Why Hydralic Lift Carts Are Essential for Safe Material Handling

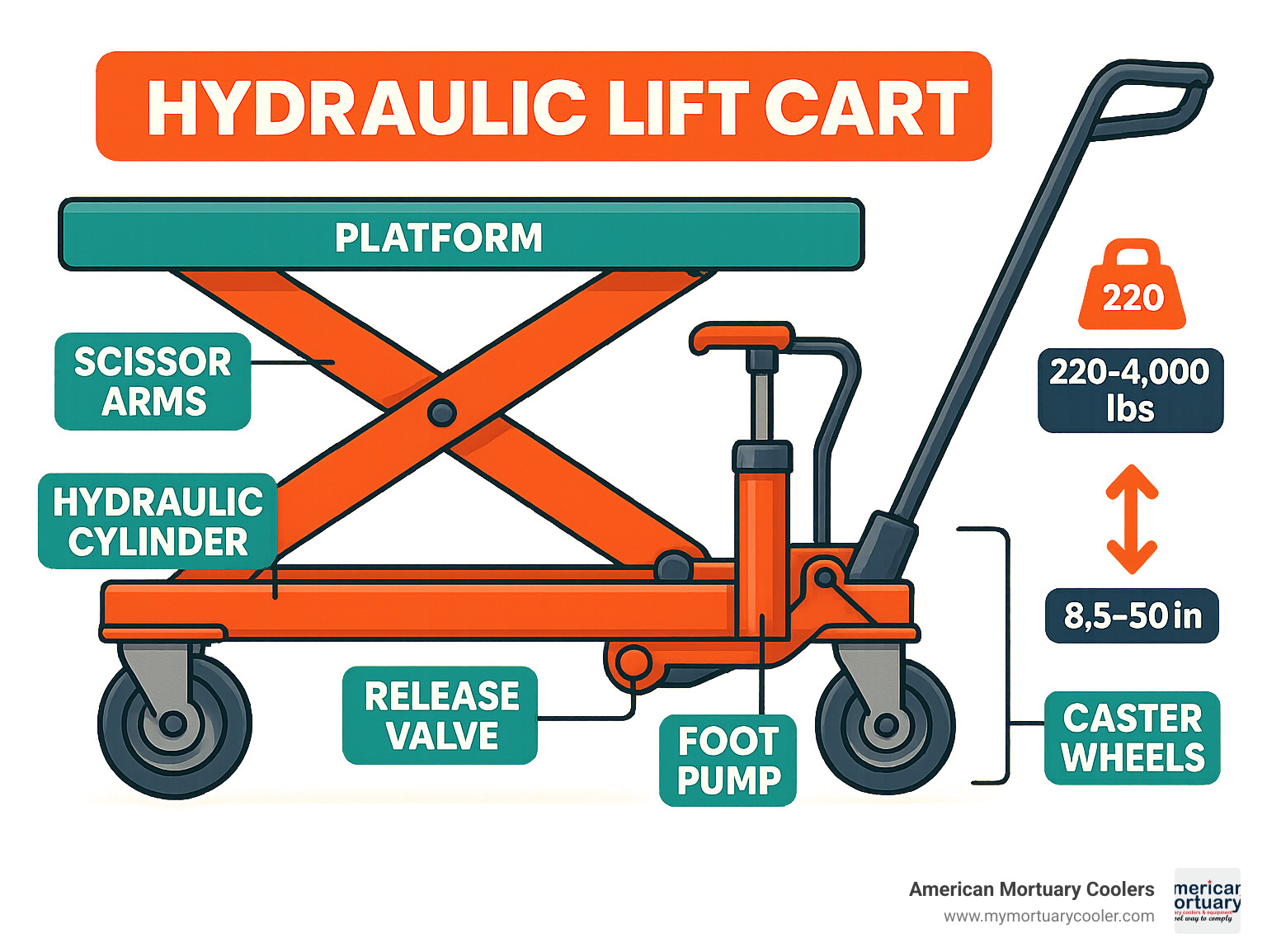

A hydralic lift cart is a wheeled platform that uses hydraulic power to raise and lower heavy loads, typically ranging from 220 to 4,000 pounds. These versatile material handling tools eliminate the need for manual lifting and reduce workplace injuries while improving workflow efficiency.

