What Makes an Embalming Station Essential for Modern Funeral Homes

An embalming station is a specialized stainless steel workstation designed for the preservation and preparation of deceased bodies in funeral home prep rooms. These integrated units combine essential components like sink basins, hydro aspirators, mixing faucets, and safety features into a single, sanitary workspace.

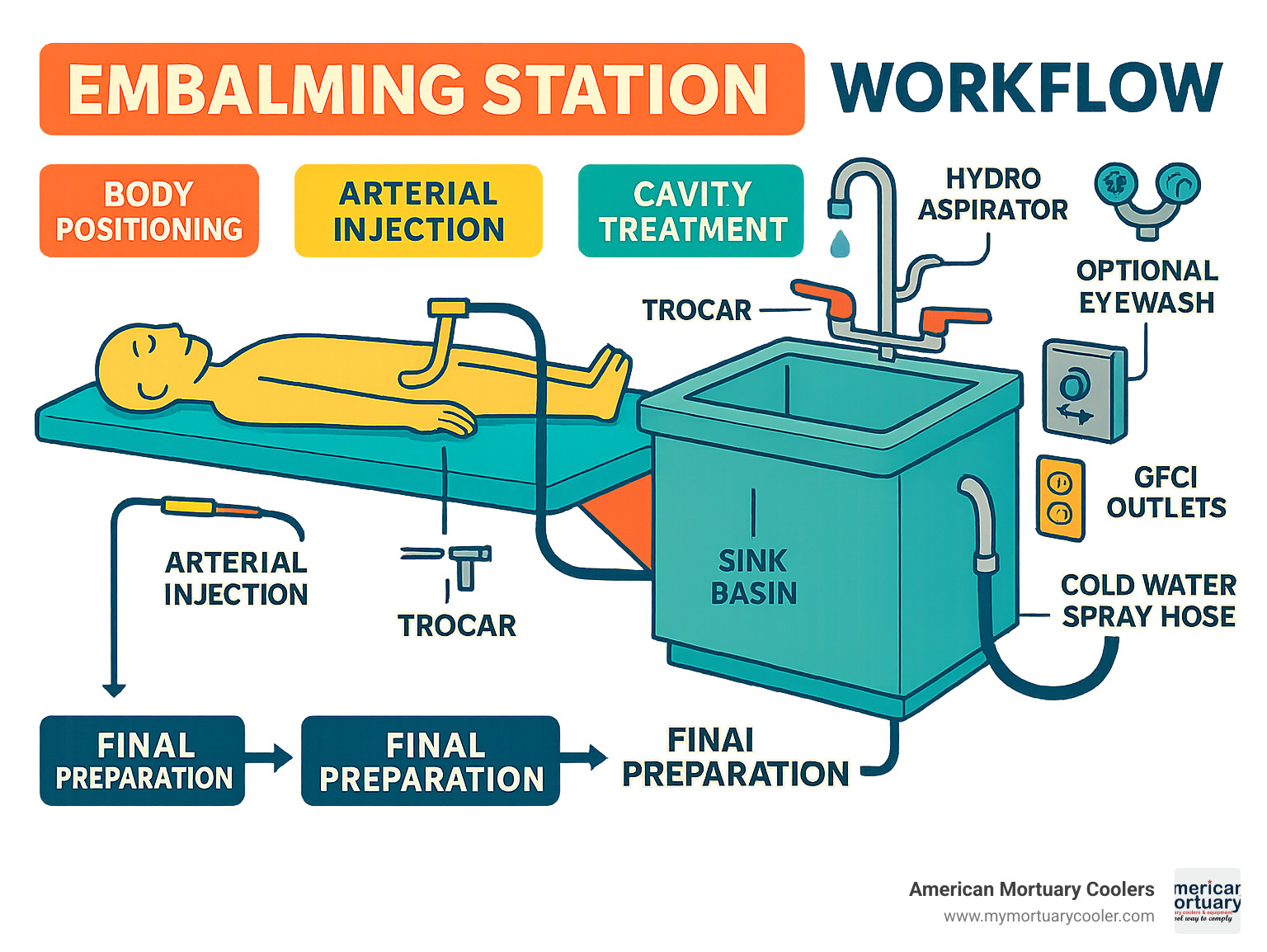

Key Components of an Embalming Station:

- Large stainless steel sink basin for body preparation

- Hydro aspirator for fluid removal and waste disposal

- Hot and cold water mixing faucet with tall spout

- GFCI-protected electrical outlets for safety

- Cold water spray hose with adjustable nozzle

- Optional eyewash attachment for emergency use

- Splash guards to contain fluids and maintain sanitation

Common Types Available:

- Wall-mounted stations - Space-saving design, typically $5,585-$6,695

- Floor-mounted units - Mobile options with adjustable height

- Flushing stations - Improved drainage and cleaning capabilities

- Ventilated models - Built-in fume extraction systems

Most modern embalming stations are constructed from 304 stainless steel for durability and easy sanitization, with typical lead times of 5-6 weeks for delivery. These stations serve as the central hub for arterial embalming, cavity treatment, and body restoration procedures that funeral homes perform daily.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right embalming station equipment for their facilities.

Must-know embalming station terms:

Why This Guide Matters

The funeral industry has evolved significantly since embalming became widespread during the Civil War era. Today, embalming remains essential for funeral homes, particularly when public viewings are planned or when bodies must be transported across state lines—requirements that many states legally mandate.

Modern funeral homes are increasingly investing in prep-room upgrades to meet stricter health and safety standards while improving workflow efficiency. With the majority of US funeral homes requiring embalming for public viewings, having the right embalming station setup directly impacts both operational success and regulatory compliance.

What Is an Embalming Station?

Think of an embalming station as the command center of any funeral home's prep room. It's a specialized workstation that brings together everything an embalmer needs in one well-designed unit. Unlike a basic sink or simple table, these stations are purpose-built for the delicate art of body preservation.

At its heart, an embalming station serves one primary purpose: providing a clean, efficient workspace for both arterial embalming (where preservative chemicals are injected through the circulatory system) and cavity embalming (treating internal organs and body cavities).

What sets these stations apart is their integrated collection systems that handle the complex fluid management requirements of embalming. The hydro aspirator removes waste fluids, while specialized drainage systems keep everything flowing smoothly throughout the process.

Core Role in the Prep Room

Every prep room needs a hub, and that's exactly what an embalming station provides. It's where the workflow naturally centers, bringing together all the major preparation activities in one logical location. The design makes perfect sense—embalmers can position the body properly while having immediate access to water, drainage, electrical power, and chemical disposal systems.

Sanitation is absolutely critical in this environment, which is why these stations feature non-porous surfaces and seamless joints that don't give bacteria anywhere to hide. The large sink basins are sized to handle thorough cleaning and disinfection procedures that keep everything safe and compliant.

Embalming Station vs. Autopsy Table

People often confuse embalming stations with autopsy tables, but they're designed for completely different jobs. Autopsy tables focus on examination and dissection work, typically featuring perforated surfaces for drainage and specialized lighting for detailed procedures.

The function focus of an embalming station is entirely different. These units prioritize fluid management and chemical handling above all else. You'll find hydro aspirators for waste removal, mixing faucets for chemical preparation, and integrated electrical systems designed specifically for embalming machines.

Drainage systems tell the whole story. Autopsy tables handle intermittent drainage needs, while embalming stations are built for continuous fluid flow throughout lengthy procedures. The ventilation requirements also differ significantly—embalming stations often need more robust fume extraction due to the chemicals involved.

Key Components & Construction Materials

When you're investing in an embalming station, understanding what makes these workhorses tick is crucial for making the right choice. Every component serves a specific purpose in creating a safe, efficient workspace.

The sink basin forms the heart of any embalming station. These aren't your typical kitchen sinks—they're large, deep basins designed to handle the realities of body preparation. The generous size accommodates bodies of all sizes while containing the various fluids and cleaning solutions that are part of daily operations.

Your hydro aspirator is where the real magic happens for fluid management. This ingenious device harnesses water pressure to create powerful suction for removing blood and bodily fluids during embalming procedures. The best modern units come with anti-clog aspirator heads that prevent those frustrating blockages, plus reverse flow functions that can instantly clear any clogs.

Safety takes center stage with GFCI outlets that protect you from electrical hazards in wet environments. The hot and cold mixing faucet with its tall spout gives you precise temperature control—essential when you're preparing solutions or cleaning instruments.

The cold water spray hose with adjustable nozzle becomes your best friend for cleaning procedures, while splash guards keep fluids contained and your prep room sanitary. Many stations also include optional eyewash attachments—a safety feature that's becoming less optional and more essential as safety standards evolve.

