Why Cart Lifts Are Essential for Modern Material Handling

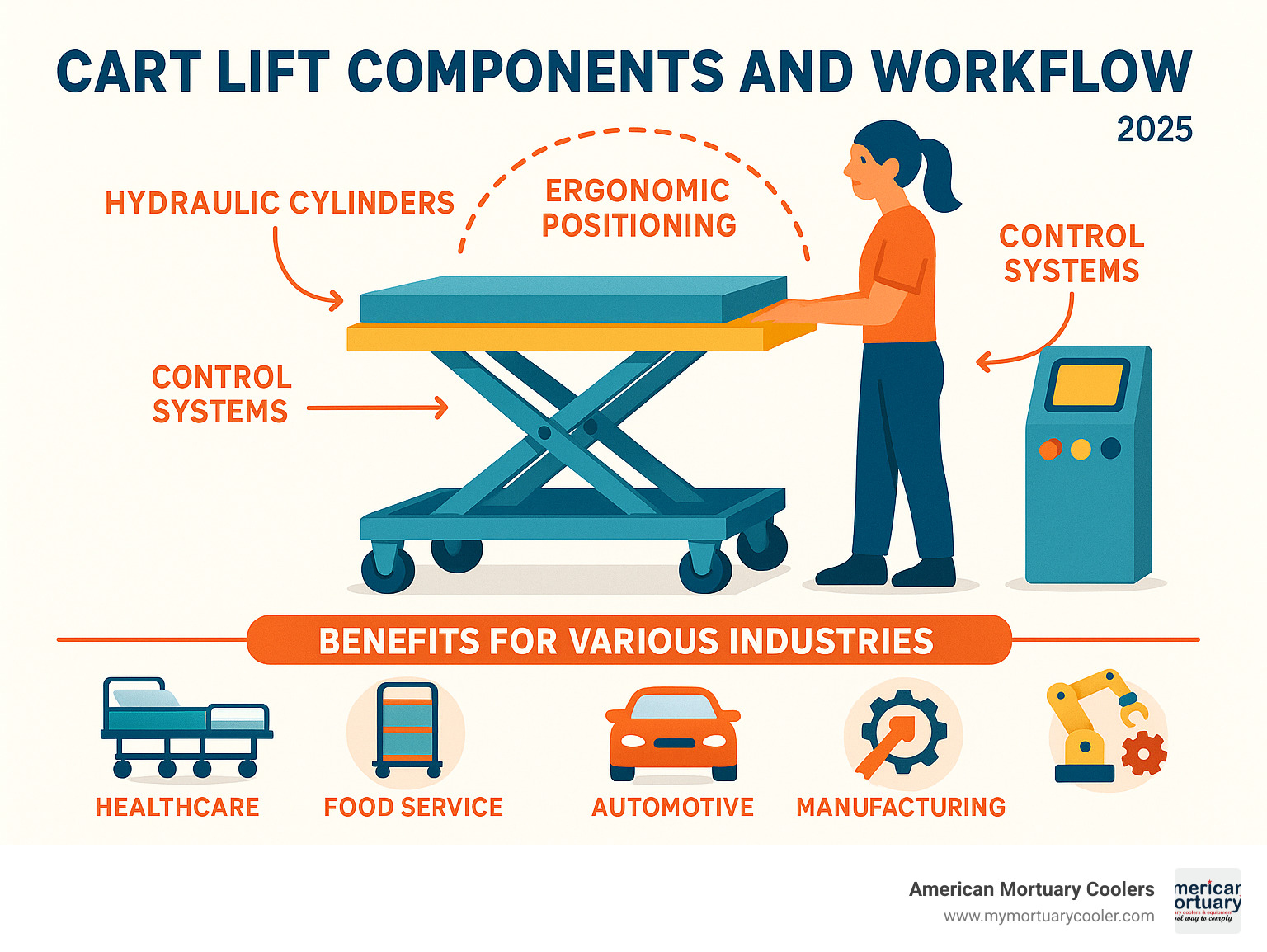

Cart lifts are specialized material handling devices designed to raise, lower, and position wheeled carts at ergonomic working heights. These mechanical lifts eliminate manual lifting hazards while improving workplace efficiency across industries from healthcare to manufacturing.