Key Features of Hydralic Lift Carts:

- Capacity Range: 220-4,000 lbs depending on model

- Lift Heights: 8.5 inches (minimum) to 50 inches (maximum)

- Operation: Foot-pump hydraulic system with hand-lever lowering

- Construction: Steel, stainless steel, or aluminum frames

- Mobility: 4-wheel design with swivel casters and locks

Research shows that hydralic lift carts significantly reduce worker bending and lifting, helping minimize workplace injuries in automotive, manufacturing, warehousing, and laboratory settings.

These carts work by using Pascal's law - a small amount of force applied to the foot pump creates much greater lifting force through hydraulic pressure multiplication. The scissor-arm design provides stable, controlled lifting from as low as 8 inches to heights reaching 50 inches on double-scissor models.

We're American Mortuary Coolers, a national-level mortuary cooler supplier with extensive experience helping funeral professionals select the right hydralic lift cart for their specific operational needs.

Basic hydralic lift cart terms:

Understanding the Mechanics of a Hydralic Lift Cart

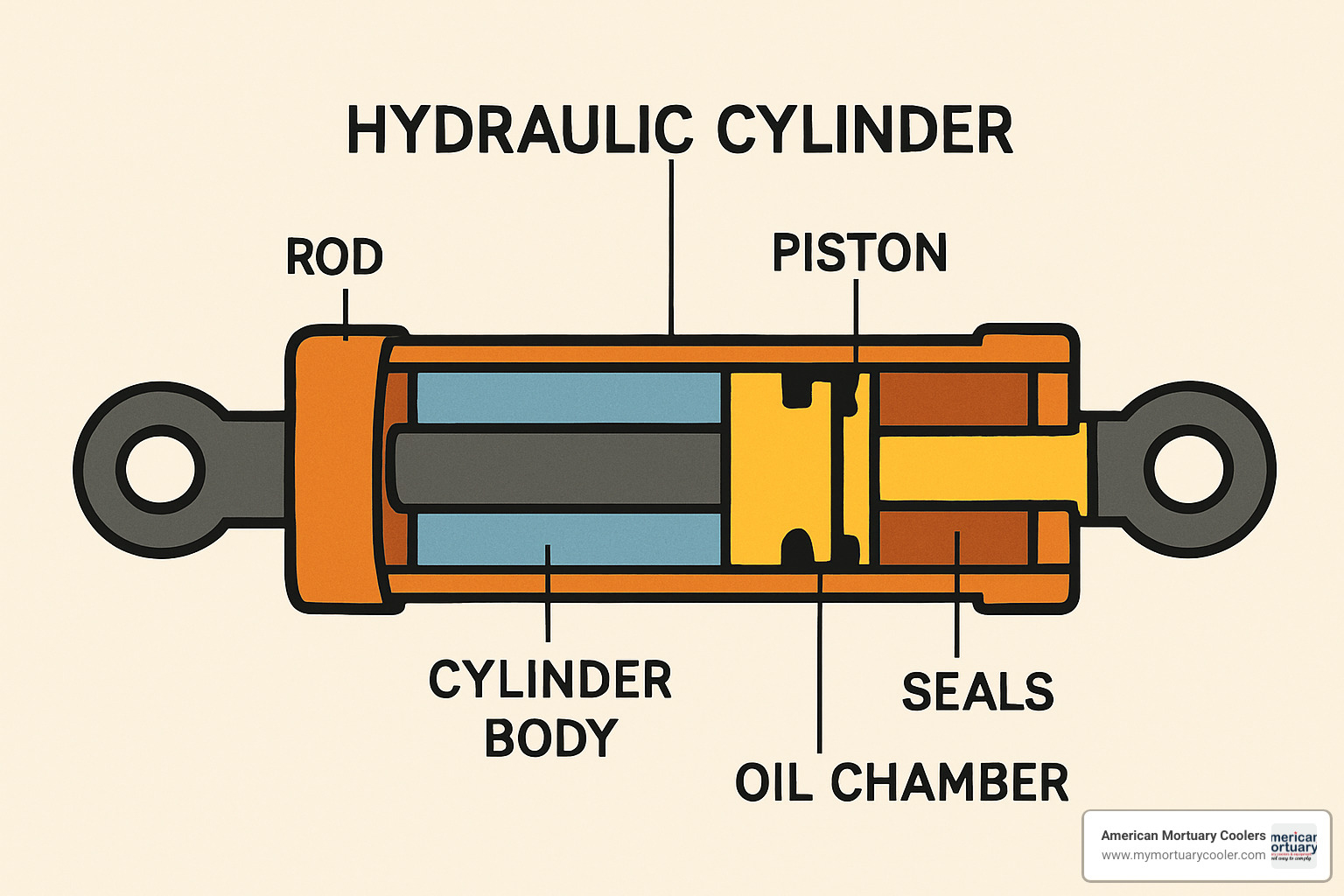

A hydralic lift cart operates through a simple yet effective hydraulic system. The hydraulic cylinder - a metal tube filled with oil - does the heavy lifting. When you step on the foot pump, you force oil from a reservoir into this cylinder, pushing a piston upward.

That piston connects to scissor arms - crossed steel beams that convert the cylinder's short stroke into impressive vertical lift. Most carts provide a 3:1 or 4:1 ratio, so every inch the piston moves translates to 3-4 inches of platform travel.

