The Complete Guide to Modern Cremation Systems

Cremation systems are specialized equipment designed to reduce human or animal remains to bone fragments through the application of intense heat or chemical processes. As cremation rates continue to climb nationwide, funeral directors need to understand their equipment options.

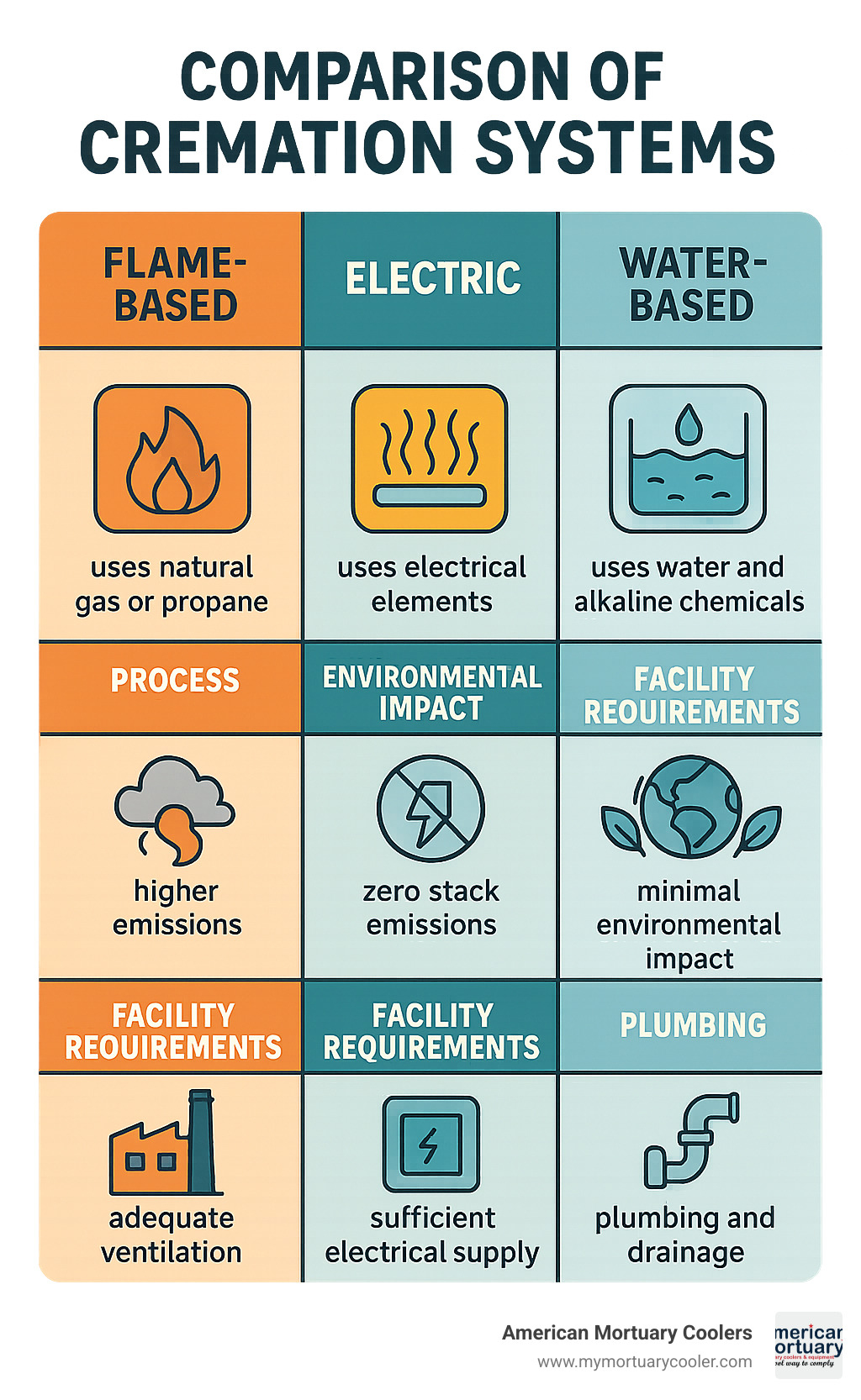

Types of Cremation Systems at a Glance:

| System Type | Process | Average Cycle Time | Capacity | Environmental Impact |

|---|---|---|---|---|

| Flame-Based | Uses natural gas or propane | 75-150 minutes | 500-1,000+ lbs | Higher emissions |

| Electric | Uses electrical elements | 90-180 minutes | 400-800 lbs | Zero stack emissions |

| Water (Alkaline Hydrolysis) | Uses water and alkaline chemicals | 3-16 hours | 450-1,000 lbs | Minimal environmental impact |

The cremation industry has undergone significant change in recent years, with advances in automation, emissions control, and alternative technologies reshaping how funeral homes approach this essential service. Modern systems now feature touchscreen controls, remote diagnostics, and modular components that simplify maintenance and reduce downtime.

For funeral directors considering adding or upgrading cremation services, understanding the differences between flame-based, electric, and water-based systems is crucial for making informed investment decisions that align with both operational needs and environmental considerations.

I'm Mortuary Cooler, a national-level supplier of mortuary coolers and cremation systems with extensive experience helping funeral homes select, install, and maintain the right equipment for their specific needs. My expertise in cremation systems spans multiple technologies and facility sizes, ensuring you receive guidance custom to your unique requirements.

Understanding Cremation Systems Today

The practice of cremation traces back thousands of years, yet modern cremation systems have come a long way from their ancient origins. Today's technology offers efficient, dignified, and environmentally conscious options for families choosing cremation over traditional burial.

As more Americans accept cremation—with rates now surpassing burial in many regions—the funeral industry has responded with remarkable innovations. The Cremation Association of North America (CANA), established in 1913 and now representing over 1,500 members, continues to lead the way in setting standards for this growing segment of death care.