Key Cart Lift Types:

- Manual Cart Lifts: Hand-crank systems for light-duty applications (up to 500 lbs)

- Hydraulic Cart Lifts: Mid-range capacity units (500-2,500 lbs) with smooth operation

- Electric Cart Lifts: High-capacity automated systems with remote controls

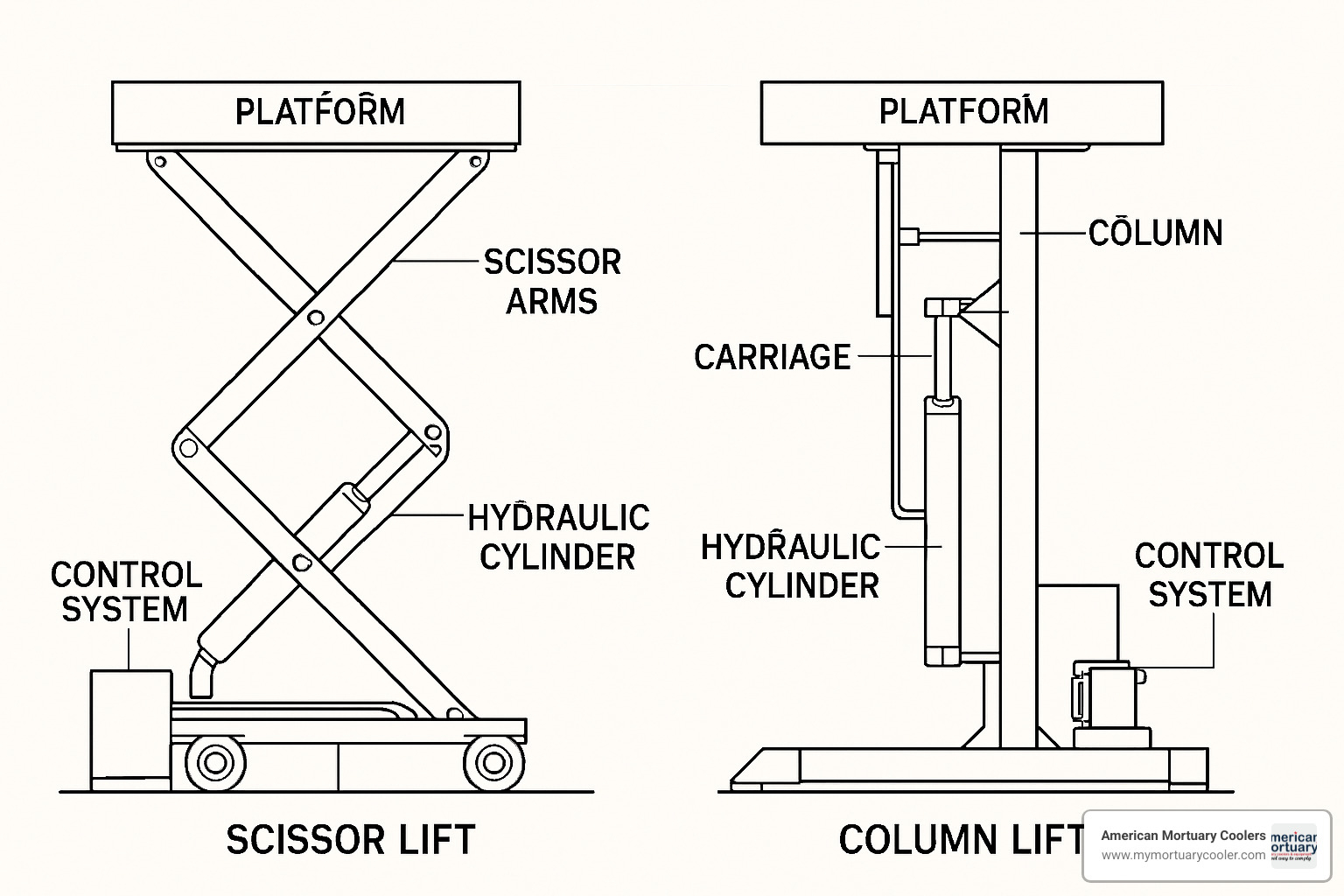

- Scissor Lifts: Compact platforms using crossed supports

- Column Lifts: Single-post designs for maximum clearance

Primary Industries:

- Hospitals for patient transport equipment

- Food service for heavy kitchen cart movement

- Automotive shops for parts positioning

- Funeral homes for body and casket handling

- Warehouses for inventory management

Cart lifts position loads in the ergonomic "Golden zone" between 36 to 48 inches, reducing workplace injuries and enhancing productivity. With capacities up to 2,500 lbs and speeds ranging from 50 to 300 feet per minute, these systems handle everything from lightweight medical carts to heavy industrial equipment.

