hours. Diesel models in the used market typically range $5,000 to $20,000, which represents substantial savings over new pricing.

Don't forget about financing options that can make the numbers work better for your cash flow. Many dealers offer zero-down leasing programs and traditional equipment loans with terms from 2-7 years. The Section 179 tax deduction can also help offset the purchase price significantly.

Do I need certification to operate one?

Yes, OSHA absolutely requires proper training before anyone can operate a scissor lift. This isn't optional - it's federal law that applies to all workplaces using aerial lifts.

The standard training follows ANSI 92.24 guidelines and covers everything from basic operation to emergency procedures. You'll learn about hazard recognition, proper setup, weight limits, and what to do when things go wrong. The training must be documented, and operators need refresher courses periodically.

Some states and local areas have additional requirements beyond federal OSHA standards. Check with your local authorities to make sure you're fully compliant. Many insurance companies also require proof of training and may offer discounts for properly certified operators.

The good news is that training is widely available through equipment dealers, safety training companies, and online programs. Most courses can be completed in a day, and the investment in proper training pays off through reduced accidents and insurance costs.

What maintenance does a battery scissor lift require?

Electric scissor lifts are generally low-maintenance compared to diesel models, but they do need regular attention to keep running reliably. Battery care is the most critical aspect - these aren't car batteries, and they need proper charging cycles and maintenance.

Proper charging means using the right charger and avoiding partial charges when possible. Most modern lifts have smart chargers that prevent overcharging, but older units may need more attention. Check battery terminals regularly for corrosion and clean them as needed.

The hydraulic system needs periodic fluid changes and filter replacement, typically every 1,000 hours or annually. Hydraulic fluid should stay clean and at proper levels. Check for leaks during daily inspections and address them promptly.

Daily walk-around inspections are required by OSHA and help catch problems early. Look for obvious damage, check tire pressure, test all controls, and verify that safety systems work properly. A few minutes of daily inspection can prevent major problems and expensive repairs.

Professional service every 150-250 hours keeps everything running smoothly. This includes lubrication of moving parts, detailed safety system checks, and addressing any wear items before they become problems. At American Mortuary Coolers, we've seen how proper maintenance extends equipment life significantly - the same principles apply whether you're maintaining mortuary equipment or scissor lifts.

Conclusion

When you're ready to buy scissor lift equipment, you're making a smart investment that goes far beyond just reaching high places. You're choosing safety over dangerous ladder work, efficiency over time-consuming setups, and professional results over makeshift solutions.

The scissor lift market has something for everyone. Whether you need a quiet electric model for indoor warehouse work or a rugged diesel unit that can handle the toughest construction sites, the right lift is out there waiting for you. The trick is knowing exactly what you need before you start shopping.

Platform height, weight capacity, power source, and safety features all matter, but they matter differently depending on your specific work. A funeral home needing to access high storage areas has completely different requirements than a construction crew working on a multi-story building project.

At American Mortuary Coolers, we've learned this lesson well through our years serving funeral professionals across Tennessee and beyond. Every industry has its unique challenges, and the equipment that works perfectly in one setting might be completely wrong for another. That's why we always recommend taking time to really understand your needs before making any major equipment purchase.

The used equipment market offers incredible opportunities for smart buyers. A well-maintained five-year-old lift can provide decades of reliable service at a fraction of new equipment cost. But buying used requires patience, knowledge, and careful inspection. Don't rush into the first deal you see.

New equipment brings peace of mind through warranties, latest safety features, and the confidence that comes with being the first owner. For businesses that depend on their equipment daily, that peace of mind often justifies the higher upfront cost.

Buying the lift is just the beginning. Proper training, regular maintenance, and staying current with safety regulations protect your investment and, more importantly, protect the people who use your equipment every day.

American Mortuary Coolers' custom solutions prove that the right lift makes every vertical task safer and faster—explore more insider tips in The Ultimate Guide to Finding the Best Scissor Lift for Sale.