Safety features include the velocity fuse that acts as an emergency brake, automatically stopping the platform from crashing down if hydraulics fail. The soft-lowering valve provides precise control when bringing loads down.

The platform is typically steel plate with a non-slip rubber mat, ranging from compact 17.5" x 27.5" models up to spacious 32" x 40" platforms. Four polyurethane casters keep everything mobile, with rear wheels featuring swivel locks for stability.

Scientific research on ergonomic lifting benefits confirms these carts significantly reduce workplace injuries by eliminating bending and lifting.

The Physics Behind the Lift

Pascal's law makes hydraulic systems work - pressure applied to oil spreads equally in all directions. A small force over a large area creates a much bigger force over a smaller area. If your foot pump has 2 square inches and you apply 50 pounds of force, that creates 25 PSI throughout the system. A 10-square-inch cylinder produces 250 pounds of lifting force - a 5:1 mechanical advantage.

Key Components Explained

The pump assembly contains a one-way check valve that lets oil flow to the cylinder but blocks backflow, keeping loads suspended between pump strokes. The release lever operates a bypass valve for controlled lowering. Seals prevent leaks and maintain pressure - the main cylinder seal is critical for proper operation.

Main Types of Hydralic Lift Carts & Where They're Used

The hydralic lift cart family breaks down into four core designs. Each one balances capacity, lift height, and price differently, so a quick overview is often enough to decide which lane you belong in:

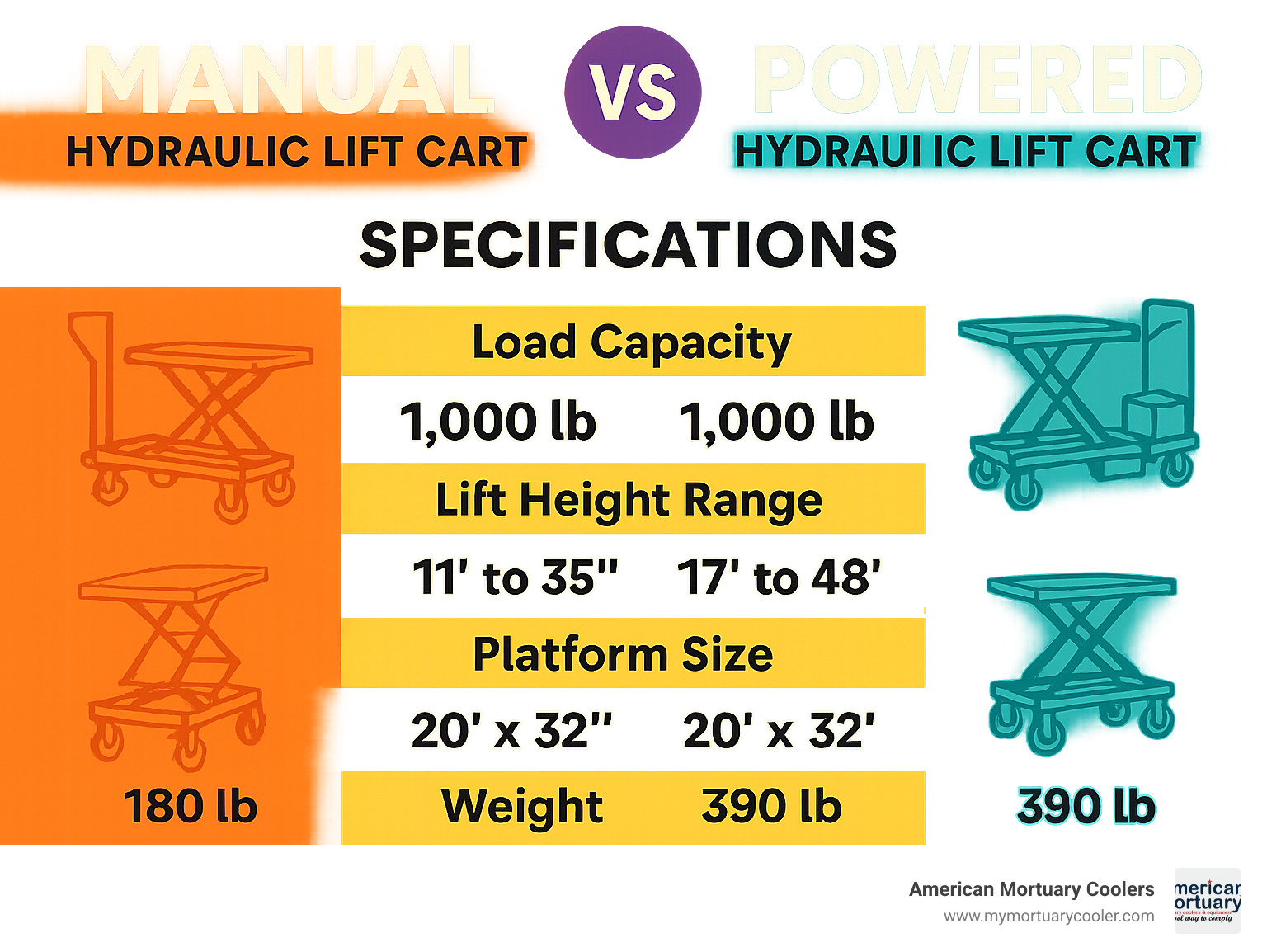

- Manual single-scissor – 220-1,100 lb, 9-35 in lift, foot-pump operation.

- Double-scissor – 500-1,500 lb, up to 50 in lift, foot or powered pump, added height at the cost of weight and price.

- Air-over-hydraulic – 770-2,000 lb, 13-51 in lift, runs on 90 PSI shop air; foot pump is the back-up.

- Battery / DC powered – 500-4,000 lb, 8-40 in lift, push-button control; best where carts cycle all day.

Material choices follow the environment: powder-coated steel for most shops, stainless for food/pharma/clean rooms, and aluminum when corrosion resistance and portability both matter.

Manual Single-Scissor Hydralic Lift Cart (500–1,000 lb)

Budget-minded shops lean on the Pittsburgh Automotive 500 lb and Haul-Master 1,000 lb carts. Both roll through standard doorways and raise loads into the ergonomic 28-35 in work zone without outside power. If you only lift a few times per shift, a manual single-scissor is usually all you need.

Powered & Air Hydralic Lift Cart (770 lb+)

High-cycle tasks wear operators out quickly, so compressed-air or battery assist pays for itself in reduced fatigue. The Roughneck 770 lb air/hydraulic model needs only 9 CFM at 90 PSI yet still works if the airline goes down, thanks to a back-up foot pump. DC units replace pumping altogether with thumb-switch control—ideal on assembly lines or in labs where repeatability matters.

Specialty Double-Scissor & Stainless Models

When the job sits higher than 35 in—think mezzanine loading or transferring to tall conveyors—a double-scissor such as the Vestil CART-800-D-TS (800 lb, 50 in lift) is the safe choice. Stainless lines like Guide’s BCART-550-SS solve sanitation or corrosion challenges, albeit at a premium price.

Industry Snapshot

- Automotive – engines, transmissions, battery packs.

- Warehousing – bridging floor level to dock plates.

