Why Cadaver Storage Racks Are Essential for Modern Morgue Operations

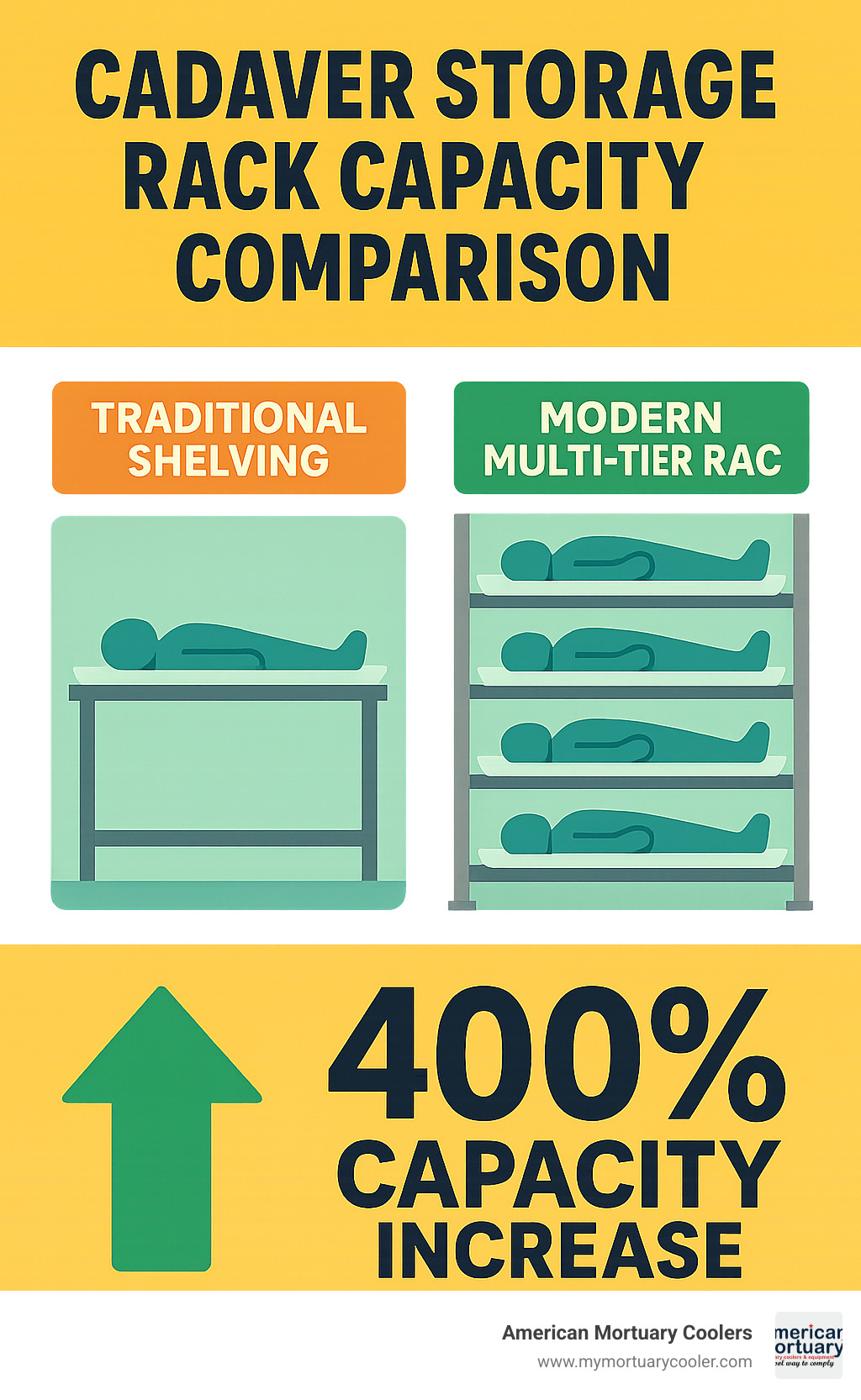

Cadaver-storage-racks- are specialized multi-tier systems designed to maximize body storage capacity in morgues, funeral homes, hospitals, and medical facilities. These racks can increase cooler storage capacity by up to 400% while improving workflow efficiency and reducing manual handling injuries.

