Why Stainless Steel Tables Are Essential for Professional Workspaces

Stainless steel tables are the industry standard for professional workspaces that demand durability, hygiene, and corrosion resistance. These versatile work surfaces are used in every commercial kitchen, food processing plant, medical facility, and mortuary across the country.

Key Benefits of Stainless Steel Tables:

- Corrosion resistant - Won't rust or stain

- Non-porous surface - Easy to clean and sanitize

- Heat resistant - Withstands high temperatures

- Durable construction - Supports 200-800+ lbs capacity

- NSF certified - Meets health and safety standards

- 100% recyclable - Environmentally sustainable

The secret to stainless steel's durability lies in its chromium content. With at least 10.5% chromium, these tables form a protective oxide film that self-heals when scratched. This makes them ideal for demanding environments where cleanliness is paramount.

Standard stainless steel worktables typically support up to 600 lbs, while deluxe models can handle 750 lbs or more. Popular sizes include 24"x48", 30"x60", and 36"x72", with custom dimensions available for specific applications.

As Mortuary Cooler, I've supplied mortuary-grade stainless steel tables nationwide for over a decade, helping funeral homes optimize their prep room workflows. My experience with stainless steel tables has shown me that choosing the right grade, gauge, and features can make the difference between a table that lasts years versus decades.

Terms related to stainless steel tables:

Stainless Steel Tables 101: What They Are & Where They're Used

Think of stainless steel tables as the workhorses of professional environments. These heavy-duty work surfaces are built from corrosion-resistant steel alloys and show up everywhere that cleanliness and durability matter most. You'll find them serving as worktables, prep tables, and utility benches in settings that range from busy restaurant kitchens to quiet hospital labs.

What makes these tables so popular? Unlike wood surfaces that can harbor bacteria or plastic that scratches and stains, stainless steel creates a surface that's truly non-porous. This means it won't absorb odors, resist thorough cleaning, or give bacteria a place to hide.

The versatility is remarkable. Whether you're running a commercial kitchen, managing a laboratory, organizing your garage, designing an outdoor kitchen, or working in hospitals and mortuaries, these tables adapt to your specific needs. They handle everything from food prep to medical procedures with the same reliable performance.

I've been in this business long enough to see why professionals keep coming back to stainless steel. The upfront cost might be higher than other materials, but the long-term value is unbeatable. These tables literally last decades with proper care.

Stainless Steel Tables in Foodservice

Walk into any professional kitchen and you'll see stainless steel tables everywhere. Restaurants, cloud kitchens, and bakeries depend on them for food preparation, plating, and temporary storage. The magic happens in that non-porous surface - it prevents cross-contamination between different ingredients, which is crucial whether you're breaking down chickens, chopping vegetables, or rolling out pastry dough.

Here's where NSF compliance becomes critical. Every commercial-grade stainless steel table needs this certification to meet health department standards. This isn't just paperwork - it guarantees the table can handle repeated cleaning with commercial sanitizers without breaking down or creating food safety issues.

Food trucks and pop-up operations especially love mobile stainless steel tables with casters. Being able to quickly reconfigure your workspace for different events or menu changes can make the difference between smooth service and kitchen chaos in those tight spaces.

Stainless Steel Tables in Medical & Mortuary Settings

Medical facilities choose stainless steel tables for one main reason: they can be truly sterile. In clean-rooms, embalming labs, and autopsy suites, these tables provide surfaces that can be completely disinfected between uses. The non-porous nature means bacteria simply can't establish a foothold, which is absolutely essential in medical environments.

Over the years, we've supplied funeral homes across the country with specialized mortuary tables that go beyond basic functionality. Features like perforated surfaces for fluid drainage, hydraulic height adjustment, and integrated identification card holders make prep room work both more efficient and more hygienic.

If you're looking to upgrade your prep room setup, our guide Prep Like a Pro with Stainless Steel Tables covers the specific considerations that matter most in mortuary applications.

