Why HVAC and Refrigeration Systems Are Essential for Modern Life

HVAC and refrigeration systems control temperature, humidity, and air quality in virtually every building we use - from homes and offices to hospitals and funeral homes. These interconnected systems use the same fundamental principles of heat transfer and thermodynamics.

Quick Overview: HVAC and Refrigeration Basics

- HVAC = Heating, Ventilation, and Air Conditioning for building comfort

- Refrigeration = Cooling systems for food preservation, medical storage, and specialized applications

- Core Components: Compressor, condenser, evaporator, expansion valve

- Common Applications: Residential comfort, commercial buildings, cold storage, mortuary facilities

- Career Requirements: 4-year apprenticeship in BC, Red Seal certification, ongoing training

The industry employs over 3,300 heating, refrigeration and air conditioning mechanics in British Columbia alone, with median earnings of $66,739 annually. Between 2023 and 2033, forecasters expect 840 new job openings as environmental regulations drive system upgrades and retirements create opportunities.

At American Mortuary Coolers, we've spent years working with specialized refrigeration systems that serve funeral homes across North America, understanding how critical proper temperature control is for maintaining dignity and service quality.

Understanding HVAC and Refrigeration

The magic behind HVAC and refrigeration systems isn't really magic at all - it's basic physics applied brilliantly. These systems don't actually create cold. Instead, they move heat from where you don't want it to where you can get rid of it safely.

