Why a Properly Functioning Cooler Door Closer is Critical for Your Operations

A cooler door closer is an essential mechanical device that automatically pulls walk-in cooler and freezer doors shut after they've been opened, ensuring a tight seal every time. Here's what you need to know:

Key Functions:

- Automatic closure - Uses hydraulic or spring mechanisms to pull doors closed

- Temperature control - Maintains safe internal temperatures between 35°F-41°F for coolers

- Energy efficiency - Prevents cold air loss that increases utility bills

- Food safety compliance - Ensures HACCP standards are met consistently

Common Types:

- Flush-mount door closers (concealed installation)

- Offset-mount door closers (visible mounting bracket)

- Hydraulic closers (adjustable speed and force)

- Spring-loaded closers (simple, reliable operation)

Without a functioning cooler door closer, your walk-in unit works harder to maintain temperature, leading to higher energy bills, uneven cooling, and increased strain on the compressor - potentially shortening your refrigeration unit's lifespan significantly.

The simple paper test reveals gasket problems: if a piece of paper slides out easily when the door is closed on it, your gasket isn't sealing properly and likely needs immediate attention.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select and maintain reliable cooler door closer systems.

Simple guide to cooler door closer terms:

Why This Guide Matters

At American Mortuary Coolers, we've seen how a properly functioning cooler door closer can make the difference between smooth operations and costly breakdowns. Based on our experience serving funeral homes across Tennessee, Georgia, Illinois, and throughout the contiguous 48 states, maintaining safe internal temperatures isn't just about compliance—it's about protecting your investment.

Our clients regularly report energy bill reductions of 15-25% after upgrading their door closer mechanisms, with some facilities saving thousands annually on utility costs alone.

What Is a Cooler Door Closer and Why You Need One

Picture this: It's a busy Tuesday morning, and your staff is rushing to prepare for a service. Someone grabs supplies from the walk-in cooler but forgets to fully close the door in their haste. Without a cooler door closer, that door stays cracked open, letting precious cold air escape and warm air creep in.

A cooler door closer is essentially your cooler's memory system—a mechanical device that automatically pulls walk-in cooler and freezer doors shut after they've been opened. It's like having a reliable assistant who never forgets to close the door behind you, ensuring consistent temperature control and energy efficiency every single time.

According to scientific research on refrigeration energy loss, even brief periods of door-open time can dramatically impact internal temperatures and energy consumption.

Definition & Core Function

Think of a cooler door closer as your first line of defense against two major problems: seal integrity failure and accidental hold-open situations. The device works behind the scenes, using hydraulic damping, spring tension, or gas-spring mechanisms to pull doors closed with just the right amount of force and speed.

Even a gap as thin as a credit card can spell trouble, allowing warm, humid air to sneak into your cooler. This creates a domino effect: frost buildup, temperature swings, and your compressor working overtime to keep up.

Key Benefits for Walk-In Operations

After working with funeral homes across Tennessee, Georgia, Illinois, and beyond, we've seen how the right door closer transforms operations.

Lower utility bills top the list of advantages. A properly sealed cooler door typically reduces energy consumption by 20-30%. One of our Chicago-area clients saved $2,400 annually after we replaced their worn door closers.

HACCP compliance becomes effortless when your door closer maintains consistent temperatures. Meeting health department requirements means keeping your cooler within that critical 35°F-41°F range automatically.

Compressor longevity might be the biggest long-term benefit. By reducing the workload on your refrigeration system, quality door closers can extend compressor life by 3-5 years. When replacement costs run $3,000-8,000, this represents substantial savings.

Understanding Cooler Door Closer Mechanics

Understanding how a cooler door closer works isn't rocket science, but it's clever engineering. Think of it like a controlled spring that's been designed to close your door at just the right speed—not too fast that it slams, and not too slow that it wastes energy.