Main Types of Stainless Steel Tables & Their Applications

When shopping for stainless steel tables, you'll encounter several distinct types, each designed for specific tasks. The main categories break down into prep tables, work tables, utility tables, and specialized equipment stands. Understanding these differences will help you choose the right table for your workspace.

Prep tables are the workhorses of commercial kitchens, featuring backsplashes to protect walls and undershelves for ingredient storage. Work tables offer heavy-duty surfaces for general tasks, while utility tables provide basic functionality at budget-friendly prices. Equipment stands are engineered to support heavy machinery like mixers or slicers safely.

Mobile carts with casters bring flexibility to any workspace, allowing you to reconfigure layouts as needed. Folding tables offer space-saving solutions when storage is tight between uses.

Most facilities benefit from combining different table types to handle various tasks efficiently. We've seen restaurants use prep tables near cooking stations, utility tables for dishwashing areas, and mobile carts for serving.

Open-Base vs Cabinet-Base

The choice between open-base and cabinet-base designs often determines how well a table fits your workflow. Open-base tables feature legs only, giving you maximum accessibility underneath for storage bins, equipment, or easy cleaning access.

This design shines in busy commercial kitchens where large pots, pans, and equipment need quick storage beneath work surfaces. The open design also makes floor cleaning much easier during deep cleaning sessions.

Cabinet-base tables include enclosed storage with doors or drawers, offering organized storage for smaller items while maintaining a professional appearance. These work well in front-of-house applications or prep areas where you want a cleaner, more finished look.

The decision usually comes down to storage needs versus accessibility. Open bases offer more flexibility and easier cleaning, while cabinet bases provide secure, organized storage that keeps supplies out of sight.

Specialty Designs

Specialty stainless steel tables address specific industry needs with targeted features. Backsplash tables protect walls from spills and splashes, making them perfect for food prep areas. Integrated sink tables combine work surface and cleanup station, streamlining food preparation workflows.

In mortuary settings, hydraulic embalming tables offer adjustable height mechanisms and specialized drainage systems. Our folding dressing tables provide space-efficient solutions for prep rooms, offering 600-lb capacity while folding to just 13 inches high for storage.

These specialized tables often include perforated surfaces for fluid drainage, integrated identification card holders, and custom sizing to fit specific room layouts. The hydraulic systems allow precise height adjustment, reducing physical strain during long procedures.

For comprehensive information on mortuary-specific options, check out our Ultimate Guide to Embalming Table Options, which covers hydraulic systems, perforated surfaces, and custom configurations in detail.

Materials & Construction: Grades, Gauges, Key Features

When you're investing in stainless steel tables, understanding the materials and construction details can save you thousands of dollars and years of headaches. Not all stainless steel is created equal, and the differences between grades and gauges will directly impact how well your table performs over time.

The three main stainless steel alloys you'll encounter are 304, 316L, and 430. Each has its own personality, if you will. Think of 304 as the reliable workhorse - it handles most commercial applications beautifully and won't break the bank. The 316L is like the overachiever in the family, offering superior protection when you're dealing with harsh chemicals or salty environments. And 430? That's your budget-friendly option that still gets the job done for basic prep work.

