The Critical Role of Medical Heat Sealers in Sterile Packaging

A medical heat sealer is a specialized device used to create hermetic seals on pouches containing medical instruments and devices, ensuring sterility until point of use. These essential pieces of equipment create reliable barriers against contamination through precisely controlled temperature, pressure, and time parameters.

Quick Reference: Medical Heat Sealers at a Glance

| Type | Best For | Price Range | Key Features |

|---|---|---|---|

| Impulse | Medical facilities, low-volume | $500-$5,000 | No warm-up time, precise control, validatable |

| Constant Heat | Thicker materials, continuous use | $1,000-$8,000 | Consistent temperature, handles multi-layer materials |

| Rotary/Band | High volume manufacturing | $10,000-$25,000 | Continuous operation, high throughput, recipe storage |

Medical heat sealers play a critical role in healthcare settings by:

- Creating sterile barriers that comply with ISO 11607 packaging standards

- Preventing contamination of medical devices and surgical instruments

- Supporting regulatory compliance with FDA/GMP requirements

- Offering validatable and repeatable sealing processes

- Accommodating various materials including Tyvek, Mylar, foil, and paper-plastic combinations

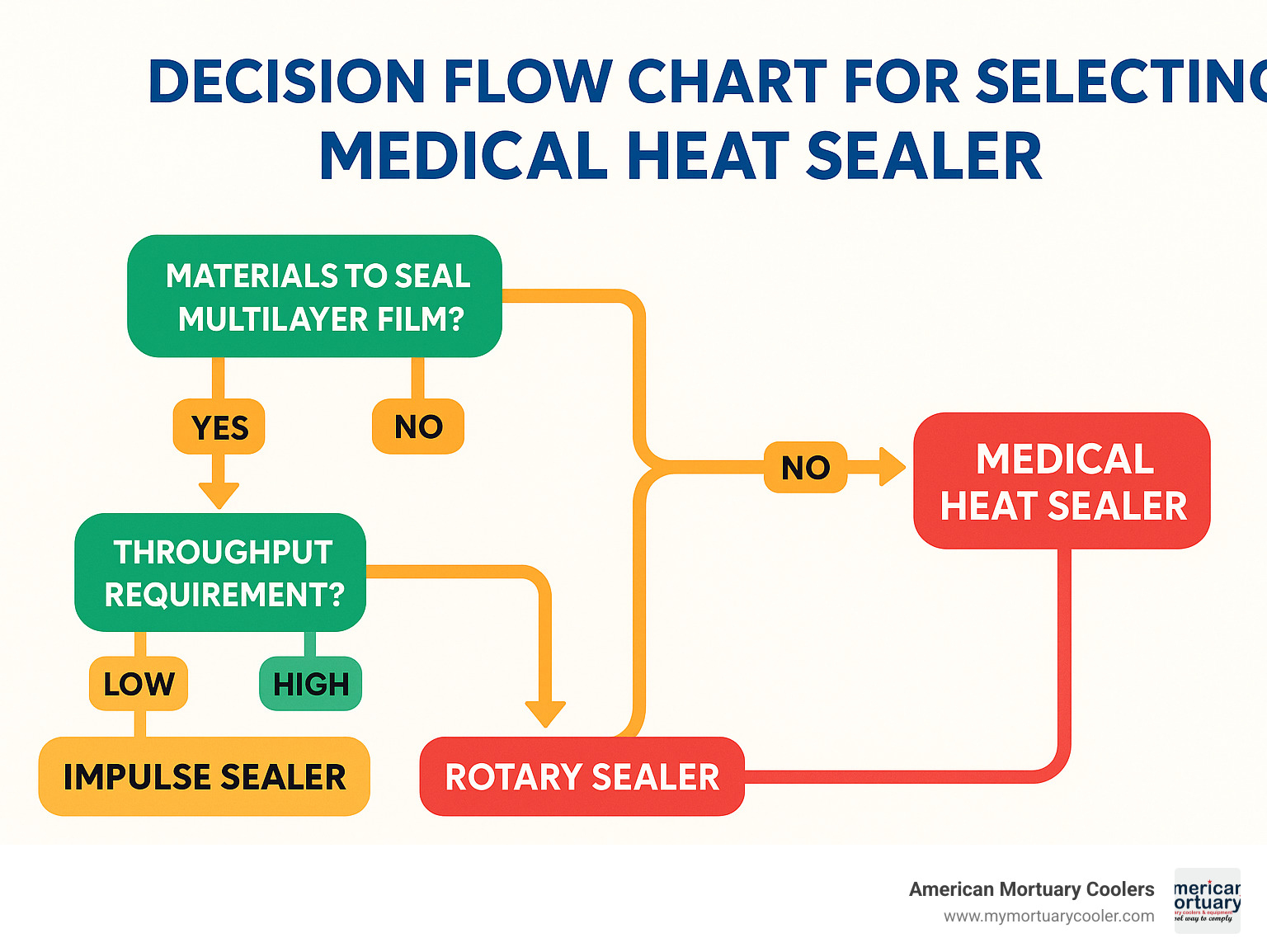

When selecting a medical heat sealer, consider your specific application needs, material types, throughput requirements, and validation capabilities to ensure you're making an investment that supports both patient safety and operational efficiency.

I'm Mortuary Cooler, a national-level supplier of mortuary equipment including medical heat sealers used in pathology departments and mortuary settings for biohazard containment and sterile packaging. My experience spans decades working with healthcare facilities to implement reliable sealing solutions that maintain sterility in critical environments.

Why This Guide Matters

When it comes to medical packaging, there's no room for error. A compromised seal can lead to contamination, putting patient safety at risk and potentially resulting in costly recalls or regulatory issues. According to industry data, over a billion seals are made on medical pouches each year worldwide, highlighting the sheer scale and importance of this process.

At American Mortuary Coolers, we understand that proper sealing is especially critical in forensic and mortuary settings where biohazard containment is essential. Whether you're packaging sterile instruments in a hospital's central sterile department or sealing biohazard specimens in a laboratory, the right medical heat sealer makes all the difference.