When exploring cremation systems today, you'll encounter three main types: traditional flame-based, modern electric, and innovative alkaline hydrolysis (water-based). Each offers unique benefits regarding environmental impact, operating costs, and regulatory compliance.

Flame-Based Cremation Systems: How They Work

The workhorse of the industry remains the flame-based cremation system. These reliable systems, commonly called retorts or cremators, typically use natural gas or propane to generate the intense heat needed for cremation.

A typical flame-based cremator consists of a primary chamber (the retort) where the body is placed, surrounded by a refractory lining that withstands extreme temperatures. The system includes powerful burners that create temperatures between 1,400-1,800°F, while a secondary chamber (afterburner) further combusts gases and particles to reduce emissions. Sophisticated control systems manage the entire process, balancing temperature, air flow, and timing.

"The CFS2300 human cremation chamber features a recessed hot hearth design accommodating cases greater than 750 lbs and offers automatic weight-based operation without timers or guesswork," explains Tom, a representative from Cremation Systems. This highlights how modern systems have evolved to handle larger cases while simplifying operation.

These workhorses of the industry, like the popular FT II and FT III models, typically complete a cremation in 75–90 minutes and can run continuously, making them ideal for busy facilities needing reliable, round-the-clock operation.

For deeper technical insights, check out our article on A Deep Dive Into Cremation Chambers.

Electric Cremation Systems: The Emission-Free Option

A newer alternative gaining popularity is the electric cremation system. Rather than burning fossil fuels, these innovative systems use powerful electric heating elements to achieve cremation temperatures.

The most compelling advantage of electric systems is their zero stack emissions—there's simply no on-site combustion, meaning no smoke or particulates released into the neighborhood air. This makes them particularly attractive in urban areas with strict air quality regulations or for funeral homes emphasizing their environmental commitment.

Electric systems do have some tradeoffs. They typically require robust electrical infrastructure to support their significant power demands. Cremation cycles generally run 10-20% longer than with flame-based systems. And while they don't produce direct emissions, they do consume substantial electricity, which may indirectly contribute to carbon emissions depending on your local power generation.

"The shift toward electric cremation systems reflects growing environmental consciousness in the death care industry," notes a representative from American Mortuary Coolers. "While the initial investment may be higher, many funeral homes find that the simplified regulatory compliance and marketing advantage of offering 'emission-free' cremation outweighs the additional costs."

Water-Based Cremation Systems: Alkaline Hydrolysis Cremation Systems Explained

Perhaps the most groundbreaking development in cremation systems is water-based cremation, also known as alkaline hydrolysis, aquamation, or water cremation. This gentle process uses water, alkaline chemicals, heat, and pressure to accelerate natural decomposition.

The innovative FC500 alkaline hydrolysis system, protected by US patent 11826803B2, represents cutting-edge technology in this field. The process begins by placing the body in a pressurized stainless steel vessel filled with a solution of water and about 5% alkaline chemicals (typically potassium hydroxide or sodium hydroxide). The solution heats to approximately 300°F under pressure. Over 3-16 hours (depending on the system), this solution gently breaks down all organic material except bone, which is then processed similarly to traditional cremation.

The resulting liquid effluent—rich in amino acids, peptides, sugars, and salts—is sterile and typically discharged into municipal wastewater systems where it returns nutrients to the environment.

"Four new Sustainable Funeral® options to increase cases and profits," notes Fireless Cremation's marketing materials, highlighting how water cremation positions funeral homes at the forefront of both environmental stewardship and business innovation.

The environmental benefits are impressive: approximately 1/10 the carbon footprint of flame cremation, no direct emissions of mercury or potentially harmful substances, significantly lower energy consumption, and a water effluent that's both sterile and nutrient-rich.