Key Types of Cadaver Storage Racks:

- Cantilever Racks - Open-frame design supporting 300-700 lbs per tier

- Roller Racks - Fully rollered surfaces for easy body positioning

- Portable Systems - Mobile units with locking casters for flexibility

- Collapsible Racks - Tool-free setup in under 60 seconds for emergency response

- Multi-Directional - Loading from multiple angles to optimize workflow

Common Configurations:

- 2-5 tier heights accommodating standard body trays (23"-32" wide)

- Side-load, end-load, or multi-directional access options

- 304 stainless steel or powder-coated construction for durability

Modern funeral homes and morgues face increasing storage demands, especially during peak periods or emergency situations. As one mortuary manager noted: "The rollered racks made pushing bodies into the system much simpler and reduced the risk of injury to our staff."

The right rack system addresses three critical challenges: maximizing limited cooler space, improving staff ergonomics, and maintaining proper body storage conditions. With weight capacities ranging from 300-500 lbs per tier and modular designs that fit existing cooler dimensions, these systems have become essential infrastructure for efficient mortuary operations.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in American-made refrigeration and storage solutions. With years of experience helping funeral homes optimize their cadaver-storage-racks- and cooling systems, I've seen how the right equipment transforms facility operations and staff safety.

Must-know cadaver-storage-racks- terms:

Cadaver Storage Rack Fundamentals

Think of a cadaver-storage-racks- as the workhorse of any modern morgue. These aren't just fancy shelves—they're carefully engineered multi-tiered systems that transform how funeral homes, hospitals, and medical facilities handle body storage.

The beauty of these systems lies in their versatility. Morgues and funeral homes depend on them for organized temporary storage during preparation periods. Hospitals turn to them when dealing with unexpected surges in mortality. Anatomy labs use them to keep educational specimens properly organized for research and teaching. Forensic facilities rely on them to maintain chain of custody and preserve evidence during investigations.

Here's where things get really interesting: a well-designed rack system can boost your storage capacity by up to 400% compared to traditional floor storage. That's not about cramming more bodies into tight spaces—it's about smart organization that actually makes your team's job easier.

The engineering behind these systems is impressive. Standard cadaver-storage-racks- handle up to 500 pounds per tier, while heavy-duty cantilever models can support over 7,000 pounds each. That's serious weight capacity built to last through years of demanding use.

One funeral director told us: "The rollered racks made pushing bodies into the system much simpler and reduced the risk of injury to our staff." That's exactly the kind of real-world impact these systems deliver.

The corrosion resistance of quality racks is crucial in morgue environments. Cold, humid conditions can destroy inferior equipment quickly, but properly built systems maintain their integrity for decades. If you're looking to understand the broader picture of morgue storage, our Cold Storage 101: Morgue Freezer Racks Explained guide covers all the essentials.

Key Components & Materials

The materials that go into cadaver-storage-racks- make all the difference between equipment that lasts decades and systems that fail after a few years.

304 stainless steel is the gold standard for good reason. This grade of steel resists corrosion for over 20 years in harsh morgue conditions. The 180-grit finish does double duty: it looks professional and resists bacterial growth, which is absolutely critical for maintaining sanitary conditions.

Powder-coated steel offers excellent value for facilities watching their budgets. The coating process creates a tough, non-porous surface that stands up to constant cleaning and disinfection. Many facilities choose this option and get years of reliable service without breaking the bank.

Nylon rollers are the unsung heroes of roller rack systems. These specially engineered components reduce the force your staff needs to position heavy body trays. They're designed to handle the unique demands of mortuary work while staying easy to clean and maintain.

HDPE strips might seem like small details, but they're essential for both safety and equipment protection. These high-density polyethylene strips provide non-slip surfaces and protect your racks and trays during loading. HDPE naturally resists bacterial growth and cleans easily with standard disinfectants.

When you combine these materials thoughtfully, you get systems that balance durability, hygiene, and cost-effectiveness. As one customer put it: "The quality combined with price is better than I have seen." That's the kind of value modern manufacturing brings to mortuary equipment.