This guide will help you steer the complex world of medical heat sealing technology, ensuring you select equipment that meets your specific needs while maintaining compliance with stringent industry standards like ISO 11607.

Medical Heat Sealer Fundamentals: Function, Compliance & Materials

What Is a Medical Heat Sealer?

A medical heat sealer is far more than just a fancy packaging tool—it's a critical guardian of sterility in healthcare settings. These specialized devices create airtight seals on medical packaging that protect instruments, devices, and specimens from contamination until they're needed.

Unlike their commercial cousins, medical heat sealers are built with precision and validation in mind. They create what professionals call a sterile barrier system (SBS)—essentially an impenetrable shield that keeps germs out while allowing sterilization agents in during processing.

I've spoken with countless customers over the years, and one central sterile processing manager put it perfectly: "The sealing process is the foundation of our sterile processing operation. Having a reliable medical heat sealer is non-negotiable—it's the best investment we've made for ensuring patient safety."

You'll find these essential machines hard at work in many healthcare environments—from busy hospital sterile processing departments to medical device manufacturing plants. They're equally important in clinical labs, dental offices, and yes, even mortuary and forensic settings where containing biohazards is paramount.

What makes these devices special is their ability to create tamper-evident seals that instantly show if package integrity has been compromised. They maintain consistent seal strength through precise control of temperature, pressure, and time—something you simply can't achieve with general-purpose sealers.

Regulatory Landscape & Documentation

When it comes to medical heat sealers, meeting regulatory requirements isn't optional—it's essential. The standards might seem overwhelming at first, but they exist for good reason: patient safety.

The gold standard in the industry is ISO 11607, which comes in two important parts. Part 1 covers the materials and barrier systems themselves, while Part 2 focuses specifically on validation of the sealing process. If you're working in medical packaging, this standard will become your best friend.

ISO 13485 takes a broader view, setting requirements for quality management systems in medical device manufacturing and related services. Meanwhile, the FDA weighs in with 21 CFR Part 820, their Quality System Regulation covering everything from manufacturing to packaging and storage.

European facilities need to be aware of EN 868 standards as well, which address packaging materials for sterilized medical devices.