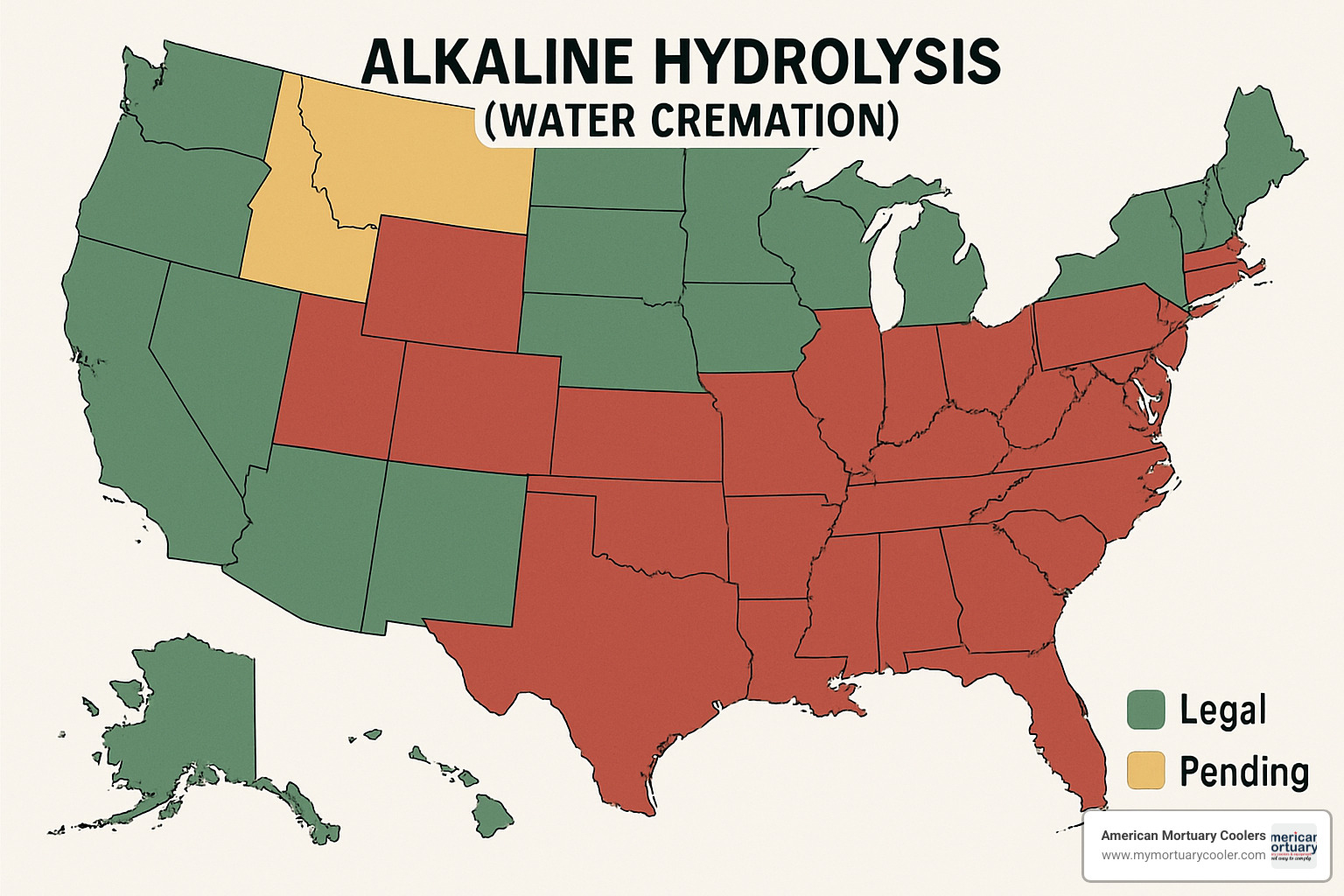

One important consideration: the legal status of alkaline hydrolysis varies by jurisdiction. While gaining acceptance rapidly, it's not yet permitted in all U.S. states or countries. Always verify your local regulations before investing in this technology.

For more information about water cremation systems, explore External research on water cremation.

Human vs. Animal Cremation Systems

When you think about cremation systems, you might not realize there's a significant difference between those designed for people and those built for our beloved pets. While they share basic principles, these systems are custom to meet very different needs.

Size and Capacity Differences

Human cremation systems are built for larger capacities and different operational demands. The CFS3000 Hi-Capacity Human Retort, for example, can handle remains exceeding 1,000 pounds and processes about 250 pounds per hour. That's quite impressive when you think about it!

Human chambers typically feature generous dimensions—usually around 42"×89" to 54"×101"—to accommodate a wide range of cases. Pet cremation chambers, on the other hand, come in more varied sizes. Some are designed for single small pets weighing 25-100 pounds, while others can handle larger animals or multiple pets at once.

The processing rates tell an interesting story too. Human systems typically handle 150-250 pounds per hour, while pet systems usually process about 75-100 pounds per hour. This difference reflects the unique demands of each type of service.

Operational Considerations

The day-to-day operation of pet cremation facilities often looks quite different from human crematories. A veterinary clinic might need to handle several small animals throughout the day, rather than fewer larger cases. This creates different workflow patterns and equipment needs.

Many pet cremation systems feature partitioned chambers that allow for multiple private cremations simultaneously—something rarely needed in human cremation. This design helps pet cremation providers offer the personalized service that many grieving pet owners desire.

I've noticed that mobility is another interesting difference. Some pet cremation units are designed to be portable or modular, allowing for mobile services that can travel to veterinary clinics or even homes. Human cremation, by contrast, almost always occurs in a fixed facility.

As one distributor of Addfield Environmental Systems notes, "Addfield equipment is in over 140 countries and the company has manufactured robust pet cremation equipment in the UK for more than 40 years." This specialized focus highlights how pet cremation has developed its own distinct equipment market.

Regulatory Differences

The rules governing human and pet cremation systems often come from entirely different authorities. Human cremation typically falls under funeral and cemetery regulatory bodies with strict oversight. Pet cremation may instead be regulated under veterinary, waste disposal, or general business regulations, depending on your location.

Emissions standards can vary between human and animal crematory permits as well. Human facilities often face more stringent air quality requirements, though this gap is narrowing in many jurisdictions as environmental awareness grows.

Record-keeping requirements are substantially different too. Human cremation requires detailed documentation for obvious legal and ethical reasons, while pet cremation documentation tends to be simpler, though still important for quality service.

For funeral homes thinking about offering both services, understanding these differences is essential for proper planning. The good news is that many facilities successfully operate both human and pet cremation systems under one roof. This approach can create valuable additional revenue streams while allowing you to share infrastructure costs like buildings, utilities, and staff.

If you're considering adding cremation services or expanding your current offerings, take time to research the specific requirements in your area. For a more detailed breakdown of different cremation machine types, check out our article on Cremation Machines 101.

Inside Modern Cremation Equipment: Features & Technology

When you step into a modern crematory, you're not just entering a room with a furnace—you're encountering sophisticated systems designed with thoughtful innovation. Today's cremation systems have evolved dramatically, changing what was once a largely manual process into an operation that balances efficiency, safety, and environmental responsibility.

Automation and Control Systems

Gone are the days of turning knobs and watching gauges. Modern cremation systems now feature intuitive touchscreen interfaces that make operation simpler and more precise. The Phoenix Series and N20 Series have replaced old analog controls with digital displays that provide clear information at a glance.

"The CFS 2300 is 'easy and efficient to operate' compared to older equipment," notes one manufacturer, and it's easy to see why. Rather than relying on timers and guesswork, systems like this use weight-based automatic operation to optimize the cremation process for each individual case.

Data management has also taken a leap forward. PC-based systems now store cremation records on flash drives and can automatically email data to stakeholders, making record-keeping seamless. Before beginning a cremation, operators can digitally enter and store all case information, creating a secure and accessible record.

Remote Diagnostics and Monitoring

Perhaps the most welcome advancement for crematory operators is the ability to receive support without waiting for a technician to arrive on-site.

