Why Finding the Right Refrigerated Truck Trailer is Critical for Your Business

Refrigerated truck trailers for sale are essential equipment for any business that needs to transport temperature-sensitive goods safely and efficiently. Whether you're hauling fresh produce, frozen foods, pharmaceuticals, or providing specialized services, the right reefer trailer can make or break your operation.

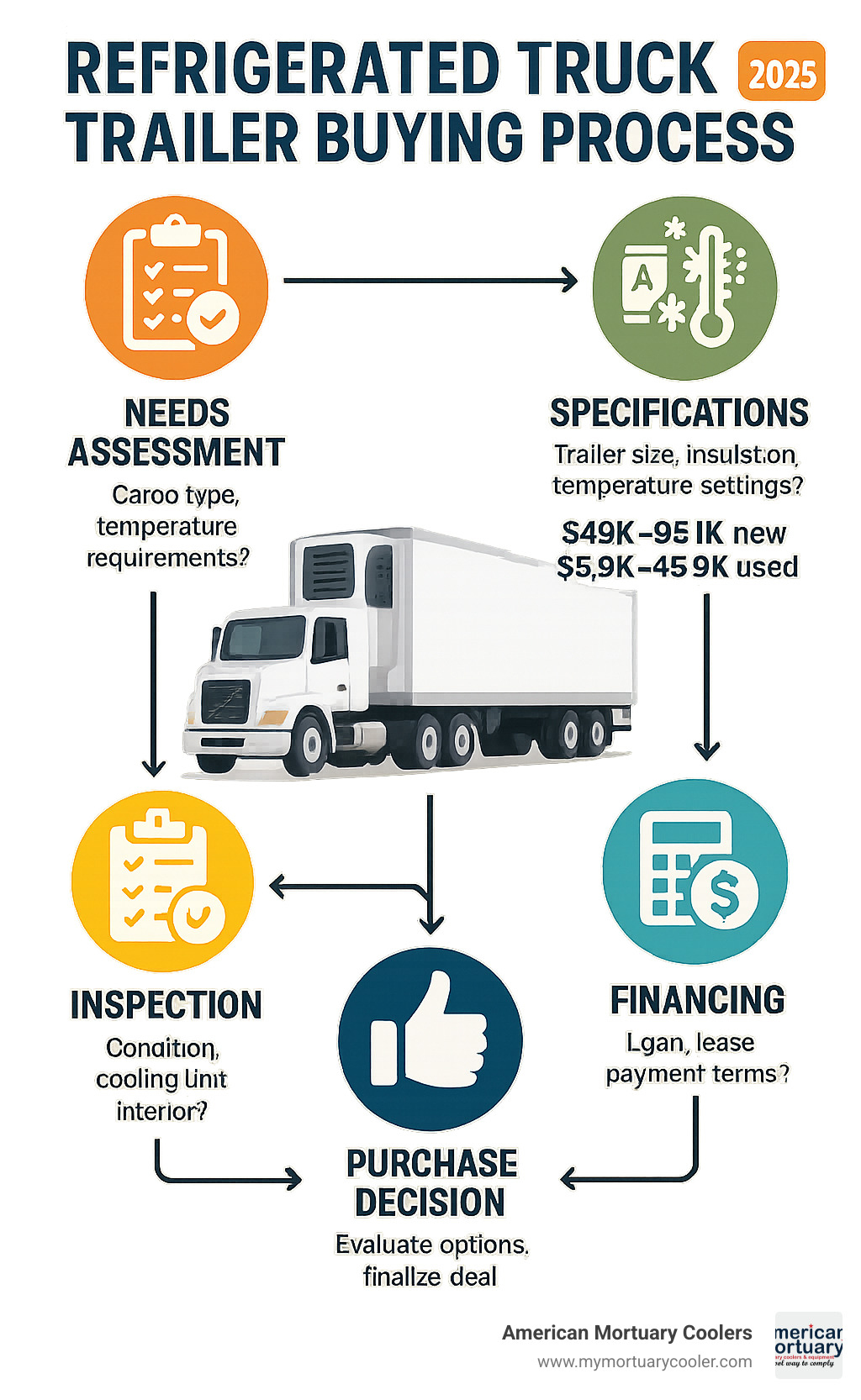

Quick Answer for Buyers:

