Understanding Cremation Ovens: The Basics

Cremation ovens are specialized high-temperature furnaces designed to reduce human or animal remains to bone fragments and ash through a controlled combustion process. If you're researching cremation equipment for your funeral home, here's what you need to know:

| Cremation Oven Basics | Details |

|---|---|

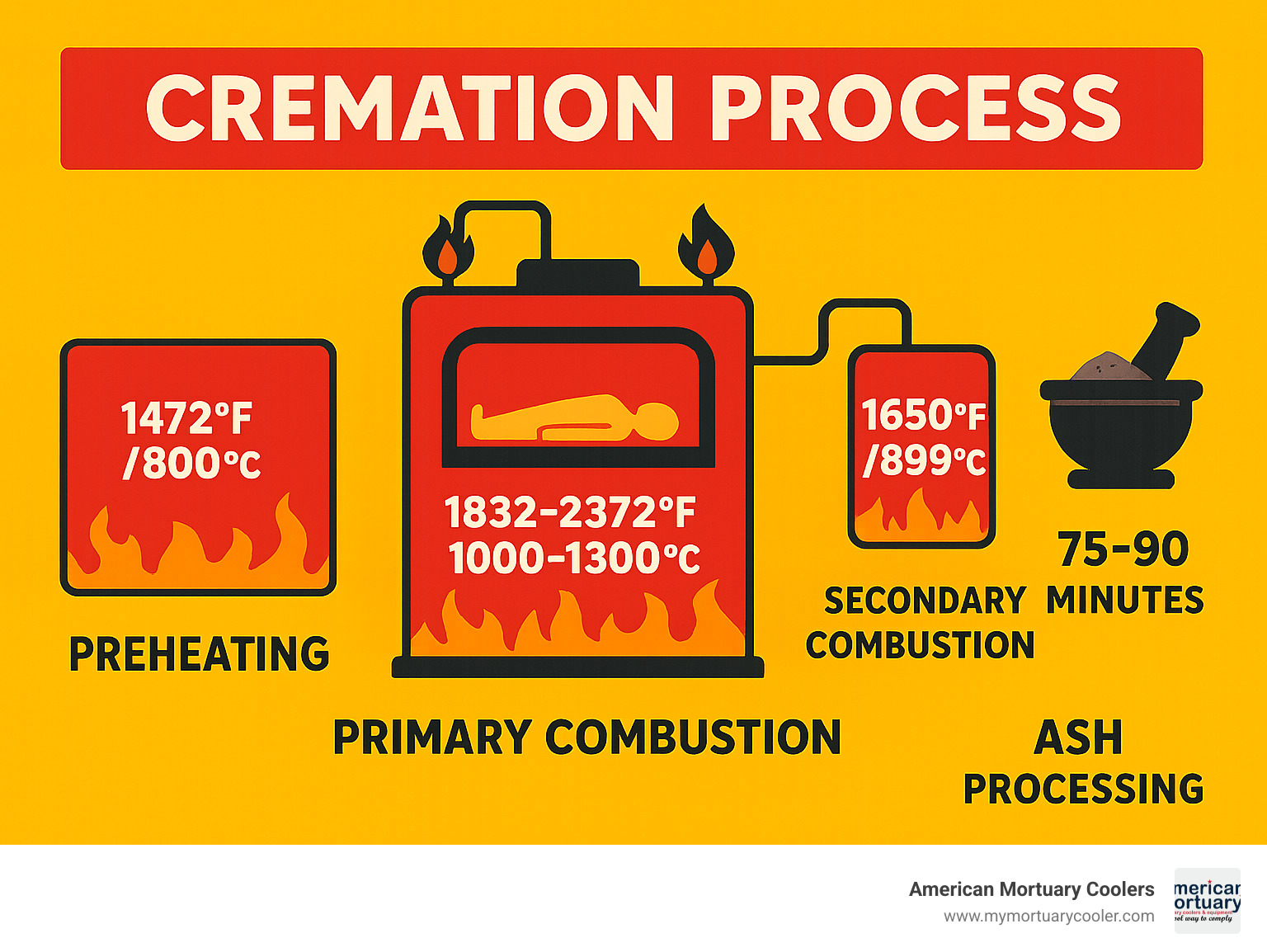

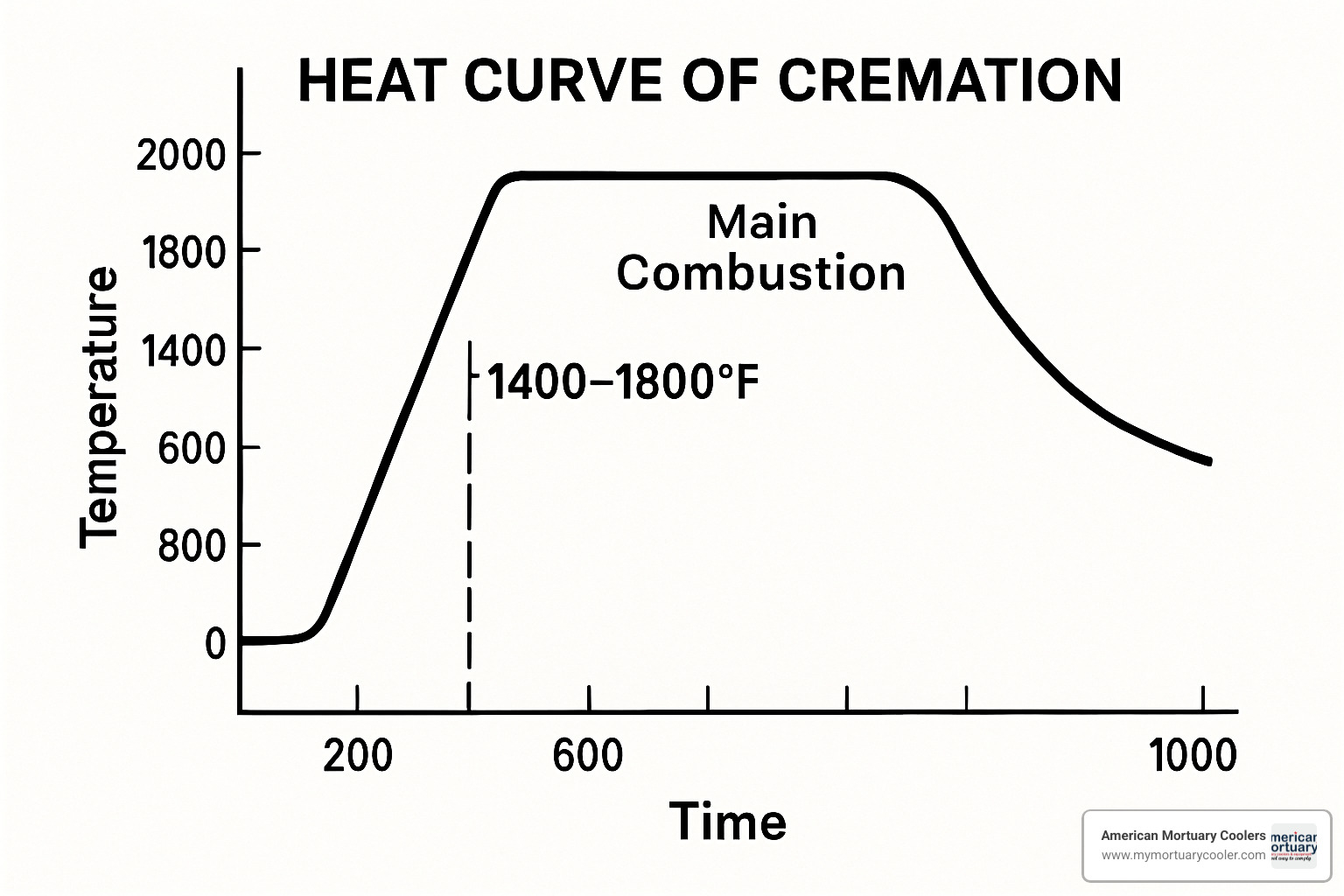

| Temperature Range | 1400-1800°F (760-982°C), typically operating at 1650°F (899°C) |

| Average Cremation Time | 75-90 minutes for human remains |

| Ash Yield | 2.5-3 kg (5.5-6.6 lbs) from an average human body |

| Fuel Types | Natural gas, propane, diesel, electricity, biodiesel |

| Capacity | Standard units accommodate bodies up to 750+ lbs |

| Environmental Features | Modern units include filtration systems for smoke-free, odorless operation |