The Tek Marshal internet-based diagnostic system allows manufacturers to remotely connect to your cremation system, troubleshooting issues from hundreds of miles away. As one manufacturer explains, "By using Tek Marshal internet diagnostics and remote access, factory personnel can guide the operator without needing to be on-site."

This connectivity extends beyond just fixing problems. Crematory managers can monitor operations remotely, receive alerts about potential maintenance needs before equipment fails, and even get remote assistance during critical startup phases. For facilities in remote locations, this technology has been nothing short of revolutionary, dramatically reducing downtime and service costs.

Emissions Control Technology

Environmental stewardship is now built directly into modern cremation systems through advanced emissions control technology. Opacity sensors continuously monitor particulate emissions, ensuring your facility stays within EPA compliance. "An opacity sensor continuously monitors emissions during the cycle to ensure all EPA requirements are met," explains a manufacturer representative.

Secondary afterburners ensure that gases are fully combusted before release, significantly reducing the environmental impact. Computer-controlled air/fuel mixtures maximize efficiency while minimizing emissions, and some advanced systems now incorporate filtration technology to further reduce environmental impact.

These features aren't just good for the planet—they're good for business, helping crematory operators maintain positive relationships with their communities and avoid costly regulatory violations.

Safety Features

Safety is paramount in crematory operations, and modern cremation systems incorporate numerous features to protect operators and facilities. Safety interlocks prevent operation unless all safety conditions are met, while UL listing provides independent certification that the equipment meets rigorous safety standards.

Some systems now draw combustion air from outside the building for improved safety, and automated emergency shutdown procedures can quickly address critical situations before they become dangerous.

These safety features work quietly in the background, giving operators confidence and peace of mind during daily operations.

Monitoring & Controlling Cremation Systems for Safety and Compliance

The brain of any modern cremator is its monitoring system. Multiple temperature probes continuously track conditions throughout the system, while data logging creates a permanent record of each operation for both quality control and compliance purposes.

CAN-bus networks allow different components to communicate with each other, creating an integrated system rather than isolated parts. Fire Marshal systems monitor critical safety parameters, while opacity alarms immediately alert operators if emissions approach regulatory thresholds.

These monitoring systems serve multiple valuable purposes. They ensure safety by confirming the system operates within safe parameters. They demonstrate compliance by documenting adherence to environmental regulations. They improve efficiency by optimizing fuel consumption and cycle times. And they support maintenance by identifying components that may need service before they fail.

For funeral directors and crematory managers, these automated monitoring systems provide genuine peace of mind that their cremation systems are operating safely, efficiently, and in full compliance with all applicable regulations.

To learn more about how different components work together in the cremation process, read our article on The Role of Cremation Retorts in the Cremation Process.

Performance Metrics: Capacities, Cycle Times & Fuel Needs

Shopping for cremation systems can feel overwhelming with all the technical specifications and performance numbers. Let's break down what these metrics really mean for your funeral home's daily operations and bottom line.

Load Capacity and Processing Rates

Think of your cremation system's capacity like your car's engine size - it determines how much work it can handle and how quickly. Different models offer varying capabilities to match your facility's needs:

The Phoenix II-3 Human Crematory handles remains up to 1,000 pounds with impressive cremation times of just 45-60 minutes per case. For higher volume operations, the CFS3000 Hi-Capacity Human Retort processes at a rate of 250 pounds per hour, easily managing cases over 1,000 pounds.

Medium-duty options like the CFS2300 accommodate cases exceeding 750 pounds while processing at about 150 pounds per hour. Meanwhile, the FT USA V2 cremator offers a more modest 500-pound maximum capacity and can typically handle up to 3 cremations daily.

"A crematorium with an average of 300 ceremonies a year places different demands on a cremator than a crematorium with 2,500 ceremonies," as one manufacturer wisely points out. Your expected case volume should be your north star when selecting equipment.

