Why Walk-In-Coolers Are Essential for Modern Cold Storage

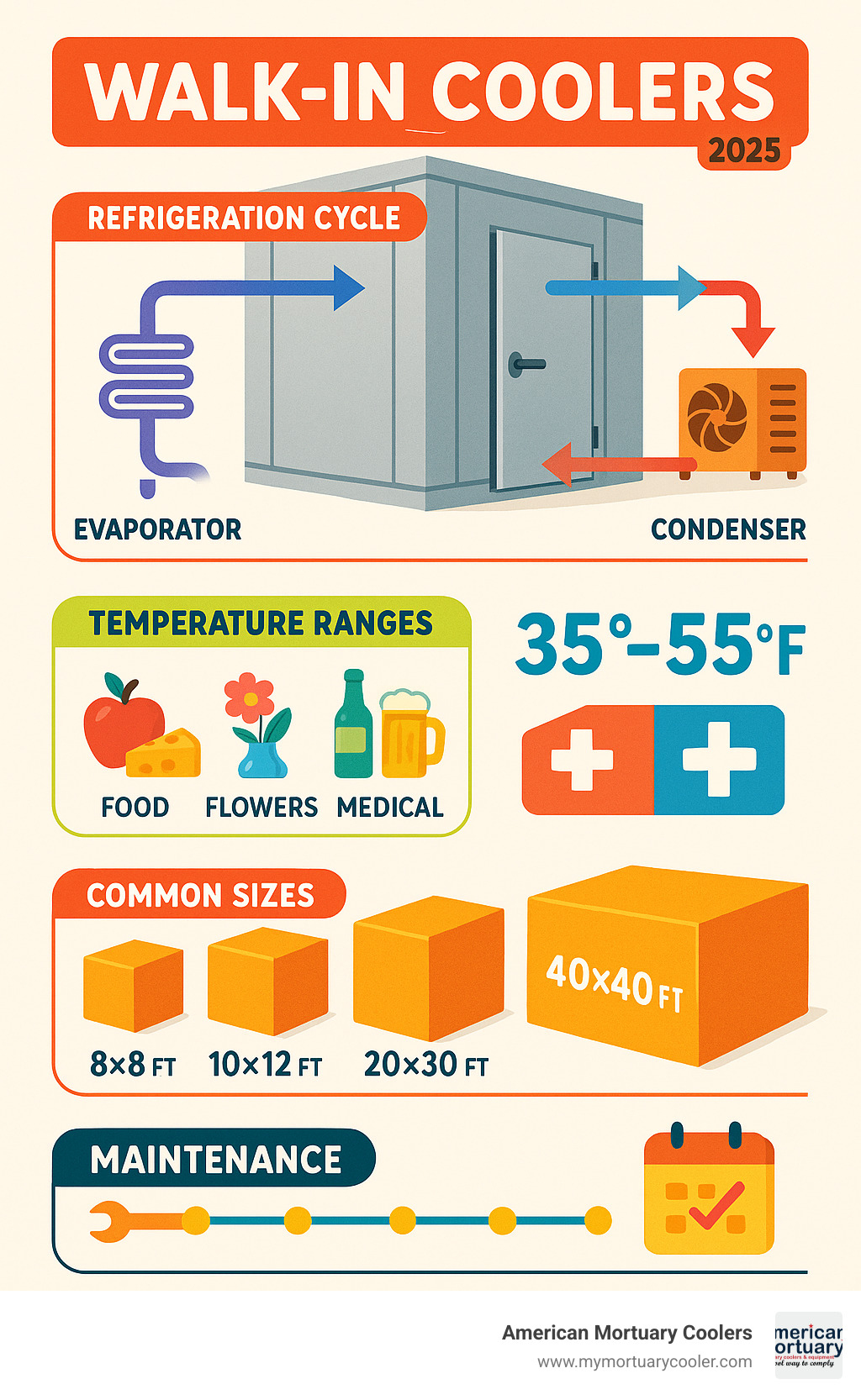

Walk-in-coolers are large refrigerated storage units that maintain temperatures between 35°F and 55°F to preserve perishable goods across diverse industries. These essential cold storage solutions provide the space and temperature control needed for restaurants, funeral homes, florists, breweries, and medical facilities.