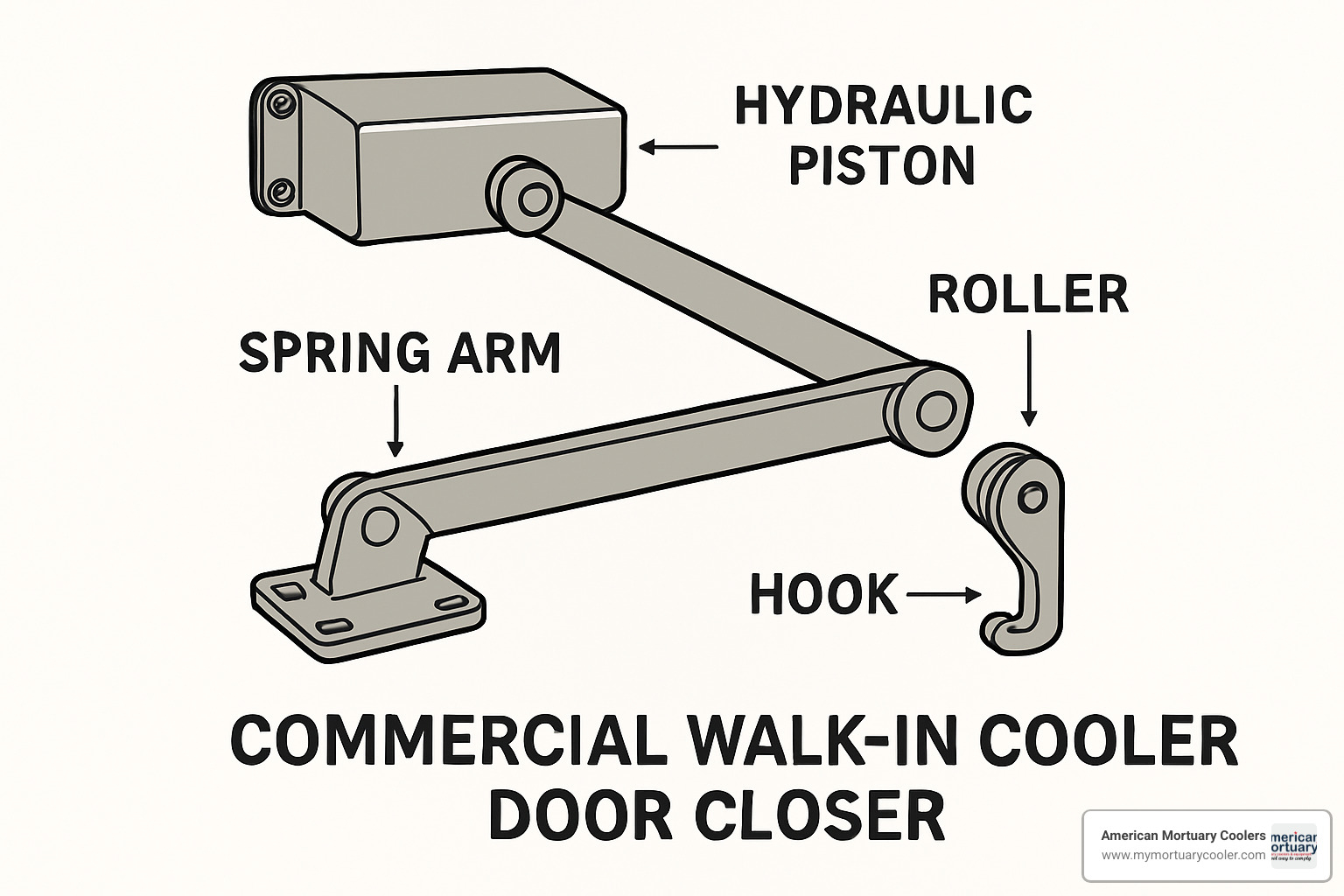

The main components work together like a well-choreographed dance. You've got your hydraulic piston or spring arm doing the heavy lifting, connected to a roller and hook system that guides the door home. Some newer models use gas springs instead, which give you smoother operation and better adjustability.

How a Cooler Door Closer Works

When you open the door, you're essentially winding up a mechanical spring or compressing a hydraulic cylinder. The lever arm attached to your door transfers this energy to the damping cylinder, which stores it like a coiled snake ready to strike.

As you let go of the door, the stored energy gets released in a controlled way. The torsion spring provides the consistent closing force, while the hydraulic system controls exactly how fast that door swings shut.

Main Components of a Cooler Door Closer System

Every cooler door closer system has five essential parts that work together to keep your cooler sealed tight. The body houses either the hydraulic cylinder or spring mechanism and provides the mounting points you'll need for installation.

The arm is your connector, transferring all that closing force from the body to the door through mechanical leverage. Your roller sits on the door itself and rolls along the track to engage with the hook bracket. The hook bracket mounts on the door frame to catch and guide that roller home every time.