- New trailers: $49,000-$95,000 (53-ft standard)

- Used trailers: $5,900-$45,900 (varies by age and condition)

- Top brands: Utility, Great Dane, Thermo King, Carrier

- Best places to shop: Penske Used Trucks (336 listings), Commercial Truck Trader, IronPlanet

- Key specs: 53'×102" standard size, R-29+ insulation, multi-temp capability

The cold-chain logistics market has exploded in recent years, driven by increased demand for fresh food delivery and pharmaceutical distribution. According to the U.S. Department of Transportation, there are over 3,400 refrigerated trucks and trailers available nationwide, with prices ranging from budget-friendly used units under $6,000 to premium new models exceeding $90,000.

The stakes are high when choosing a reefer trailer. A single temperature failure can cost thousands in spoiled inventory, regulatory fines, and damaged customer relationships.

This comprehensive guide will walk you through everything you need to know about buying refrigerated truck trailers – from understanding how they work to finding the best deals and avoiding costly mistakes.

We're American Mortuary Coolers, a national-level supplier with experience in temperature-controlled transportation equipment. Having worked with countless businesses seeking refrigerated truck trailers for sale, we understand the unique challenges of finding reliable, cost-effective cold-chain solutions.

How Reefer Trailers Work & Why They're Essential

Think of a reefer trailer as a massive, mobile refrigerator that maintains perfect temperatures while traveling at highway speeds. The magic happens through a heat-exchange system using a compressor-condenser-evaporator loop that continuously moves heat from inside the trailer to the outside.

Two names dominate the reefer world: Thermo King and Carrier Transicold. Thermo King units offer extensive service networks and easy parts availability. Carrier units excel in fuel efficiency, saving money on diesel costs over time.

Modern refrigerated truck trailers for sale come with fuel or electric units—or both. Diesel units provide complete mobility, while electric standby power cuts operating costs when parked and ensures CARB compliance for California operations.

Airflow management can make or break your load. The best reefer unit won't save you if cold air isn't circulating properly; hot spots develop quickly, leading to spoiled cargo and major losses.

Anatomy of a Refrigerated Trailer

A typical 53-foot trailer measures 53'×102'×13'6"—dimensions designed to maximize cargo space while staying road-legal. The reefer unit mounted up front includes the compressor, condenser, evaporator, and controls, plus a diesel tank holding 50-100 gallons.

Inside, an air-chute system distributes cold air evenly. The bulkhead keeps refrigerated air in when rear doors open. Modern trailers include data loggers that record temperature readings throughout transport.

Temperature Science & FSMA Compliance

Temperature control requires hitting precise °F set-points and maintaining them consistently. Fresh lettuce needs 32–38 °F, while ice cream demands 0 °F or below. Pharmaceuticals require even tighter tolerances.

The Food Safety Modernization Act (FSMA) requires proof that cargo stayed at correct temperatures throughout transport. Temperature violations trigger recalls, fines, and business-damaging publicity.

For technical details, check our In-Depth Guide to Understanding Reefer Truck Reefers.

Main Types & Sizes of Refrigerated Truck Trailers for Sale

When shopping for refrigerated truck trailers for sale, size directly impacts your profitability and route flexibility.

The 53-foot trailer is the long-haul standard, measuring 53'×102'×13'6" and maximizing cargo capacity within federal bridge laws. 48-foot trailers offer better maneuverability with slightly less capacity.

28-foot "pup" trailers excel in urban delivery where larger trailers can't steer. Multi-temperature trailers feature separate compartments with independent controls, letting you haul frozen and fresh goods simultaneously.

