Why Finding the Right Scissor Lift Makes All the Difference

Finding the perfect scissor lift for sale can transform how your team handles liftd work tasks, but with over 4,000 listings available online and prices ranging from under $3,000 to $60,000+, knowing where to start makes all the difference.

Quick Answer for Scissor Lift Buyers:

- Electric models ($15,000-$30,000 new): Best for indoor use, 19-32 ft heights

- Rough terrain lifts ($25,000-$50,000 new): 4WD for outdoor construction sites

- Used options (50-70% savings): Check hour meters, battery health, compliance dates

- Where to buy: EquipmentTrader (4,000+ listings), eBay (425+ options), local dealers

- Key specs: Platform height, lift capacity, power source, indoor vs outdoor use

Whether you need a compact 19-foot electric model for warehouse maintenance or a heavy-duty rough terrain unit for construction work, the right scissor lift eliminates manual lifting risks while boosting productivity. With major brands like JLG (400,000+ units sold worldwide), Genie, and Skyjack dominating the market, buyers have proven options across every price range.

The key lies in matching your specific requirements—work environment, height needs, load capacity, and budget—to the right type of lift before you start shopping.

I'm Mortuary Cooler, a national-level mortuary cooler supplier who has helped funeral homes nationwide find specialized lifting equipment including scissor lift for sale options that meet their unique space and operational requirements. My experience with custom mortuary equipment gives me insight into the critical factors that separate a smart purchase from an expensive mistake.

Scissors lift for sale terms simplified:

What Is a Scissor Lift & How Does It Work?

Think of a scissor lift as your reliable vertical elevator to the sky. It's an aerial work platform that uses crossed hydraulic cylinders arranged in a scissor-like pattern to raise and lower a work platform straight up and down. Unlike boom lifts that swing out horizontally, scissor lifts keep you stable and secure as they move only vertically—perfect when you need steady overhead access.

The real magic of scissor lifts lies in their rock-solid stability. When you're 30 feet up changing warehouse lights or maintaining equipment, you want a platform that doesn't wobble or sway. That's exactly what scissor lifts deliver with their wide base and pantograph arms that distribute weight evenly.

We've helped funeral homes across the country find the right scissors lift for sale for their unique needs—from maintaining chapel lighting to accessing storage areas. The versatility of these machines makes them workhorses in industries from construction to warehousing, and increasingly in specialized sectors where precision and safety matter most.

Core Mechanism Explained

The heart of every scissor lift beats with hydraulic power. A hydraulic pump pressurizes fluid that flows into those crossed cylinders—the famous "scissor arms" that give these lifts their name. As hydraulic pressure builds, these arms extend smoothly, pushing your platform skyward in a controlled, steady motion.

Most electric models achieve lift speeds of 25-45 seconds to reach full height. That might sound slow, but it's actually perfect for safety and control. The descent can be adjusted to various speeds using the platform controls, giving operators complete command over their vertical movement.

What makes this system brilliant is how those crossed cylinders work together. They create exceptional stability because the weight gets distributed evenly across the entire base. Even at maximum height, you're standing on a solid, secure platform that won't leave you white-knuckling the rails.

Key Components That Matter

When you're evaluating any scissors lift for sale, three components deserve your closest attention.

Platform rails are your lifeline up there. Look for sturdy, OSHA-compliant guardrails that feel solid under pressure—no flexing or wobbling allowed. The best models have fold-down sections that make loading materials easier while keeping you safe. These rails should feel like they could stop a charging rhino, not bend like a pool noodle.

Emergency descent systems aren't just nice-to-have features—they're mandatory safety equipment that could save your life. If the primary hydraulic power fails, this backup system lets you lower the platform safely. It's like having a parachute; you hope you'll never need it, but you'll be grateful it's there if you do.

Non-marking tires might seem like a small detail, but they're huge for indoor work. These specialized tires prevent ugly scuff marks on polished floors—absolutely critical in facilities like hospitals, funeral homes, or retail spaces where appearance matters. Nobody wants to explain black tire marks on a pristine marble floor to an unhappy facility manager.