- Manufacturing – feeding parts to assembly cells.

- Mortuary & Laboratory – stainless units for respectful, hygienic handling.

More info about lifting tables

How to Choose the Best Hydralic Lift Cart for Your Needs

Buying decisions get simple once you put first things first: capacity, height, footprint, and environment. Everything else—brand, power source, add-ons—flows from those numbers.

1. Capacity with a 25 % safety margin. If your heaviest realistic load is 500 lb, shop for a cart rated at 625 lb or more. That cushion covers off-center loading and dynamic bumps while you roll.

2. Lift range that matches your work. Single-scissor carts (8-10 in lowered, 27-35 in raised) cover most bench or dock tasks. Only step up to a double-scissor if you truly need 40-50 in of travel—the added height costs weight, dollars, and maintenance.

3. Platform size vs. doorway clearance. A 24 × 36 in deck stabilizes most loads yet still slips through a 36 in doorway. Measure the narrowest pinch-point in your facility before you fall in love with a bigger platform.

4. Construction material. Powder-coated steel handles 90 % of jobs. Stainless pays off where wash-down, chemicals, or regulations demand it. Aluminum splits the difference when you need corrosion resistance without stainless pricing.

5. Mobility and brakes. Polyurethane casters roll quietly and protect floors; rear swivel locks stop unwanted motion during lift or load.

6. Power source.

- Foot pump – lowest cost, highest reliability.

- Air-over-hydraulic – no pumping, but you need 90 PSI.

- Battery/DC – ultimate convenience; justify it with high daily cycles.

Quick Quality Checks

- Continuous, clean welds at stress points.

- Velocity fuse in each cylinder for drop protection.

- Easy-to-source seal kits and casters.

- At least a 1-year warranty (2-year is better).