As part of American Mortuary Coolers, we've helped funeral facilities select cart lift solutions that improve both worker safety and operational efficiency while maintaining the dignity these environments demand.

Basic cart lifts terms:

What Are Cart Lifts and How Do They Work?

Cart lifts are specialized devices designed to grab wheeled carts and lift them to optimal working heights. Unlike regular lift tables, these machines have guide rails and platforms that cradle four-wheeled carts safely during lifting.

Three main power systems drive these lifts. Hydraulic systems use pressurized fluid for smooth movement handling up to 2,500 pounds. Electric motors provide whisper-quiet precision, perfect for hospitals. Manual mechanisms rely on hand cranks or foot pumps for reliable operation without power.

Most powered cart lifts move at 50 to 300 feet per minute - fast enough for productivity but controlled for safety. Platforms range from 18" x 24" for compact carts up to 60" x 96" for industrial equipment.

The key benefit is positioning everything in the ergonomic "Golden zone" between 36 and 48 inches high, eliminating dangerous bending and stretching.

Core Components of Cart Lifts

Hydraulic cylinders convert fluid pressure into lifting power. Quality units feature chrome-plated rods and high-grade seals for durability.

Hydraulic pumps create the pressure that powers operation. Variable-speed pumps provide smooth starts and stops, while dual-flow systems enable precise positioning.

Lift platforms support carts during operation. Quality platforms include non-slip surfaces and guide rails for security.

Limit switches prevent over-extension and dangerous pressure buildup, acting as essential safety guards.

Modern cart lifts feature control panels with UL-approved microprocessor systems for smooth, safe operation. Some include variable frequency drives for ultra-precise speed control.

How Cart Lifts Improve Workplace Safety and Ergonomics

Cart lifts prevent injuries by eliminating back-breaking bending and stretching. By bringing loads to the perfect 36-48 inch height, they reduce musculoskeletal stress on workers' backs, shoulders, and knees.

OSHA compliance recognizes mechanical lifting aids as essential safety tools. Installing cart lifts demonstrates commitment to worker protection while reducing workers' compensation costs.

Beyond safety, productivity increases significantly. Tasks requiring multiple workers can often be handled by one person, and workers who aren't exhausted from manual lifting can focus on core responsibilities.

Types, Applications, and Industry Use Cases

Cart lifts serve diverse industries with specialized solutions. Healthcare facilities use quiet electric models for patient equipment and meal service. Food service operations rely on them for heavy prep carts and dish transport. Automotive shops position tool carts at optimal heights, while warehouses match cart heights with truck beds and conveyors.