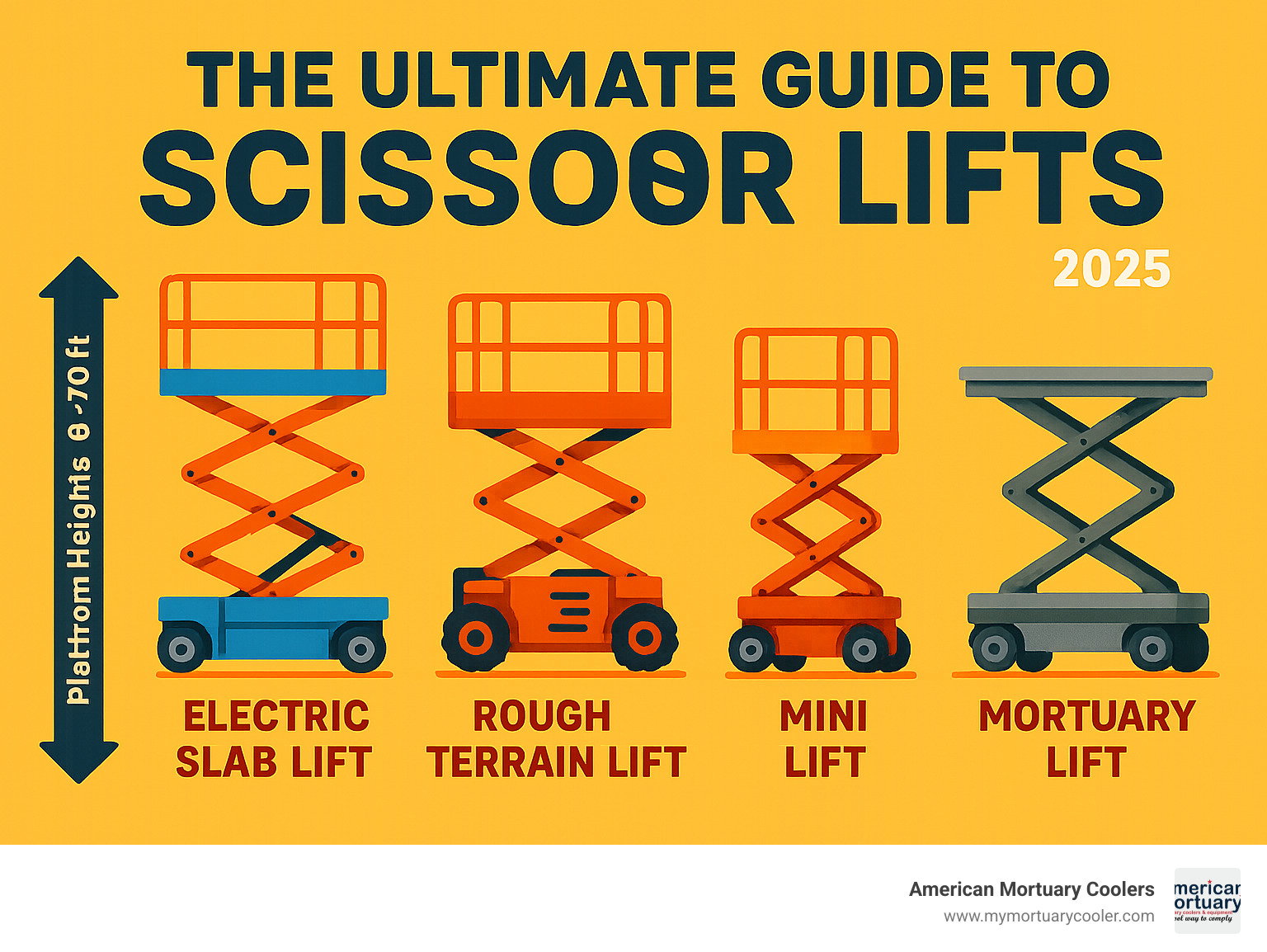

Major Types of Scissors Lift for Sale & Their Ideal Uses

Walking into the scissors lift for sale market can feel overwhelming until you understand that most lifts fall into just a few main categories. Each type has evolved to solve specific problems, and knowing which one matches your work environment saves both money and headaches down the road.

Think of it like choosing the right vehicle—you wouldn't take a sports car off-roading or drive a bulldozer to the grocery store. The same logic applies to scissor lifts, where matching the equipment to your environment determines success.

Electric & Slab Scissors Lift for Sale

Electric scissor lifts have become the go-to choice for indoor work, and once you understand why, it's obvious. These battery-powered workhorses run whisper-quiet, produce zero emissions, and maneuver through tight spaces like they were designed by someone who actually had to use them.

The 19-foot, 26-foot, and 32-foot platform heights cover about 90% of indoor tasks. Whether you're changing light fixtures in a warehouse, installing ceiling tiles in an office, or performing maintenance in a hospital, these heights hit the sweet spot for most overhead work.