Documentation is where many facilities fall short. A proper medical heat sealer should come with a comprehensive validation package including:

- Installation Qualification (IQ) paperwork that verifies proper setup

- Operational Qualification (OQ) protocols confirming it works as intended

- Performance Qualification (PQ) guidance for your specific applications

- Calibration certificates from accredited labs (ideally ISO/IEC 17025)

- Ready-to-use SOP templates to streamline your validation process

When we help facilities select equipment at American Mortuary Coolers, we emphasize the importance of these validation documents. They're not just paperwork—they're your protection against regulatory issues and your proof that you're maintaining the highest standards of care.

Materials You Can Seal Today

Today's medical heat sealers are remarkably versatile when it comes to handling different packaging materials. Each material has its own personality and purpose in the medical packaging world.

Tyvek® is perhaps the most recognized name in the business. This DuPont creation looks like paper but is actually made from high-density polyethylene fibers. Its superpower? Being breathable enough to let sterilization gases through while keeping microbes out. It's commonly paired with film to create those familiar peel-open pouches you see everywhere in healthcare.

Medical-grade papers are workhorses in steam sterilization applications. When combined with plastic films, they create economical pouches that allow steam to penetrate during sterilization while maintaining a solid barrier afterward.

Polyethylene (PE) brings flexibility and moisture resistance to the table. Available in different densities from low (LDPE) to high (HDPE), it's a versatile option for many applications. Its cousin polypropylene (PP) offers better clarity and chemical resistance, making it ideal for applications where you need to see what's inside.

For applications requiring superior protection, Mylar® (PET) and foil laminates provide exceptional barriers against moisture, gases, light, and oxygen. When you need extra durability and puncture resistance, nylon materials step up to the challenge.

Choosing the right material involves considering several factors: the sterilization method you'll use, how long items need to stay sterile, whether staff need to see inside the package, and how the package will be opened. Most materials range from 2-20 mil in thickness, with thicker materials generally providing better durability but requiring more robust sealing parameters.

At American Mortuary Coolers, we've found that K-type thermocouples provide the most accurate temperature verification for medical heat sealers, ensuring consistent results across different material types. For facilities concerned about cleanroom compatibility, many modern units offer stainless steel construction and smooth surfaces that minimize particle generation and are easy to clean and sanitize.

For a deeper dive into heat sealing principles and applications, heat sealing.info offers excellent resources that can help you better understand the science behind creating perfect seals.