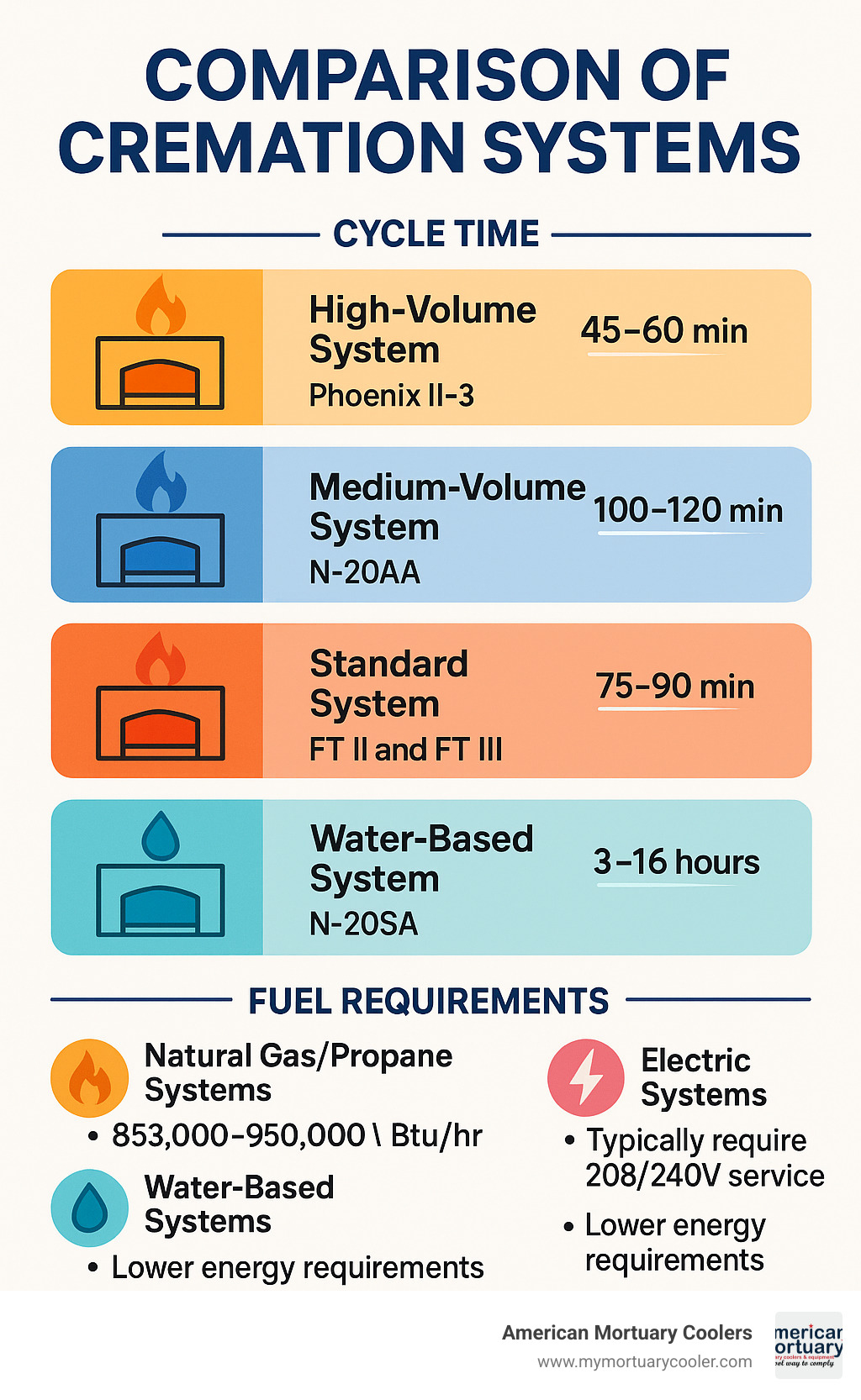

Cycle Times

The time required to complete a single cremation varies significantly between models and technologies - this directly impacts how many cases you can handle in a day:

High-volume systems like the Phoenix II-3 complete a cremation in just 45–60 minutes, while standard systems such as the FT II and FT III typically require 75–90 minutes. More basic models like the N-20SA might need up to 150 minutes per case.

Water-based cremation systems operate on a different timeline altogether, requiring 3-16 hours depending on the specific technology used.

These differences matter tremendously for scheduling. A system with 60-minute cycles could potentially handle 12 cases in a 12-hour workday, while one with 120-minute cycles would max out at 6 cases. For many funeral homes, this throughput capacity directly impacts revenue potential.

Fuel Requirements and Energy Consumption

Your utility bills will reflect your choice of cremation system, so understanding energy consumption is crucial for budgeting operating costs:

Natural gas and propane systems vary widely in their appetite for fuel. The FT II's primary burner consumes 853,000 Btu/hr, while the larger FT III needs 950,000 Btu/hr. The high-capacity CFS3000 requires 3,380 CFH of natural gas at 7" water column pressure, and the CFS2300 uses either 2,350 CFH of natural gas or 940 CFH of propane.

Electric cremation systems have different infrastructure requirements. The CFS2300 needs 240V, single-phase, 40A electrical service, while the larger CFS3000 demands 208/240V, single-phase, 60A service with 6 AWG wiring.

Water-based systems offer a different energy profile altogether - they generally use less energy than flame-based systems but require significant water (typically 100-300 gallons per case) and standard 240V electrical service.

As one manufacturer notes, there's "continuous development of both hardware and computer controls to minimize energy consumption amid rising energy costs." This focus on efficiency helps protect your bottom line as utility rates continue to climb.

When you're ready to select a cremation system for your facility, we at American Mortuary Coolers can help you match these performance metrics to your anticipated case volume, ensuring you invest in equipment that meets your needs without paying for excess capacity you won't use.

Environmental Regulations, Emissions & Sustainability Trends

The environmental impact of cremation systems has become a hot topic in recent years, and for good reason. As someone who's helped countless funeral homes steer these waters, I've seen how understanding environmental regulations isn't just about compliance—it's increasingly becoming a business necessity.

EPA and Local Emissions Requirements

Every cremation system in operation today must dance to the tune of both federal EPA regulations and local air quality standards. This isn't as intimidating as it sounds once you understand the basics.

The EPA primarily focuses on opacity—essentially how much visible smoke your stack emits. Modern systems include continuous opacity monitoring to ensure you're staying within acceptable limits. Particulate matter is also closely regulated, with specific concentration limits that vary by location.

One crematory owner in Colorado told me, "When we first started looking into adding cremation, the air quality permitting seemed overwhelming. But our equipment manufacturer walked us through every step." This has become standard practice in the industry—no one expects you to steer these waters alone.

Mercury emissions, particularly from dental amalgams, have received increased attention. While not yet universally regulated, many jurisdictions are moving in this direction, so forward-thinking funeral homes are already addressing this concern.

"An opacity sensor continuously monitors emissions during the cycle to ensure all EPA requirements are met," as one manufacturer representative explained to me during a recent installation. This kind of built-in compliance monitoring has become standard in quality cremation systems.

Filtration and Emissions Control Technology

The technology behind modern cremation systems has advanced dramatically to address environmental concerns. Secondary afterburners are now standard in quality systems, ensuring gases and particulates undergo complete combustion before being released.

Some areas with particularly strict air quality standards may require additional filtration systems. These can be retrofitted to existing units or included in new installations. Computer-controlled combustion is another game-changer, optimizing the air/fuel mixture in real-time to minimize emissions while maximizing efficiency.

I recently visited a crematory in California that installed a system with continuous emissions monitoring. "The real-time data doesn't just keep us compliant," the manager explained, "it actually helps us operate more efficiently and save on fuel costs." This highlights how environmental improvements often yield operational benefits as well.