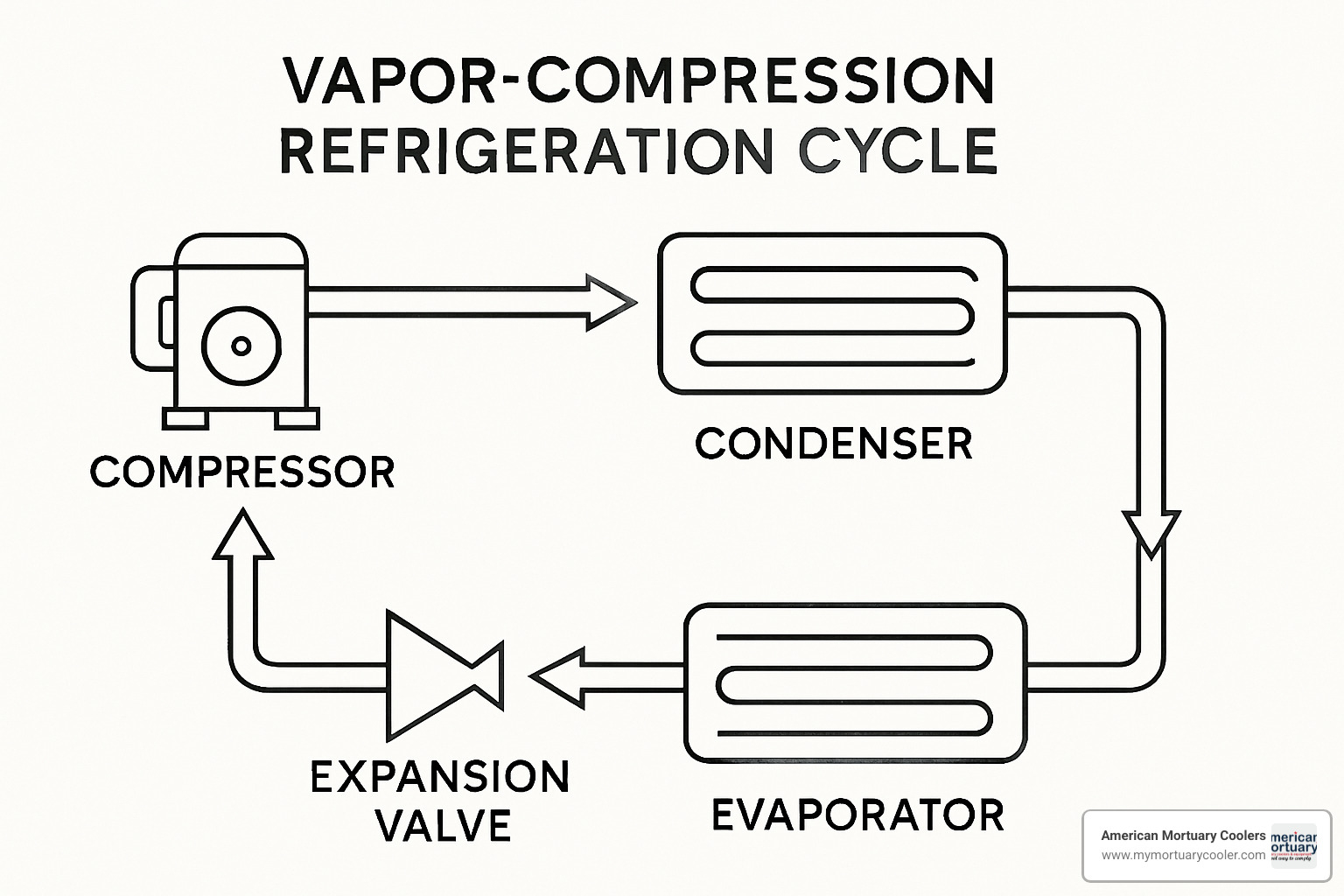

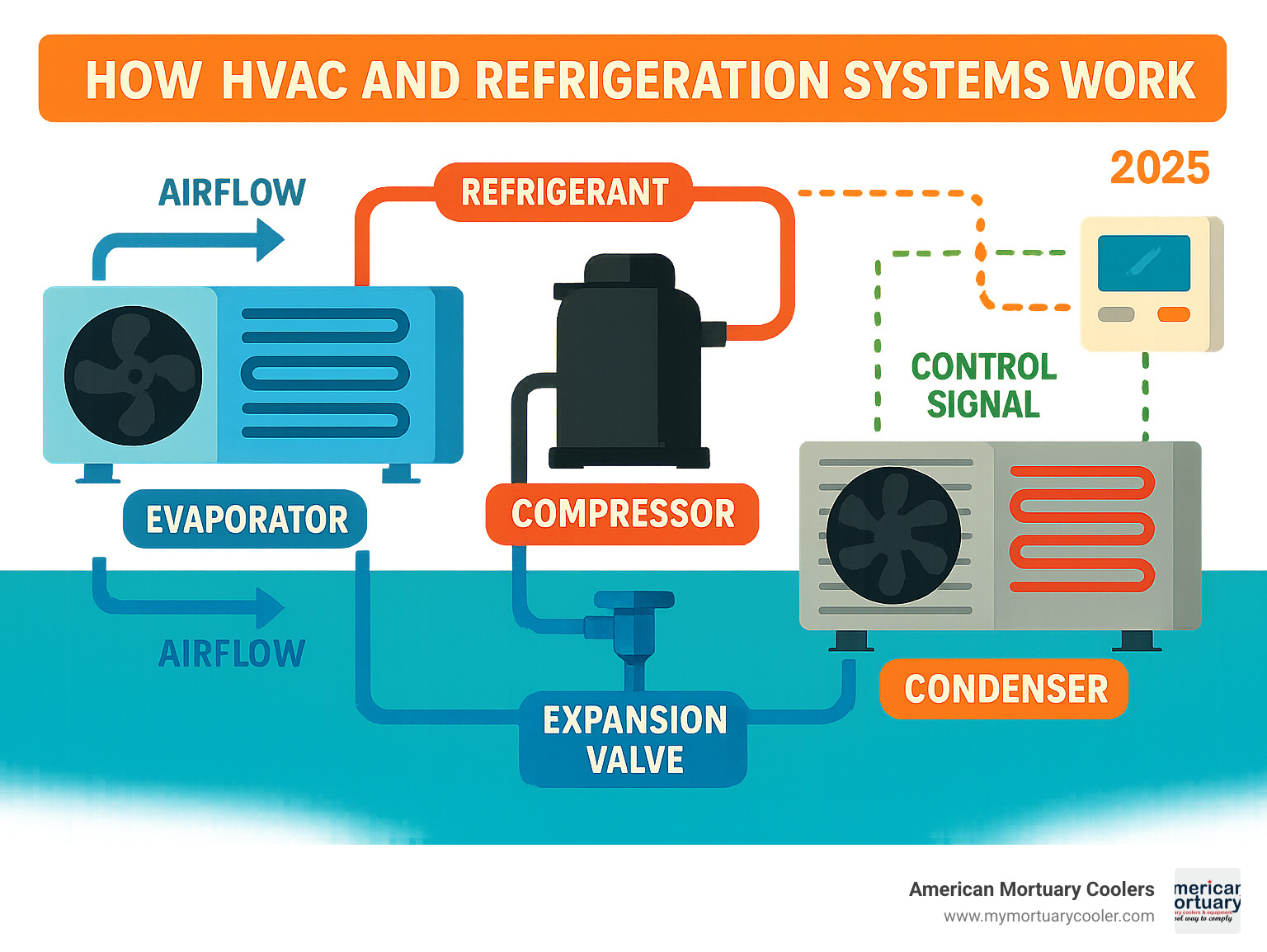

The refrigeration cycle forms the backbone of every cooling system. This cycle has four main stages that work together seamlessly. First, the compressor pressurizes refrigerant gas, which makes it hot. Next, in the condenser, this hot gas releases its heat and turns into liquid. Then the liquid refrigerant expands through a valve, dropping both pressure and temperature dramatically. Finally, in the evaporator, the cold refrigerant absorbs heat from whatever needs cooling and turns back into gas.

This cycle repeats endlessly, with modern control systems automatically adjusting based on temperature demands. Load calculations are critical for system performance - too small a system runs constantly without reaching the right temperature, while too large systems short cycle, giving poor humidity control and high energy bills.

How HVAC and Refrigeration Systems Work

The vapor-compression cycle has been the star of the show since the 1800s. Everything starts in the evaporator, where cold refrigerant acts like a heat sponge. The compressor then grabs this low-pressure gas and squeezes it hard, dramatically raising both pressure and temperature. Next, the condenser becomes the system's heat dump, releasing heat to the outside air or water. Finally, the expansion valve lets the high-pressure liquid expand rapidly, making the temperature plummet.

Airflow keeps everything moving smoothly. Fans circulate air over evaporator coils to spread cooling throughout buildings, while other fans ensure condensers can reject heat properly.

Key Components Explained

Compressors are truly the heart of any system. Scroll compressors have become popular in residential and light commercial work because they're quieter and more efficient than older piston-style models.

Condensers have one job: get rid of heat. Air-cooled condensers use fans to blow air over coil surfaces, while water-cooled condensers use cooling towers or city water.

Evaporators come in many shapes and sizes, each designed for specific jobs. Expansion valves control the refrigerant flow and maintain proper system pressures.

Thermostats and sensors have gotten incredibly smart. Today's controls can learn your schedule, adjust for weather changes, and even talk to utility companies during peak demand periods.

Types of HVAC and Refrigeration Systems Across Sectors

The world of HVAC and refrigeration is surprisingly diverse, stretching from simple window units to massive industrial systems. Each sector has unique challenges that shape equipment choices.

Residential systems typically rely on split systems where the noisy compressor lives outside while the quiet air handler stays indoors. Heat pumps are becoming the go-to choice since they handle both heating and cooling efficiently.

Commercial applications step up the complexity with rooftop packaged units serving smaller businesses and sophisticated central plant systems for office towers. Variable refrigerant flow (VRF) systems can simultaneously heat one zone while cooling another.