Don't forget about the gaskets—while they're not technically part of the closer mechanism, they work hand-in-hand with your closer to create that perfect seal.

The Role of a Cooler Door Closer in Energy Management

Here's where a cooler door closer really earns its keep. Your walk-in cooler is designed to maintain specific R-values and hit those critical 35-41°F targets consistently. When your door closer is working properly, it ensures your insulation system performs exactly as designed.

When doors stay open or don't seal properly, you're looking at energy consumption increases of 40-60%. That's not just higher utility bills; it's also frost prevention going out the window.

| Mount Type | Installation Time | Visibility | Clearance Required | Best For |

|---|---|---|---|---|

| Flush Mount | 45-60 minutes | Concealed | Minimal | New installations, aesthetic concerns |

| Offset Mount | 30-45 minutes | Visible bracket | 1-2 inches | Retrofits, heavy doors |

We've seen facilities cut their energy costs by thousands of dollars annually just by maintaining proper door closer function.

Types of Cooler Door Closers & How to Choose the Right One

Choosing the right cooler door closer isn't rocket science, but it does require understanding your specific needs. After installing hundreds of systems across our service territories, we've learned that one size definitely doesn't fit all.

The good news? Door closers are designed to absorb high impacts and extend the life of your walk-in door, which means fewer headaches and repair bills down the road. Whether you need a hydraulic system for smooth, adjustable operation or a spring-loaded closer for simple reliability, there's a solution that fits your situation perfectly.