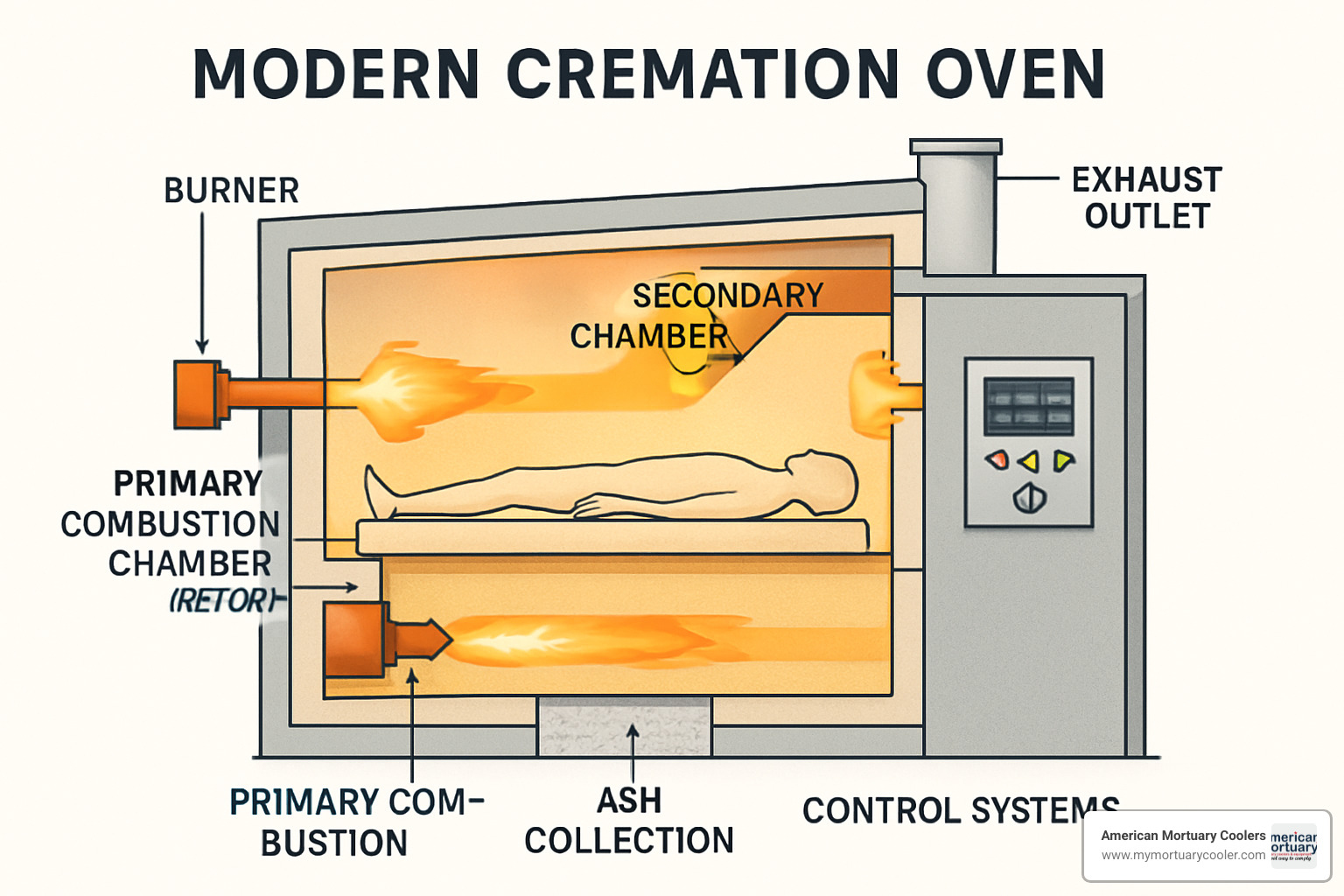

Modern cremation ovens are engineered for efficiency, environmental compliance, and respectful handling of the deceased. They consist of a primary combustion chamber (retort), a secondary chamber for exhaust gases, burners, and sophisticated control systems to ensure complete incineration while minimizing emissions.

The cremation process begins with preheating the chamber to approximately 800°C (1472°F). The body, contained in a combustible container, is placed inside using a charging mechanism. During cremation, temperatures rise to 1000-1300°C (1832-2372°F), reducing organic matter to ash while calcifying bone fragments. Afterward, remaining metal items are removed, and the bone fragments are processed into a fine ash for return to the family.

High-capacity cremation furnaces, such as the KM-1 and KM-2 models, can perform 6-7 cremations in a 12-hour period, making them suitable for busier funeral homes. Smaller models like the DFW 4000 are designed for facilities performing up to approximately 750 cremations per year.

I'm Mortuary Cooler, a national supplier of mortuary equipment with experience in the selection, installation, and maintenance of cremation ovens and complementary mortuary systems for funeral homes across the United States.

Basic cremation ovens glossary: - funeral signage - trolley with lift - hydraulic lift pumps

Cremation Ovens Explained: Design, Types & Working Principles

Definition & Core Components

When you strip away the technical jargon, a cremation oven is essentially a specialized furnace designed with one purpose: to respectfully transform human or animal remains into bone fragments and ash. These remarkable machines blend engineering precision with compassionate purpose.

At the heart of every cremation system is the primary combustion chamber, commonly called the retort. Think of this as the main sanctuary where the body rests during cremation. It's lined with specialized refractory materials that can withstand the extreme heat – like a protective cocoon engineered for temperatures most materials simply couldn't endure.

Working in harmony with the primary chamber is the secondary chamber, sometimes called the afterburner. This crucial component ensures that gases released during cremation are fully oxidized, eliminating smoke and odor. It's not just about efficiency – it's about showing respect for the surrounding community.