Industrial refrigeration often turns to ammonia-based systems despite their complexity. Ammonia transfers heat incredibly well and doesn't harm the ozone layer, making it ideal for large-scale operations.

| Sector | Common Systems | Key Requirements | Typical Applications |

|---|---|---|---|

| Residential | Split systems, heat pumps, mini-splits | Energy efficiency, quiet operation, smart controls | Homes, apartments, condos |

| Commercial | Rooftop units, VRF systems, central plants | Precise control, zone flexibility, reliability | Offices, retail, restaurants |

| Industrial | Ammonia systems, large chillers, process cooling | High capacity, 24/7 operation, specialized temperatures | Food processing, warehouses, manufacturing |

Residential Options

Split systems separate the noisy outdoor work from the quiet indoor comfort. Heat pumps are the efficiency champions, delivering 2-4 times more heating energy than they consume in electricity. Mini-split systems shine in homes without existing ductwork, offering zone control that can slash energy bills by 30% or more.

Commercial & Industrial Installations

Packaged rooftop units dominate smaller commercial buildings. Large commercial buildings often choose central plant systems with chillers and boilers. Supermarket refrigeration represents one of the most challenging commercial applications, with central rack systems serving dozens of display cases.

More info about walk-in cooler systems demonstrates the complexity involved in commercial refrigeration design.

Specialized Applications for Mortuaries

Mortuary refrigeration operates differently from typical commercial cooling. Body coolers typically maintain temperatures between 36-40°F - warmer than food refrigeration but essential for proper preservation. Humidity control becomes critical, requiring sophisticated controls and monitoring.

At American Mortuary Coolers, we understand that funeral homes need more than just cold storage. Our custom solutions fit specific space constraints while operating quietly enough not to disturb services.

Cold Comfort: Choosing the Right Mortuary Refrigeration Unit provides detailed guidance on selecting appropriate equipment.

Careers, Training & Certification Pathways in BC

If you're looking for a stable, well-paying career that combines technical skills with problem-solving, HVAC and refrigeration work in British Columbia offers excellent opportunities. With 840 job openings expected between 2023 and 2033, there's real job security here.

The path to becoming a certified technician requires a four-year apprenticeship that blends hands-on workplace training with classroom learning. You'll spend 6,210 hours working alongside experienced technicians while completing 33 weeks of technical schooling.

SkilledTradesBC manages the apprenticeship system. The Red Seal certification is your ticket to working anywhere in Canada without additional testing.

HVAC and Refrigeration Technician Pathway in BC

The apprenticeship pathway gives you comprehensive training in every aspect of HVAC and refrigeration work. Work-based training happens under certified journeypersons who become your mentors. The 33 weeks of technical training cover theory and hands-on practice in controlled environments.

BCIT HVAC & Refrigeration Technician Certificate Details

BCIT's 41-week HVAC and Refrigeration Technician certificate program offers an intensive alternative route. Graduates receive credit for the first three levels of technical training. The program costs approximately $1,118 for books and supplies plus tuition.

Entrance requirements include English proficiency, mathematics prerequisites, and passing the BCIT Mechanical Reasoning Trades Entry Assessment. Gas B ticket training is included, allowing graduates to work on gas-fired heating equipment.

Skills for Success & Advancement

Critical thinking and problem-solving abilities become essential as you encounter complex system problems. Digital controls and building automation systems require ongoing education throughout your career. Specialization opportunities exist in areas like industrial refrigeration, building automation, and green technologies.

Industry Demand & Earnings

The numbers for HVAC and refrigeration careers in BC are impressive. Median annual earnings of $66,739 compare favorably to many other trades, with hourly wages ranging from $19.00 to $47.00 depending on experience and specialization. The Mainland/Southwest region accounts for 60.3% of employment in the trade.