Loading Orientations & Workflow

The way your cadaver-storage-racks- load can make or break your daily workflow. Getting this right means the difference between smooth operations and constant frustration for your staff.

Side-loading configurations work beautifully in tight spaces. When your cooler is narrow or your racks sit against walls, side-loading lets your team work efficiently from a single approach direction. This setup is perfect for linear cooler layouts where space is at a premium.

End-loading systems shine in open floor plans where staff can move around freely. These configurations often provide better visibility of stored bodies and can be more comfortable for team members of different heights.

Multi-directional loading offers the ultimate flexibility. Your staff can approach from multiple angles, reducing the need to steer around obstacles. This design significantly cuts down on manual handling injuries—a huge win for workplace safety.

The ergonomic benefits of proper loading orientation are game-changing. Facilities report dramatic reductions in workplace injuries when they move from manual lifting to systems with proper rack positioning and ergonomic lifts. Setting the bottom shelf at 40 cm (about 16 inches) allows seamless trolley use, eliminating most of the manual lifting that traditionally caused staff injuries.

Modern facilities increasingly pair their rack systems with hydraulic or battery-powered scissor lifts. These lifts handle loads from 650 pounds to over 1,000 pounds, changing physically demanding work into smooth, controlled operations.

Comparing Types of Cadaver Storage Racks

When you're shopping for cadaver-storage-racks-, you'll quickly find there's no one-size-fits-all solution. Different facilities have different needs, and manufacturers have responded with a variety of rack types to match those requirements.

Cantilever racks are like the workhorses of the mortuary world. Their open-frame design gives you excellent visibility and access to stored bodies, which makes daily operations much smoother. These sturdy systems typically handle anywhere from 300 to 700 pounds per tier, and their adjustable arms can be positioned in 2.75-inch increments. This means you can customize them to fit different tray widths without buying entirely new equipment.

Roller racks have become increasingly popular, and once you use one, you'll understand why. These systems feature fully rollered surfaces that make positioning body trays feel almost effortless. Instead of pushing and pulling heavy loads across static surfaces, the nylon roller assemblies create smooth sliding motion that reduces physical strain dramatically.

One mortuary manager put it perfectly: "The rollered racks made pushing bodies into the system much simpler and reduced the risk of injury to our staff." That's not just convenience talking—that's workplace safety in action.

Portable systems offer the ultimate in flexibility. Equipped with locking swivel casters, these units give you mobility when you need it and rock-solid stability when you don't. They ship fully assembled and can boost your cooler capacity by up to 400%. You can choose from 2, 3, 4, or 5 tier configurations, with each level typically supporting 300 pounds.

For emergency situations, collapsible racks are absolute lifesavers. These ingenious systems set up in under 60 seconds without any tools—perfect for disaster response or sudden overflow situations. Each unit can store up to 4 bodies and comes in standard, bariatric, and coffin configurations.

The choice between refrigerated and unrefrigerated systems depends on your preservation approach. Refrigerated units control decomposition through temperature management and may include specialized cadaver moisturizing systems. Unrefrigerated systems work well in anatomy labs where chemical preservation with formalin is the standard practice.

If you're leaning toward portable solutions, our The Complete Guide to Portable Morgue Racks walks you through everything you need to know about selection and setup.

Portable vs. Stationary Systems

The portable versus stationary debate usually boils down to one question: Do you value flexibility or maximum stability more?

Portable systems shine when adaptability matters. Their quick deploy capabilities mean you can reconfigure your storage layout in minutes, not hours. Whether you're dealing with routine operations or emergency overflow, being able to move racks where you need them most is incredibly valuable.

The locking casters on quality portable systems give you the best of both worlds. When you need to move a rack, they roll smoothly across cooler floors. When you need stability, they lock down tight and won't budge during loading operations.

Knock-down designs offer practical benefits beyond just flexibility. They reduce shipping costs significantly and make storage much easier when racks aren't in use. These systems disassemble for compact shipping and storage, then reassemble quickly without welding or specialized tools.

For stationary systems in earthquake-prone areas, seismic anchoring becomes crucial. Heavy-duty leveling feet rated over 7,000 pounds each provide the foundation for seismic anchoring kits that keep racks stable during ground movement.