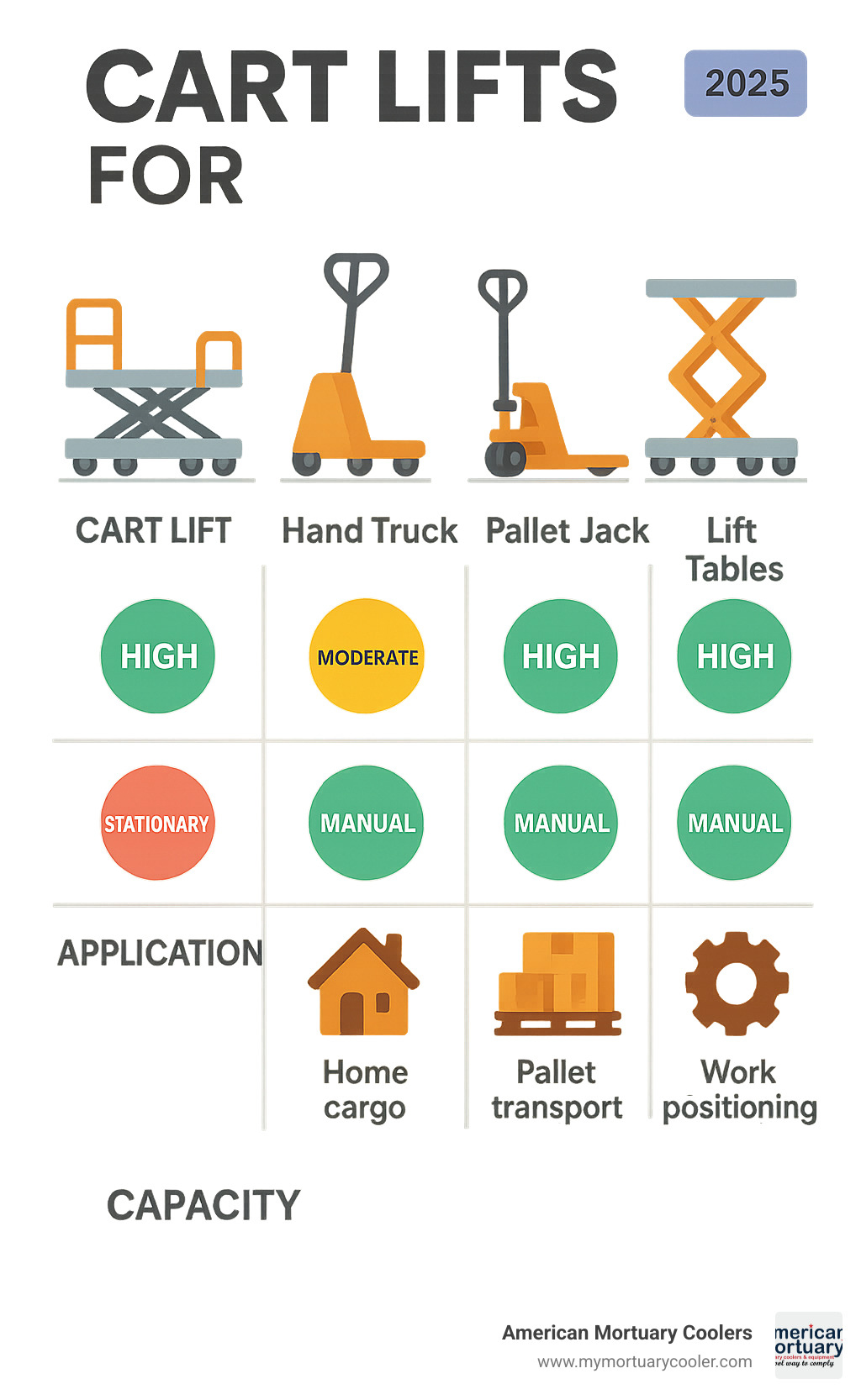

Manual vs. Powered Cart Lifts

Manual cart lifts excel where simplicity matters. Hand-crank systems don't need electricity, making them reliable for areas without power access. They're perfect for specialized applications like cadaver lifts, providing precise control in respectful funeral environments.

Powered systems handle frequent operation and maximum capacity. Battery-powered units offer electric convenience without power cords. Hydraulic cart lifts deliver smooth operation and highest weight capacities with precise positioning. Pneumatic lifts use compressed air, ideal for clean environments where hydraulic leaks would be problematic.

Choose based on duty cycle - frequent daily use justifies powered systems, while occasional use suits well-built manual units.

Specialized Cart Lifts for Mortuaries and Crematories

Funeral industry cart lifts require specialized features beyond basic functionality. Body and casket lifts handle 500 to 1,000+ pounds with whisper-quiet operation and stainless steel construction for hygiene standards.

These units offer incredible range - lowering to 12 inches for easy loading, extending to over 80 inches for high vehicle access. This flexibility eliminates dangerous manual lifting in funeral operations.

Cadaver transport systems focus on mobility and security with low-profile designs for tight spaces and removable handles for compact storage.

For detailed mortuary lift information: More info about mortuary lift systems.

Residential and Cargo Cart Lifts

Residential cart lifts help homeowners with multi-story challenges. Beach house cargo lifts handle coolers, furniture, and groceries with 1,000-pound capacities and remote control operation.

Lift It USA models offer weather-resistant construction and compact designs that integrate with home layouts. These systems often increase property value while improving daily convenience and reducing injury risks.

Installation requires structural support, electrical service, and building code compliance. For residential solutions: External research on cargo lifts.

How to Choose the Best Cart Lifts for Your Facility

Choosing the right cart lifts requires matching equipment to your specific needs, budget, and goals.

Weight capacity is most important. Choose capacity 20% higher than your heaviest load for safety margin. Lift height should reach your ergonomic "Golden zone" of 36-48 inches. Platform size must accommodate your largest carts with clearance.

Mobility determines flexibility - fixed units offer maximum stability, while mobile cart lifts provide versatility. Power options include battery (works anywhere), hardwired electric (consistent power), or manual (reliable backup).

Safety features like UL-approved controls, emergency stops, and engagement guides are essential, not optional.

Key Specifications Checklist for Cart Lifts

Capacity ratings should reflect dynamic lifting capacity, not static loads. Height specifications include lowered height, raised height, and total travel distance.

Platform dimensions must consider load center requirements and overhang limitations. Power specifications vary - electric units need proper voltage/amperage, battery units need runtime specs.