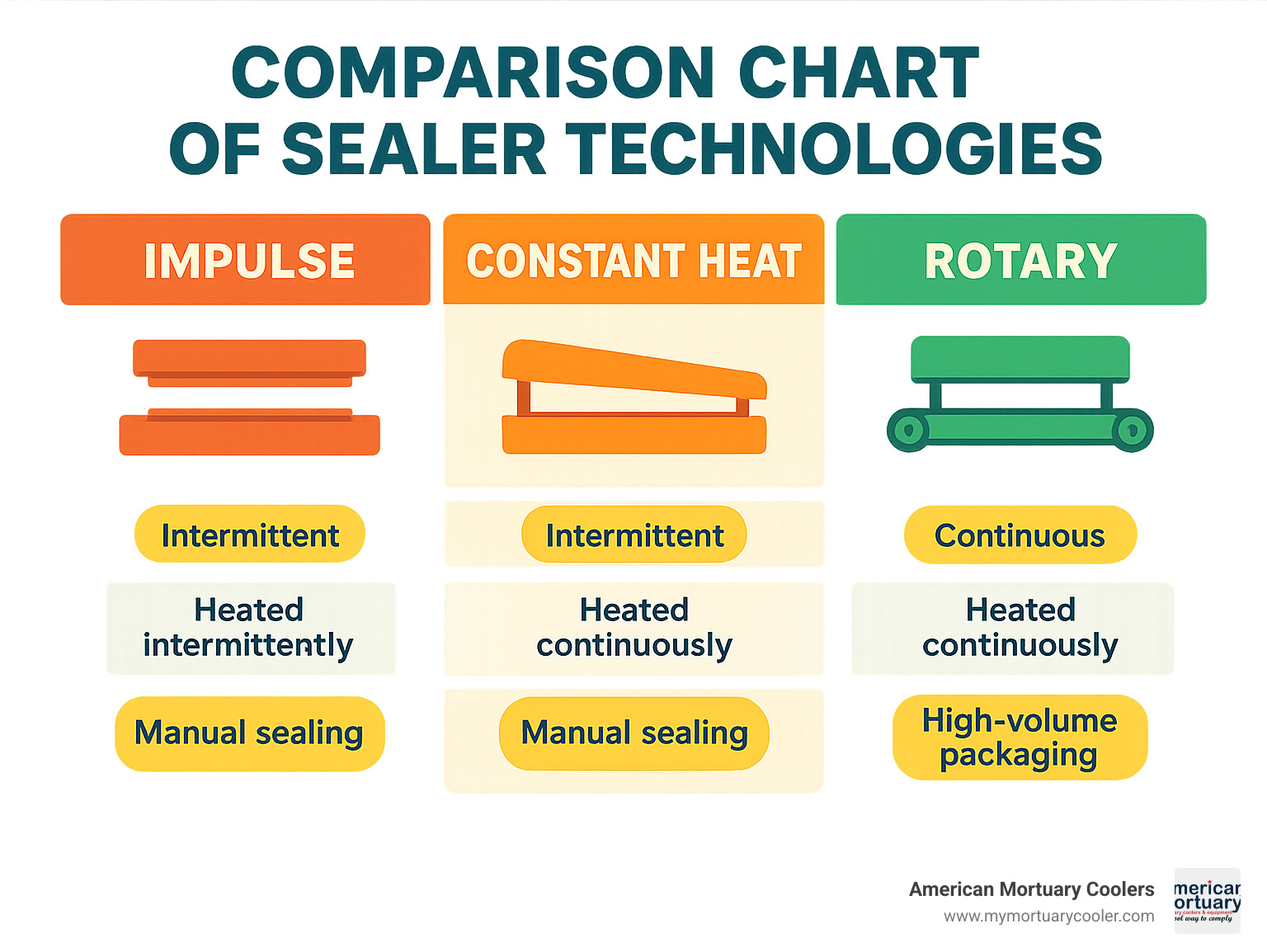

Type-by-Type Comparison of Medical Heat Sealers

Choosing the right medical heat sealer is a bit like finding the perfect pair of shoes – what works wonderfully for one application might leave another completely unsupported. Let's walk through the main technologies so you can find your perfect fit.

Impulse Technology Explained

Impulse sealers have become the darlings of the medical packaging world, and for good reason. These clever devices work by quickly heating a sealing element to the exact temperature needed, holding it there just long enough to create a perfect seal, then cooling down before releasing your pouch.

Think of impulse sealers as the sprinters of the sealing world – they burst into action when needed, then rest until the next cycle. This makes them incredibly energy-efficient since they only draw power during the actual sealing process.

One of our hospital customers recently told me, "We switched to the MS-350 impulse sealer last year, and the difference in seal consistency is night and day." It's no wonder – these machines offer temperature accuracy within ±1°C, with readings every millisecond or two.

Medical heat sealers with impulse technology require no warm-up time, allowing staff to use them immediately when needed. This feature alone can be a game-changer in busy environments where efficiency matters. The D-3010HCA model exemplifies this ready-when-you-are functionality.

Perhaps most importantly for medical applications, impulse technology provides a fully validatable process. Every critical parameter – temperature, time, pressure – can be precisely controlled and documented, ensuring compliance with stringent regulations.

Constant Heat Systems in Medical Packaging

While impulse sealers might be the sprinters, constant heat systems are the marathon runners of the medical heat sealer world. These workhorses maintain a continuous temperature in their sealing bars or jaws, making them ideal for thicker materials up to 6mm and applications requiring wider seal bands.

The SN-008 manual heat sealer represents this category well, featuring adjustable temperatures from 50-300°C and a generous 10mm sealing width. These systems really shine when working with multiple layers or thicker materials because they provide better heat penetration.