The intense heat needed comes from powerful burners positioned strategically in both chambers. These are the workhorses that generate temperatures hot enough to complete the cremation process thoroughly and efficiently.

Inside, the refractory lining serves as both shield and thermal regulator. Made from specialized firebrick, pre-cast shapes, and ceramic fiber insulation, this lining can withstand temperatures beyond 2000°F while maintaining thermal efficiency. As one seasoned crematory operator with over 20 years of experience shared with us, "The refractory lining is the heart of any cremation oven. With proper maintenance, a quality refractory can last for thousands of cremations, but it needs regular inspection and care."

The stack or chimney safely channels emissions upward after they've been processed, while sophisticated control systems monitor and adjust temperatures, airflow, and combustion parameters throughout the entire cremation cycle – much like a vigilant guardian ensuring everything proceeds with dignity and care.

Primary Types of Cremation Ovens

Just as families have unique needs, cremation ovens come in various configurations to meet different facility requirements. Let's explore the main types:

When it comes to fuel sources, gas-fired units reign supreme in North America. Running on natural gas or propane, they offer quick heat-up times and reliable performance. The CFS2300 model is particularly popular, accommodating cases over 750 lbs with ease.

In areas without natural gas infrastructure, diesel/oil-fired systems provide a dependable alternative. Some high-volume facilities use specialized oil burners with temperature-controlled oil guns, achieving remarkably short cremation times of just 20-40 minutes.

The newest kid on the block is the electric cremator, gaining popularity for its zero stack emissions and compatibility with renewable energy. DFW Europe's electric model exemplifies this eco-friendly approach. For facilities wanting the best of both worlds, hybrid systems combine electric heating elements with gas burners to maximize efficiency while minimizing environmental impact.

Size matters too. High-capacity models like the Classic-XCEL can handle remains at impressive rates up to 400 lb/hr with a maximum capacity of 1200 lbs – perfect for busy urban facilities. Most funeral homes opt for standard units like the DFW 4000, designed for facilities performing up to approximately 750 cremations yearly. Smaller operations might choose low-capacity units that balance efficiency with more modest needs.

The operational approach varies as well. Some facilities prefer cold-start units that heat from ambient temperature before each cremation, while others choose warm-start systems that maintain liftd temperatures between procedures – more energy-efficient for locations performing multiple daily cremations.

Human vs. Pet Cremation Ovens

While the fundamental technology remains similar, human and pet cremation ovens differ in several meaningful ways that reflect their specific purposes.

Human cremation equipment typically features larger door dimensions (usually 110-130 cm wide by 90 cm high) to accommodate standard caskets with dignity. These units focus on processing one body at a time, with designs accommodating bodies up to 750+ lbs at cremation rates of approximately 150 lbs per hour. They're subject to stricter regulatory oversight and typically incorporate sophisticated emission control systems to meet local environmental requirements.

Pet cremation equipment, in contrast, offers more flexibility. Available in various sizes from the compact Sierra-300 (300 lb capacity) to the substantial Sierra-1200 (1200 lb capacity), these units often feature multi-chamber designs. This clever configuration allows for simultaneous cremation of several animals, with some models from manufacturers like Addfield accommodating up to 7 pet cremations per cycle.

"The biggest difference in pet cremation equipment is the need for partitioned chambers," explains a pet crematory owner from Dallas. "Many pet owners want private cremations where their pet's ashes aren't mixed with others, so we need equipment designed specifically for that purpose."

These partitioned chambers ensure that when families request individual cremations, their beloved companion's ashes remain separate – an important consideration for many grieving pet owners.

Why Choose Electric Cremation Ovens

Electric cremation ovens are gaining traction in our increasingly environmentally-conscious world, offering several compelling advantages for forward-thinking funeral homes.

Perhaps most notably, these units produce zero stack emissions. Without combustion, there's no need for a traditional chimney, making them ideal for urban installations where air quality permits can be challenging to obtain. This clean operation pairs beautifully with renewable energy sources – whether solar, wind, or other sustainable options – dramatically reducing the carbon footprint of each service.

From an operational standpoint, electric elements provide exceptionally precise temperature control throughout the cremation cycle. With fewer moving parts and no burners to maintain or adjust, these systems typically require less maintenance over their lifespan. They also operate more quietly than their gas or oil-fired counterparts – a subtle but meaningful benefit in creating a peaceful environment.

According to Scientific research on electric cremators, these modern units achieve the same performance standards as traditional fuel-burning systems while significantly reducing environmental impact. However, it's worth noting they typically come with higher upfront costs and may require substantial electrical infrastructure upgrades.