Lift-gate equipped trailers add $3,000-$5,000 but enable deliveries to locations without loading docks. Pharmaceutical-spec trailers meet strict FDA requirements with superior insulation and redundant monitoring.

| Length | Cubic Feet | Axle Rating | Turning Radius | Typical Use |

|---|---|---|---|---|

| 28' Pup | 1,800 | 12,000 lbs | 35 ft | Regional delivery |

| 48' Standard | 3,400 | 25,000 lbs | 55 ft | Medium haul |

| 53' Standard | 3,800 | 25,000 lbs | 60 ft | Long haul OTR |

Door Styles and Specialized Features

Swing-door trailers provide full-width access and excellent sealing but need clearance space. Roll-up doors work in tight quarters but may not seal as effectively.

Meat-hanger rail systems are essential for transporting hanging carcasses, while floor rail systems provide tie-down points for palletized cargo.

Key Specs, Features & Custom Options to Evaluate

When shopping for refrigerated truck trailers for sale, the specifications you choose impact operating costs for years.

Insulation is your first defense against temperature loss. Look for R-29 or higher for cooler applications and R-32 for freezer work. Spray foam insulation delivers roughly 3.5 times better performance than fiberglass panels.

Air-ride suspension costs more than spring suspension but protects delicate cargo and reduces damage claims. Telematics systems like Thermo King TracKing provide real-time temperature and location monitoring.

Solar panels extend runtime during stops, while electric standby capability runs on shore power instead of diesel when parked. CARB compliance is mandatory for California operations and protects resale value.

Hot-gas defrost systems automatically clear ice buildup, maintaining peak efficiency for frozen loads. Generator kits provide backup power for extended stops.

Safety & Regulatory Features

FSMA sensors are legally required for food transport, continuously monitoring temperatures and providing compliance documentation. NATM compliance stickers indicate quality construction meeting industry standards.

DOT reflective tape must meet visibility standards, while ATP certification is mandatory for international perishable transport.

Popular Add-Ons

E-track systems provide flexible load securement, while load bars and cargo straps prevent shifting during transport. Pallet stops are inexpensive insurance against load damage.

For specialized applications, our mobile morgue trailer options provide insights into custom refrigeration solutions.

Price Guide & Best Places to Find Refrigerated Truck Trailers for Sale

Understanding current pricing helps you spot genuine deals and avoid overpriced units when shopping for refrigerated truck trailers for sale.