"We seal a lot of multi-layer Tyvek pouches, and our constant heat sealer handles them beautifully," shared a medical device manufacturer we work with. "The consistent temperature throughout the sealing process gives us perfect results every time."

For applications requiring mobility, handheld constant heat sealers offer a practical solution. These portable units typically feature Teflon-coated heating elements to prevent sticking and ergonomic designs that reduce operator fatigue – a thoughtful touch for those long packaging sessions.

Rotary/Band Sealers for High Throughput

When volume is the name of the game, rotary or band sealers step into the spotlight. These high-throughput champions are the assembly lines of the medical heat sealer world, offering continuous operation that significantly boosts productivity.

The OKI Supersealer MBS20 exemplifies the capabilities of medical-grade band sealers, with impressive sealing speeds up to 48 feet per minute. It can store up to 65 different sealing profiles, making product changeovers quick and painless.

As one production manager told us, "Our rotary sealer replaced three traditional bar sealers and still finished the job faster." OKI confirms this efficiency, noting that a single continuous rotary band sealer can replace up to five traditional bar sealers.

These systems integrate beautifully with conveyor systems for fully automated packaging lines. Many models also offer inline printing capabilities for lot numbers and expiration dates – a handy feature that eliminates an extra step in the packaging process.

Hybrid & Specialty Options

Sometimes, standard sealing options just won't cut it. That's when specialty medical heat sealers come to the rescue with their unique capabilities.

Vacuum and gas purge systems don't just seal your medical pouches – they first remove the air and can replace it with an inert gas before sealing. This feature is invaluable for oxygen-sensitive products. Accu-Seal has designed these systems with quick-release components that make cleaning and maintenance a breeze.

For those tricky applications involving ports or valves, port and fitment sealers offer specialized solutions. As Thermal Press explains, heat sealing creates high-quality attachments without the degradation or debris that can occur with ultrasonic welding – a critical consideration for medical applications.

When you're dealing with oversized medical drapes or covers, large-area systems provide the extended sealing area needed. And for those who want the best of all worlds, hybrid systems like Van der Stähl's MS-451-PV combine impulse sealing technology with integrated peel-testing for on-the-spot quality verification.

At American Mortuary Coolers, we've seen how the right medical heat sealer can transform packaging operations in pathology departments and mortuary settings. Whether you're sealing standard pouches or specialized biohazard containment materials, understanding these different technologies helps ensure you select equipment that perfectly matches your unique needs.

Seal Quality Mastery: Parameters, Validation & Testing

Controlling the "Big Three"

Creating perfect medical package seals isn't magic—it's science. At the heart of this science are three critical parameters that experienced technicians call "The Big Three": temperature, time, and pressure. Getting these right is like finding the perfect recipe for patient safety.

Temperature control in modern medical heat sealers has become remarkably sophisticated. Today's machines use PID (Proportional-Integral-Derivative) control loops that constantly adjust to maintain precise temperatures. Think of them as the smart thermostats of the medical packaging world. The best systems use K-Type thermocouples that can detect temperature changes in milliseconds, with multi-zone monitoring ensuring heat spreads evenly across your entire seal.

I was impressed when testing IMPAK's iS2 Series tabletop sealers, which maintain temperature accuracy within +/-1 degree Celsius. When you're creating barriers that protect patients from infection, this level of precision isn't just nice to have—it's essential.

Dwell time—how long the sealing elements "dwell" on your packaging material—needs equally precise management. Modern medical heat sealers feature digital timers accurate to the millisecond and programmable cycle times that can be matched perfectly to different material thicknesses. As one technician told me, "Getting the dwell time wrong is like overcooking a steak—there's no going back once it's done."

The third piece of the puzzle is pressure—how firmly the sealing elements compress your packaging material. Today's best machines use either pneumatic systems with precision regulators or direct-drive solenoid force systems. Some can maintain pressure consistency as precise as 0.1 PSI, which is remarkable engineering that translates directly to patient safety.

I particularly like Van der Stähl Scientific's approach with their "Airless direct-drive solenoid" technology. It eliminates the need for an external air supply while maintaining ±2% force measurement accuracy—simplifying both operation and validation.