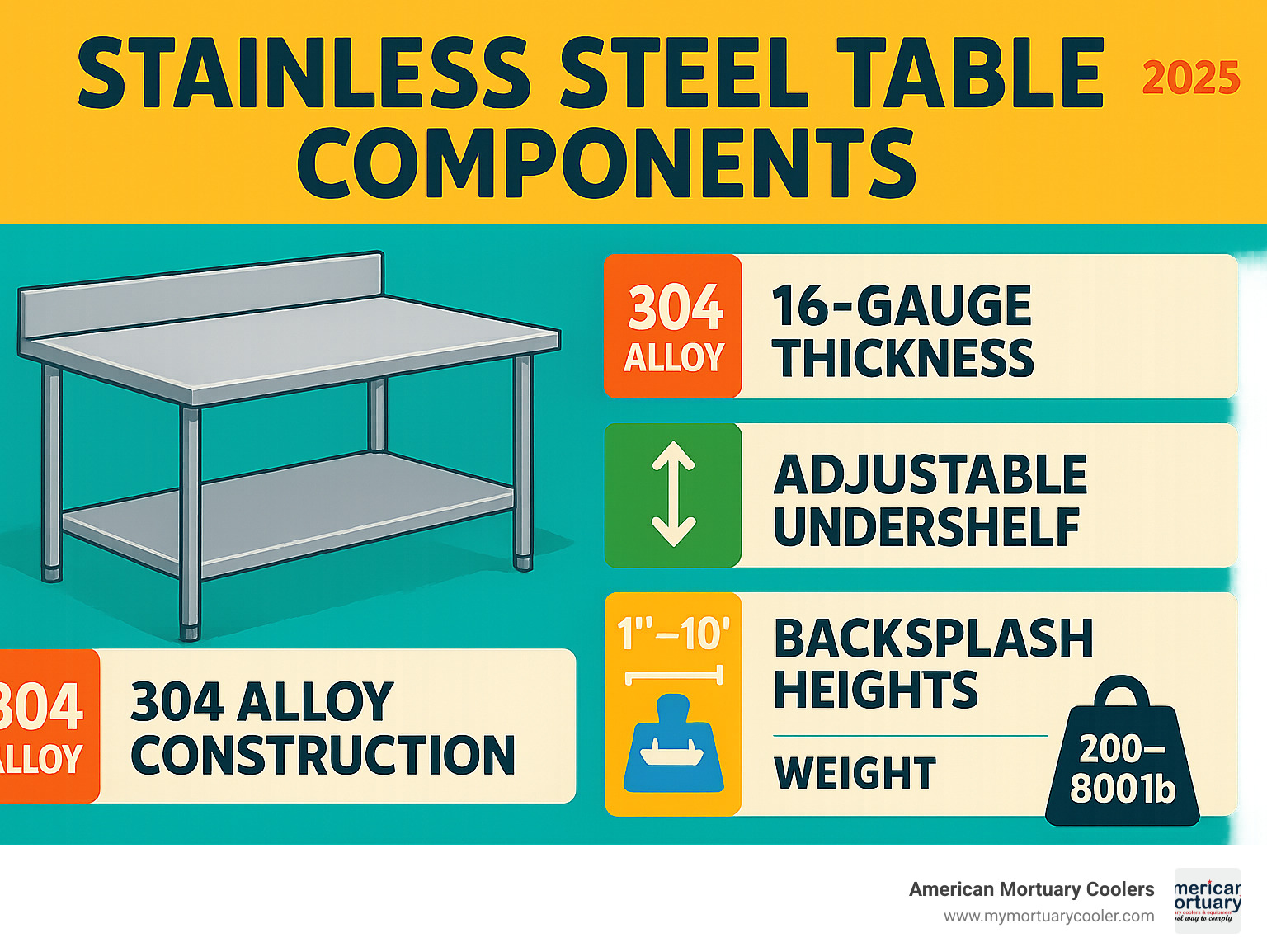

Gauge thickness is equally important, and here's where it gets a bit counterintuitive - lower numbers mean thicker steel. A 14-gauge table is significantly thicker and stronger than an 18-gauge model. We typically recommend 16-gauge as the sweet spot for most commercial applications.

| Grade | Chromium % | Nickel % | Best For | Corrosion Resistance |

|---|---|---|---|---|

| 304 | 18-20% | 8-10% | Food service, general use | Excellent |

| 316L | 16-18% | 10-14% | Marine, chemical environments | Superior |

| 430 | 16-18% | 0% | Budget applications | Good |

Why Alloy Choice Matters

Your choice of alloy grade isn't just about the initial price tag - it's about long-term performance and replacement costs. 304 stainless steel contains both chromium and nickel, giving it excellent corrosion resistance for most indoor applications. This is what we use for the majority of our mortuary tables because it handles frequent cleaning with disinfectants without showing wear.

316L stainless steel takes things up a notch with molybdenum added to the mix. This extra element makes it incredibly resistant to saltwater and aggressive chemicals. If you're setting up an outdoor kitchen near the coast or working with particularly harsh embalming chemicals, the extra cost of 316L pays for itself by avoiding premature replacement.