Carbon Footprint Considerations

Different cremation systems leave very different carbon footprints:

Traditional flame-based systems produce the highest direct CO₂ emissions due to their reliance on fossil fuels. However, newer models are significantly more efficient than those from even a decade ago.

Electric cremation systems produce zero direct emissions from your facility, but their true environmental impact depends on your local electricity source. In areas powered primarily by renewable energy, these systems can be remarkably green.

Water-based alkaline hydrolysis systems stand out as the environmental champions, with approximately 1/10 the carbon footprint of traditional flame cremation. As one provider told me, "Water cremation is presented as a zero-emission, earth-regenerative alternative to flame-based cremation." While this technology isn't yet legal everywhere, its adoption continues to grow as regulations evolve.

Maintenance and Sustainability

Sustainability in cremation systems extends beyond just what comes out of the stack—it includes how long equipment lasts and how efficiently it operates day-to-day.

Innovations like the Quick Change Modular Hearth System™ significantly reduce downtime and extend equipment life by making repairs faster and less invasive. As one manufacturer proudly explained, this system "reduces downtime and repair costs" while also extending the overall lifespan of the equipment.

Remote diagnostic capabilities now allow many issues to be identified and sometimes even resolved without an on-site service call, reducing the carbon footprint associated with maintenance visits. Energy efficiency improvements mean newer systems typically use less fuel per cremation, saving both money and emissions.

The modular design approach of modern equipment allows for component replacement rather than complete system replacement when parts eventually wear out—a win for both your budget and the planet.

Future Trends in Sustainable Cremation

The cremation industry continues moving toward greater sustainability, with several exciting developments on the horizon:

Alkaline hydrolysis (water cremation) is gaining legal recognition in more states each year, offering families a significantly greener option. Human composting, while still very new, has been legalized in Washington, Colorado, Oregon, and Vermont, with more states likely to follow.

Some innovative facilities are now implementing energy recovery systems that capture and use waste heat from the cremation process. Others are exploring the integration of renewable fuels like biogas.

I've even started seeing carbon offset programs being offered by forward-thinking crematories, allowing families to choose carbon-neutral services by investing in environmental projects that counterbalance emissions.

For those interested in diving deeper into emissions research and environmental considerations, the Latest research on cremation emissions provides valuable insights.

At American Mortuary Coolers, we're committed to helping funeral homes steer this evolving landscape. Whether you're looking to upgrade existing equipment or install a completely new cremation system, we can help you balance environmental responsibility with operational efficiency and budget considerations.

Selecting, Installing & Operating a Cremation System

Choosing the right cremation system for your funeral home isn't just a purchase decision—it's a long-term investment in your business. At American Mortuary Coolers, we've guided countless funeral directors through this journey, helping them find equipment that not only meets their immediate needs but also accommodates future growth.