Validation & Calibration Essentials

When it comes to medical packaging, "I think it's good enough" just doesn't cut it. Validation and calibration aren't bureaucratic hoops to jump through—they're your best defense against packaging failures that could harm patients.

A proper validation process follows a three-step dance: Installation Qualification (IQ) confirms your medical heat sealer is installed correctly according to manufacturer specifications. Operational Qualification (OQ) verifies the equipment operates as intended across its operational range. Performance Qualification (PQ) proves the equipment consistently performs for your specific application.

As PackworldUSA notes, most modern machines are "designed to meet stringent validation requirements (FDA/GMP/NIST) out of the box," but remember—you still need to complete validation for your specific materials and processes.

Calibration should be performed by qualified technicians, ideally from ISO/IEC 17025 accredited laboratories. Don't be tempted to skip this step! I've seen facilities face serious compliance issues because they thought calibration was optional. Different levels of service are typically available, from basic temperature verification at a single setpoint to comprehensive calibration of temperature, pressure, and timing with full NIST-traceable documentation.

Your documentation needs to be meticulous and complete. This includes calibration certificates with NIST traceability, validation protocols and reports, clear Standard Operating Procedures, and thorough training records for operators. Many modern medical heat sealers now include "password-protected settings to prevent unauthorized parameter changes," which helps maintain validation integrity during daily operations.

Testing the Seal—Don't Skip It

After creating your seals, testing is crucial. Think of it as the final quality check between your process and the patient.

The gold standard is ASTM F88 peel testing, which measures seal strength by determining the force required to separate the sealed materials. Specimens are cut to specific widths, tested at controlled rates (typically 200-300 mm/min), and results are documented as force per unit width. One manufacturer notes that a "standard pouch study uses 35 samples for peel testing per ASTM F88," giving you statistically significant data on your seal quality.

Visual inspection may seem old-fashioned, but it remains effective for catching obvious defects like incomplete seals, channel leaks, or material wrinkles in the seal area. I always recommend training operators on what good seals should look like—the human eye is still an amazing inspection tool when properly trained.

For more sensitive applications, dye penetration testing uses colored solutions to detect even tiny leaks in the seal. If any color appears outside the package, you've got a problem. Similarly, bubble leak testing involves submerging packages in water and watching for telltale bubbles that indicate escaping air.

For high-volume operations, consider inline testing systems like Van der Stähl's PTT-100V that can "catch seal defects before sterilization." These systems provide immediate feedback, potentially saving thousands of dollars in materials and preventing compromised products from reaching sterilization.

Common Medical Heat Sealer Mistakes to Avoid

Even with top-notch equipment, human error can compromise seal quality. Here are the mistakes I see most often in facilities:

Process drift happens gradually, often unnoticed until it causes problems. Parameters slowly shift from their validated settings, like a boat drifting off course. Implement regular verification checks, document all parameter adjustments, and use password protection for critical settings to prevent this common issue.

PTFE cover neglect is surprisingly common. Those non-stick PTFE (Teflon) covers on sealing elements need regular attention. They should be replaced when worn, burned, or damaged, and kept clean and free of debris. I always recommend keeping spares on hand—nothing brings production to a halt faster than damaged PTFE covers with no replacements available.

Unverified pressure systems can cause inconsistent seals. For pneumatic medical heat sealers, regularly check air supply quality (clean, dry air), verify pressure gauge accuracy, and ensure consistent supply pressure. One manufacturing supervisor told me, "We chased seal quality issues for weeks before realizing our air compressor was the culprit."

Operator error remains a significant factor in seal quality. Develop comprehensive training programs, create clear work instructions with visual aids, and implement error-proofing wherever possible. As PackworldUSA wisely advises, "Use repeatable heat sealing processes to maintain cGMP compliance." The best equipment in the world can't overcome poor training or inconsistent processes.

At American Mortuary Coolers, we understand that proper sealing is critical not just for traditional medical applications, but also in mortuary settings where proper containment is essential for both dignity and safety. The principles of good sealing apply whether you're packaging surgical instruments or handling sensitive mortuary materials.