430 stainless steel is the budget option that still delivers decent performance. It lacks nickel, which makes it magnetic and less expensive to produce. While it won't handle harsh environments as well as 304 or 316L, it's perfectly adequate for basic food prep or light-duty applications where budget is the primary concern.

Gauge & Finish

Gauge thickness determines both the table's load capacity and its resistance to denting. 18-gauge steel works fine for light tasks like sandwich assembly or paperwork, but you'll want 14-gauge construction for heavy-duty work like meat processing or supporting heavy equipment. Most commercial kitchens find 16-gauge offers the best balance of strength and cost.

The surface finish affects both appearance and maintenance. The most popular brushed #4 finish has fine lines that help hide minor scratches and fingerprints. This finish is forgiving and easy to maintain with regular cleaning. Matte finishes reduce glare, which is helpful in brightly lit kitchens, while polished surfaces look stunning but show every fingerprint and water spot.

Sound-deadened tops are worth considering if noise is a concern. These tables have a special undercoating that reduces the metallic ringing when pots and pans hit the surface. This feature is particularly valuable in open kitchen designs or quiet environments like medical facilities.

Welded seams throughout the construction ensure no gaps where bacteria can hide, while adjustable feet help level the table on uneven floors. These details might seem minor, but they make a significant difference in daily use and long-term durability.

How to Choose the Best Stainless Steel Table

Finding the perfect stainless steel table doesn't have to be overwhelming. I've helped hundreds of clients choose the right table for their needs, and it always starts with the same simple question: what's your space like?

Start by measuring your available area carefully. Don't just measure the table footprint - you need clearance around it too. I've seen too many folks order a beautiful table that barely fits through their door! Consider how people will move around it during busy periods.

Standard sizes make shopping easier and keep costs down. The most popular size is 48"x24", which gives you plenty of workspace without dominating smaller rooms. Compact 24"x24" models work great in tight spaces, while large operations might need 96"x30" tables or bigger.

If standard sizes don't fit your needs, custom builds are absolutely worth considering. Yes, they typically cost 20-30% more, but when you're using the table daily for years, that perfect fit pays for itself.

Weight capacity matters more than most people realize. Basic tables handle 200 lbs, while heavy-duty models support 800 lbs or more. Think beyond just what you'll place on top - consider the dynamic forces from prep work, especially in busy kitchens or prep rooms.

Storage features can make or break your workflow. An undershelf gives you organized storage, while cross-bracing offers maximum strength. Overshelves keep frequently used items within reach, and drawers secure smaller tools and supplies.

Backsplash height depends on your work. Light prep needs just 1.5", but heavy-duty applications benefit from 10" or higher. Trust me - cleaning walls is much harder than cleaning backsplashes!

Casters add fantastic mobility, but they reduce stability. Locking casters give you the best of both worlds - roll it where you need it, then lock it down for stable work.

Price ranges tell a story. Basic models run $100-$300 and handle light duty just fine. Mid-range tables ($300-$1,000) offer better construction and features. Premium custom tables ($2,000-$5,000) deliver decades of reliable service in demanding environments.

For specialized medical storage needs, our Stainless Steel Medical Cabinets 101: Compare Top Options guide covers complementary solutions that work perfectly with your new table.

Budget vs Premium Brands

Budget brands on Amazon and similar platforms keep costs low, but you might sacrifice gauge thickness or weld quality. They're fine for occasional use, but daily heavy work will show their limitations quickly.

Mid-range brands like Gridmann and Uline offer solid NSF-certified tables with 16-gauge or 18-gauge construction. These hit the sweet spot for most commercial applications without breaking the budget.

Premium brands like Metro TableWorx, EnduraSteel, and Aero Manufacturing cost more upfront but deliver superior value. Their seamless welds, heavy-gauge steel, and comprehensive customization options create tables that last decades, not years.

I always tell clients that quality pays for itself. Premium stainless steel tables maintain their appearance and function longer, reducing replacement costs and eliminating frustrating downtime when you need them most.