What makes electric models shine indoors is their zero inside turning radius. Picture navigating a narrow warehouse aisle or squeezing through standard doorways—electric lifts pivot in place, making tight spaces manageable instead of impossible.

Battery life typically runs 6-8 hours of continuous operation, which covers most work shifts. The quiet operation becomes crucial in environments like hospitals, schools, retail stores, and funeral homes where noise disruption can't be tolerated.

Rough Terrain Scissors Lift for Sale

When your work moves outdoors or onto uneven ground, electric lifts become useless fast. That's where rough terrain scissor lifts earn their keep. These 4WD units tackle construction sites, outdoor maintenance, and anywhere the ground isn't perfectly level.

Foam-filled pneumatic tires handle debris, nails, and rough surfaces that would sideline electric models. The higher ground clearance lets you roll over obstacles, while outriggers provide extra stability on slopes that would make other lifts unsafe.

Platform heights for rough terrain models typically start at 26 feet and stretch past 50 feet, with lift capacities often exceeding their indoor cousins. The diesel or dual-fuel engines deliver the muscle needed for demanding outdoor environments, though you'll pay more in fuel costs and deal with noise and emissions.

Specialty & Industry-Specific Lifts

Beyond the standard categories, specialized scissor lifts solve unique problems across different industries. Automotive scissor lifts handle vehicle service with capacities reaching 7,000 pounds, featuring open-center designs that provide clear access to undercarriages.

In our work at American Mortuary Coolers, we've seen growing interest in mortuary-specific scissor lifts. These units feature low-profile designs for tight spaces, stainless steel construction for easy sanitization, and precise height control for positioning tasks. More info about comparing low profile lifts covers the specific requirements funeral facilities face.

Even more specialized are robotic camera lifts—compact electric units designed for surveillance applications. These typically range from 39-60 inches in height and mount camera systems on unmanned vehicles for security work.

The key insight here is that specialized doesn't always mean expensive. Sometimes a purpose-built solution costs less and performs better than trying to adapt a general-purpose lift to specific needs.

How to Choose the Right Scissor Lift: 10 Buyer Checkpoints

Finding the perfect scissors lift for sale doesn't have to feel overwhelming. After helping countless clients match their needs to the right equipment, I've learned that the best purchases happen when you know exactly what questions to ask before you start shopping.

The difference between a smart buy and an expensive mistake often comes down to ten critical factors. Let me walk you through each one, so you can shop with confidence.

| Factor | New Scissor Lifts | Used Scissor Lifts |

|---|---|---|

| Initial Cost | $15,000-$60,000+ | $5,000-$30,000 |

| Warranty | 1-3 years full coverage | Limited or none |

| Condition | Perfect, latest features | Varies, may need repairs |

| Availability | 1-12 weeks delivery | Immediate |

| Financing | Full options available | Limited financing |

| Technology | Latest safety features | Older technology |

| Depreciation | High first-year loss | Already depreciated |

| Parts Support | Guaranteed availability | May be discontinued |

Platform height is where most people start, and for good reason. Measure your highest work area, then add 6-10 feet for comfortable reach. The 19-foot, 26-foot, and 32-foot categories are popular because they handle most real-world jobs perfectly.

Lift capacity matters more than you might think. While 500-1,000 pounds covers basic tasks, you'll want extra capacity if you're moving heavy materials or multiple workers. Heavy-duty models lifting 2,500+ pounds give you that safety margin.

Power source can make or break your project. Electric models shine indoors with their whisper-quiet operation and zero emissions. Diesel units power through demanding outdoor work. Dual-fuel options give you the best of both worlds, though at a higher price point.

Your footprint constraints will quickly narrow your options. Measure those doorways and aisles carefully—compact models squeeze through 30-inch spaces, while standard units need 5-6 feet of clearance. Nothing's more frustrating than buying a lift that won't fit where you need it.

Indoor versus outdoor use determines everything from tire type to weather protection. Non-marking tires are essential for polished floors, while rough terrain models need foam-filled tires for outdoor durability.

Duty cycle tells you how hard you can work the equipment. Light-duty models handle occasional use perfectly, while heavy-duty units power through daily commercial applications without breaking down.

Terrain considerations go beyond just indoor or outdoor. Will you cross gravel, grass, or uneven surfaces? Rough terrain models with 4WD and higher ground clearance handle challenging conditions that would stop standard units.

Emissions requirements vary by location and application. Electric models produce zero emissions, making them perfect for enclosed spaces or areas with strict environmental rules.