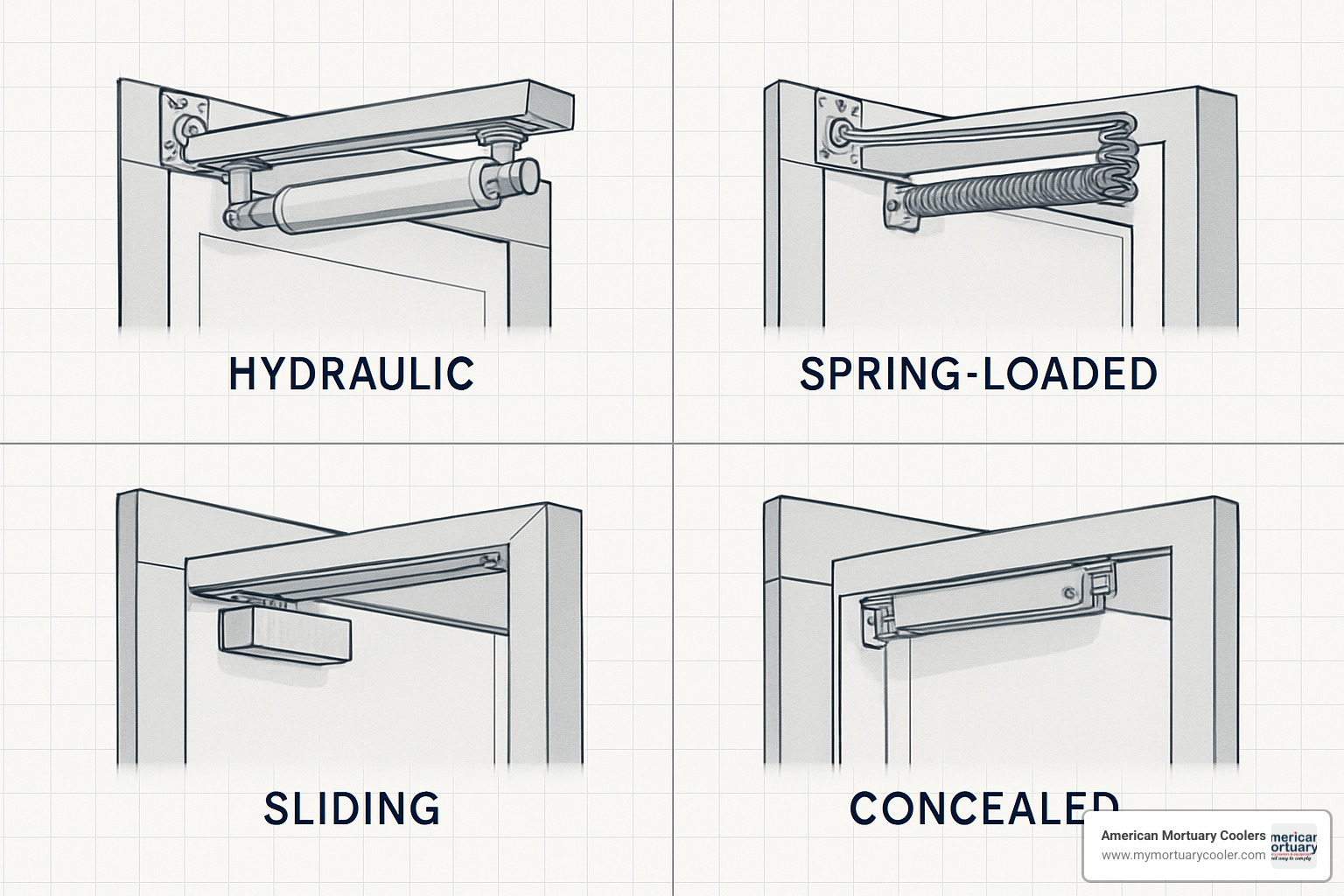

Hydraulic closers offer the most control over closing speed and force, making them ideal for heavy doors or high-traffic areas. Spring-loaded systems are the workhorses of the industry—simple, reliable, and easy to maintain. Sliding door closers work great when space is tight, while concealed closers keep things looking clean and professional.

For mortuary applications, we always recommend systems rated for continuous operation in high-humidity environments. Standard commercial closers might work initially, but they often fail prematurely in the demanding conditions of funeral home operations. We've seen this happen too many times in our Dallas, Los Angeles, and New York installations.

Heavy-duty models are essential for mortuary coolers, which typically have thicker insulation and more robust construction than standard commercial units. For more info about door hardware, including compatibility considerations for different door types and weights.

Flush-Mount vs Offset-Mount Cooler Door Closer

The choice between flush-mount and offset-mount systems often comes down to what matters more to you: looks or practicality.

Flush-mount systems hide the closer mechanism inside the door frame, giving you that clean, professional appearance that many funeral homes prefer. The downside? They're trickier to install and require precise measurements. You'll need about 45-60 minutes for installation and minimal clearance around the door frame.

Offset-mount systems are the practical choice. Yes, you can see the mounting bracket, but they're much easier to install, adjust, and service when something goes wrong. They also handle heavier doors better and work great for retrofit situations where you're upgrading an existing door.

We typically recommend flush-mount for new construction where aesthetics matter, and offset-mount for retrofits or heavy-duty applications where function trumps form.

Sizing & Force Calculations for Cooler Door Closers

Getting the sizing right is crucial for your cooler door closer. Too weak, and the door won't close properly. Too strong, and it'll slam shut like a bank vault.

Door width is your starting point. Most cooler doors run between 32" and 48" wide, though we've installed custom units up to 60". Wider doors need more closing force because of the increased leverage working against the closer.

Door weight is the big factor. Standard insulated cooler doors weigh 150-300 pounds, but mortuary cooler doors can exceed 400 pounds when fully insulated. That extra weight requires significantly more closing force to operate reliably.

Closing torque represents the rotational force needed to overcome the door's weight, any wind resistance, and the compression force of the gasket. We always specify closers with 25-50% excess capacity because it's better to have too much power than not enough.

Recommended Brands & Models for Mortuary Coolers

After years of real-world testing, we've narrowed down our recommendations to four proven performers:

The Kason 1094 Series is our go-to choice for most mortuary applications. These hydraulic closers offer adjustable closing speed and force, plus they hold up beautifully in high-humidity environments. They run $180-280 depending on configuration, and they're worth every penny.

For a simpler approach, the Component W95-1020 spring-loaded closer has proven incredibly reliable in our Tennessee and Southeast installations. Fewer moving parts mean fewer things can break, and maintenance is straightforward. These run $92-150 and offer excellent value.

When you're dealing with sliding doors, Ultra Glide Systems are hard to beat. They're particularly useful in space-constrained mortuaries where traditional swing doors won't work. No electricity required, adjustable closing speed, and they operate smoothly even after years of use. Expect to pay $200-350.

Finally, Slideback Closers offer an innovative solution for glass sliding doors, which are becoming more popular in modern funeral home viewing areas. They provide smooth, quiet operation that won't disturb families during services. These run $150-250 and are worth considering for customer-facing areas.