Disaster response scenarios really highlight why portable systems matter. During mass casualty events or disease outbreaks, the ability to rapidly deploy additional morgue capacity can make the difference between managing a crisis and being overwhelmed by it.

Roller Racks vs. Static Shelves

If you've ever struggled to slide a heavy body tray across a static shelf, you'll immediately appreciate the difference roller systems make.

The reduced push force is the most obvious benefit. While static shelves can require significant effort to move heavy loads, roller systems reduce that effort by up to 80%. That's not just a minor improvement—it's a fundamental change in how the work feels and how much strain your staff experiences.

Multi-directional arms on advanced roller systems take this convenience even further. Instead of forcing staff to approach racks from specific angles, these systems allow body positioning from multiple directions. Your team can work from whatever angle makes most sense for the situation.

The numbers tell the story clearly: facilities using roller systems report 60% fewer lifting-related injuries compared to those using static systems. This improvement protects your staff, reduces workers' compensation costs, and helps with employee retention.

For detailed guidance on selecting the right roller system for your facility, check out our The Ultimate Guide to Choosing the Right Roller Rack. It covers everything from load requirements to maintenance considerations.

How to Choose cadaver-storage-racks- for Your Facility

Choosing the right cadaver-storage-racks- for your facility feels overwhelming at first, but breaking it down into manageable pieces makes the decision much clearer. Think of it like buying a car—you need to know your budget, how many people you'll carry, and what features matter most to your daily life.

Capacity planning starts with honest assessment of your needs. Most funeral homes think they know their storage requirements, but peak periods tell a different story. That facility handling 10 bodies monthly might suddenly need space for 20 during flu season or unexpected circumstances. Planning for these surges prevents the nightmare of turning families away during their most difficult moments.