Quick Walk-In-Cooler Overview:

- Temperature Range: 35°F to 55°F (coolers) vs sub-zero (freezers)

- Common Sizes: 8' x 8' to 40' x 40' (68 to 1,600+ sq ft)

- Types: Indoor/outdoor, prefab panels, custom builds

- Applications: Food service, mortuary, pharmaceutical, floral

- Lifespan: 15-20 years with proper maintenance

- Installation: Simple electrical hookup after delivery

Walk-in coolers work through a refrigeration cycle where refrigerant absorbs heat inside the unit, gets compressed and releases heat outside, then expands to cool again. The insulated panels, doors, and refrigeration system work together to maintain consistent temperatures.

These units offer significant advantages over traditional reach-in refrigerators. They provide bulk storage capacity, better organization, and the ability to walk inside for easy access. Whether you need to store large quantities of food, preserve floral arrangements, or maintain pharmaceutical products at precise temperatures, walk-in coolers deliver reliable performance.

As American Mortuary Coolers, we've worked as a national level mortuary cooler supplier helping funeral homes and other industries find the right walk-in-coolers for their specific needs. Our experience includes custom sizing, installation support, and understanding the unique requirements of different applications.

Walk-In-Coolers 101: How They Work & Core Components

Think of walk-in-coolers as your reliable cold storage partner that works around the clock. Understanding how these units operate helps you choose the right features and keep them running smoothly for years to come.

The magic happens through a continuous refrigeration cycle that's been perfected over decades. It's essentially the same process your home refrigerator uses, just scaled up with industrial-grade components designed for heavy-duty use.

How Do Walk-In-Coolers Work?

The refrigeration cycle in walk-in-coolers follows a simple four-step process that repeats continuously. The refrigerant starts inside your cooler, where the evaporator coils absorb heat from the warm air around your stored items. This heat absorption causes the refrigerant to change from liquid to gas.

Next, the compressor pressurizes this refrigerant gas, which raises its temperature significantly. The hot, pressurized gas then travels to the condenser, typically located outside your building or in a separate mechanical room.

At the condenser, the refrigerant releases all that absorbed heat to the outside air, cooling down and condensing back into liquid form. Finally, the liquid refrigerant passes through an expansion valve where it expands rapidly, dropping its temperature dramatically before returning to the evaporator to start the cycle again.

Your thermostat acts as the conductor, telling the compressor when to kick on and off. Most walk-in-coolers maintain temperatures between 35°F and 55°F, though food storage typically stays around 38°F - safely below the FDA's 41°F requirement.

The defrost cycle prevents ice buildup when moisture in the air hits those cold evaporator coils. Smart defrost controls automatically warm the coils just enough to melt this ice, then drain it away. This humidity control keeps your cooler running efficiently without you having to think about it.

Key Components of Walk-In-Coolers

Modern walk-in-coolers are marvels of engineering, with each component playing a specific role in keeping your products at the perfect temperature.

The insulated panels form the backbone of your cooler's performance. These sophisticated thermal barriers are typically 4 inches thick with polyurethane foam insulation that achieves impressive R-values of R-25 or higher. The panels connect using cam-lock systems that create seamless joints, preventing thermal bridges that can waste energy.

Doors and gaskets feature triple hinges that handle thousands of openings, while magnetic gaskets create airtight seals. Standard doors measure 35½" by 78", though we can customize sizes up to 10' x 10' for special applications. Every door includes interior safety releases - an OSHA requirement that could save a life.

The refrigeration system offers a key decision between packaged and remote units. Packaged systems sit on top of your cooler and need about 2 feet of clearance above, while remote systems keep the noisy compressor elsewhere and only need 2 inches of clearance. Most systems use 1.5 to 3 horsepower compressors that require 15-30 amps of 208-230 volt, 3-phase power.

Airflow fans circulate air throughout your cooler, ensuring even temperatures from floor to ceiling. Modern units use energy-efficient EC motors that adjust their speed based on cooling demand.

Your thermostat and controls have evolved beyond simple on-off switches. Digital thermostats provide precise temperature control, while monitoring sensors and alarms alert you to issues before they become expensive problems. Many newer units include IoT connectivity for remote monitoring.

LED lighting has become standard, often paired with motion sensors to save energy. These vapor-proof fixtures handle the humid environment while providing excellent visibility.