More info about essential equipment

Why 304 Stainless Steel Dominates

There's a reason why 304 stainless steel has become the gold standard for embalming station construction. This specific grade of stainless steel stands up to the harsh realities of prep room life like nothing else.

Corrosion resistance is the big winner here. Embalming chemicals, blood, and other bodily fluids can be incredibly corrosive to lesser materials. With 304 stainless steel, you're looking at decades of reliable service.

The ease of disinfection that comes with 304 stainless steel is a game-changer for maintaining the hospital-grade cleanliness your prep room demands. Its non-porous surface means bacteria can't hide in tiny cracks or crevices, and you can hit it with strong disinfectants without worrying about damaging the material.

Safety Features That Matter

Modern embalming stations pack more safety features than ever before. Eyewash attachments are becoming standard equipment rather than optional extras, providing immediate emergency response when chemical splashes happen.

Anti-clog aspirator systems prevent those dangerous backups that could expose you to contaminated fluids. The reverse flow function found in deluxe aspirators can instantly clear blockages, keeping fluid flow moving smoothly and reducing your exposure to potentially hazardous materials.

GFCI protection and sealed wiring systems ensure electrical safety in the inherently wet environment of prep rooms.

Types & Configurations of Embalming Stations

When it comes to choosing the right embalming station for your funeral home, you'll find there's no one-size-fits-all solution. The variety of configurations available today reflects the real-world challenges funeral directors face—from cramped prep rooms in historic buildings to modern facilities with unlimited space.

The main decision points usually come down to your available space, daily case volume, and how your staff prefers to work. Wall-mounted stations are fantastic space-savers but require more complex installation. Floor-mounted units give you flexibility to rearrange your prep room later.

| Station Type | Space Required | Price Range | Best For |

|---|---|---|---|

| Wall-Mounted | Minimal floor space | $5,585-$6,695 | Small prep rooms |

| Floor-Mounted | Standard footprint | $5,375-$6,695 | Flexible layouts |

| Flushing System | Standard + drainage | Premium pricing | High-volume facilities |

| Ventilated | Standard + ventilation | Premium pricing | Safety-focused operations |

Wall-Mounted Embalming Station Variants

Wall-mounted embalming stations are the go-to choice when floor space is precious. These units attach directly to your wall, freeing up that valuable prep room real estate for other essential equipment or simply making it easier for staff to move around during procedures.

The trade-off is installation complexity. Your walls need proper reinforcement, and coordinating the plumbing and electrical connections requires more planning than floor-mounted alternatives. You'll also need to factor in the 5-6 week lead time, similar to other configurations.

Despite the higher upfront investment and installation challenges, many funeral homes find the space savings worth every penny. This is especially true in urban locations where every square foot of prep room space comes at a premium.

Floor-Mounted & Pedestal Options

Floor-mounted embalming stations offer the ultimate in flexibility. Many models come with adjustable height features, letting your staff customize the working level for different procedures or operator comfort. Some units even include casters for mobility, though most are designed as permanent installations.

One of the standout features in many floor-mounted units is the integrated disposal system. These typically include powerful 0.75 hp waste disposal units that can handle the organic matter you encounter during embalming procedures. This means less manual waste handling and better overall sanitation in your prep room.

Ventilated & Flushing Systems

Ventilated embalming stations address the growing focus on operator safety and chemical exposure management. These systems feature built-in fume capture technology that removes hazardous vapors right at the source. This protects your staff while maintaining better air quality throughout your prep room.

Flushing systems take the cleaning and sanitation game to the next level. They feature rapid rinse capabilities with pressure hoses and high-performance spray assemblies that make your daily cleaning procedures much more efficient. The improved drainage systems can handle larger volumes of fluids, making them particularly valuable for high-volume facilities.

Safety, Sanitation & Regulation Essentials

Running a prep room means dealing with some serious safety rules. OSHA's Formaldehyde Standard sets the bar high for chemical exposure limits, and for good reason—formaldehyde isn't something you want to mess around with. These regulations work hand-in-hand with state embalming laws and NFPA 99 standards to create a comprehensive safety framework that every funeral home must follow.

The beauty of a well-designed embalming station is that it helps you meet these requirements without turning your prep room into a maze of safety equipment. When safety features are built into the station itself, you're not scrambling to add eyewash stations here and ventilation there—it's all integrated into one cohesive workspace.

