Why Walk-In Cooler Parts Matter for Your Business Operations

Walk-in cooler parts are the essential components that keep your refrigeration system running efficiently and your products at safe temperatures. Here's what you need to know:

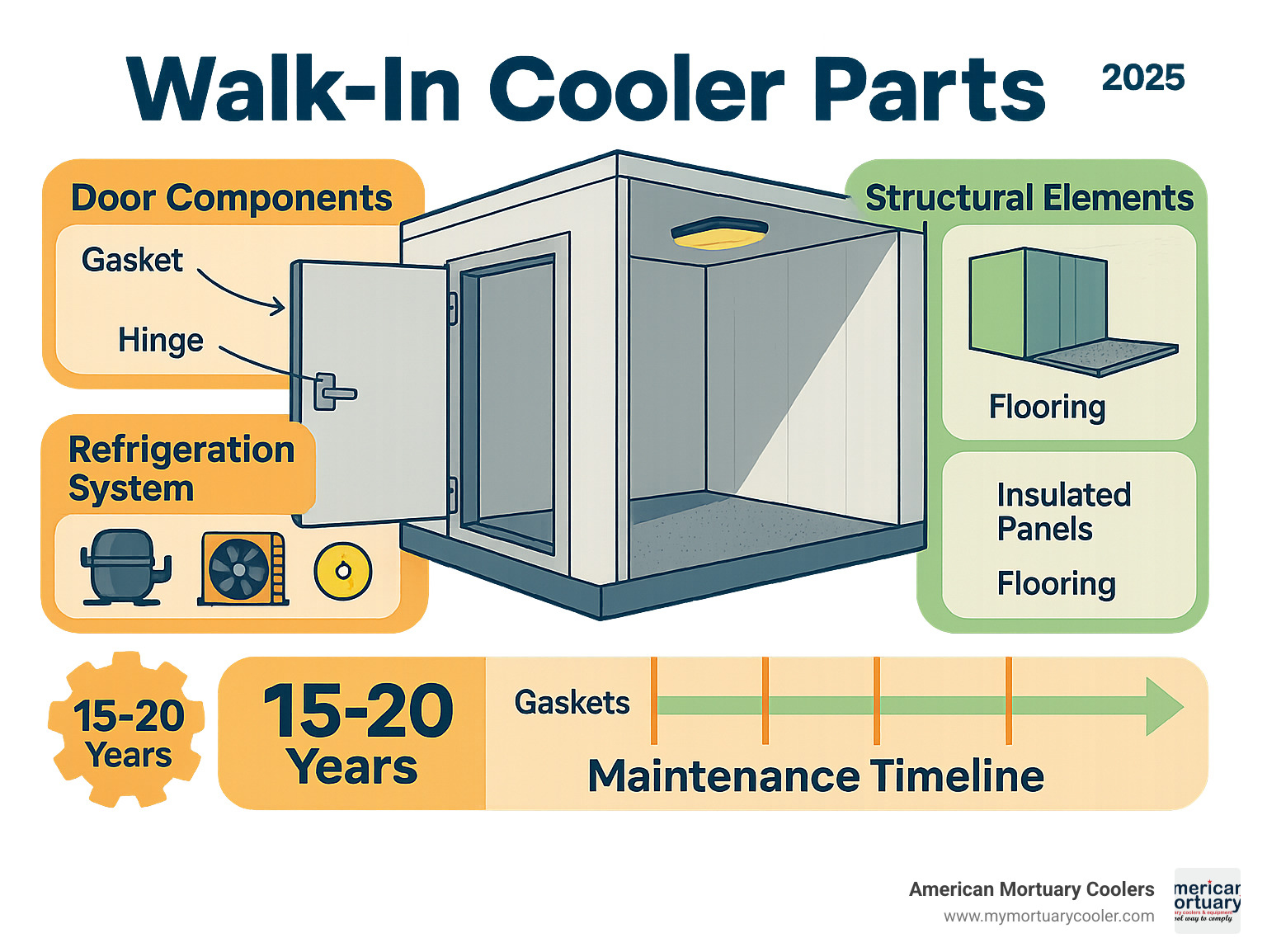

Essential Walk-In Cooler Parts:

- Door components - gaskets, hinges, handles, latches, and closers

- Refrigeration system - compressor, condenser, evaporator, expansion valve, thermostat

- Structural elements - insulated panels, cam-locks, flooring, lighting

- Accessories - shelving, strip curtains, pressure relief ports, thermometers

Most frequently replaced parts: Door gaskets, hinges, evaporator fans, and handles due to daily wear and temperature stress.