Selecting, Maintaining & Upgrading Your Medical Heat Sealer

Choosing a Medical Heat Sealer for Your Facility

Finding the right medical heat sealer for your facility shouldn't feel like navigating a maze. Let's break down what really matters when making this important investment.

First, take a good look at what you'll actually be sealing. Are you working with Tyvek pouches in a hospital setting, or sealing specialized materials in a high-volume manufacturing environment? The materials you'll be sealing, how many pouches you need to process daily, and your available space all impact which sealer will serve you best.

Feature-wise, several aspects deserve your attention. Seal width is a practical starting point – standard medical seals typically range from 0.25" to 10mm wide. The D-3010HCA impulse sealer, for example, creates a robust "10mm wide sealing seam to prevent bacteria from penetrating into sterile packs."

Don't overlook seal length capacity either. The popular MS-350 "can seal a pouch up to approximately 13 inches wide," while IMPAK's units come "available in seal lengths of 15", 20", and 25"." Always choose a sealer that accommodates your largest pouches with room to spare.

For medical environments, validation capability isn't optional – it's essential. Look for units like those from PackworldUSA that are "fully validatable and meet FDA/GMP/NIST validation requirements." This documentation will save countless headaches during inspections.

Your facility environment matters too. If you're operating in a cleanroom, opt for models with "US-made stainless steel construction" like those from IMPAK. For busy production floors, consider a unit with data logging capabilities to track your sealing parameters over time.

As one of our customers at American Mortuary Coolers shared: "Speaking with their experts helped us identify features we hadn't even considered but that proved essential for our operation." Sometimes, a quick consultation can reveal needs you hadn't anticipated.

Cost Breakdown & Hidden Expenses

When budgeting for a medical heat sealer, the sticker price is just the beginning of the story. Initial costs vary widely based on technology and capabilities:

Basic tabletop impulse sealers typically run $500-$5,000, while validation-ready models with advanced features jump to $5,000-$10,000. For high-volume production environments, rotary/band sealers represent a bigger investment at $10,000-$25,000+.

But the true cost of ownership extends well beyond the purchase price. Factor in consumables like PTFE (Teflon) covers and tapes that need regular replacement. Heating elements, sealing wires, and silicone pressure pads all have finite lifespans too.

The calibration and validation expenses often surprise first-time buyers. Annual calibration services typically run $500-$2,000 depending on the level of documentation required. Initial validation protocol execution can cost $1,000-$5,000, with additional costs for re-validation after repairs or modifications.

Don't forget to calculate what downtime might cost your operation. Having backup equipment or service contracts can minimize interruptions, but these represent additional budget items. Even energy consumption varies by technology – impulse sealers draw power only during sealing cycles, while constant heat models use more continuous energy.

Preventive Maintenance & Troubleshooting

A well-maintained medical heat sealer is a reliable partner in your sterile packaging process. A simple maintenance routine pays dividends in equipment longevity and consistent performance.

Start with basic cleaning – daily wipe-downs of external surfaces, weekly cleaning of sealing surfaces, and monthly inspection of electrical connections. The "easy wipe-down" design highlighted in Van der Stähl Scientific's MS-350 makes this routine more manageable.

Pay special attention to those PTFE covers – they're the unsung heroes of consistent sealing. Inspect them before each use and replace at the first signs of wear, burning, or damage. Having spares on hand prevents the panic of unexpected downtime.

Jaw alignment deserves weekly verification, especially after any bumps or impacts to the machine. Even slight misalignment can create inconsistent pressure distribution across your seals, leading to potential failures. Document all adjustments for your validation records.

When troubleshooting, start with the basics. Temperature issues often point to heating elements or controllers. Pressure faults typically involve pneumatic systems or connections. Cycle interruptions could be safety interlocks or power supply problems.

Keeping detailed service logs isn't just good practice – it's often a regulatory requirement. Document all maintenance activities, calibration results, repairs, and validation status. These records prove invaluable during audits and inspections.

When to Retrofit vs Replace

Every medical heat sealer eventually reaches a crossroads – upgrade the existing unit or replace it entirely? This decision impacts both your budget and operations.