Scientific research on embalming safety

How Stations Improve Operator Safety

Think about how many times you reach for controls, adjust hoses, or clean surfaces during a single embalming procedure. A poorly designed workspace turns each of these actions into a potential safety hazard. Modern embalming stations tackle this problem by creating ergonomic reach zones where everything you need is within comfortable range.

Splash control goes way beyond just having a drain. The best stations feature integrated splash guards and contained drainage systems that keep chemicals where they belong—not on your clothes or skin.

Quick-disconnect hoses might seem like a small detail, but they're a game-changer for safety. When you can connect and disconnect equipment quickly and cleanly, you spend less time fumbling with connections in a chemical-rich environment.

Meeting Health-Department Inspections

Health department inspectors know what they're looking for, and they've seen every shortcut in the book. The good news is that a quality embalming station makes their job—and yours—much easier. Inspectors focus heavily on sanitation practices and equipment condition, two areas where integrated stations really shine.

Recordkeeping requirements can feel overwhelming, but they're much simpler when your equipment is designed for easy maintenance. Eyewash systems need regular testing and documentation—stations with built-in eyewash make this routine rather than a hassle.

Installation, Pricing & Maintenance Guide

Setting up your new embalming station doesn't have to be a headache, but it does require some planning. Think of it like installing a high-end kitchen—you need the right connections in the right places before anything else can happen.

Most modern stations are designed with single-point connections that make installation much simpler than older models. Your plumber will need to run hot and cold water supply lines, connect the drainage system, and ensure proper vent stack access. The electrical work is usually straightforward—most units run on standard 110-120V service with GFCI protection.

Current pricing for quality stainless steel embalming stations typically falls between $5,375 and $6,695. Wall-mounted units often cost more due to the extra installation complexity, while floor-mounted options can offer better value if you have the floor space to spare.

Custom lead times usually run 5-6 weeks for most configurations. At American Mortuary Coolers, we work hard to keep our lead times reasonable while maintaining the quality craftsmanship you need.

More info about comparing options

Choosing the Right Embalming Station

Picking the right embalming station is about more than just finding the lowest price. Your facility size and layout will largely determine whether a wall-mounted or floor-mounted unit makes the most sense. If you're working with a smaller prep room, that wall-mounted station might be worth the extra cost for the space savings alone.

Case volume matters too. If you're handling dozens of cases each month, you'll want the durability and features that come with higher-end models. A station that breaks down during your busy season isn't saving you any money.

Don't forget to think about the total cost of ownership. That includes installation expenses, ongoing maintenance, and potential future upgrades. Some stations offer modular designs that let you add features as your needs grow or your budget allows.

Maintenance Checklist & Cleaning Schedule

Keeping your embalming station in top condition isn't complicated, but it does require consistency. Daily maintenance should include a thorough rinse of all surfaces and drainage systems. This prevents chemical buildup and keeps bacteria from taking hold.

Weekly disinfection procedures should use chemical disinfectants that play nice with stainless steel surfaces. Monthly inspections are your chance to catch small problems before they become big headaches. Check gaskets, seals, and any moving parts for wear or damage.

Annual professional service should include a detailed inspection of all systems, calibration of pressure and flow controls, and replacement of any wear items. The hydro aspirator deserves special attention since clogs or reduced suction can bring your workflow to a grinding halt.

Latest Innovations & Future Trends

The embalming station industry is experiencing exciting changes as manufacturers respond to evolving safety standards and operator needs. These innovations aren't just about adding bells and whistles—they're focused on making daily operations safer, more efficient, and less physically demanding for funeral professionals.

Height-adjustable sinks represent one of the most practical advances in recent years. These systems recognize that embalmers come in different heights and that procedures vary in their physical demands. Instead of forcing operators to work at uncomfortable angles, adjustable stations can accommodate everyone, reducing back strain and improving precision during delicate procedures.

Touchless faucets and controls might seem like a luxury, but they address a real contamination concern. When you're working with bodily fluids and chemicals, the last thing you want is to spread contamination by touching controls with soiled gloves. These systems use sensors to activate water flow and adjust temperatures, keeping the workspace cleaner and safer.