A well-maintained walk-in cooler can last between 15 and 20 years, but only with proper care and timely replacement of worn components. Daily usage in busy foodservice workspaces can be rough on your walk-in cooler.

The stakes are high when parts fail. Worn door gaskets can cause air leaks and ice buildup that eventually push panels apart, making your entire unit inoperable. Failed hinges or handles create safety hazards and temperature control problems. Damaged insulation drives up energy costs and puts product safety at risk.

Walk-in freezer parts face even greater challenges than cooler parts. Sub-zero temperatures create extra stress on components, causing them to crack and break more frequently than their cooler counterparts.

I'm Mortuary Cooler, a national level mortuary cooler supplier and us cooler supplier with extensive experience helping facilities maintain their refrigeration systems through quality walk-in cooler parts and expert guidance.

Simple walk-in cooler parts glossary:

Anatomy & Function: Inside a Modern Walk-In Cooler

Think of your walk-in cooler as a carefully orchestrated system where every component has a specific job. When you understand how these walk-in cooler parts work together, you'll be better equipped to spot problems before they become costly breakdowns.

The magic happens through the refrigeration cycle - a continuous loop that moves heat from inside your cooler to the outside world. The compressor acts like the system's heart, pumping refrigerant gas under high pressure to the condenser. The condenser releases heat outside while turning the gas into liquid.

Next, the liquid refrigerant hits the expansion valve that drops both pressure and temperature. This super-cold liquid then enters the evaporator, where it absorbs heat from inside your cooler and transforms back into gas, completing the circle.

Your cooler's structural elements trap the cold air inside. Insulated panels with cam-locks create an airtight fortress, while door gaskets and pressure relief ports maintain the perfect balance. Modern sensors and thermostats keep everything running smoothly.

Refrigeration System Components Explained

The compressor is your system's workhorse - it's constantly circulating refrigerant flow and creating the pressure differences that make cooling possible. Modern compressors come with electronic controls that improve efficiency and help you stay compliant with food safety regulations.

Your condenser is where heat rejection happens. Remote systems place this component away from your walk-in, preventing unwanted heat buildup. Self-contained units keep everything together for convenience.

The evaporator is where cooling occurs inside your box. Penthouse units mount the evaporator outside to give you maximum interior space and headroom.

The expansion valve controls refrigerant flow and pressure reduction with precision. Your thermostat serves as the brain, monitoring temperature and controlling when the system kicks on and off.

Scientific research on commercial refrigeration efficiency shows that properly maintained systems can slash energy consumption by 20-30% compared to poorly maintained units.

Structural Elements That Hold the Cold

Insulated panels are your first line of defense against heat infiltration. Most walk-in cooler panels pack 4 inches of insulation between inner and outer metal skins. Urethane insulation can deliver an impressive R-value of up to R-32 for freezers, easily exceeding the R-25 requirement for coolers.

Cam-action locks connect panels and create airtight seals. Combined with quality gaskets, these locking devices prevent air infiltration that could compromise temperature control.

Floor systems provide thermal protection when needed. Vapor-proof lighting withstands cold, humid conditions, ensuring consistent illumination. Interior ramps provide safe entry for carts while maintaining structural integrity.

High-Wear Walk-In Cooler Parts & Freezer Counterparts

When you're managing a commercial facility, understanding which walk-in cooler parts take the biggest beating can save you both money and headaches. Some components endure constant stress, while others live relatively easy lives.

Door components face the toughest conditions. Hinges support heavy doors through thousands of cycles monthly. Handles get grabbed and pulled by staff during busy periods. Door closers fight against spring tension and temperature differences constantly.

The refrigeration side isn't easier. Fan motors run around the clock, circulating air to keep temperatures steady. In freezer applications, defrost heaters cycle constantly, dealing with dramatic temperature swings. Thermostats and sensors monitor conditions non-stop, with electronic components vulnerable to power surges and moisture.