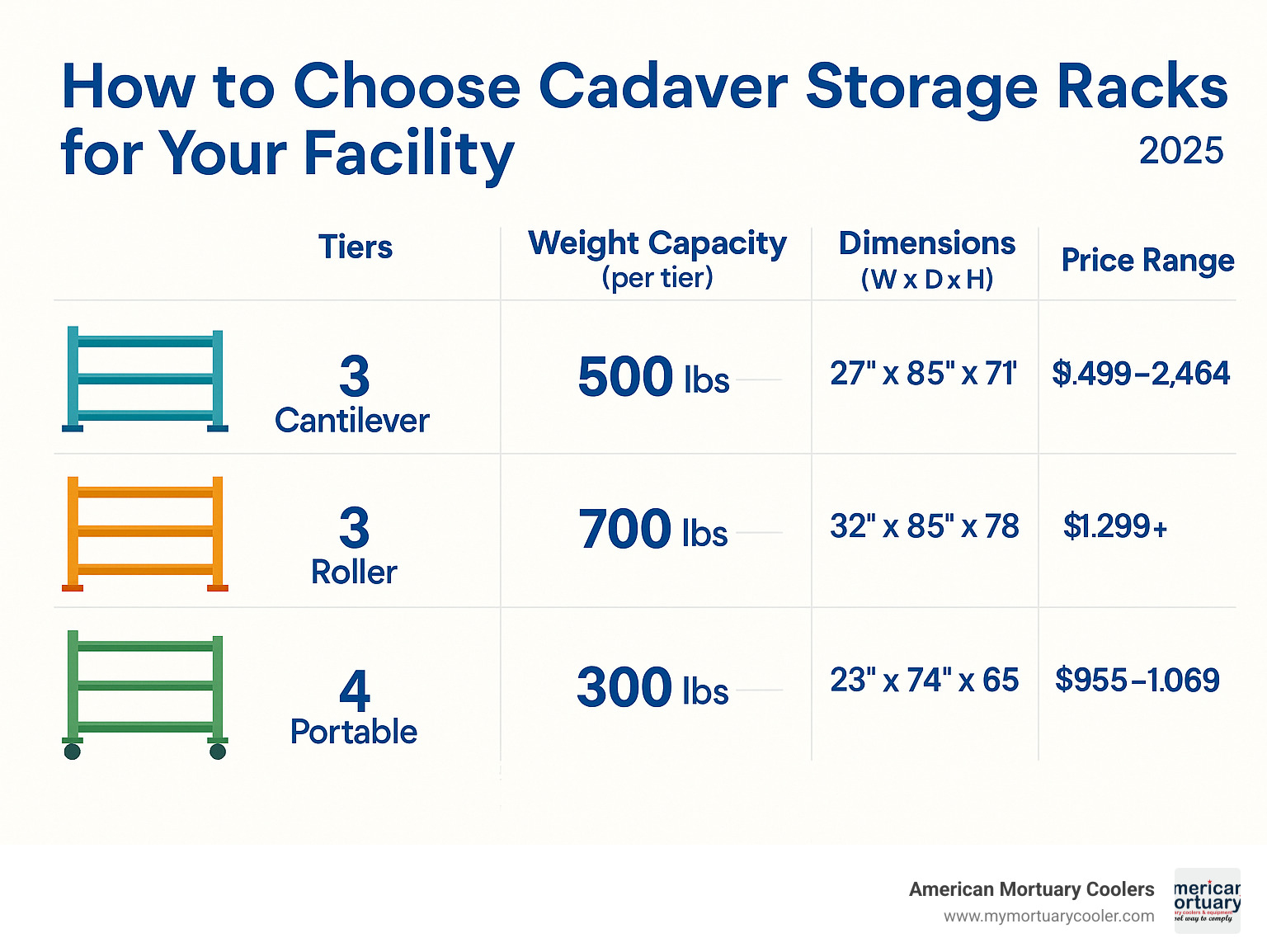

Tier counts offer different solutions for different situations. A 2-tier system costing $955-$1,069 works perfectly for smaller operations that need basic capacity increases. 3-tier systems starting at $1,299 hit the sweet spot for many facilities—enough capacity increase to matter, but still manageable for daily operations. 4-tier systems ranging from $1,499-$2,464 maximize space in standard coolers, while 5-tier systems at $1,945-$2,130 serve high-volume facilities that need every inch of storage.

Tray compatibility can make or break your investment. Standard widths of 23", 27", and 32" serve most facilities, but verify your existing equipment before ordering. Nothing's more frustrating than finding your new racks don't fit your trays.

Weight ratings vary dramatically between systems. Portable racks typically handle 300 lbs per level, which works fine for standard operations. Standard cantilever systems support 500 lbs per tier, while heavy-duty options manage up to 700 lbs. Consider your typical case load—facilities handling larger individuals or using heavier caskets need the extra capacity.

Adjustability features provide flexibility that pays dividends over time. Arms adjustable in 2.75-inch increments let you fine-tune configurations as your needs change. This adaptability means your investment grows with your facility rather than becoming obsolete.

Custom colors might seem like a luxury, but they help create the professional atmosphere families expect. Budget factors ultimately guide decisions, but quality racks serve facilities for decades. Spending slightly more upfront often saves money over the equipment's lifetime.

Sizing cadaver-storage-racks- for Capacity & Workflow

Getting the sizing right for your cadaver-storage-racks- requires measuring twice and ordering once. Too many facilities rush this step and end up with equipment that technically fits but creates daily operational headaches.

Cooler footprint analysis starts with your tape measure and ends with careful consideration of how people actually move through the space. That perfect rack configuration on paper might block your ventilation system or make routine maintenance impossible.

Door clearance creates more problems than most people expect. Your cooler door might be 36 inches wide, but that doesn't mean a 35-inch rack will fit easily through it. Consider door swing patterns, any protruding hardware, and the reality of maneuvering equipment through tight spaces.

Future expansion planning prevents costly mistakes. Today's perfect solution might become tomorrow's bottleneck if your facility grows. Modular systems that allow adding tiers or bays provide flexibility for expanding operations.

Forklift versus manual loading requirements dramatically influence your options. Facilities with forklift access can use taller racks and higher tier counts, maximizing vertical space efficiently. Manual-loading operations benefit from lower profiles and improved ergonomic features that protect staff from injury.

Standard dimensions illustrate the space planning considerations clearly. Compact systems measuring 30" W x 83" L work in tight spaces but limit capacity. Standard configurations at 44.3" L x 36" W with heights from 45.4" to 79.4" serve most facilities well. Large systems reaching 160 cm wide provide maximum capacity for high-volume installations.