Installation, Adjustment & Maintenance of a Cooler Door Closer

Getting your cooler door closer installed and maintained properly makes all the difference between smooth daily operations and frustrating breakdowns. After installing hundreds of these systems across funeral homes nationwide, we've learned that attention to detail during installation saves countless headaches down the road.

While we recommend professional installation for critical applications, most routine adjustments and maintenance tasks are well within reach of your facility maintenance staff. You'll need basic tools like a drill, level, wrenches, and the right torque specifications.

Regular inspection every 3-6 months has helped our clients avoid 80% of emergency service calls.

For related door hardware procedures, check out our Step-by-Step Guide to Replacing a Walk-In Cooler Handle, which covers similar installation techniques.

Step-by-Step Installation Process

Installing a cooler door closer requires precision. Think of it like hanging a heavy picture—measure twice, drill once.

Start with the marking template that comes with your closer. Place the template carefully and mark your holes with a center punch. Accurate positioning here prevents headaches later when the roller and hook need to play nicely together.

Mount the hook bracket on your door frame next, using the provided hardware and specified torque settings. This bracket bears the full closing load every single time someone opens your door, so make sure it's level and rock-solid.

Set the roller assembly on the door itself, double-checking alignment with the hook bracket. The roller should glide smoothly into the hook without binding or excessive wobble.

Test the complete cycle by opening and closing the door multiple times. Listen for smooth operation and watch for any binding or irregular movement.

How to Adjust a Cooler Door Closer for a Perfect Seal

Fine-tuning your cooler door closer is where the magic happens. Even a perfectly installed system usually needs some adjustment to achieve that satisfying "thunk" of a properly sealed door.

Washer shimming is your primary adjustment tool. The hook bracket is the only part designed to be adjustable—never try to bend or force other components. If your roller sits too low and doesn't engage properly, add flat washers behind the top two mounting screws. Make small adjustments and test between each change.

Hydraulic valve tweaking applies to hydraulic closers and controls closing speed. Turn the adjustment screw clockwise to slow things down if your door slams shut, or counterclockwise to speed up a sluggish closer. Stick to quarter-turn increments—these valves are sensitive.

Maintenance Checklist & When to Replace Gaskets

Monthly maintenance keeps your cooler door closer running smoothly and prevents most failures before they start. We've developed a simple routine that takes about 10 minutes but saves hours of downtime.

The paper test reveals gasket problems instantly. Close your door on a regular piece of paper, then try to slide it out. If it comes out easily, your gasket isn't sealing properly and needs attention.

Gasket inspection should look for visible cracks, tears, or permanent compression marks. Replace any gasket showing damage—it's much cheaper than dealing with temperature control problems later.

Hydraulic leak checking involves looking around cylinder seals for any fluid residue. Even tiny leaks will eventually cause closing failure, so address them immediately.

Regular lubrication of moving parts with appropriate low-temperature grease keeps everything operating smoothly.

Troubleshooting Common Cooler Door Closer Problems

Even the most reliable cooler door closer will eventually need some attention. After years of helping funeral homes across the country, we've seen just about every problem that can crop up with these systems. The good news? Most issues have straightforward solutions.

Door closers are workhorses designed to absorb impacts and extend door life, but like any hardworking equipment, they need occasional TLC. The key is catching problems early before they turn into expensive headaches.

Quick Fixes You Can DIY

When your door slams shut like it's angry, you're dealing with excessive closing force or speed. For hydraulic closers, locate the small adjustment valve (usually on the cylinder body) and turn it clockwise to slow things down. Think "righty-tighty" to reduce the slamming action. Spring closers are trickier—you may need to reduce spring tension, but this often requires partial disassembly.