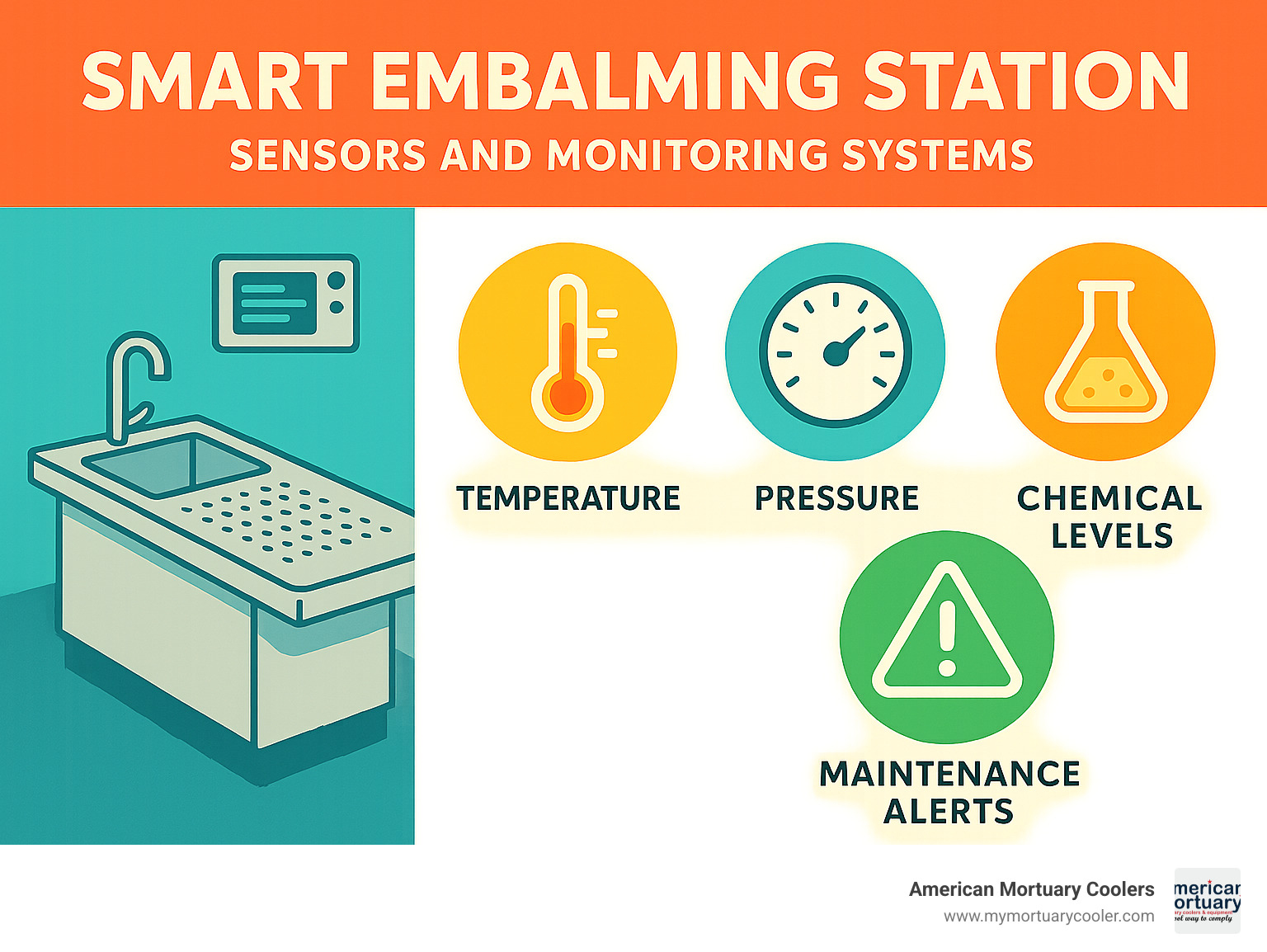

Built-in data loggers are changing how funeral homes track their operations. These systems quietly monitor chemical usage, procedure times, and equipment performance, providing valuable insights for facility management. Imagine being able to track exactly how much embalming fluid you're using per case or identifying patterns that could improve efficiency.

The push toward eco-friendly materials reflects growing environmental awareness in the funeral industry. Manufacturers are exploring sustainable alternatives to traditional materials while maintaining the durability and sanitation standards that funeral homes require.

Modular add-on systems are perhaps the most practical innovation for budget-conscious funeral homes. Instead of replacing an entire embalming station when needs change, these systems allow you to upgrade specific components or add new capabilities.