Walk-in freezer parts face a whole different level of punishment compared to cooler counterparts. Sub-zero temperatures make materials brittle and prone to cracking. Ice formation creates mechanical stress that can push components apart. This harsh environment explains why freezer parts need replacement much more frequently.

Most Frequently Replaced Walk-In Cooler Parts

Door gaskets top the list. These flexible seals prevent air leaks but constantly get compressed and deal with temperature changes. When they fail, warm air creates condensation that freezes solid. In severe cases, ice buildup can push panels apart and make your entire walk-in unusable.

Hinges work hard supporting door weight through countless cycles. Heavy doors and frequent use accelerate wear. Failed hinges throw off door alignment and stress other components.

Handles and latches get direct abuse from staff, carts, and equipment. A broken handle creates safety hazards and access problems during critical operations.

Evaporator fans run continuously to circulate air and maintain uniform temperatures. Motor bearings wear out from constant use, and fan blades can get damaged.

Defrost components in freezer applications face extreme temperature swings. These components often fail without warning, leading to ice buildup and system problems.

More info about walk-in cooler door hardware provides detailed guidance on maintaining these critical components.

Walk-In Cooler Parts vs Walk-In Freezer Parts

The difference between operating at 35°F versus -10°F creates completely different maintenance challenges.

Temperature stress hits freezer components hard. Sub-zero environments make materials brittle and prone to cracking. Ice formation causes immediate problems - even tiny air leaks create ice buildup that interferes with door operation and blocks drainage.

Heater wire circuits are essential for freezer doors to prevent ice buildup around seals. Inside safety releases become critical in freezer applications where someone could become trapped. Gasket compression affects freezer gaskets more severely due to extreme temperature cycling.

Maintenance & Replacement Strategies for Long-Lasting Performance

Taking care of your walk-in cooler parts before they break down saves you from major headaches later. Smart maintenance keeps your cooler running smoothly for years and prevents emergency calls when your system fails.

Stay ahead of problems instead of chasing them. Monthly door component inspections, quarterly refrigeration system checks, and annual professional maintenance create a safety net that protects your investment.

A failing door gasket might seem small, but it can lead to ice buildup that pushes panels apart. What starts as a $20 gasket replacement can become a multi-thousand-dollar disaster if ignored.

Cleaning condenser coils and evaporator fins regularly makes a huge difference. Dirty coils force your system to work twice as hard. Simple cleaning with mild detergent solution can cut energy bills significantly.

Door gasket inspection deserves special attention. Close your door on a dollar bill and try to pull it out. If it slides out easily, your gasket needs replacement.

Lubrication for moving parts like hinges and latches prevents grinding and sticking. Use food-safe lubricants to keep everything operating smoothly.

How to Spot a Failing Component

Your walk-in cooler talks to you - you just need to know its language.

Frost patterns tell a story. Ice forming in unusual places means air is leaking. Ice around door frames suggests gasket problems. Ice on evaporator coils points to airflow issues.

Listen to your equipment. When that gentle hum changes to grinding, clicking, or squealing, pay attention. Fan motors grind when bearings wear out. Compressors that click repeatedly might have electrical problems.

Temperature drift is your early warning system. Gradual temperature increases mean something is struggling - dirty coils, failing thermostats, or small refrigerant leaks.

Utility bills can be better diagnostics than expensive testing. Sudden energy cost jumps mean your system is working harder than it should.

Step-by-Step Guide: Replacing Walk-In Cooler Parts Safely

Safety is essential when working on refrigeration equipment. Cold temperatures, electrical components, and sharp edges create real hazards.

Start with proper protective equipment. Safety glasses, gloves, and appropriate clothing protect you from debris, sharp edges, and cold surfaces.

Lock-out and tag-out procedures prevent accidents. Disconnect power at the main panel and physically lock it out. Tag the disconnect with your name and date.

Match OEM part numbers exactly for safety and warranty protection. Using wrong parts creates dangerous conditions and voids warranties.

Follow manufacturer instructions for proper torque specifications, electrical connections, and mounting procedures.

Test everything before finishing to ensure your repair solved the problem. Check temperatures, listen for unusual sounds, and verify safety features work.

More info about walk-in cooler handle replacement walks you through one of the most common repairs.