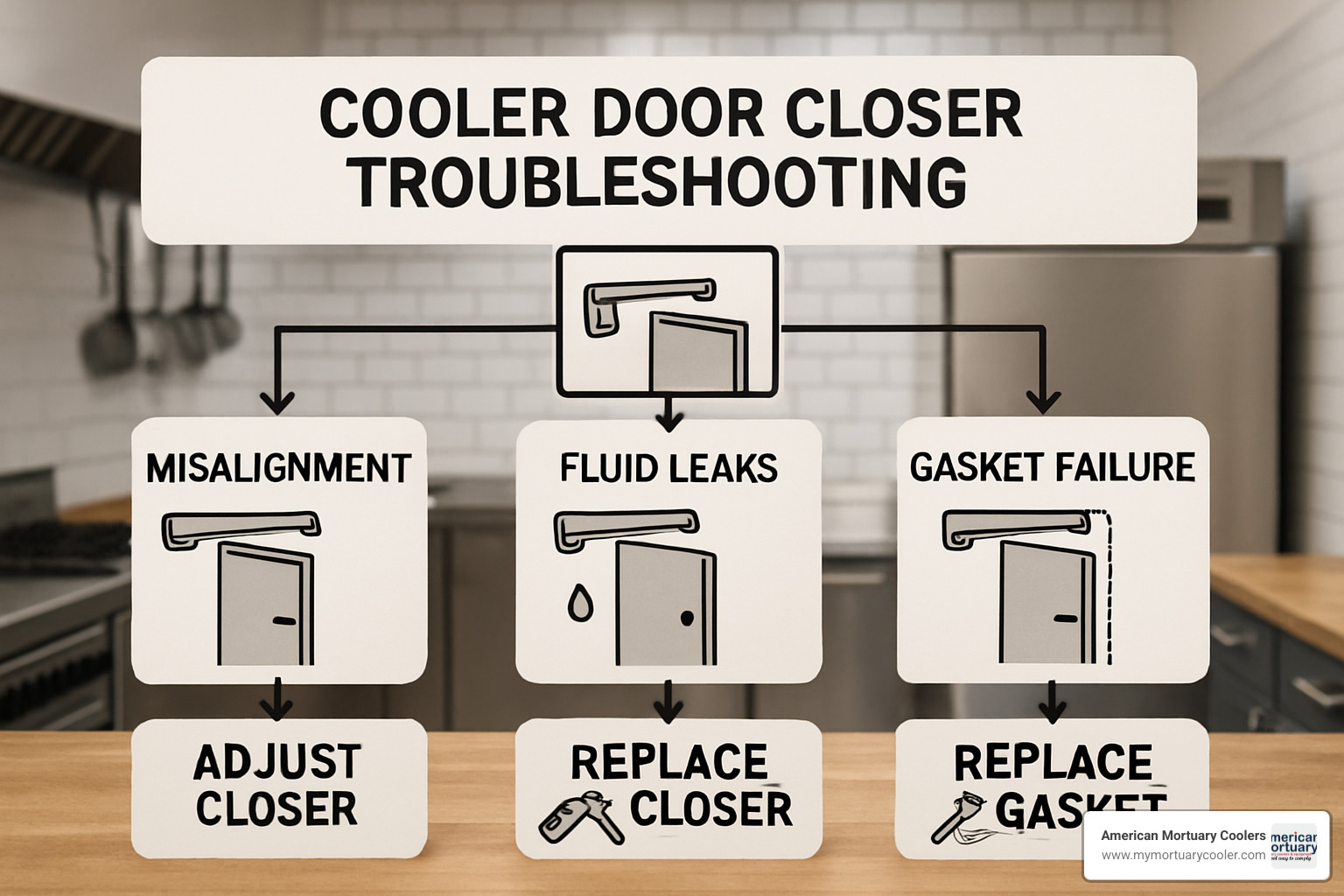

If your door fails to latch completely, nine times out of ten it's a misalignment issue between the hook and roller. Before you panic, check if someone accidentally bumped the roller arm into a vertical position—it happens more often than you'd think. If alignment looks off, loosen the hook bracket screws and use those flat washers to nudge things back into position.

Misalignment problems are frustrating but totally fixable once you know what you're doing. The secret is patience and small adjustments. Loosen all the hook bracket screws, add or remove washers to shift position, then retighten everything and test. Remember our golden rule: never bend the tempered hook bracket.

Ice buildup around the closer mechanism can cause all sorts of strange behavior. This often happens when the door gasket isn't sealing properly, allowing humid air to freeze around the components. Clean off the ice, then investigate why moisture is getting where it shouldn't be.

When to Call a Professional

Some cooler door closer problems are best left to people who know what they're doing. We've seen too many well-intentioned DIY attempts turn minor issues into major repairs.

Hydraulic fluid leaks are a definite call-the-pros situation. You might notice puddles under the closer or see wet spots on the cylinder. These leaks start small but always get worse, and the repair involves seal replacement or cylinder rebuilding.