Scientific research on refrigeration efficiency confirms what we've seen in practice - proper component sizing and quality insulation make the difference between a cooler that serves you well for decades and one that constantly needs repairs.

At American Mortuary Coolers, we've learned that understanding these components helps our customers make better decisions about features, maintenance, and long-term performance. Whether you're storing food, flowers, or other temperature-sensitive items, knowing how your walk-in-cooler works gives you confidence in your investment.

Types, Configurations & Industry Applications

When it comes to walk-in-coolers, one size definitely doesn't fit all. Whether you're running a small flower shop or managing a large funeral home, there's a configuration that'll work perfectly for your space and needs.

Standard vs Custom Builds

Standard prefabricated units are the workhorses of the industry - reliable, affordable, and ready to ship fast. The most popular quick-ship sizes include the 8×8 foot model (perfect for tight spaces), the 8×12 foot unit (great for growing businesses), and the 8×20 foot cooler (ideal when you need serious storage space).

These standard units use modular panels that snap together with cam-lock connections, making installation surprisingly straightforward. Most feature seamless fiberglass construction that stands up to daily use, and you can often get same-day quotes with delivery in just 10 days.

Custom builds are where things get interesting. Need a cooler that fits into an odd-shaped space? No problem. Want specialized features like reinforced flooring or unique door configurations? We've got you covered. Custom units can stretch up to massive dimensions - we're talking 16 feet wide by 60 feet long with heights reaching 28 feet.

At American Mortuary Coolers, we specialize in these custom solutions. Funeral homes often need specific dimensions or features that standard units just can't provide, and that's exactly what we do best.

Indoor vs Outdoor Units—Pros & Cons

Choosing between indoor and outdoor units often comes down to space and priorities. Indoor units are the traditional choice - they're protected from weather, need less maintenance, and connect easily to your electrical system. The downside? They eat up valuable indoor space and their heat rejection can make your building's air conditioning work harder.

Outdoor units have become increasingly popular as businesses realize how much indoor space they can reclaim. These units free up your building's footprint and don't affect your indoor climate. However, they need special weatherproofing and may require accessories like rain hoods or low-ambient kits for extreme climates.

Your local codes and building footprint will often make the decision for you. Some areas have restrictions on outdoor units, while others encourage them to reduce building load requirements.

| Feature | Indoor Units | Outdoor Units |

|---|---|---|

| Weather Protection | Excellent | Requires weatherproofing |

| Space Usage | Uses indoor space | Frees indoor space |

| Maintenance | Lower | Higher due to exposure |

| Installation | Easier electrical | May need special accessories |

| Building Impact | Affects HVAC load | No indoor climate impact |

Where Walk-In Coolers Are Used

Walk-in-coolers show up in more places than you might expect, each with their own unique requirements.

Restaurants and food service operations rely on these units to meet the FDA's 41°F rule for food safety. The industry standard is simple: one cubic foot of cooler space holds about 28 pounds of food. Whether it's a small café or a large institutional kitchen, proper cold storage isn't optional.

Florists need specialized humidity control to keep flowers fresh. These units typically run around 35°F with carefully controlled moisture levels - too dry and flowers wilt, too humid and they develop mold.

Breweries use keg storage coolers and beverage caves to maintain consistent temperatures for both fermentation and serving. These often feature specialized racking systems designed specifically for kegs and bottles.

Medical and pharmaceutical facilities require precise temperature control for vaccine integrity and medication storage. These applications often need backup alarms, continuous monitoring, and validated temperature mapping to meet regulatory requirements.

Mortuary and funeral homes - our specialty - need body holding coolers with reinforced floors, specialized drainage, and custom dimensions to accommodate equipment and workflow. These aren't your typical coolers, and they require expertise that most suppliers simply don't have.

The beauty of walk-in-coolers is their adaptability. From combo cooler-freezer units that handle multiple temperature zones to blast chillers for rapid cooling, there's a solution for virtually every industry need.

More info about industry options explores the specific requirements and benefits for different applications, helping you understand exactly what features matter most for your particular use case.

Sizing, Materials & Energy Efficiency Essentials

Getting the size right for your walk-in-coolers is like finding the perfect pair of shoes - too small and you'll be uncomfortable, too large and you're wasting money. The same principle applies to materials and energy features. Smart choices here can save you thousands over the life of your cooler.