Technology Trends, Regulations & Sustainability

The HVAC and refrigeration world is changing faster than ever before. Low-GWP refrigerants are the biggest game-changer right now. The old standby refrigerants like R-410A are being phased out because they contribute to global warming. The new A2L refrigerants have ultra-low global warming potential, but they're mildly flammable, requiring new safety procedures and updated training.

The heat pump revolution is happening right now, especially in Canada where building codes are pushing toward electrification. IoT monitoring and building automation are making systems smarter than ever, with equipment that can predict problems before they cause failures.

The AIM Act is driving change by phasing down HFC production to just 15% of historic levels by 2036. ASHRAE 15 provides the safety standards for new A2L refrigerants.

Scientific research on low-GWP refrigerants shows why these changes are necessary and how the industry is adapting.

Environmental Regulations Shaping HVAC and Refrigeration

The Clean Air Act started this journey by addressing ozone-depleting substances. The SNAP program evaluates new refrigerants for safety and environmental impact. Energy codes are getting stricter every year, requiring high-efficiency equipment that would have been considered premium options just a decade ago.

Emerging Smart & Green Solutions

Variable-speed drives are probably the biggest energy-saving technology, allowing equipment to adjust output based on actual demand. Predictive maintenance uses sensors to spot problems before they cause failures. Waste-heat recovery captures heat that would normally be thrown away and puts it to good use.