A funeral director in Chicago who recently made the switch shared: "The initial investment was higher, but we've seen a 30% reduction in operating costs and eliminated the annual stack testing requirements. Plus, our families appreciate knowing we've chosen the most environmentally responsible option."

For many funeral homes, this investment in cleaner technology aligns perfectly with their commitment to serving families with respect while also honoring our shared environment.

Technical Specs & Process: Temperatures, Fuels, Step-by-Step Cycle, Ash Handling

Operating Temperatures, Fuels & Cycle Times

When we talk about cremation ovens, we're discussing equipment that operates at truly intense temperatures. The heat required to respectfully transform human remains into ashes is something most people never experience firsthand.

Most modern cremation ovens operate around 1650°F (899°C), though the full range typically spans from 1400°F to 1800°F (760°C to 982°C). Before the day's first cremation, chambers need preheating to approximately 800°C (1472°F) to ensure efficient operation. In the secondary chamber—often called the afterburner—temperatures must reach at least 850°C (1562°F), with many units actually pushing up to 1300°C (2372°F) to completely consume gases and eliminate emissions.

As for fuel options, each comes with its own set of considerations. Natural gas remains the most popular choice across North America—it burns cleanly, costs less than alternatives, and is widely available, though it does require proper gas infrastructure. A typical cremation consumes about 2,350 CFH @ 7"W.C. of natural gas.

Propane offers portability and high energy density, making it suitable for facilities without natural gas lines, though it generally costs more. Diesel or oil systems serve remote locations well but require more maintenance and produce higher emissions. Electric cremators are gaining popularity for their zero direct emissions and quiet operation, though they demand substantial power requirements (typically 240V, 1φ, 40A minimum) and higher initial investment. Some forward-thinking facilities in Scandinavia have even begun using biodiesel as a renewable alternative.

"People often ask me how long cremation takes," shares James, a crematory operator I met while researching this article. "I always tell them it's not like what they see in movies. A thoughtful, complete cremation for an average adult takes 75 to 90 minutes—roughly processing 150 pounds per hour. Then we need another 30 to 60 minutes of cooling before we can safely collect the ashes. All told, we're looking at 2 to 3 hours from start to finish."

Higher-capacity units can process remains faster—some reaching 400 pounds per hour—but the process can never be rushed without compromising quality or equipment longevity.

The Cremation Process Step-by-Step

Behind the solemn exterior of cremation ovens lies a carefully orchestrated process that combines tradition with modern technology to ensure dignity for the deceased and peace of mind for families.

The journey begins with thorough identification procedures. Multiple checkpoints verify the identity of the deceased, while any medical devices like pacemakers are removed to prevent damage to the chamber. The preheating stage brings the chamber to operational temperature—a crucial step for efficient cremation.

When it's time for loading, the body, enclosed in a simple combustible container (typically unfinished wood, fiberboard, or cardboard), is placed on a mechanized charging bier. Modern systems like the CFS2300 feature a recessed hot hearth design that minimizes heat loss during the loading process.

"The moment of insertion is handled with great care and respect," explains Linda, a funeral director I spoke with in Memphis. "Once the container enters the chamber, the intense heat immediately begins the cremation process, with the primary chamber burner maintaining optimal temperature based on continuous monitoring."

As cremation progresses, gases released from the primary chamber flow into the secondary chamber where they're fully oxidized at extremely high temperatures. Throughout this process, sophisticated computerized controls monitor and adjust temperatures, oxygen levels, and air distribution to ensure efficient combustion.

The completion of cremation isn't determined by a simple timer. In fact, advanced systems like the CFS2300 use weight-based automatic controls to determine when the process is complete—typically after those 75-90 minutes we mentioned earlier.

After cooling, the cremated remains—primarily bone fragments—are carefully swept into a cooling pan. Many modern facilities use specialized ash pan refrigerators to accelerate cooling while maintaining dignity in the process.

Post-Processing & Ash Handling

The final stages of cremation require just as much care and attention as the initial process. Once cremation is complete, several important steps remain before the ashes can be returned to the family.

First, the collected bone fragments and ash must cool completely. This happens either naturally or in specialized ash pan refrigerators that accelerate the process. Next comes metal removal—any remaining metal objects such as joint replacements, dental work, or casket hardware are carefully removed using strong magnets and/or manual inspection.

Processing is where the cooled bone fragments are transformed into what most people recognize as "ashes." A specialized machine called a cremulator processes the fragments into a uniform, fine consistency. This step is crucial for creating the dignified presentation families expect.

"Families often don't realize that what they receive isn't actually ash in the traditional sense," notes Michael, a crematory technician with over 15 years of experience. "It's primarily processed bone fragments, which is why the remains have that distinctive appearance and texture."

Throughout every step, identification protocols remain strict. Many facilities use identification stones with unique cremation numbers to prevent any possibility of cross-contamination—a small but important detail that provides peace of mind.