Choosing the Right Size

The old industry rule says one cubic foot holds about 28 pounds of product, but that's just a starting point. Your actual needs depend on what you're storing and how you operate.

Start with a storage audit of your current peak requirements. Then add 25-50% for future growth - trust us, you'll be glad you did. We've seen too many businesses outgrow their coolers within just a few years.

Don't forget about workflow considerations. You'll need 40-inch aisles for cart access and adequate space around the door for it to swing open. Plan your shelving layout with perimeter shelving to maximize every square foot.

Walk-in-coolers range from compact 68 square feet (8' x 8') up to warehouse-sized 1,600+ square feet (40' x 40'). Standard heights are 7'7", 8', 10', and 12', though we can build custom units up to 28 feet tall.

In our experience with funeral homes, we often recommend going larger than initially planned. Storage needs can spike unexpectedly, and having extra capacity prevents stressful situations during busy periods.

More info about dimensions provides detailed guidance for sizing your specific application.

Materials & Insulation That Drive Performance

The heart of any walk-in-cooler is its insulation. Most modern units use 4-inch thick panels with polyurethane foam insulation that achieves R-32 performance - way better than the minimum R-25 code requirement.

Polyurethane foamed-in-place is the gold standard. It sticks perfectly to the panel skins and resists moisture better than alternatives. Some manufacturers still use polystyrene because it's cheaper, but you get what you pay for in performance.

Panel construction has come a long way. Modern cam-lock systems let you assemble panels quickly without creating thermal bridges where heat can sneak through. The best panels have galvanized steel exteriors that resist rust and aluminum interiors that are easy to clean and NSF-approved for food contact.

For outdoor installations, seamless fiberglass construction eliminates panel joints entirely. These units cost more upfront but offer superior durability and some come with 25-year warranties on the foam structure.

Don't overlook vapor barriers - they prevent moisture from getting into the insulation where it can cause problems over time.

Energy-Saving Features & Accessories

Modern walk-in-coolers are packed with energy-saving technology that can dramatically reduce your operating costs.

EC evaporator fans use 50-70% less energy than traditional motors and provide variable speed control. They're quieter too, which your neighbors will appreciate.

LED lighting with motion sensors cuts lighting energy by 80% while providing better illumination. The lights only come on when you need them, and they last much longer than old-style bulbs.

Smart controls do more than just maintain temperature. Digital thermostats with IoT temperature logging let you monitor your cooler remotely and spot problems before they become expensive failures. Some systems integrate with building management systems for comprehensive control.

Simple accessories make a big difference too. Auto-closing doors prevent energy waste from doors left open. Vinyl strip curtains are incredibly effective in high-traffic situations - they reduce air infiltration while still allowing easy access.

Solar-ready condensing units are becoming popular as businesses look to reduce energy costs and environmental impact.

Scientific research on insulation ageing shows that insulation panels over 10 years old lose significant performance. Investing in quality construction and energy-efficient features pays dividends for decades.

Buying & Installing Your Walk-In Cooler

Purchasing and installing walk-in-coolers might seem daunting, but it's actually more straightforward than you'd expect. With proper planning and the right partner, you can have your unit up and running smoothly within a few weeks.

The key is understanding what goes into the process - from site preparation to final startup. At American Mortuary Coolers, we've guided countless customers through this journey, and we've learned that preparation makes all the difference.

Budget & Pricing Breakdown

Walk-in-cooler pricing depends on several factors, but understanding the cost breakdown helps you budget effectively and avoid surprises.

Base unit costs typically range from $8,000 for a basic 8' x 8' unit up to $100,000+ for large custom installations. A standard 8' x 12' unit usually falls between $12,000 and $20,000, while larger 12' x 20' units range from $25,000 to $45,000.

Panel cost and refrigeration horsepower are your biggest cost drivers. Higher-quality insulation and more powerful refrigeration systems cost more upfront but save money long-term through better efficiency and durability. Outdoor units typically cost 15-20% more than indoor versions due to weatherproofing requirements.