Controller upgrades offer an attractive middle ground for many facilities. IMPAK provides "retrofit services with an upgraded Siemens controller for validation," bringing older equipment into the modern era. Digital PID controllers can replace analog systems, while new HMIs add recipe storage and data logging capabilities.

For older units lacking validation features, validation-ready conversion kits might bridge the gap. These typically include external validation ports for temperature measurement, pressure verification systems, and comprehensive documentation packages.

When replacement becomes necessary, explore trade-in programs to offset costs. Ask about compatibility of existing accessories with new models, and ensure proper training for your team during the transition.

Your decision ultimately hinges on several factors: the age and condition of your existing equipment, cost comparison between upgrading versus buying new, potential downtime during transition, and validation requirements for the upgraded or new system.

Tech Innovations to Watch

The medical heat sealer market continues evolving with exciting new technologies that improve both performance and compliance.

Closed-loop pressure control represents a significant advance, with real-time pressure monitoring and automatic adjustments to maintain consistent force throughout the sealing cycle. IMPAK's iS2 Series showcases this technology with "pressure consistency of 0.1 PSI on the iS2 proportional valve."

Recipe analytics and optimization capabilities are changing how facilities approach sealing. Smart sealers now analyze performance across batches, suggest parameter optimizations, and even predict maintenance needs based on performance trends.

For demanding environments, washdown-rated designs provide peace of mind. Look for IP65 and IP69K ratings that withstand high-pressure cleaning, with materials resistant to cleaning chemicals and fully sealed electronics compartments. OKI notes their "washdown versions are available with IP65 and IP69K ratings for clean-room environments."

Perhaps most exciting is the trend toward inline testing integration. Van der Stähl Scientific offers "onboard PTT-100V peel-testing integration available in the hybrid MS-451-PV model," allowing real-time feedback on seal quality without separate testing equipment.

At American Mortuary Coolers, we stay current with these innovations to provide our customers with effective sealing solutions for their specialized needs. Whether you're in a hospital, laboratory, or mortuary setting, we'll help you steer these options to find the right fit for your unique requirements.

Conclusion

Choosing the right medical heat sealer isn't just a purchasing decision—it's an investment in patient safety and regulatory compliance. Throughout this guide, we've walked through everything from basic tabletop units to sophisticated systems with integrated testing capabilities, all designed to create that critical sterile barrier that healthcare depends on.

Here at American Mortuary Coolers, we've helped countless medical facilities, labs, and mortuary services find their perfect sealing solution. From our conversations with customers in small-town clinics to major urban hospitals, we've learned that success starts with understanding your unique needs.

Before making your decision, take time to clearly define what materials you'll be sealing daily. Are you working primarily with Tyvek-film pouches or heavier multi-layer materials? Your volume requirements matter too—a busy central sterile department needs different capabilities than a small dental office.

Remember the "Big Three" we discussed: temperature, time, and pressure. These aren't just technical specifications—they're your guarantee of consistent, reliable seals that protect patients. The best medical heat sealer for your facility will offer precise control of these parameters, with documentation to prove it.

Speaking of documentation, don't let validation become an afterthought. We've seen too many facilities purchase equipment only to find it doesn't support their validation protocols. The right sealer comes with comprehensive documentation and calibration services to keep you compliant year after year.

Look beyond the price tag when budgeting for your sealer. One hospital administrator told us, "We thought we were saving money with a cheaper unit, but the maintenance and downtime costs far exceeded what we would have spent on better equipment." Consider consumables like PTFE covers, calibration services, and potential production delays in your calculations.

Your needs will evolve over time, so choose equipment that can grow with you. Whether through controller upgrades, additional features, or integration capabilities, the right medical heat sealer should serve your facility for many years.

As one of our long-term customers with 30 years in central sterile processing shared: "The best investment we ever made was in quality sealing equipment. It's the foundation of everything we do."

We'd love to help you find your perfect sealing solution. With our nationwide presence and specialized expertise, American Mortuary Coolers can match you with equipment that ensures both compliance and performance for years to come.

For more information about our full range of equipment, including specialized forensic tools and mortuary supplies, visit our website or learn about equipment upgrade options. We deliver directly to facilities across the contiguous 48 states, bringing expertise right to your door.