The final remains typically weigh between 2.5-3 kg (5.5-6.6 lbs) for an average adult. These are carefully transferred into either a temporary container or the permanent urn selected by the family. Modern facilities often use specialized equipment like Ventless Cremated Remains Processing Stations, which contain dust and ensure hygienic handling of remains.

For those interested in learning more about the entire cremation process, including detailed ash handling procedures, you can visit our comprehensive guide: More info about ash processing.

At American Mortuary Coolers, we understand that while these technical details are important, what matters most is handling each step with the respect and dignity families deserve during their time of loss.

Compliance, Safety & Innovations

Emission Control & Regulations

Let's talk about the environmental side of cremation ovens – it's an aspect that's become increasingly important in recent years. Gone are the days when crematories could simply vent their emissions without a second thought.

Today's regulatory landscape is comprehensive and demanding. Across the United States, crematories must steer a complex web of federal Clean Air Act requirements, state-specific regulations, and local permits. Most jurisdictions limit visible emissions to less than 10% opacity – in plain English, that means little to no visible smoke should come from a properly functioning modern crematory.

"The days of seeing smoke coming from a crematory chimney are over," shared an environmental compliance officer who works with crematories throughout the Southeast. "Modern equipment is designed to be completely smoke-free and odorless when properly operated and maintained."

The heart of emission control in modern cremation ovens is the secondary combustion chamber, or afterburner. These chambers maintain temperatures of at least 870°C (1600°F) – hot enough to break down complex organic compounds into simpler, cleaner emissions. The gases must stay in this high-temperature zone for 1-2 seconds, ensuring complete combustion.

Many newer units go beyond these basics, incorporating sophisticated filtration systems. These might include wet scrubbers that "wash" the emissions, ceramic or fabric filters that trap particulates, or activated carbon systems that capture mercury and other heavy metals.

Staying compliant isn't just about having the right equipment – it's also about proving compliance. Most facilities undergo periodic stack testing to verify their emissions meet requirements. Many also use continuous opacity monitoring systems that constantly check what's coming out of the stack. And of course, thorough record-keeping is essential, documenting everything from temperatures to maintenance activities.

According to scientific research on emissions, today's properly maintained cremation ovens can achieve emission levels far below regulatory thresholds. It's an impressive achievement, though it does come with higher equipment costs and ongoing maintenance requirements.

Automation & Safety Features

The technology behind cremation ovens has evolved dramatically over the past couple of decades. What was once largely manual equipment now incorporates sophisticated automation that improves both safety and consistency.

At the heart of modern systems are computerized brains – Programmable Logic Controllers (PLCs) that constantly monitor and adjust the cremation process. These systems display information through user-friendly touch screens, giving operators real-time data on temperatures, air flow, and other critical parameters.

"Twenty years ago, we were using manual timers and visual inspections," recalled a crematory manager from our Chicago service area. "Today, the computer handles everything from temperature control to emission monitoring, making the process safer and more consistent."

Some of the most advanced cremation ovens, like the CFS2300, have moved beyond simple timers to weight-based operation. These smart systems adjust the cremation cycle based on the actual weight of the deceased, providing more precise control and better efficiency.

Safety features have also become more comprehensive. Modern units incorporate multiple emergency shutoffs that can immediately halt operation if something goes wrong. Auto-chargers like the AC-1 ($23,998.95) mechanically load the chamber, keeping operators safely away from the intense heat. Sophisticated door systems prevent flame propagation during loading and unloading, while advanced insulation keeps exterior surfaces at safe temperatures.

Many facilities now take advantage of remote monitoring capabilities. Systems like Tek Marshal allow for internet-based diagnostics, so technicians can troubleshoot issues without necessarily needing to visit in person. This capability has proven especially valuable for facilities in remote locations.

The benefits of these technological advances extend to record-keeping as well. Automated data logging creates detailed records of each cremation, helping with both quality control and regulatory compliance. Some systems even generate automated reports and maintenance alerts, helping facilities stay on top of their service needs.

For a deeper dive into these technological advances, check out more info about cremation systems.

Routine Maintenance & Operator Training

Ask any experienced crematory operator about the key to longevity for cremation ovens, and they'll likely point to one thing: maintenance. These sophisticated systems operate under extreme conditions, and proper care is essential for both performance and compliance.

A thoughtful maintenance program starts with daily visual inspections of critical components like refractory condition, door seals, and control systems. Weekly tasks typically include cleaning air intakes, checking burners, and lubricating moving parts. Monthly, the maintenance becomes more thorough, with deeper inspection of the refractory, testing of safety systems, and calibration checks.

"Proper maintenance isn't just about keeping the equipment running—it's about respect for the deceased and their families," explained a crematory technician with over 15 years of experience. "A well-maintained cremator ensures dignified, efficient cremations without delays or issues that could cause distress to families."