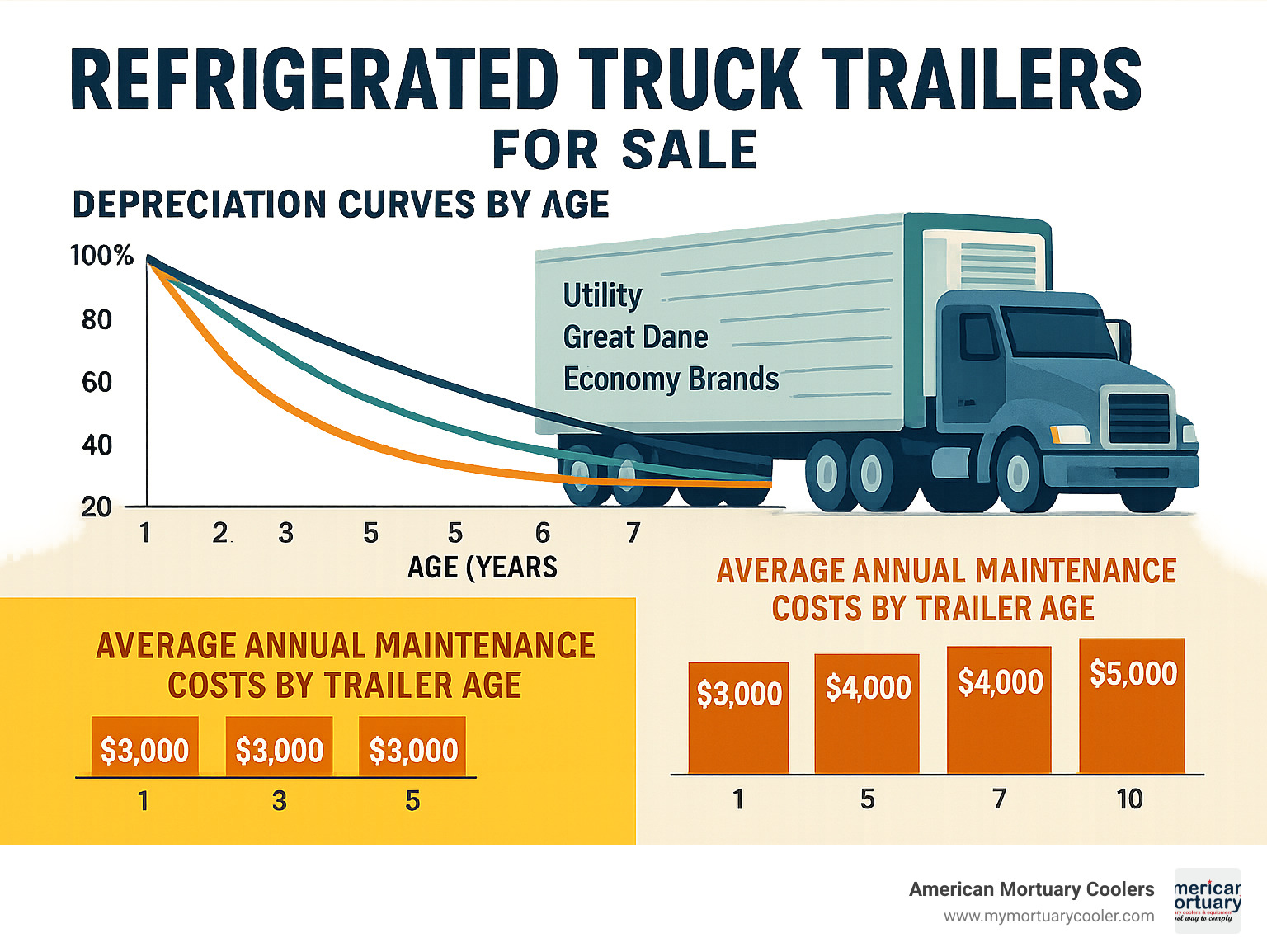

Mileage tells part of the story - trailers under 300,000 miles command premium prices, while 300,000-600,000 miles offer the value sweet spot. Reefer unit hours matter equally - units with 15,000+ hours approach major service time.

Brand reputation affects resale values significantly. Utility trailers hold value exceptionally well, while Great Dane units also maintain strong resale prices.

Cost Ranges

New 53-foot trailers range from $49,000 for basic models to $95,000 for pharmaceutical-spec units. Most standard units fall in the $65,000-$75,000 range.

Five-year-old used trailers offer excellent value at $25,000-$45,000. Ten-year-old trailers represent budget options at $5,000-$20,000.

Budget $3,000-$5,000 annually for maintenance reserves on used trailers.

Where to Shop

Penske Used Trucks leads with 336 refrigerated truck trailers for sale, including 208 Utility trailers and 97 Great Dane units.

IronPlanet offers 1,225 refrigerated trailers through auctions and direct sales. Commercial Truck Trader provides the widest selection with over 3,400 units nationwide.

Ryder offers certified, verified, and as-is condition levels with warranties on certified units.

Price Factors

Age dominates pricing, but maintenance history matters more than mileage alone. CARB compliance adds $2,000-$5,000 to values. Multi-temperature capability and pharmaceutical specifications can add $10,000-$20,000.

Regional demand varies - California, Texas, and Florida markets typically see higher prices due to strong agricultural activity.

Buying Decision Playbook: New vs Used, Inspection, Financing

Making smart choices when shopping for refrigerated truck trailers for sale requires asking the right questions and thorough inspection.

Start with basics: frame condition, refrigeration performance, and regulatory compliance. Frame rust inspection focuses on structural corrosion in cross members and support beams, especially the king pin area.

King pin integrity is critical for safety - look for cracks or excessive wear. Door seals affect operating costs through air leakage, forcing reefer units to work harder.

Reefer unit diagnostics require expert evaluation including compression tests, refrigerant leak checks, and electrical system testing. Oil analysis reveals maintenance history, while blow-by testing measures internal engine wear.