Smart Upgrades: Doors, Shelving, Lighting, Insulation & Flooring

When your walk-in cooler parts start showing their age, smart upgrades can breathe new life into your system while improving efficiency and safety.

Modern replacement doors offer superior insulation, upgraded hardware, and improved safety features. You'll choose between flush mount doors for recessed frames, or overlap doors for face-case frames - the overlap style works with many different walk-in brands.

For retail applications, glass view doors improve product visibility while maintaining temperature control. LED lighting upgrades deliver immediate benefits - brighter illumination using less energy while generating less heat. Motion sensors provide additional energy savings.

NSF-approved shelving systems maximize storage flexibility while meeting health requirements. Strip curtains reduce energy costs in high-traffic operations by minimizing cold air loss during loading.

Choosing the Right Replacement Door & Hardware

Getting the right replacement door requires careful measurements and frame compatibility considerations. Doors are available up to 60 inches wide by 94 inches high, but you must account for your specific frame style.

Flush mount doors work with recessed frames where the door sits inside the opening. Overlap doors accommodate face-case frames where the door covers the frame from outside.

Regulatory compliance is crucial. Your new door must meet USDA and NSF requirements plus local health department standards. UL-listed components provide safety assurance.

For freezer applications, anti-sweat heater systems prevent ice buildup around door frames. Security features like retrofit door locks improve security while maintaining emergency egress.

All About Cooler Door Handles explains different handle types and their applications.

Accessories That Boost Workflow & Food Safety

Adjustable shelving systems adapt to changing inventory needs while maintaining proper air circulation. Wire shelving meeting NSF standards ensures sanitation compliance while maximizing storage flexibility.

Vapor-proof lighting fixtures withstand cold, humid conditions that destroy standard fixtures. LED options reduce energy consumption while providing consistent illumination.

Motion sensor controls ensure adequate illumination when someone enters while automatically turning lights off when empty. Access ramps provide safe entry while protecting door frames from impact damage.

Digital thermometers with alarm capabilities alert you to temperature excursions before product damage occurs. Some include data logging for compliance documentation.

Thermometers | precise monitoring offers various monitoring solutions for different applications.

Buying Guide: Sourcing, Shipping & Compliance for Walk-In Cooler Parts

When your walk-in cooler breaks down at 2 AM on Saturday, you'll appreciate having a trusted supplier who can get you the right parts fast. Finding reliable sources for walk-in cooler parts isn't just about price - it's about building relationships that keep your operation running.

The first decision is choosing between OEM and universal parts. Original equipment manufacturer parts guarantee perfect compatibility but cost more. Universal parts can save money, but you'll need to verify specifications carefully.

Warranty coverage separates quality suppliers from the rest. Look for comprehensive warranties covering both parts and labor for major components. Lead times can make or break your operation during emergencies. Smart managers keep critical parts like door gaskets, handles, and fan motors in stock.

Most quality suppliers offer free ground shipping on orders over $50. For emergencies, expedited shipping minimizes costly downtime. Don't overlook compliance requirements - components need proper DOE, EISA, NSF, and UL certifications to meet safety standards.

How to Evaluate Walk-In Cooler Parts Suppliers

The best suppliers become true partners in keeping your equipment running.

Inventory depth matters more than you think. Suppliers with comprehensive stock can fill complete orders from one source, simplifying procurement and reducing shipping costs.

Technical support saves hours of troubleshooting and prevents costly mistakes. Knowledgeable staff help identify correct parts and provide installation guidance when needed most.

Flexible return policies protect you from ordering errors and compatibility issues. Quality suppliers accept returns on unused parts without hassle.

Online resources like digital catalogs, installation guides, and parts lookup tools make ordering easier and faster, especially during after-hours emergencies.

Regional coverage significantly impacts delivery times and support quality. At American Mortuary Coolers, we serve customers across the contiguous 48 states from our locations in Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania.

Replacement Walk-In Parts catalog shows how comprehensive suppliers approach parts availability and customer support.

Regulations & Certifications You Must Know

Compliance protects your business and ensures safe operation. Understanding key regulations helps you make informed decisions about replacement parts.

DOE standards set minimum efficiency requirements for walk-in coolers and freezers. Replacement components must maintain compliance with Department of Energy regulations.