Remote monitoring capabilities enable proactive maintenance. These systems can detect when equipment needs attention before it fails, reducing unexpected downtime and service costs. For funeral homes that can't afford equipment failures during critical procedures, this predictive approach to maintenance is invaluable.

At American Mortuary Coolers, we're watching these trends closely and incorporating the most practical innovations into our custom solutions. The goal isn't to add complexity—it's to make your daily operations smoother, safer, and more efficient.

Frequently Asked Questions about Embalming Stations

When funeral directors are considering a new embalming station, they often have practical questions about functionality, installation, and maintenance. Let me address the most common concerns I hear from funeral home owners across the country.

How does a flushing station differ from a standard unit?

The difference between a flushing station and a standard embalming station comes down to cleaning power and drainage capacity. While standard units handle basic fluid management well, flushing stations take it up a notch with rapid rinse capabilities that include pressure hoses and high-performance spray assemblies.

Think of it this way: if you're running a high-volume facility where you're performing multiple procedures daily, the improved drainage systems in flushing stations can handle much larger volumes of fluids without backing up or slowing down your workflow. The improved cleaning efficiency means less time spent on sanitation between cases, which translates to better productivity.

The trade-off is cost—flushing systems typically command premium pricing over standard configurations. But for busy funeral homes, the time savings and improved sanitation capabilities often justify the investment.

What plumbing connections are required for installation?

Most modern embalming stations are designed with single-point connections to keep installation straightforward and costs reasonable. You'll need hot and cold water supply lines—typically 3/4" connections to ensure adequate flow rates for mixing chemicals and cleaning procedures.

The drainage side requires 2" or larger drain lines to handle the substantial fluid volumes generated during embalming procedures. This isn't like a regular sink drain—you're dealing with blood, embalming fluids, and cleaning solutions that need to move quickly through the system.

Vent stack connections may also be required depending on your local plumbing codes and the specific drainage system design. The good news is that most manufacturers, including us at American Mortuary Coolers, design our stations to work with standard plumbing rough-ins, so your plumber won't be scratching their head trying to figure out unusual requirements.

How often should the hydro aspirator be serviced?

The hydro aspirator is the workhorse of your embalming station, so keeping it in good shape is crucial for smooth operations. I recommend a weekly inspection and cleaning to prevent clogs and maintain optimal suction performance—it's much easier to prevent problems than fix them after they've disrupted your workflow.

Monthly detailed cleaning should include taking apart the aspirator components for thorough inspection. Look for wear, buildup, or any signs that suction performance is declining. This is when you'll catch small issues before they become big headaches.

Annual professional service is where you'll want to bring in a technician to replace wear items and calibrate suction levels properly. Units with anti-clogging features and reverse flow capabilities—like the deluxe aspirators we install—may need less frequent intensive service, but that regular maintenance is still essential.

A well-maintained aspirator prevents those frustrating moments when suction fails in the middle of a procedure. It's one of those investments in routine maintenance that pays for itself in prevented downtime and smoother operations.

Conclusion

Choosing the right embalming station isn't just about buying equipment—it's about investing in the heart of your prep room operations. The decisions you make today will impact your daily workflow, staff safety, and regulatory compliance for years to come. Quality equipment pays for itself through improved efficiency, reduced downtime, and the peace of mind that comes from reliable performance.

At American Mortuary Coolers, we understand that every funeral home has unique needs. That's why we craft custom mortuary equipment right here in Tennessee, designed specifically for your facility's requirements. Whether you're working with a compact prep room that needs a space-saving wall-mounted unit or running a high-volume operation that demands a fully-featured flushing system, we've got you covered.

Our custom U.S. craftsmanship means you're not getting a one-size-fits-all solution. We take the time to understand your specific challenges—from space constraints to case volume—and build equipment that addresses your real-world needs.

Durability is at the core of everything we build. We use premium 304 stainless steel construction because we know your embalming station needs to perform reliably day after day, year after year. The funeral industry doesn't allow for equipment failures, and neither do we.

Nationwide delivery across the contiguous 48 states means distance isn't a barrier to getting the right equipment. We handle the logistics so you can focus on what matters most—serving families in their time of need.

By understanding your options and partnering with a manufacturer who puts your needs first, you're not just buying equipment—you're investing in your facility's future success.