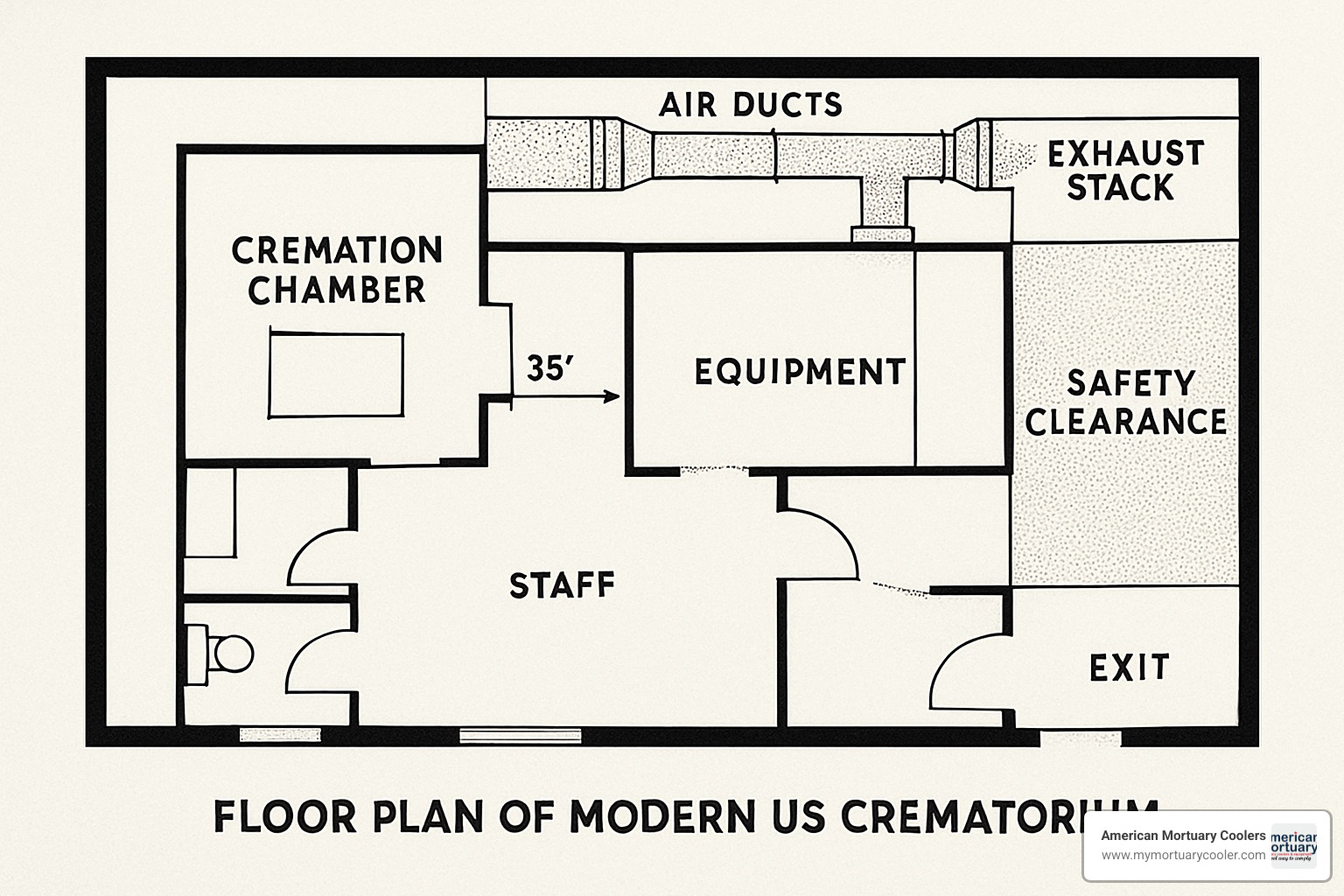

Site and Facility Considerations

When planning for a cremation system, your physical space matters tremendously. Human cremators aren't exactly compact—they typically need at least a 15'×6'×8' space to operate safely. These systems are heavy too, weighing between 25,000-32,000 pounds, so your floor needs to be up to the task.

"I remember visiting a funeral home that forgot to check their ceiling height," shares one of our installation specialists. "We had to modify the entire plan on the spot because they only had 8 feet of clearance when the system needed 10."

Don't overlook ventilation and utilities either. Your cremation system will need proper makeup air, a correctly configured stack, and appropriate gas and electrical connections to function safely and efficiently.

If you're starting fresh, the good news is that prefabricated metal-building crematories can be surprisingly cost-effective—around $50 per square foot, with total costs often under $200,000 including equipment. For existing buildings, we'll help you assess doorway access, floor reinforcement needs, and utility modifications before installation day arrives.

Permitting and Regulatory Approval

The paperwork marathon begins long before your cremation system arrives. You'll typically need:

Zoning approval confirming crematory use is permitted at your location Building permits for any necessary construction or modifications Environmental permits covering air quality and emissions Funeral/cemetery board approval where applicable for human cremation

This process can feel overwhelming, but as one of our clients recently told us, "Having American Mortuary Coolers handle the permit applications saved us months of headaches." We're happy to assist with these requirements as part of our service package.

Volume Analysis and Equipment Sizing

Matching your equipment to your expected case volume is crucial for operational efficiency. Installing a high-capacity system for a low-volume operation wastes money, while undersizing creates bottlenecks and frustration.

For funeral homes handling 1-3 cases daily, basic systems like the N-20SA or FT USA V2 provide reliable service. Medium-volume operations (4-8 cases daily) are better served by mid-range systems like the N-20AA or FT II. High-volume facilities processing 8+ cases daily need powerhouse systems like the Phoenix II-3 or CFS3000.

As one manufacturer wisely notes, "A crematorium with 300 ceremonies a year has very different needs than one handling 2,500." We'll help you analyze your current volume and growth projections to find the right fit.

Financing and Budgeting

Let's be candid about costs—cremation systems represent a significant investment. Basic systems start around $135,000, while high-capacity units can exceed $200,000. Installation typically adds $15,000-$30,000 depending on your site's requirements, and permitting fees range from $5,000-$15,000 based on your location.

The good news? Specialized financing options exist for funeral industry equipment. "Financing is available through Live Oak Bank," as one manufacturer points out, offering custom solutions that understand the unique nature of funeral service businesses.

Maintenance Planning

A well-maintained cremation system is a reliable one. Modern equipment offers significant advantages in this area, with preventative maintenance typically scheduled quarterly or semi-annually.

One game-changer in recent years has been the Quick Change hearth system, which allows for rapid replacement of refractory components. "Quick Change hearth is the 'fastest repair option in the industry,'" one manufacturer proudly states, noting their system allows full hearth replacement in just one day instead of the week or more traditional repairs might require.

Many of our clients opt for comprehensive service agreements that include regular inspections and priority service. And with remote diagnostic systems like Tek Marshal, many issues can be identified and sometimes even resolved without an on-site visit, minimizing downtime.

For a deeper dive into selecting and installing cremation equipment, our article on Cremation Equipment 101: Tools of the Trade provides additional insights.

Cost Breakdown of Cremation Systems

Understanding the complete financial picture helps you make informed decisions about your cremation system investment. Beyond the equipment itself, a typical new crematory installation includes building costs (approximately $60,000 for a 1,200 sq ft facility at $50/sq ft), ancillary equipment ($15,000-$50,000), and permits ($5,000-$15,000).

"A typical 1,200 sq ft crematory facility with a human retort and accessories can be built and equipped for less than $200,000 in most U.S. markets," notes one turnkey provider we work with. This comprehensive approach eliminates surprise costs down the road.

Day-to-day expenses include fuel (natural gas or propane), electricity, maintenance contracts ($2,500-$7,500 annually), periodic refractory replacement, and labor. Your return on investment timeline will depend on case volume, local market pricing, and operational efficiency.

For a detailed breakdown of equipment costs, check out our article on Burning Through Budgets: Crematorium Machine Prices Explained.

Ancillary Equipment & Accessories Every Crematory Needs

Your cremation system is just one part of a complete operational setup. For safe, efficient operation, you'll also need:

Loading systems like the Flex 180 Autoloader ($15,799-$35,304) or hydraulic scissors lifts that protect your staff from injury and ensure dignified transfers.

Processing equipment including deluxe processing stations for handling cremated remains, remains processors that ensure consistent particle size, and cooling racks for safe handling.

Safety gear is non-negotiable—reflectorized aluminum jackets, face shields, heat-resistant gloves, and leather aprons protect your team from the intense heat of cremation operations.

Refrigeration solutions ensure proper body preservation before cremation. At American Mortuary Coolers, this is our specialty, and we can integrate these systems seamlessly with your crematory setup.

Our comprehensive [Cremation / Ship Outs catalog] showcases all these essential accessories, allowing you to outfit your facility completely through one trusted partner.