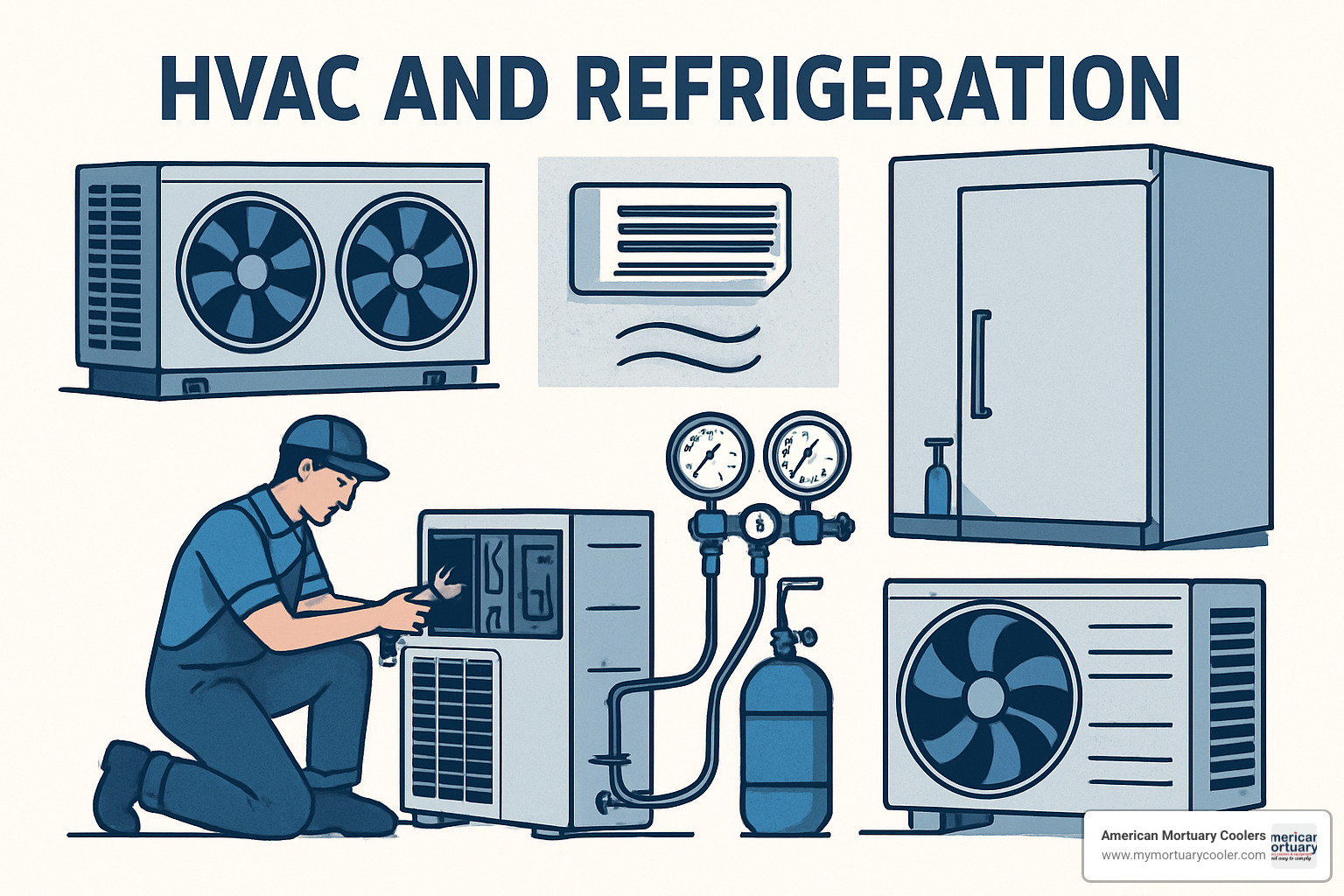

Safety, Maintenance & Common Challenges

Working with HVAC and refrigeration systems presents unique safety challenges. Between electrical hazards, pressurized refrigerant systems, and often working in tight spaces, technicians face real risks every day.

Lock-out/tag-out procedures form the foundation of electrical safety. Refrigerant handling has become more complex as the industry transitions to new refrigerants. EPA certification is mandatory, but real-world safety requirements go far beyond passing a test.

Leak detection technology has advanced significantly, with electronic detectors capable of identifying refrigerant concentrations as low as a few parts per million.

More info about refrigeration repair provides practical guidance for troubleshooting common problems.

Typical Troubleshooting Issues

Short cycling indicates an oversized system, low refrigerant charge, or faulty controls. Frozen evaporator coils create a cascade of problems, usually caused by dirty air filters, low refrigerant charge, or faulty defrost controls. Oil return problems plague systems with long refrigerant lines. Airflow imbalances cause hot and cold spots that make occupants uncomfortable.