The warranty tells you everything about a manufacturer's confidence. Budget brands offer minimal coverage, while premium manufacturers provide lifetime workmanship guarantees and responsive customer support.

Assembly & Installation Tips

Most stainless steel tables arrive either fully assembled or as knock-down kits. Fully welded tables offer superior strength but cost significantly more to ship. Knock-down tables require some assembly time but keep shipping costs reasonable.

Assembly typically takes 30-60 minutes with basic tools. The process involves attaching legs, installing shelves, and adjusting leveling feet. Most people find it straightforward, though having a helper makes positioning easier.

Here's a crucial tip: check your floor level before final adjustment. Uneven floors stress the frame and affect stability. If your floor has significant variations, address them before assembly or use adjustable feet to compensate.

Professional installation makes sense for complex tables with integrated sinks, electrical components, or custom mounting requirements. It ensures proper function and often maintains warranty coverage - a small investment for peace of mind.

Take time to read the manual completely before starting. While assembly is generally straightforward, understanding the sequence prevents mistakes that could damage components or create safety issues.

Care, Maintenance & Longevity

Taking care of your stainless steel tables isn't complicated, but doing it right makes all the difference. I've seen tables that look brand new after decades of heavy use, and others that look worn out after just a few years. The secret? Consistent, proper maintenance.

Daily cleaning is your best friend here. Use mild detergent and warm water to wipe down surfaces after each use. This simple step prevents buildup of grease, food particles, and other contaminants that can cause staining or corrosion over time.

Here's something many people don't know: always wipe in the direction of the grain. Stainless steel has a subtle grain pattern from manufacturing, and cleaning with the grain maintains that smooth finish. Going against the grain can create visible scratches that trap bacteria and make future cleaning harder.

For those stubborn stains or heat discoloration that sometimes appear, don't panic. Dedicated stainless steel cleaners contain mild acids that restore the surface to its original luster. These cleaners are specifically formulated to be safe for food-contact surfaces while being tough on stains.

What you want to avoid are abrasive cleaners, steel wool, or scouring pads. These might seem like they're doing a good job, but they're actually creating microscopic scratches where bacteria can hide. Stick to soft cloths and non-abrasive cleaning pads.

Periodic inspection should be part of your routine, especially in high-use environments. Check the welds for any signs of stress or cracking, make sure the leveling feet are still properly adjusted, and lubricate any moving parts like casters or drawer slides. Catching small issues early prevents expensive repairs down the road.

In mortuary settings, we recommend checking hydraulic systems monthly and ensuring drainage channels remain clear. For detailed maintenance schedules specific to embalming equipment, our guide on Hydraulic Embalming Tables & Prep Room Supplies covers everything you need to know.

One aspect of stainless steel tables that doesn't get enough attention is their environmental impact - or rather, their lack of negative impact. These tables are 100% recyclable at the end of their service life. Combined with their incredible durability, this makes them one of the most sustainable choices you can make for professional equipment.

I've personally delivered tables that are still in daily use after 20+ years. That kind of longevity isn't just good for your budget - it's good for the planet too. When you invest in quality stainless steel, you're making a choice that pays dividends for decades.

Frequently Asked Questions about Stainless Steel Tables

When it comes to stainless steel tables, we get the same questions over and over again. Having worked with funeral homes across the country for years, I've learned that most folks have similar concerns about weight capacity, maintenance, and choosing the right grade for their specific needs.

Let me share the answers to the three most common questions we hear at American Mortuary Coolers. These insights come from real-world experience helping funeral directors choose the right equipment for their prep rooms.

What weight can a typical table hold?

Most standard stainless steel tables are built to handle 600 pounds safely. That's plenty for typical prep room work, but if you need something beefier, deluxe models can support 750 pounds or more. The key factors that determine weight capacity are the gauge thickness of the steel, how the frame is constructed, and the leg design.

Here's what really matters though - you need to think beyond just static weight. When you're working on a table, there's movement and pressure that creates what we call dynamic loads. A table might hold 600 pounds sitting still, but working on that same weight requires a stronger table.