One of the most significant maintenance considerations is the refractory – the specialized heat-resistant lining inside the cremation chamber. Traditional hearths typically require replacement every 1,500-2,000 cremations. However, newer modular systems like the Quick Change allow for sectional replacement, often completed in just one day without the extended curing or dry-out cycles required by traditional methods.

Beyond regular maintenance, proper operator training is absolutely essential. Comprehensive initial training should cover equipment operation, safety procedures, and regulatory requirements. Many industry associations offer certification programs for crematory operators, providing standardized training and credentials.

At American Mortuary Coolers, we've seen how proper maintenance and training pay dividends in equipment longevity and operational excellence. We strongly recommend establishing a comprehensive maintenance schedule and keeping detailed records of all service performed – not just for regulatory compliance, but as a best practice that respects both the equipment and the families you serve.

The investment in proper maintenance and training might seem substantial, but it's far less than the cost of premature equipment replacement or the reputational damage that could come from operational problems. When it comes to cremation ovens, an ounce of prevention truly is worth a pound of cure.

Costs, Suppliers, History & Ethical Dimensions

Cost Breakdown & ROI

Investing in a cremation oven is one of the biggest decisions a funeral home will make. While the price tag might cause some sticker shock initially, a well-chosen system can deliver excellent returns over its lifetime.

The upfront costs start with the equipment itself. Basic models begin around $80,000, while feature-rich, high-capacity units can run north of $250,000. But that's just the beginning of your investment journey. Installation typically adds another $15,000-$30,000 depending on your facility's layout and accessibility. Then there are utility connections – getting proper gas lines, electrical upgrades, and ventilation systems in place might cost you $10,000-$20,000 more.

Don't forget about paperwork! Environmental permits, building approvals, and other regulatory hoops can add $5,000-$15,000 to your startup costs, varying widely based on your location. As one of our Tennessee clients told us, "The permitting process took twice as long as the actual installation – but having all those documents in order from day one saved us headaches down the road."

Once you're up and running, the ongoing expenses become more predictable. Natural gas costs typically run $12-25 per cremation, depending on local rates and your equipment's efficiency. Electricity for running controls and auxiliary systems adds roughly $5-10 per case. Annual maintenance generally runs about 3-5% of your initial equipment cost – a worthwhile investment to prevent costlier repairs later.

One major expense to plan for is refractory replacement. Traditional hearth systems need replacement every 1,500-2,000 cremations, costing $15,000-$25,000 each time. This is where newer modular systems can save money in the long run, despite higher initial costs.

The good news? Most cremation ovens pay for themselves within 2-4 years. A facility performing 750 cremations annually at $1,000 per service generates $750,000 in revenue. With typical gross margins of 60-70%, that's a healthy return on investment. Many manufacturers also offer financing with 5-7 year terms, making the initial investment more manageable for smaller operations.

Leading Manufacturers & Models

The cremation oven marketplace features several respected manufacturers, each bringing their own strengths and specialties to the table.

American Crematory Equipment Company has been a trusted name since 1974. They've built their reputation on durable equipment and exceptional warranty coverage. Their A-200 model has proven particularly reliable, with documented cases of processing over 400 cremations in eight months while keeping gas costs to around $12 per case. Their company motto, "Service Is Everything™," isn't just marketing talk – their support team's responsiveness has earned them loyal customers nationwide.

DFW Europe stands out for their focus on environmental compliance. Their DFW 4000 model, designed for facilities performing up to 750 cremations yearly, comes fully assembled to minimize installation headaches. What really sets them apart is their continuous measurement system that monitors oxygen, temperature, and pressure in real-time, optimizing efficiency while ensuring clean operation.

For operations with varying capacity needs, BL Cremation Systems offers a tiered approach with their Classic series. Their Classic-PRO handles standard needs (90-minute cycles, 200 lb/hr, 800 lb capacity), while the Classic-XCEL caters to high-volume operations (60-minute cycles, 400 lb/hr, 1200 lb capacity). Their mid-range Classic-PLUS splits the difference for growing facilities.

Armil CFS (now Cremation Systems) entered the market in 2001, bringing valuable experience from industrial furnace manufacturing. Their CFS2300 features a recessed hot hearth design that accommodates cases over 750 lbs. They pioneered the Quick Change hearth system – a game-changer that allows for one-day replacement rather than the traditional lengthy process. Their Tek Marshal internet diagnostics system lets technicians troubleshoot issues remotely, often saving service calls.

"We looked at so many options I thought my head would spin," laughed a funeral director from Nashville who recently purchased through us. "What finally sold us wasn't just specs on paper, but talking to other funeral directors who'd been using the equipment for years. The real-world experience matters more than brochure promises."