Training, Service & Support for Crematory Operators

Even the finest cremation system is only as good as the people operating it. Most manufacturers provide comprehensive initial training—typically 1-3 days of on-site instruction during installation and startup, along with detailed documentation and video resources.

"We're one of the few cremation furnace manufacturers who install the equipment we build," notes one company representative. "This allows us to provide truly turnkey solutions including installation, firing, and personalized training."

Beyond manufacturer training, we strongly recommend industry certifications like those offered by the Cremation Association of North America (CANA). Some states also require specific crematory operator training, which we can help you steer.

Modern cremation systems often include remote support capabilities that dramatically improve service response. "By using Tek Marshal internet diagnostics and remote access, factory personnel can guide the operator without needing to be on-site," explains one manufacturer. This technology has been a game-changer for facilities in rural areas where on-site service might take days to arrange.

At American Mortuary Coolers, we partner with leading equipment manufacturers to ensure our clients receive not just equipment, but comprehensive support throughout the life of their cremation system. After all, we're not just selling you a machine—we're helping you provide an essential service to your community for years to come.

Frequently Asked Questions about Cremation Systems

What permits and environmental reports are required before installation?

When you're ready to install a cremation system, navigating the permitting process can feel overwhelming. Most funeral directors find they need several approvals before they can break ground.

You'll typically need zoning approval first, which confirms that a crematory is allowed at your location. This is particularly important if you're adding cremation to an existing funeral home in a residential area.

Building permits come next, covering any construction or modification to your facility. These ensure your building will safely accommodate the weight and operational needs of the equipment.

Perhaps the most critical is the air quality permit from your state or local environmental agency. This looks at potential emissions and ensures your system will meet air quality standards.

"We've helped hundreds of funeral homes steer the permitting maze," shares our installation specialist at American Mortuary Coolers. "What surprises many directors is how much the requirements vary from one county to the next."

In some jurisdictions, you may also need a full environmental assessment, especially in sensitive areas or communities with stricter environmental regulations.

If you're feeling lost in paperwork, remember we're just a phone call away. Our team at American Mortuary Coolers can guide you through the specific requirements for your area and connect you with manufacturer resources to simplify the process.

How long does a typical cremation cycle take in different systems?

The time needed to complete a cremation varies significantly depending on which cremation system you choose, which affects how many cases you can handle daily.

High-volume flame systems like the Phoenix II-3 can complete a cremation in just 45-60 minutes, making them ideal for busy urban crematories. Standard systems such as the FT II or FT III typically require 75-90 minutes per case.

More basic flame systems might need up to 150 minutes for a complete cycle. If you're considering an electric system, prepare for slightly longer times, usually 90-180 minutes per cremation.

Water-based alkaline hydrolysis takes considerably longer – anywhere from 3 to 16 hours depending on the specific technology and settings used. While this is significantly longer than flame cremation, many facilities operate these systems overnight.

"The days of setting a timer and hoping for the best are behind us," explains our equipment specialist. "Today's cremation systems use weight-based operation to optimize each cycle automatically, which is both more efficient and more respectful."

These times represent averages. Larger cases or those with high body mass may require longer cycles, which your system will adjust for automatically.

Is alkaline hydrolysis legal in my state or country?

The legal landscape for water cremation (alkaline hydrolysis) continues to evolve rapidly, with new states approving this technology every year. Currently, about 20 U.S. states have explicitly legalized this process, with legislation pending in several others.

In Canada, alkaline hydrolysis is legal in most provinces, while the United Kingdom has approved it nationwide. Australia permits the process in most states, and throughout Europe, the legal status varies country by country.

One provider proudly notes that "Fireless Cremation® and Sustainable Funeral® are registered trademarks," highlighting how this alternative is gaining commercial acceptance despite its varying legal status.

What makes this question complicated is that some states haven't specifically addressed alkaline hydrolysis in their legislation. In these regulatory gray areas, get clear guidance before investing.

"We had one client in Colorado who was ready to purchase a water cremation system before the legislation was finalized," recalls our sales director. "We helped them develop a contingency plan while the bill moved through the state legislature. Thankfully, it passed, and they were ready to go on day one."

At American Mortuary Coolers, we stay current on the rapidly changing legal status of alternative cremation systems and can advise you on the options available in your specific location. If you're considering water cremation, let's talk about whether it's a viable option for your facility.

Conclusion

The landscape of cremation systems continues to evolve rapidly, driven by technological innovation, environmental concerns, and changing consumer preferences. As more families choose cremation over traditional burial, funeral directors face important decisions about equipment investments that will serve their communities for years to come.

Whether you're considering a traditional flame-based system, exploring electric alternatives, or investigating water-based technologies like alkaline hydrolysis, understanding the operational requirements, environmental implications, and financial considerations is essential for making informed decisions. Each option offers distinct advantages, and the right choice depends on your specific facility needs, case volume, and market demands.

At American Mortuary Coolers, we don't just sell equipment – we build partnerships with funeral professionals navigating these complex choices. With our presence across the United States including Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, and comprehensive regional coverage, we're never far when you need support.

"We understand that adding or upgrading cremation services represents a significant investment," says Tom, our lead cremation specialist. "That's why we walk alongside you through the entire process – from initial planning through installation and beyond."

Our approach goes beyond the transaction. We help with site preparation, permitting guidance, staff training, and ongoing maintenance support. We believe your cremation system should align perfectly with both your immediate operational needs and your long-term business vision.

The future of cremation technology promises continued advancement in efficiency, environmental performance, and operational flexibility. As environmental concerns grow and consumer preferences evolve, manufacturers are responding with innovations that reduce emissions, improve efficiency, and offer more sustainable options. By partnering with American Mortuary Coolers, you'll stay at the forefront of these developments, equipped to serve families with dignity and respect while meeting the changing demands of the industry.

For more information about our full range of mortuary solutions, including industry-leading mortuary coolers that complement your cremation operations, visit More info about our mortuary cooler solutions.