Additional expenses often catch buyers off guard. Site preparation and concrete work can add $2,000-$5,000 to your project. Electrical installation requiring 208-230V 3-phase power typically costs $1,500-$3,000 depending on distance from your electrical panel. Don't forget about permits and inspections, which vary by location but usually run $200-$500.

Freight costs depend on your location and unit size. Crane or forklift delivery adds $500-$1,500 to the total. If you're in a remote area, expect higher freight charges.

Many manufacturers offer financing options with terms up to 10 years. Some energy-efficient units qualify for utility rebates, and recent tax incentives can offset 10-30% of costs. Refurbished units can provide significant savings - often 40-50% off new prices - and many come with warranties.

ROI calculators help justify the investment. Most businesses see payback within 2-4 years through reduced food waste, improved inventory management, and energy savings compared to multiple reach-in units.

Step-by-Step Installation Timeline

The installation process typically takes 4-12 weeks from order to startup, depending on whether you choose standard or custom construction.

Planning and approval usually takes 2-4 weeks. Your supplier will create detailed approval drawings showing dimensions, door locations, and refrigeration placement. This is when you'll handle permits and coordinate with your electrician for power requirements.

Production time varies dramatically. Quick-ship standard sizes can be ready in 10 days, while custom units may take 6-8 weeks. During this time, you'll need to complete site preparation - primarily ensuring you have a level concrete slab within ¼" per 10 feet.

Delivery and placement typically happens in one day. You'll need access for the delivery truck and either a crane or forklift for panel placement. Most suppliers coordinate this equipment, but you'll need to arrange for a dumpster to handle packaging materials.

Assembly and startup usually takes 1-2 days. Modern packaged refrigeration systems often require just simple electrical connections - literally plug-and-play in many cases. Remote systems need refrigerant lines run between indoor and outdoor components.

Final inspection and startup includes temperature testing, alarm verification, and operator training. Most units reach operating temperature within 4-6 hours of initial startup.

The beauty of modern walk-in-coolers is how simple the installation has become. Cam-lock panel systems eliminate complex assembly, and pre-charged refrigeration means no field welding or refrigerant handling in most cases.

Code compliance varies by location, but most jurisdictions require electrical and building permits. Your supplier should guide you through local requirements and provide documentation for inspections.

We've found that customers who prepare thoroughly have the smoothest installations. Having your electrical ready, site prepared, and delivery access cleared makes the difference between a one-day installation and a week-long headache.

More info about installation provides comprehensive checklists and preparation guides to ensure your installation goes smoothly.

Maintenance, Safety & Frequently Asked Questions about Walk-In-Coolers

Taking care of your walk-in-coolers isn't rocket science, but it does make the difference between a unit that lasts 15-20 years and one that breaks down when you need it most. Think of maintenance like caring for your car - a little attention goes a long way toward preventing expensive repairs and keeping everything running smoothly.

Safety is equally important. Walk-in-coolers are designed with OSHA-compliant interior safety releases, but proper personal protective equipment and temperature logging procedures protect both your staff and your stored products.

Preventive Maintenance Checklist

The secret to long-lasting walk-in-coolers is staying ahead of problems before they become emergencies. Your maintenance routine should focus on the components that work hardest - the refrigeration system, door seals, and air circulation.

Monthly maintenance keeps your cooler running efficiently. Clean those condenser coils with a soft brush or vacuum - dirty coils make your compressor work overtime and drive up energy costs. Check door gaskets for tears or warping that let warm air sneak in. Inspect evaporator fan blades for ice buildup or damage, and always monitor your temperature logs for unusual patterns that signal trouble ahead.

Test your alarm systems monthly too. When a cooler fails at 2 AM on a weekend, that alarm might be the only thing standing between you and thousands of dollars in spoiled products.

Every three months, dig a little deeper. Inspect refrigerant lines for oil spots or frost that indicate leaks. Clean interior surfaces and drain lines to prevent bacteria growth and water backup. Lubricate door hinges so they close properly, and check insulation panels for dents or damage that compromise efficiency.

Annual professional inspections catch problems your daily checks might miss. A qualified technician can test electrical connections, verify thermostat calibration, and spot refrigerant issues before they cause system failures.

Summer heat puts extra stress on outdoor units. During peak summer months, you'll want to clean condenser coils more frequently and watch for signs of compressor overheating. Keeping your cooler properly loaded - around 75-90% capacity - helps the system maintain temperature without overworking.