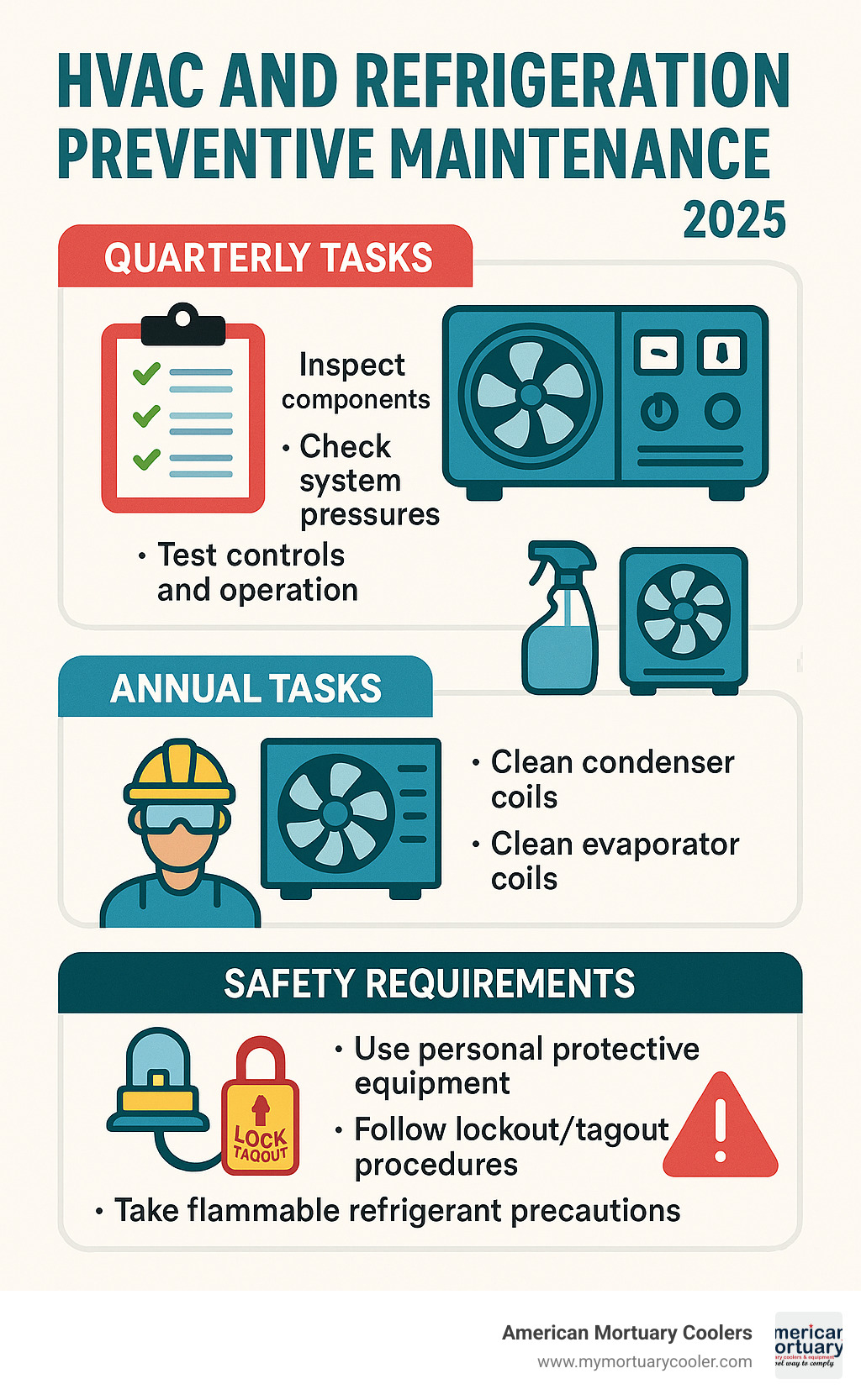

Best-Practice Maintenance Schedules

Quarterly inspections should include visual inspection of components, checking refrigerant levels, cleaning condenser coils, and verifying proper operation of controls. Semi-annual coil cleaning is essential for maintaining efficiency. Annual oil analysis for larger systems can identify developing problems months before they cause failures.

Frequently Asked Questions about HVAC and Refrigeration

What is the difference between HVAC and refrigeration?

Think of HVAC and refrigeration as cousins in the same family - they share the same DNA but have different jobs. HVAC systems focus on keeping people comfortable in buildings, while refrigeration systems are all about preserving things at cold temperatures.

HVAC systems are the ones keeping your office at a comfortable 72°F in summer and warming your home in winter. They care about air quality, humidity levels, and making sure everyone feels comfortable. These systems typically work in the 68-78°F range - temperatures that feel good to humans.

Refrigeration systems, on the other hand, are the workhorses keeping your food fresh and, in our case at American Mortuary Coolers, maintaining the dignity and preservation that funeral homes require. These systems operate much colder - often below 40°F for standard refrigeration or even below 0°F for freezing applications.

The interesting thing is that both systems use the same basic principles - that refrigeration cycle we talked about earlier. A technician who understands how to work on your home air conditioner can also work on a walk-in cooler. The compressor, condenser, evaporator, and expansion valve are doing the same job whether they're cooling your living room or preserving food.

Many technicians work on both types of systems, though specialization is common. Some focus on residential comfort systems, others become experts in commercial refrigeration, and still others specialize in unique applications like mortuary cooling systems.