Energy Star certification identifies high-efficiency equipment and may qualify you for utility rebates. NSF sanitation standards ensure food safety compliance in commercial applications.

UL listing provides electrical safety assurance, reducing fire and shock hazards while protecting insurance coverage. Local health codes may impose additional requirements beyond federal standards.

Frequently Asked Questions about Walk-In Cooler Parts

Let me answer the three questions I hear most often about walk-in cooler parts maintenance and replacement. These come up regularly in conversations with facility managers and maintenance teams across the country.

How often should door gaskets be replaced?

Door gaskets live a tough life, and their replacement schedule depends on your specific situation. In typical cooler applications, expect to replace gaskets every 3 to 5 years. Walk-in freezers are harder on gaskets due to extreme temperatures, so plan on replacement every 2 to 3 years.

High-traffic operations wear out gaskets faster. If your staff opens the door dozens of times daily, or if you're constantly moving carts in and out, you might need replacements sooner.

The good news is that checking gasket condition is simple. Do the dollar bill test monthly - close a dollar bill in the door and try to pull it out. If it slides out easily, your gasket isn't sealing properly and needs replacement.

Watch for other warning signs like tears, hardening, or permanent compression marks. Don't wait until you see ice buildup around the door frame - that means you're already losing money on energy costs and risking your stored products.

What's the difference between OEM and aftermarket walk-in cooler parts?

This choice comes down to balancing cost with peace of mind. OEM parts come from the same manufacturer who built your walk-in cooler. They guarantee exact fit and compatibility, but you'll pay more for that certainty.

Aftermarket parts offer potential savings while often maintaining good quality. Many are designed to work across multiple cooler brands, which gives you more sourcing options. The key is choosing reputable suppliers who provide proper specifications and stand behind their products.

I've seen both approaches work well. OEM parts make sense for critical components where failure would be costly, or when you need warranty coverage. Aftermarket parts can be smart choices for routine maintenance items like gaskets and handles, especially when you're managing multiple units.

The most important factor isn't the source - it's finding a supplier who understands your needs and provides quality components with proper support.

Can I retrofit energy-efficient lighting in an older box?

Absolutely, and it's one of the smartest upgrades you can make. Most older walk-in coolers can accommodate modern LED lighting without major modifications.

Vapor-proof LED fixtures handle cold, humid conditions much better than old fluorescent lights. They provide brighter, more consistent illumination while using significantly less energy. The upgrade typically pays for itself through reduced electricity bills and longer bulb life.

Make sure any new fixtures are properly rated for your cooler's temperature range. This is especially important in freezer applications where extreme cold can affect electronic components.

Consider adding motion sensors while you're upgrading. They provide additional energy savings by turning lights off when the cooler isn't in use. This simple addition can extend the payback period even further.

The installation is usually straightforward, but if you're not comfortable with electrical work, hire a qualified technician. Proper installation ensures safety and optimal performance from your new lighting system.

Conclusion

Taking care of your walk-in cooler parts isn't just about fixing things when they break - it's about protecting your entire operation. When you stay on top of maintenance and replace worn components before they fail, you're making one of the smartest business decisions possible.

Spending a few hundred dollars on new door gaskets beats losing thousands in spoiled inventory. Replacing a failing evaporator fan during regular maintenance costs far less than an emergency service call at midnight.

Your walk-in cooler can serve you faithfully for 15-20 years, but only if you treat it right. That means understanding what makes it tick, listening for warning signs, and having a reliable source for quality replacement parts.

The most successful operations plan ahead. They keep spare gaskets on hand. They know their supplier's phone number. They schedule maintenance instead of waiting for breakdowns.

At American Mortuary Coolers, we've seen what happens when refrigeration systems fail unexpectedly. Whether it's a funeral home losing critical storage capacity or a restaurant facing health department violations, the consequences go far beyond repair costs.

From our locations in Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania, we've learned that every facility is different. But they all need walk-in cooler parts that work reliably when it matters most.

Don't gamble with your operation's success. Whether you're dealing with a simple handle replacement or planning a complete lighting upgrade, having the right parts and knowledgeable support makes all the difference.

More info about our solutions can help you develop a maintenance strategy that keeps your walk-in cooler running smoothly for decades to come. Because when your refrigeration works, your business works.