Hidden Problems to Check

Floor moisture can destroy insulation and create unusable conditions for food transport. Delamination in wall panels kills insulation value - tap walls with a coin to detect hollow sounds.

Service records separate well-maintained trailers from neglected ones. Complete maintenance logs indicate proper care and predict future reliability.

Financing Options

Fair Market Value leases offer lower payments but build no equity. TRAC leases provide more ownership benefits with residual value adjustments.

Bank loans mean immediate ownership with higher payments. Shop multiple lenders including Wells Fargo Equipment Finance, Bank of America, and local credit unions.

Dealer vs Private Seller

Dealers cost more but provide warranties, reconditioning services, and DOT compliance assistance. They handle title processing and ensure clean transfers - valuable for major purchases.

Maintenance, Operation & Compliance Best Practices

Proper maintenance of your refrigerated truck trailers for sale protects cargo, ensures compliance, and maximizes your investment.

Preventive maintenance based on operating hours prevents expensive surprises. The 500-hour service interval includes oil changes, belt inspection, refrigerant checks, and electrical testing.

Battery maintenance prevents more roadside calls than any other single issue. Clean terminals monthly and load-test annually. Software updates can improve fuel economy by 10-20%.

Driver training prevents cargo damage through proper procedures for inspections, temperature settings, and emergency responses. Remote monitoring systems provide real-time alerts for temperature excursions and mechanical problems.

Critical Regulations

FSMA Section 1.906 requires temperature monitoring and documentation for food transport. Violations result in recalls and hefty fines.

CARB TRU regulations limit emissions from diesel units, affecting operations nationwide as other states adopt similar standards. EPA Tier-4 standards require specific fuel and maintenance procedures.

Industries Served

Fresh produce requires precise temperatures—leafy greens need 32–34 °F while bananas require 56–58 °F. Frozen food demands consistent 0 °F with no temperature cycling.

Pharmaceutical distribution has the strictest requirements with 2–8 °C temperatures and extensive documentation. Mortuary services require absolutely reliable refrigeration for public health and dignity.

Frequently Asked Questions about Refrigerated Truck Trailers for Sale

What temperature range can a standard reefer maintain?

Standard reefer units handle −20 °F to +70 °F, covering virtually all transport needs. Frozen foods typically require 0 °F or below, fresh produce stays at 32–38 °F, and pharmaceuticals need precise 36–46 °F ranges.

How many hours is "too many" on a used refrigeration unit?

Units under 8,000 hours are in their prime. 8,000-12,000 hours indicates a mature unit with good life remaining. Over 15,000 hours suggests major service needs soon.

Maintenance history matters more than total hours—a well-maintained 15,000-hour unit often outperforms a neglected 8,000-hour unit.

Do I need different specs to haul pharmaceuticals versus produce?

Absolutely. Pharmaceutical transport requires redundant monitoring systems, backup power, tighter temperature tolerances, and extensive documentation. These requirements typically add $10,000-$20,000 to trailer costs but are essential for FDA compliance.

Conclusion

Finding the perfect refrigerated truck trailers for sale becomes manageable when you focus on total cost of ownership rather than just purchase price. With over 3,400 units available nationwide, there's truly something for every operation and budget.

Successful buyers prioritize reliability over lowest cost. A well-maintained trailer with complete service records often proves a smarter investment than the cheapest option available.

Your operating territory matters - CARB compliance isn't optional for California operations, and pharmaceutical transport requires specialized equipment that costs more but opens higher-paying opportunities.

At American Mortuary Coolers, we understand that reliable temperature control isn't negotiable when sensitive cargo is involved. Whether delivering custom solutions across the contiguous 48 states or helping clients steer equipment choices, we know what's at stake.

The fundamentals remain constant: proper maintenance, regulatory compliance, and quality equipment keep operations running smoothly for years.

Ready to take the next step? Our Comprehensive Guide to Choosing a Truck with Refrigeration provides deeper insights into selecting the perfect vehicle for your specific needs.

We're here to help you steer the cold-chain world with confidence. When your cargo depends on staying at the right temperature, you need equipment you can trust - and partners who understand what's at stake.