How long does it take to become a certified HVAC and refrigeration technician in BC?

The path to becoming a certified HVAC and refrigeration technician in British Columbia is a four-year journey that combines hands-on work experience with classroom learning. You'll need to complete 6,210 hours of work-based training alongside 33 weeks of technical training - that's roughly 8,000 total hours of learning.

But here's the thing - everyone's path looks a little different. If you're starting from scratch, the full four-year apprenticeship is your route. You'll work under experienced technicians who'll teach you everything from basic refrigeration principles to complex troubleshooting.

The BCIT 41-week certificate program can give you a head start. Graduates receive credit for the first three levels of technical training, which can shorten your apprenticeship time. It's like getting a running start in a race - you're still running the same distance, but you begin ahead of the pack.

If you already have relevant experience, you might be able to challenge portions of the apprenticeship. This means proving you already know certain skills rather than learning them from scratch. However, finding employers willing to take on apprentices can sometimes be the biggest challenge, especially in competitive markets.

After completing your apprenticeship, you'll take the Certificate of Qualification exam to become certified in BC. Want to work anywhere in Canada? The Red Seal certification requires passing an additional interprovincial exam, but it opens doors across the country.

Are new refrigerants like A2L safe to use?

The short answer is yes - A2L refrigerants are safe when handled properly. The "mild flammability" classification sounds scary, but these refrigerants are actually safer than many everyday substances you use without thinking twice.

Here's what "mildly flammable" really means: A2L refrigerants need three things to happen at once to create a fire risk - the right concentration in the air, an ignition source, and the perfect conditions. It's like trying to light a campfire with damp wood - technically possible, but unlikely under normal circumstances.

The HVAC and refrigeration industry has spent years developing safety standards specifically for A2L refrigerants. ASHRAE 15 and UL 60335-2-89 require leak detection systems that automatically shut down equipment if refrigerant concentrations get too high. Think of it as a smoke detector for your refrigeration system.

Proper ventilation prevents refrigerant from accumulating in dangerous concentrations. Updated training ensures technicians know how to handle these refrigerants safely. And clear labeling makes sure everyone knows what they're working with.

European countries have been using A2L refrigerants successfully for years, providing real-world proof that these systems work safely when proper procedures are followed. The reason for the switch? A2L refrigerants have up to 99% lower global warming potential than traditional refrigerants - they're much better for the environment.

At American Mortuary Coolers, we stay current with all refrigerant transitions to ensure our mortuary cooling systems meet the latest safety and environmental standards. The industry's move toward A2L refrigerants represents progress toward more sustainable cooling solutions without compromising safety or performance.

Conclusion

The world of HVAC and refrigeration never stops moving forward. What hasn't changed is how much we all depend on these systems, from climate-controlled bedrooms to fresh milk in refrigerators.

The career outlook remains bright, especially in British Columbia. With 840 forecasted job openings between 2023 and 2033, there's real opportunity for people willing to learn. The industry rewards those who stay curious and keep learning about A2L refrigerants, smart building controls, and heat pump technology.

At American Mortuary Coolers, we've watched this industry transform while staying focused on reliability when it counts. Our custom mortuary coolers serve funeral homes across the contiguous 48 states because funeral directors need equipment they can trust completely.

Our Tennessee-based craftsmen understand that mortuary refrigeration isn't just about maintaining temperature - it's about preserving dignity and giving families peace of mind. Eco-friendly refrigerants and energy-efficient designs help funeral homes control operating costs so they can focus on serving families.

For funeral directors researching their options, A Comprehensive Guide to Refrigeration Units and How They Work breaks down the technical details in plain English.

The future looks promising for anyone connected to this industry. Change will keep coming, but the core mission remains the same: creating the right environment for whatever matters most. In our case, that means helping funeral homes provide the dignified care that families deserve during their most difficult moments.