Transportability becomes crucial if you move between job sites. Self-propelled units offer excellent mobility, while trailer-mounted options work well for regular transport between locations.

Available options can transform a basic lift into the perfect tool for your specific needs. Extended platforms, auxiliary power outlets, and specialized attachments often make the difference between adequate and exceptional performance.

Using a Selection Checklist

The smartest buyers I work with approach their purchase systematically. They start by clearly defining their jobsite requirements—not just what they need today, but what they might need six months from now.

Uptime targets matter more in some industries than others. If equipment downtime costs you serious money, investing in newer, more reliable equipment often pays for itself quickly. Used equipment can offer great value, but factor in potential repair time.

Operator training requirements vary significantly between models. Simple electric lifts are generally easier for new operators to master safely, while complex rough terrain units require more extensive training and certification.

Deep-Dive Resources

For specialized applications, particularly in funeral services where precision and reliability are critical, More info about choosing hydraulic lifts provides detailed technical guidance on hydraulic system selection and maintenance requirements.

The key is matching your specific needs to the right equipment before you start shopping. Take time to work through these checkpoints thoroughly—it's much easier to get it right the first time than to realize you bought the wrong lift after it's delivered.

Pricing, Marketplaces & Negotiation Strategies

The scissor lift for sale market can feel overwhelming when you're staring at price tags ranging from $2,000 for a basic used unit to $60,000+ for a brand-new specialty lift. But here's the thing—understanding how this market actually works can save you thousands.

New scissor lifts follow pretty predictable pricing patterns. Compact electric models (19-26 feet) typically run $15,000-$25,000, while standard 32-foot electric units jump to $20,000-$35,000. Need something for outdoor work? Rough terrain lifts (26-40 feet) will cost you $25,000-$45,000, and heavy-duty or specialty units can easily hit $40,000-$60,000 or more.

The used market tells a different story entirely. Based on current marketplace data, you're looking at 30-70% of new prices, depending on how many hours are on the machine and how well it's been maintained. I've seen everything from $3,775 for basic older models to over $30,000 for nearly-new heavy-duty units on eBay.

Here's something most buyers don't realize: the steepest depreciation happens in years 2-3, not year one. That makes 3-5 year old units with 2,000-4,000 hours often your best bet. You get most of the remaining useful life without paying the new equipment premium.

Auction timing matters more than you'd think. Equipment auctions during winter months or economic downturns often yield better prices. Dealer inventory cycles also create opportunities—end of fiscal year or when new model years arrive.

Where to Spot the Best Scissors Lift for Sale Deals

EquipmentTrader dominates the market with over 4,000 scissor lift listings. Their advanced filtering system lets you narrow down by location, specifications, and price range. More importantly, their dealer network often provides warranties even on used equipment—something you won't get from private sellers.

eBay offers a different approach with 425+ scissor lift listings mixing auctions and buy-it-now options. The auction format can work in your favor, especially if you're patient. Mid-week auction endings typically see less bidding competition than weekend closings. I've watched identical units sell for $3,000-$5,000 less simply because they ended on a Tuesday afternoon instead of Sunday evening.

Local dealers often provide the best overall value, even if their initial prices seem higher. They offer trade-in programs, financing options, and ongoing service support that online purchases can't match. Building relationships with local dealers can give you access to off-market inventory and better pricing on future purchases.

The latest research on aftermarket accessories shows that accessory availability varies dramatically by brand and model age. This affects your long-term ownership costs more than most buyers realize.

New vs Used: Pros, Cons & Hidden Costs

Used scissor lifts offer immediate availability—no waiting 1-12 weeks for delivery. You get 50-70% cost savings over new, and the equipment has already taken its depreciation hit. Plus, you're buying something with proven reliability in real field conditions.

But hidden costs can bite you. Battery replacement on electric models runs $2,000-$4,000. Hydraulic system rebuilds can cost $3,000-$8,000. Then there are compliance inspections, certifications, and generally higher maintenance costs compared to new equipment.

Here's a reality check about hour meters: Low hours don't automatically mean better condition. A lift with 1,000 hours used daily by a professional crew might be better maintained than one with 500 hours that sat unused for years. Battery health deteriorates with age regardless of usage—something that catches many buyers off guard.

Compliance stickers tell you when the last inspection happened and when the next one's due. Expired certifications can add $500-$1,500 to your purchase cost before you can legally operate the equipment.