For comprehensive guidance on optimizing your storage layout, our Detailed Guide to Body Storage Racks covers space optimization strategies and workflow integration techniques that many facilities overlook.

Cost & Customization Variables

Understanding what drives cadaver-storage-racks- pricing helps you make smart decisions and avoid budget surprises. Like most professional equipment, the initial sticker price tells only part of the story.

Material grade creates the biggest cost differences while dramatically affecting longevity. 304 stainless steel commands premium pricing but delivers superior corrosion resistance and 20+ year service life. Powder-coated steel provides solid durability at lower cost, making it perfect for budget-conscious installations that still need reliable performance.

Caster options add functionality but increase costs predictably. Basic fixed feet provide maximum stability at the lowest price point. Locking swivel casters offer mobility when needed while maintaining stability during use, though at premium pricing.

Security straps and accessories address specific operational requirements. Facilities handling forensic cases might need locking mechanisms for chain of custody requirements. High-volume operations often benefit from ergonomic accessories that speed workflow and reduce staff fatigue.

Lead times vary significantly based on customization level. Standard configurations typically ship within 2 weeks, while custom designs require 6-8 weeks. Rush orders usually incur premium charges, making advance planning valuable for budget management.

Price bands reflect the full range of available options. Budget systems costing $955-$1,500 provide basic 2-3 tier configurations suitable for smaller operations. Mid-range options from $1,500-$2,500 offer improved features and larger capacities that serve most facilities well. Premium systems costing $2,500-$4,400 provide maximum capacity and advanced features for demanding applications.

Custom sizing, colors, and configurations typically add 15-25% to base pricing. However, the operational benefits of properly fitted equipment often justify this investment through improved efficiency and reduced labor costs.

Maintaining & Optimizing cadaver-storage-racks-

Taking care of your cadaver-storage-racks- isn't just about keeping them looking good—it's about ensuring safe operations, protecting your investment, and maintaining the spotless conditions that mortuary work demands. Think of maintenance as an insurance policy that prevents those middle-of-the-night emergencies when equipment fails at the worst possible moment.

Daily cleaning should become as routine as your morning coffee. The beauty of modern rack systems lies in their non-porous surfaces—whether stainless steel or powder-coated—that make cleaning straightforward. A quick daily wipe-down prevents the buildup of organic materials that can turn into serious hygiene problems down the road.

Here's where disinfectant choice gets interesting. While bleach packs a powerful antimicrobial punch, it can be rough on metal components over time. Many facilities have switched to quaternary ammonium compounds for daily use—they're gentler on equipment while still providing excellent disinfection.

Weekly corrosion checks take just a few minutes but can save thousands in replacement costs. Focus on joints, welds, and anywhere moisture might collect. Catching corrosion early means a simple touch-up instead of major repairs or replacement.

Don't forget about those roller assemblies if you have them. A little food-grade lubricant designed for cold environments keeps everything moving smoothly. Your staff will thank you when body positioning stays effortless instead of becoming a wrestling match.

Annual load testing might sound overly cautious, but it's actually smart business. Verifying that your racks still meet their weight ratings protects both your staff and your liability coverage. Plus, OSHA compliance documentation shows you're serious about workplace safety.

Staff PPE during maintenance isn't negotiable—gloves, eye protection, and proper respiratory gear when using chemical cleaners. It's a small investment that prevents big problems later.

For refrigerated units, clean racks actually improve energy efficiency by maintaining proper airflow. It's one of those happy situations where doing the right thing also saves money on utility bills.

Cleaning & Disinfecting cadaver-storage-racks-

Getting your cleaning routine right makes all the difference between equipment that lasts decades and systems that need constant replacement. The good news? Modern cadaver-storage-racks- are designed to make your life easier.

Those non-porous surfaces on quality racks aren't just for show—they're your secret weapon against contamination. Unlike older porous materials that could harbor nasties in tiny cracks and crevices, today's stainless steel and powder-coated surfaces clean completely and stay clean.

Bleach alternatives have come a long way in recent years. Hydrogen peroxide-based cleaners offer broad-spectrum killing power while being much gentler on your equipment. They break down into water and oxygen, so there's no harmful residue to worry about. Quaternary ammonium compounds provide that extra benefit of residual activity—they keep working even after you've finished cleaning.