For heavy-duty applications, look for tables with 14-gauge tops and reinforced frames. These can handle over 800 pounds and are built to last decades. If you're dealing with extremely heavy equipment or need maximum stability, consider tables with additional cross-bracing or pedestal bases.

How do I prevent scratches & stains?

The secret to keeping your stainless steel looking great is simple: prevention beats cure every time. Use cutting boards for any knife work, never drag heavy items across the surface, and clean up spills right away. When you're cleaning, always wipe in the direction of the grain - this keeps the brushed finish looking uniform.

If you do get scratches (and let's be honest, you will), light ones can often be buffed out with stainless steel polish. Deeper scratches might need professional refinishing, but that's rare if you take good care of your table.

Regular maintenance with the right cleaners prevents most staining issues. We've seen tables that are decades old still looking nearly new because the owners took a few minutes each day to clean them properly. It's not complicated - just consistent care makes all the difference.

Which alloy is best for outdoor or marine use?

If you're dealing with outdoor conditions or saltwater exposure, 316L stainless steel is your best friend. The molybdenum content in this grade provides excellent protection against saltwater corrosion and harsh weather that would eat through lesser materials.

Yes, 316L costs more than standard 304 stainless steel, but it's worth every penny for outdoor kitchens, marine applications, or anywhere you've got salt air. I've seen 304 tables start showing corrosion within months near the ocean, while 316L tables look perfect after years of exposure.

This grade maintains both its appearance and functionality even in challenging environments. If you're investing in a table that will face the elements, don't cut corners on the alloy - you'll just end up replacing it sooner and spending more in the long run.

Conclusion

When it comes to selecting the perfect stainless steel table for your facility, success lies in understanding your specific needs and matching them with the right combination of features. The decision involves weighing alloy grade against budget, gauge thickness against intended use, and standard sizes against custom configurations.

Pricing factors play a crucial role in your investment decision. Gauge thickness typically has the biggest impact on cost - 14-gauge tables can cost 40% more than 18-gauge models. Alloy grade follows closely, with 316L commanding a premium over standard 304 stainless steel. Size matters too, with larger tables costing proportionally more due to material and shipping considerations.

Customization options open up exciting possibilities for optimizing your workflow. Whether you need integrated sinks for prep work, hydraulic height adjustment for ergonomics, or specialized drainage systems for mortuary applications, these features can transform a basic table into a productivity powerhouse. The typical 20-30% premium for customization often pays for itself through improved efficiency and reduced labor costs.

Here's where the lifetime value equation becomes interesting. We've watched funeral homes struggle with cheap tables that develop rust spots, wobbly legs, or damaged surfaces within just a few years. Meanwhile, facilities that invested in premium stainless steel tables from the start are still using the same equipment decades later with minimal maintenance.

At American Mortuary Coolers, we've built our reputation on understanding exactly what funeral homes need from their prep room equipment. Our custom mortuary-grade stainless solutions aren't just tables - they're carefully engineered workstations designed to handle the unique demands of funeral service professionals. We deliver these custom solutions nationwide across the contiguous 48 states, ensuring your facility gets equipment that truly fits your space and workflow.

The beauty of working with specialized suppliers is the attention to detail. We know that mortuary work requires features like perforated surfaces for drainage, chemical-resistant finishes, and height adjustability for ergonomics. These aren't afterthoughts - they're integral design elements that make your daily work easier and more efficient.

Whether your needs run toward a straightforward prep table for basic embalming work or a sophisticated hydraulic system with integrated accessories, the right stainless steel table becomes the foundation of your prep room operations. For detailed guidance on navigating the supplier landscape and finding the right partner for your facility, our A-Z Guide to Finding Mortuary Table Suppliers walks you through the entire selection process.

The combination of durability, hygiene benefits, and long-term value makes quality stainless steel tables an easy choice for serious professionals. With thoughtful selection and proper care, these tables become reliable partners in your daily work - equipment you can count on for years of dependable service while maintaining the professional standards your families deserve.