At American Mortuary Coolers, we've seen clients save significant money by buying quality used equipment and investing in proper maintenance from day one. The key is knowing what to look for and budgeting for the hidden costs upfront.

Maintenance, Safety & Inspection Essentials

When you invest in a scissor lift for sale, you're not just buying equipment—you're taking on the responsibility of keeping your operators safe while protecting your investment. The good news? A solid maintenance routine isn't rocket science, and it can save you thousands in repairs while preventing dangerous accidents.

Think of scissor lift maintenance like caring for your car. Skip the oil changes and regular checkups, and you'll eventually face expensive breakdowns at the worst possible moment. The same principle applies to scissor lifts, except the stakes are higher when someone's working 30 feet in the air.

Daily pre-start inspections form the foundation of safe operation. Before anyone steps onto that platform, take five minutes to check the guardrails and platform integrity—look for loose bolts, bent rails, or any damage that could compromise safety. A quick hydraulic system leak check reveals potential problems before they become dangerous failures.

For electric models, battery charge levels need daily attention. Nothing's more frustrating than getting halfway through a job and losing power. Check tire condition and proper inflation too—worn or under-inflated tires affect stability and can cause premature wear on other components.

The emergency lowering system test might seem like overkill, but it's your lifeline if something goes wrong. Test it regularly, and make sure everyone knows how to use it. Finally, verify all control functions work smoothly before starting work.

ANSI and OSHA don't mess around when it comes to scissor lift safety. They require annual inspections by qualified technicians, plus more frequent checks based on how heavily you use the equipment. Keep detailed records of every inspection and maintenance activity—your insurance company and lawyers will thank you if anything ever goes wrong.

Modern scissor lifts come equipped with critical safety systems that work behind the scenes to keep operators safe. Tilt sensors prevent operation on excessive slopes—trust me, you don't want to test what happens when a scissor lift tips over. Emergency stop buttons should be accessible from both the platform and base controls, giving operators multiple ways to shut down in emergencies.

Load testing deserves special attention. This annual procedure involves lifting the maximum rated capacity to verify that both the structure and hydraulic system can handle their design limits. It's not optional—it's essential for safe operation and often required by insurance policies.

Quick Inspection Guide Before You Buy a Used Unit

Walking around a used scissor lift for sale without knowing what to look for is like buying a used car in the dark. Here's what separates smart buyers from those who learn expensive lessons later.

Start with the hour meter analysis. Compare operating hours to the unit's age—if you see a five-year-old lift with only 200 hours, ask why it sat unused. Sometimes low hours indicate neglect rather than gentle use. Conversely, extremely high hours might mean the unit lived a hard life on busy construction sites.

Structural inspection requires your full attention. Look carefully for weld cracks, especially around pivot points and hydraulic cylinder mounts. These stress points bear the most load, and repairs here can cost more than the lift is worth. Run your hands along welds—you can often feel cracks before you see them.

Tire wear patterns tell stories about how the lift was operated. Uneven wear suggests alignment problems, overloading, or operators who didn't follow proper procedures. Replacement costs vary from $200-$800 per tire depending on size and type, so factor this into your budget.

Don't skip the tilt sensor test. This critical safety feature prevents tip-overs by shutting down operation on excessive slopes. If it's not working properly, walk away—the repair costs are significant, and the safety risk isn't worth it.

For specialized applications like funeral homes, our More info about ultimate inspection checklist provides detailed guidance on evaluating lifting equipment for professional environments where reliability and cleanliness are paramount.

Ownership Tips to Maximize ROI

Smart scissor lift ownership starts with scheduled service programs. Yes, spending $500-$1,500 annually on maintenance feels expensive until you face a $10,000 hydraulic system rebuild that could have been prevented with regular service. Think of it as insurance you actually want to pay for.

Parts sourcing strategy affects both your wallet and your uptime. OEM parts cost more but ensure proper fit and performance—there's something to be said for parts designed specifically for your equipment. Aftermarket parts can save 20-40% but may affect reliability and warranty coverage. Choose wisely based on the part's criticality and your risk tolerance.

Resale value protection starts the day you buy your lift. Maintain service records, keep original manuals, and address cosmetic issues before selling. These simple steps can improve resale value by 10-20%—money that goes straight to your bottom line when it's time to upgrade.

The reality is that well-maintained scissor lifts can provide decades of reliable service. We've seen units with over 10,000 hours still operating safely because their owners understood that consistent care pays dividends. Take care of your equipment, and it'll take care of you and your operators for years to come.