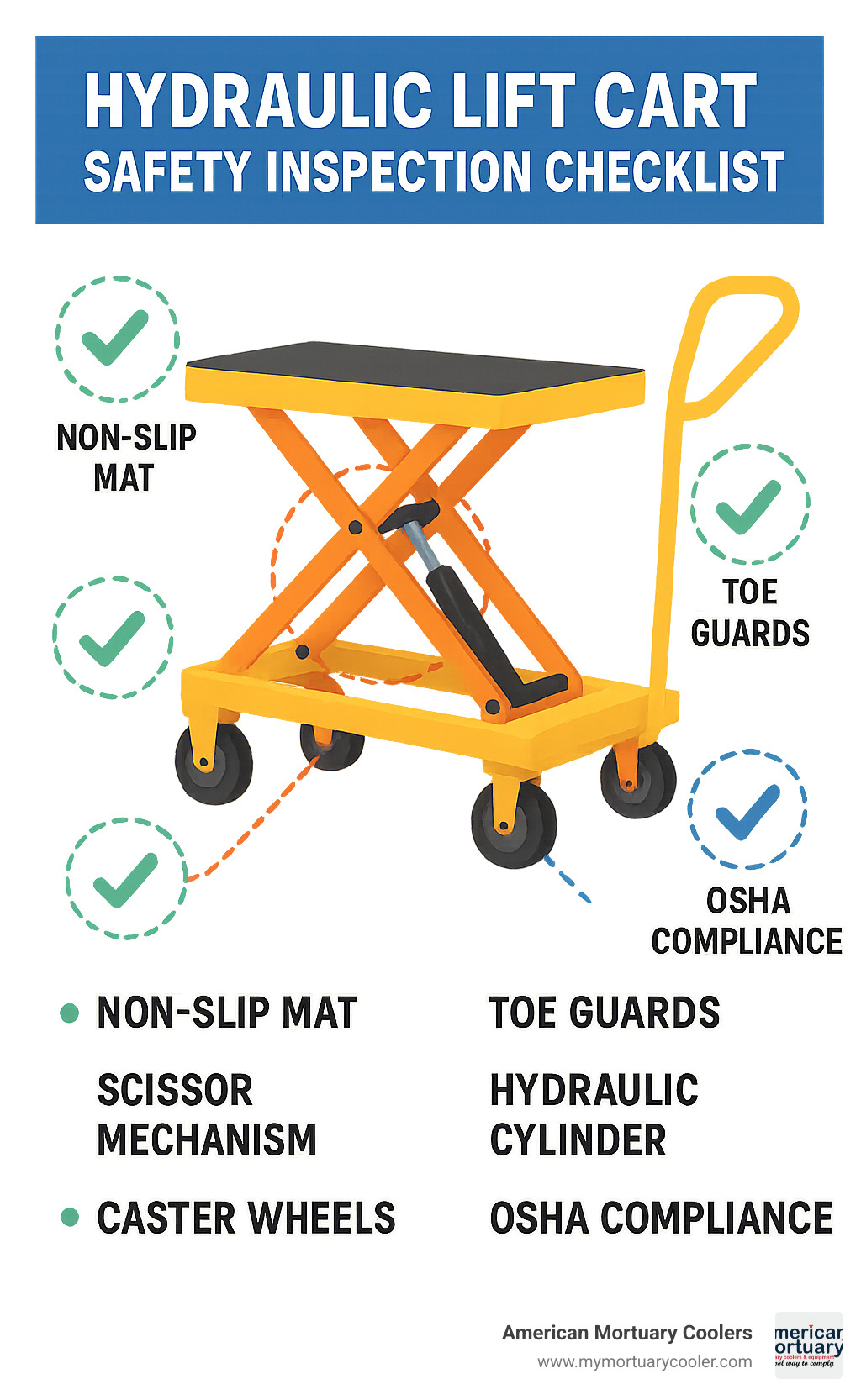

Compliance & Accessories

Toe guards, non-slip mats, and OSHA-style inspection tags take the question marks out of daily use. If your facility falls under ANSI/ITSDF B56.1, document a monthly inspection routine and log it.

Safe Operation, Maintenance & Troubleshooting

Daily safety takes less than two minutes: verify fluid level, look for leaks, roll the cart a few feet, pump it up once, and lock the casters. That short ritual prevents almost every surprise.

Fast Loading Rules

- Center the load; block or strap anything that can roll.

- Stand beside the cart while pumping—never directly behind.

- Lock both rear casters before you raise or lower.

- Wear safety glasses and steel-toed shoes as a minimum.

Maintenance in Three Lines

- Daily: visual once-over and fluid check.

- Monthly: grease pivot points, inspect casters, wipe the cylinder clean.

- Annually: drain/replace hydraulic oil unless contaminated sooner.

Quick Fix Chart

| Symptom | Likely Cause | First Fix |

|---|---|---|

| Won’t lift | Low fluid | Top off with spec oil |

| Spongy action | Air in system | Bleed at cylinder high-point |

| Drifts down | Internal seal leak | Re-seal or replace cylinder |

| Drops suddenly | Velocity fuse tripped | Find & repair leak before reset |

Storage Tips

Lower the platform, engage wheel locks, and park indoors when you can. If outside storage is unavoidable, cover the cart and inspect for rust monthly.

Prices, Leading Brands & Buying Tips

Price bands line up neatly with features:

- Under $400 – basic manual single-scissor carts (Pittsburgh 500 lb, Haul-Master 1,000 lb). Great for occasional lifts, limited parts support.

- $400–$1,000 – heavier frames, smoother pumps, longer warranties. JEGS’ 1,100 lb unit at around $300 on sale often lands here.

- $1,000–$4,000 – double-scissor, air, or battery power. Vestil’s CART-800-D-TS (~$2,000) is the poster child.

- $4,000+ – stainless or aluminum specialty builds; Guide’s BCART-550-SS tops $11k but meets strict sanitary rules.

Freight runs $150-$200 for a 300 lb cart, so factor shipping into your budget. Local pick-up or combining orders with other shop equipment can trim that bill.

Parts & Service

Vestil and Guide keep seal kits, wheels, and cylinders on the shelf; that’s worth real money over a 10-year life. Harbor Freight units save cash up-front but may require a full replacement if a pump fails.

Total Cost of Ownership Snapshot

- Simple designs cut maintenance hours.

- Readily available parts minimize downtime.

- Recognized brands hold resale value.

- Warranty length signals manufacturer confidence.

Frequently Asked Questions About Hydralic Lift Carts

Let's tackle the most common questions we hear about hydralic lift cart selection and operation. These answers come from years of helping customers find the right equipment for their specific needs.