Construction details reveal quality differences. Frame material, platform surface, and hydraulic cylinder specifications determine durability and performance.

Safety features like UL listing, emergency stops, and overload protection prevent accidents. Warranty terms significantly impact total ownership costs.

Budget & ROI: Cost Ranges and Financing Options

Entry-level manual units cost $500-$2,000 for light-duty applications. Mid-range hydraulic/electric units run $2,000-$6,000 for most commercial needs. High-end specialized systems range $6,000-$15,000+ for demanding applications.

Financing options include equipment leasing starting around $191/month, rent-to-own arrangements, and volume discounts.

ROI comes from injury prevention, productivity gains, and reduced equipment wear. Preventing one workplace injury often covers the entire investment cost.

Accessories & Customizations to Maximize Value

Mechanical accessories like fork extensions, tilt modules, and adjustable restraints expand functionality. Electronic improvements include digital scales, remote controls, and variable frequency drives.

Safety upgrades provide additional protection through security cages, light curtains, and emergency systems. Custom options include paint colors, stainless steel construction, and specialized attachments for unique applications.

Installation, Maintenance, and Compliance Essentials

Proper cart lift installation ensures safe, reliable operation for years. Floor loading is most common, requiring secure anchoring to concrete floors at least 4-6 inches thick with 3,000 PSI strength. Pit installations need excavation but provide floor-level loading.

Seismic anchoring is required in earthquake zones. Electrical needs vary from standard outlets for battery units to 480V service for large hydraulic systems.

Step-by-Step Cart Lift Installation Overview

Site surveys evaluate floor conditions and clearances. Layout drawings show exact anchor locations and space requirements. Concrete core drilling creates precise anchor holes. Power hookup must meet codes and OSHA requirements. Load testing verifies safe capacity and safety system operation.

Routine Maintenance & Troubleshooting for Cart Lifts

Daily checks include visual inspection for leaks and testing emergency stops. Weekly maintenance covers fluid levels and battery charging. Monthly reviews test all safety features and lubricate moving parts. Annual professional inspections are mandatory for safety certification.

Common issues include slow operation (low fluid/worn seals), excessive noise (loose bolts/worn bearings), and platform drift (hydraulic leaks).

Safety Standards and Certifications Relevant to Cart Lifts

ANSI/ALI ALCTV-2017 sets automotive lift safety requirements. OSHA 1910.178 governs powered industrial equipment. UL 201 covers electrical safety. ISO 3691 provides international guidelines. Local building codes may have additional requirements.

Frequently Asked Questions about Cart Lifts

What is the difference between cart lifts and lift tables?

Cart lifts are specialized for wheeled equipment with guides and restraints that secure carts during operation. They're sized for standard cart dimensions and often mobile.

Lift tables are flat platforms for pallets and loose materials without specialized cart-handling features. If you're moving wheeled equipment regularly, cart lifts are the safer, more effective choice.

How often should cart lifts be inspected for safety?

Daily checks should test emergency stops and check for leaks. Weekly inspections cover fluid levels and battery status. Monthly reviews test all safety systems and lubricate components. Annual professional inspections with load testing are mandatory for safety certification.

High-usage applications may need more frequent professional inspections.

Can cart lifts be customized for unique load shapes?

Yes, cart lifts offer extensive customization options. Platform modifications adjust size and surface treatments. Specialized attachments include fork extensions and tilt mechanisms. Control systems can be programmed for specific workflows.

Construction materials like stainless steel suit medical and food applications. Most manufacturers offer custom engineering services to meet unique operational requirements.

Conclusion

Choosing the right cart lifts is an investment in your team's wellbeing and operational success. Whether in hospitals, warehouses, or funeral homes, proper lifting solutions transform daily challenges into safe, efficient processes.

Start with your heaviest, most frequent lifting tasks. Remember: capacity should exceed your heaviest load by 20%, target the ergonomic "Golden zone" of 36-48 inches, and prioritize safety features. A $2,000 unit that prevents one workplace injury pays for itself immediately.

At American Mortuary Coolers, we've helped funeral professionals across the contiguous 48 states find lifting solutions that honor both worker safety and environmental dignity. Our Tennessee-based team understands that mortuary cart lifts require special consideration for quiet operation and reliable performance.

The funeral industry presents unique challenges requiring specialized expertise. We've developed custom cart lift solutions designed specifically for funeral home operations. More info about American Mortuary Lifts.

Take time to evaluate your needs thoroughly, ask about capacity and safety features, and choose suppliers who understand your industry. The perfect cart lift will serve your operation reliably for many years to come.