Frequently Asked Questions about Scissor Lifts

When you're shopping for a scissors lift for sale, these common questions come up again and again. Let me share the answers that matter most to buyers, based on real conversations with customers across the country.

What financing and warranty options exist?

Here's the good news: financing a scissor lift is usually straightforward, even for smaller businesses. Most dealers work with equipment finance companies that understand this equipment holds its value well.

Financing terms typically run 24-84 months, with rates between 4-12% depending on your credit and the equipment's age. Newer lifts get better rates, while used equipment might cost a bit more to finance. Many buyers find the monthly payments more manageable than a large upfront purchase.

Leasing options offer lower monthly payments if you don't need to own the equipment. This works especially well if you only need the lift for specific projects or want to upgrade regularly without dealing with resale.

For warranties, new scissor lifts come with solid coverage—usually 1-3 years on major components like hydraulics and structural elements. Used equipment is trickier. Some dealers offer 30-90 day limited warranties, while others sell everything "as-is."

If you're buying used, ask about extended warranty programs. They cost extra but can save thousands if something major breaks down.

Do I need certification to operate a scissor lift?

The short answer is yes—OSHA requires proper training for anyone operating aerial lifts, including scissor lifts. But don't let this scare you away from a purchase. The training isn't complicated, and most operators pick it up quickly.

Training requirements cover the basics you'd expect: pre-operation inspections, safe operating procedures, what to do in emergencies, and simple maintenance tasks. Many employers handle this training internally, but formal certification programs are available through organizations like IPAF if you prefer professional instruction.

The key point: operators must be re-evaluated every three years or after any incidents. This keeps everyone sharp and helps prevent accidents that could shut down your operation.

Most of our customers at American Mortuary Coolers find that proper training actually makes their teams more confident and productive with the equipment. It's an investment that pays for itself in safety and efficiency.

How often should a scissor lift be inspected?

This is where many buyers get surprised by the ongoing responsibilities. ANSI A92.20 standards lay out a clear inspection schedule that you'll need to follow:

Daily inspections happen before each use—your operator checks guardrails, hydraulic leaks, battery levels, and basic functions. This takes just a few minutes but catches problems before they become dangerous.

Monthly inspections dig deeper into hydraulic systems and safety features. Quarterly reviews cover all safety systems comprehensively. And annual inspections require a certified technician to perform complete testing, including load testing to verify the lift can safely handle its rated capacity.

High-usage equipment might need professional inspections more often. The real key is keeping detailed records of every inspection and maintenance task. Your insurance company and OSHA inspectors will want to see this documentation, and it protects you legally if anything goes wrong.

The inspection requirements might seem demanding, but they're designed to keep your investment running safely for years. Most owners find that following the schedule actually reduces unexpected breakdowns and repair costs.

Conclusion

Your search for the perfect scissor lift for sale doesn't have to be overwhelming. With the right approach, you can find equipment that transforms how your team works while staying within budget. Whether you're eyeing that compact 19-foot electric model for warehouse tasks or need a rugged 4WD unit for outdoor construction, success comes down to matching your real-world needs to the right equipment.

The current market is actually pretty exciting for buyers. Those 4,000+ listings on EquipmentTrader and hundreds more on eBay mean you've got options—lots of them. And with used units offering 50-70% savings over new, there's never been a better time to upgrade your lifting capabilities without breaking the bank.

Here at American Mortuary Coolers, we've seen how the right lifting equipment changes everything. From our Tennessee headquarters, we've helped funeral homes across the country solve complex lifting challenges with custom solutions. It's taught us that the perfect scissor lift isn't just about specs on paper—it's about what works day in and day out in your specific environment.

If you're working in the funeral industry, don't miss our specialized guide: Lift for Less: Your Guide to Buying Used Mortuary Lifts. We cover the unique requirements and solutions that make sense for funeral service professionals.

Before you make that final purchase decision, remember these game-changing tips: Always see used equipment in person before you buy—photos hide a lot of problems. Think total ownership costs, not just the sticker price, because a cheap lift that needs constant repairs isn't really cheap at all. Check parts availability for older models before you fall in love with that "great deal."

Most importantly, keep detailed service records from day one. Your future self (and your resale value) will thank you. And please, invest in proper operator training. It's not just about compliance—it's about getting home safe every day.

A smart scissor lift for sale purchase is really an investment in your team's safety and your operation's efficiency. Take the time to do it right, ask the tough questions, and don't rush the decision. The perfect lift is out there waiting for you—and when you find it, you'll know the difference it makes every single day.