Structural warping of the door or frame is another professional-only territory. This can happen in facilities with extreme temperature fluctuations or after minor accidents. When the basic geometry is off, even a perfectly functioning closer can't do its job properly.

Any safety concerns should trigger an immediate service call. If your closer is creating excessive force that could injure staff, or if the door won't stay closed and creates temperature control issues, don't wait.

At American Mortuary Coolers, we maintain a service network that covers the contiguous 48 states. When you call us with a complex closer problem, we can usually have a qualified technician on-site within 24-48 hours.

Frequently Asked Questions about Cooler Door Closers

Over the years, we've helped countless funeral homes troubleshoot their cooler door closer systems. These are the questions that come up most often in our service calls and customer conversations.

How do I know the gasket needs replacing?

The trusty paper test remains your best friend here. Simply close the door on a piece of paper—if it slides out without resistance, your gasket has lost its sealing power and needs replacement. It's that simple.

Beyond the paper test, take a close look at the gasket itself. Visible cracks, tears, or permanent compression are dead giveaways that it's time for a new one. If the gasket stays flattened after the door opens instead of bouncing back to its original shape, it's done its job and deserves retirement.

We've seen gaskets that looked fine from a distance but failed the paper test miserably. Don't trust appearances alone—that simple paper test has saved our clients thousands in energy costs by catching failing seals early.

Can I adjust closing speed myself?

For hydraulic cooler door closers, absolutely! Most models feature an adjustment valve that controls how fast the hydraulic fluid flows, which directly affects closing speed. Turn clockwise to slow things down, counterclockwise to speed things up.

Here's the key: make tiny adjustments. We're talking 1/4 turn increments here. Test the door operation after each small adjustment. It's tempting to give that valve a big turn when you're frustrated, but patience pays off with smooth, controlled closing action.

Spring-loaded closers are a different story. They typically don't offer speed adjustment, though some models do allow you to modify the closing force. Check your manufacturer's documentation—every system has its own personality.

What's the lifespan of a quality door closer?

A well-maintained cooler door closer should give you 8-12 years of reliable service in typical commercial settings. That's assuming regular maintenance and reasonable usage patterns.

Mortuary environments present unique challenges that can reduce this lifespan to 6-10 years. The higher humidity levels and more frequent door cycles that come with funeral home operations put extra stress on these systems. We've seen this pattern consistently across our installations from Chicago to Dallas.

Several factors influence how long your closer will last: door weight, usage frequency, maintenance quality, and environmental conditions all play important roles. A 400-pound mortuary cooler door that gets opened 50 times daily will wear out a closer faster than a lighter door with occasional use.

The good news? Proper maintenance can push even mortuary installations toward the upper end of that lifespan range. Our clients who follow our 3-6 month inspection schedule consistently get better longevity from their door closer systems.

Conclusion

Your cooler door closer might seem like a small component, but it's actually the unsung hero of your walk-in cooler system. This simple device works 24/7 to protect your investment, keep your energy bills reasonable, and ensure everything stays at the right temperature.

A quality cooler door closer system pays for itself many times over through reduced energy costs, longer equipment life, and fewer headaches. Our clients tell us the same story again and again: after upgrading their door closer systems, they see energy savings of 15-25% and way fewer emergency service calls.

At American Mortuary Coolers, we understand that funeral homes aren't just another commercial kitchen. You need systems that work reliably when families are counting on you. That's why we focus on custom solutions that handle the unique demands of mortuary operations—higher humidity, frequent door cycles, and the absolute need for consistent temperatures.

Whether you're dealing with our Tennessee weather or the heat of Arizona, we deliver directly across all 48 contiguous states. From our Johnson City headquarters to our service network spanning Atlanta to the Pacific Coast, we're here when you need us.

Planning a bigger door project? Check out our comprehensive guide to replacement walk-in doors for tips on selecting doors that work perfectly with modern closer systems.

Here's the bottom line: a cooler door closer isn't just a nice-to-have convenience. It's essential equipment that protects your operation, keeps you compliant with health regulations, and gives families the reliability they deserve during difficult times.

Don't wait until your current system fails. A small investment in a quality door closer system today can save you thousands in energy costs and prevent those middle-of-the-night emergency calls that nobody wants.