International options include Addfield Environmental Systems, a UK-based manufacturer with equipment in over 140 countries and 40+ years of experience, and Kalfrisa, whose KM-1 and KM-2 models can handle 6-7 cremations per 12-hour period with full automation capabilities.

From Holocaust Ovens to Modern Ethics

The history of cremation ovens includes a dark chapter that cannot and should not be overlooked. Understanding this history helps us appreciate the ethical frameworks that guide modern cremation practices.

The ovens used in Holocaust concentration camps like Auschwitz and Majdanek were fundamentally different from today's equipment in both design and, crucially, in purpose. Those systems typically used coke (a coal derivative) as fuel, required manual operation, and lacked any environmental controls. At Majdanek, historical documentation shows the second crematorium contained five Kori ovens, while the first had two ovens transferred from Sachsenhausen.

Perhaps the most significant difference was the intent behind their design. While modern cremation ovens are engineered for individual, dignified processing, Holocaust ovens were built for mass disposal with multiple chambers (muffles) stacked vertically. They represent one of history's darkest technological applications – equipment designed specifically to facilitate genocide.

Modern cremation equipment stands in stark contrast. Today's systems prioritize dignity through individual processing, strict identification protocols, and careful handling procedures. They incorporate sophisticated environmental controls that were entirely absent in historical ovens, ensuring clean operation that respects both the deceased and surrounding communities.

"We never forget that each cremation represents someone's loved one," shared a crematory operator with 25 years of experience. "The technology has advanced tremendously, but the heart of what we do is providing a respectful transition. That human element can never be automated."

Contemporary cremation is guided by several core ethical principles. Dignity and respect form the foundation, ensuring that each deceased person is handled with care throughout the process. Environmental justice considerations ensure that cremation facilities don't disproportionately impact vulnerable communities through emissions or other factors. Religious and cultural sensitivity has become increasingly important as cremation grows more common across diverse populations with varying traditions and requirements.

Perhaps most importantly, modern cremation emphasizes transparency – providing families with clear information about the process, handling procedures, and final disposition of remains. This openness stands in sharp contrast to the secrecy that surrounded historical misuse of cremation technology.

At American Mortuary Coolers, we believe understanding this history strengthens our commitment to providing equipment that serves families with dignity while respecting broader community and environmental concerns. The evolution from Holocaust ovens to modern cremation ovens represents not just technological advancement but a fundamental ethical change – from instruments of horror to tools for dignified end-of-life care.

For more information about modern cremation equipment and comprehensive solutions for funeral homes, visit More info about turnkey mortuary solutions.

Conclusion

As cremation rates continue to climb across America, understanding cremation ovens becomes increasingly vital for funeral service professionals. These sophisticated machines aren't just equipment—they're the cornerstone of providing dignified final arrangements for families choosing cremation.

The future of cremation technology looks promising and increasingly sustainable. We're already seeing exciting innovations emerging in the marketplace: electric cremation ovens powered by renewable energy, sophisticated filtration systems that virtually eliminate emissions, and AI-assisted operation that ensures consistent, efficient performance. These advancements reflect our industry's commitment to both environmental responsibility and compassionate service.

When you're considering a cremation oven for your facility, this decision will impact your operations for years to come. Take time to evaluate:

Your expected cremation volume and how many cases you'll need to handle daily or weekly. A busy urban funeral home has very different needs than a rural provider performing occasional cremations.

Available utilities at your location—natural gas access, electrical capacity, and water connections will influence which systems work best for your facility. Some locations simply can't support certain types of equipment without significant infrastructure investments.

Environmental regulations in your area, which can vary dramatically between states and even counties. What's permitted in Tennessee might face strict limitations in California.

Your budget for both initial purchase and long-term operation. A lower upfront cost might mean higher operational expenses over time. As one of our clients in Chicago put it, "I wish I'd spent the extra $20,000 upfront for better efficiency—it would have paid for itself twice over by now."

Here at American Mortuary Coolers, we've guided hundreds of funeral homes through the process of selecting, installing, and maintaining cremation ovens. Our team understands that this equipment represents not just a significant financial investment but also your commitment to serving families with dignity and care.

Whether you're in Johnson City, Atlanta, Chicago, or anywhere across the contiguous United States, we're here to help you steer the complexities of cremation equipment. We believe in straight talk, honest advice, and ongoing support—because in this business, relationships matter as much as equipment reliability.

For more comprehensive guidance on building a complete mortuary solution that integrates seamlessly with your cremation equipment, visit More info about turnkey mortuary solutions.

Modern cremation represents a careful balance of technological precision, environmental responsibility, and above all, respect for the deceased and their families. With the right equipment and proper training, your funeral home can provide cremation services that honor loved ones while meeting all ethical and regulatory standards—and that's something we're proud to help you achieve.