Freeze-up prevention saves countless headaches. Ice forms when warm, humid air gets inside through damaged door seals or stays too long from frequent door openings. Installing vinyl strip curtains and training staff to minimize door-open time makes a huge difference.

More info about maintenance covers seasonal care tips and troubleshooting common problems.

Top FAQs on Walk-In-Coolers

After years of helping funeral homes and other businesses with their cooling needs, we've heard just about every question imaginable. Here are the ones that come up most often.

What size cooler do I need? Start with the rule of thumb that one cubic foot holds about 28 pounds of food, but remember that's just the beginning. You'll also need space for aisles, future growth, and different storage requirements. In our experience with funeral homes, it's better to go slightly larger than your initial calculation.

What are ideal temperature settings? For food storage, 35-38°F hits the sweet spot. The FDA requires temperatures below 41°F, but staying around 38°F gives you a safety buffer for door openings and system fluctuations. Other products have different needs - vaccines require much tighter temperature control, while flowers do best with specific humidity levels too.

How long does it take to cool down? An empty cooler reaches temperature in 30 minutes to 2 hours, depending on size and ambient conditions. But when you load it with products at room temperature, expect 12-24 hours for everything to stabilize. Pre-cooling items before loading makes a big difference in cool-down time and energy consumption.

What factors affect energy costs? Your biggest influences are insulation quality, door sealing, and usage patterns. A well-maintained cooler typically uses 15-30 amps and runs 16-18 hours daily. Upgrading to LED lighting and EC motors can cut energy costs by 30-50% - savings that add up quickly over the unit's lifetime.

Can a cooler be converted to a freezer? Converting requires major system modifications that often cost more than buying a dedicated freezer. Some dual-temperature units can switch between cooling and freezing, but if you need permanent freezing, a purpose-built freezer is more efficient and reliable.

What warranty coverage should I expect? Quality manufacturers offer 20-25 year panel warranties and 5-year compressor warranties, with 1-year parts and labor coverage. At American Mortuary Coolers, we stand behind our work because we understand how critical reliable refrigeration is for funeral homes.

The bottom line? Walk-in-coolers are remarkably reliable when properly maintained and correctly sized for your needs. A little preventive care and understanding your system's requirements will keep your cooler running efficiently for decades.

Conclusion & Next Steps

Choosing the right walk-in-coolers is more than just buying equipment - it's investing in your business's future success. Whether you're keeping food fresh, preserving delicate flowers, or maintaining the dignity of funeral services, the right cooling solution becomes the backbone of your operation.

At American Mortuary Coolers, we've spent over a decade helping businesses across Tennessee and beyond find their perfect cooling match. What started as a focus on funeral home needs has grown into serving restaurants, florists, breweries, and medical facilities nationwide. Every installation teaches us something new about what really matters to our customers.

The walk-in-cooler industry keeps getting better. Smart controls now let you monitor temperatures from your phone. Energy-efficient motors cut utility bills in half. Better insulation means units last longer and perform better. These aren't just nice features - they're investments that pay for themselves.

Your success depends on getting these key decisions right: sizing for growth rather than just current needs, choosing quality insulation that saves money for decades, and working with professionals who understand your specific industry requirements. A properly sized and installed walk-in-cooler will serve you faithfully for 15-20 years or more.

We've learned that the best installations happen when customers take time to plan properly. Think beyond today's needs - what will your business look like in five years? Will you need more storage? Different temperature zones? Special features for your industry?

Our custom approach means your cooling solution fits your space, your workflow, and your budget. From quick-ship standard units to fully engineered custom builds, we provide same-day quotes and detailed specifications. Our nationwide delivery reaches all 48 contiguous states, backed by warranties up to 25 years on structural components.

Ready to move forward? We're here to guide you through every step - from initial sizing calculations to final startup and training. Our team understands that downtime isn't an option when you're storing perishable products or serving families during difficult times.

More info about custom walk-ins shows how we've solved unique challenges for customers across different industries.

Contact American Mortuary Coolers today to start your walk-in-cooler journey. Whether you're in Johnson City, Tennessee, or Los Angeles, California, we're positioned to deliver durable, reliable cooling solutions that keep your business running smoothly for years to come.