Drainage management sounds fancy, but it's really about not letting water sit around where it shouldn't. Modern rack designs help water drain away naturally, but your cleaning procedures need to ensure everything dries completely. Standing water is like an invitation for bacteria and corrosion to move in and make themselves at home.

Documented SOPs might feel like paperwork overkill, but they're actually your best friend during inspections or if questions arise about your procedures. A simple checklist showing what gets cleaned, when, and with what products demonstrates professionalism and protects your facility.

Safety & Ergonomic Best Practices

Working with cadaver-storage-racks- safely isn't just about following rules—it's about creating an environment where your staff can do their important work without risking injury or burnout.

Proper lift heights make an enormous difference in daily operations. That industry-standard bottom shelf height of 40 cm isn't arbitrary—it's designed to work seamlessly with trolleys and minimize manual lifting. When staff can slide rather than lift, everyone wins.

Locking casters on mobile units might seem like a small detail, but they prevent the kind of accidents that can seriously injure someone. Make it a non-negotiable rule: locks get engaged before any loading begins. No exceptions, no shortcuts.

In earthquake country, seismic kits aren't optional—they're essential safety equipment. These systems keep loaded racks from becoming dangerous projectiles during ground movement. The installation cost is minimal compared to the potential consequences of unsecured equipment during a seismic event.

Staff training works best when it's practical and relevant. Show people the right way to lift, how to operate equipment safely, and what to do in emergencies. Regular refresher sessions keep safety top-of-mind as new staff join and equipment changes.

The ergonomic benefits extend far beyond injury prevention. Staff working with well-designed, properly maintained systems report less fatigue, better job satisfaction, and more confidence handling challenging situations. That translates into better employee retention and improved service quality.

For facilities ready to optimize their entire storage approach, our The Complete Guide to Choosing the Best Cooler Racks covers everything from initial selection through long-term optimization strategies.

Conclusion & Next Steps

Choosing the right cadaver-storage-racks- transforms how your facility operates every single day. These systems aren't just storage solutions—they're investments in staff safety, operational efficiency, and the respectful care of those entrusted to your facility.

The numbers speak for themselves. Facilities see up to 400% increases in storage capacity, dramatic reductions in workplace injuries, and smoother workflows that reduce stress during already challenging times. More importantly, modern rack systems help maintain the dignity and professionalism that families deserve during their most difficult moments.

Your decision should balance several key factors. Capacity planning starts with understanding your current needs but must account for seasonal peaks and unexpected situations. Space constraints in your cooler will influence tier counts and loading orientations, while budget considerations help determine the right balance of features and durability.

Don't overlook operational workflow patterns—the way your staff moves through daily tasks matters enormously. Side-loading versus end-loading configurations can make the difference between smooth operations and daily frustration. Future flexibility also deserves consideration, especially if your facility might expand or change its service offerings.

The investment in quality cadaver-storage-racks- typically pays for itself through reduced labor costs, fewer workplace injuries, and improved staff retention. Facilities consistently report that upgrading to modern rack systems improves both efficiency and job satisfaction among their teams.

At American Mortuary Coolers, we've spent years helping facilities across the contiguous 48 states solve their storage challenges. Based here in Tennessee, we understand that every funeral home, hospital, and medical facility has unique needs that require custom solutions rather than one-size-fits-all approaches.

What sets us apart is our focus on custom U.S.-made solutions that address your specific situation. Whether you're a small funeral home installing your first rack system or a large medical facility needing complex multi-tier installations, we design and build equipment that works for your space, your workflow, and your budget.

We've seen how the right equipment transforms daily operations. Staff work more safely and confidently. Families receive better service because operations run smoothly. Facility owners sleep better knowing their equipment will perform reliably for decades to come.

Ready to optimize your facility's storage capacity and improve your daily operations? We'd love to discuss how cadaver-storage-racks- can solve your specific challenges. Every consultation is personalized because every facility is different.

Contact us today for a design consultation that addresses your unique needs and budget requirements.

For more information about our complete range of mortuary cooling and storage solutions, visit More info about morgue coolers.