What weight capacities and lift heights are most common?

The sweet spot for most operations falls into three capacity ranges: 500 pounds, 1,000 pounds, and 1,100 pounds. These cover about 80% of what most shops and facilities need to handle.

The 500-pound class works perfectly for automotive parts, small machinery components, and general shop tasks. It's light enough to maneuver easily but strong enough for serious work. The 1,000-pound range steps up to handle engines, transmissions, and heavier fabrications - this is probably the most versatile choice for mixed applications.

For lift heights, single scissor hydralic lift carts typically start around 8-10 inches when fully lowered and reach 27-35 inches at maximum height. That 30-35 inch peak works great for most workbenches and loading docks.

Double scissor models can reach impressive heights - up to 50 inches in some cases - but they're heavier, more complex, and cost significantly more. Most people find the single scissor range handles their needs just fine.

How do I operate a hydralic lift cart safely and efficiently?

Safety starts before you even load anything. Check the hydraulic fluid level through the sight gauge, test the lifting and lowering functions, and make sure all four casters roll smoothly. This two-minute inspection prevents most problems.

When loading, center everything on the platform and secure it with straps or clamps. Never exceed the weight rating - if you're not sure how much something weighs, err on the side of caution. Side loading or off-center loads can damage the scissor mechanism.

Here's a technique tip: stand to one side while pumping, not directly behind the cart. Use smooth, steady strokes rather than rapid pumping. Your back will thank you, and the hydraulic system will last longer.

Always engage those caster locks before loading or unloading. The rear wheels typically have foot-operated locks that prevent both rolling and swiveling. Lock them both - a moving cart during operation is asking for trouble.

What maintenance keeps a hydralic lift cart in top condition?

The good news is that hydralic lift carts don't need much maintenance if you stay on top of the basics. Check fluid levels daily if you use the cart regularly - it takes 30 seconds and prevents major headaches.

Monthly lubrication of the scissor arm pivot points keeps everything moving smoothly. Use good bearing grease, but don't overdo it - too much grease attracts dirt and debris. Apply until you see a little grease at the seal, then stop.

Watch for small leaks around the cylinder and pump connections. Address them immediately before they become big problems. A $5 seal replacement today beats a $500 cylinder rebuild next month.

Store the cart with the platform lowered when not in use. This reduces stress on the hydraulic seals and scissor mechanism. If you can store it indoors, even better - weather and temperature swings are hard on rubber seals.

The hydraulic fluid itself can last for years if it stays clean. Only change it when you see contamination - milky fluid means water got in, while metallic-looking fluid suggests internal wear. Clean fluid is happy fluid.

Conclusion

Choosing the right hydralic lift cart can completely transform how you handle heavy materials in your workspace. What once required multiple people straining their backs becomes a smooth, one-person operation that protects your team and improves productivity.

The path to finding your perfect cart starts with matching capacity to your heaviest loads - remember that 25% safety margin we discussed. From there, consider your typical working heights and whether you need the extra reach of a double-scissor design. Don't forget about your work environment - that stainless steel option might seem expensive until you consider the long-term costs of corrosion in a harsh setting.

Total cost of ownership often tells a different story than the initial price tag. A well-built cart from a manufacturer with strong parts support might cost more upfront but save thousands in downtime and repairs over its lifetime. Those Harbor Freight bargains look less appealing when you need a seal kit that doesn't exist.

The beauty of hydraulic lift technology lies in its simplicity - Pascal's law has been working the same way for centuries, and a quality hydralic lift cart can serve your operation for decades with proper care. Whether you're moving engines in an automotive shop or positioning equipment in a manufacturing facility, the right cart becomes an indispensable part of your workflow.

At American Mortuary Coolers, we've seen how the right lifting equipment makes all the difference in professional operations. Our Tennessee-based team understands that funeral professionals need equipment that combines reliable performance with the respectful handling your profession demands. That's why we offer custom mortuary lift solutions designed specifically for the unique requirements of funeral service.

When you're ready to explore specialized lifting solutions for mortuary applications, our guide to mortuary lift systems provides detailed information about equipment designed specifically for funeral professionals. The right lifting system doesn't just improve efficiency - it helps maintain the dignity and respect that defines quality funeral service.