Understanding the Precision Tool of Surgery

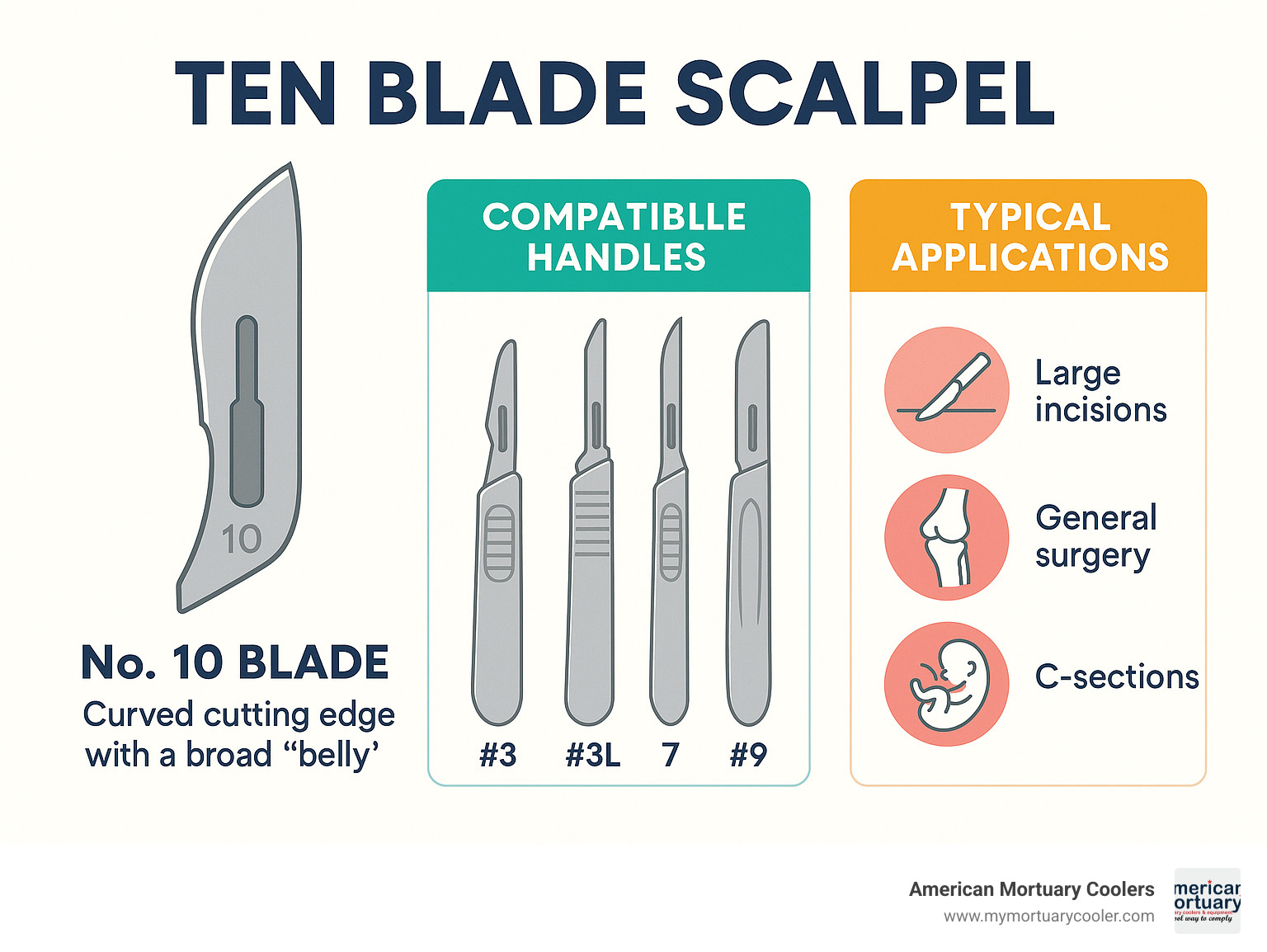

A ten blade scalpel is a curved surgical cutting instrument with a broad belly shape, designed for making large incisions through skin and subcutaneous tissues. It is one of the most commonly used scalpel blades in medical and mortuary settings.

Quick Facts About Ten Blade Scalpels:

- Shape: Curved with a broad "belly" design

- Size: Approximately 41.7 mm length, 7.2 mm width, 0.4 mm thickness

- Best For: Large incisions in skin and muscle tissue

- Compatible Handles: #3, 3L, 3 Graduated, 5B, 7, 9, and B3

- Materials: Available in both carbon steel and stainless steel

- Packaging: Sterile (individual foil packs) or non-sterile options

The No. 10 scalpel blade stands out for its versatility and effectiveness in making continuous deep incisions. Its curved design allows surgeons and morticians to create smooth, precise cuts with minimal tissue damage. The blade's sharpest point is at the apex of its curve or "belly," making it ideal for slicing rather than stabbing motions.

Unlike pointed blades such as the No. 11, the ten blade scalpel excels at creating longer incisions with a single, controlled movement. This makes it particularly valuable in general surgery, orthopedic operations, C-sections, and autopsy procedures where larger tissue planes must be accessed.

While American Mortuary Coolers specializes in refrigeration solutions, we recognize the importance of quality surgical instruments in mortuary practice. Other companies like Mopec, Mortech Manufacturing, and Thermo Fisher Scientific also provide high-quality scalpels and mortuary instruments to complement their equipment offerings.

For readers interested in related topics, our resources on morgue cold storage and overhead track systems provide additional insights that pair well with understanding the role of precision instruments like the ten blade scalpel.

Understanding the Ten Blade Scalpel

The ten blade scalpel has remained largely unchanged for decades because its design perfectly balances functionality that surgeons and morticians rely on daily. At 41.7 mm long, 7.2 mm wide, and just 0.4 mm thick, this blade offers strength without bulk and flexibility without weakness. The single-bevel edge delivers exceptional sharpness for clean tissue slicing.

These blades come in either high-grade carbon steel or stainless steel. Carbon steel provides superior initial sharpness but requires vigilance against corrosion. Stainless steel offers greater durability and corrosion resistance with a slight trade-off in initial sharpness. For absolute sterility, individually foil-packed blades are available, while non-sterile bulk packaging provides a more economical option for educational or mortuary settings.

Research on cutting-edge geometry confirms that a blade's angle and finish dramatically impacts both initial sharpness and edge retention through use.

Ten Blade Scalpel Design & Specs

The ten blade scalpel's curved design isn't merely aesthetic—it's engineering brilliance that enables smooth, continuous cutting motions. The sharpest point at the curve's apex concentrates cutting force precisely where needed. The lateral slot is precision-manufactured to grip compatible handles securely, eliminating wobble during delicate procedures.

The grinding angles represent a careful balance—narrower angles (20-25 degrees) provide exceptional initial sharpness but may dull faster, while wider angles sacrifice some initial keenness for extended edge life. Stainless steel variants often include VCI (Volatile Corrosion Inhibitor) paper in packaging to prevent oxidation during storage.

Competitors like Integra Miltex, Fine Science Tools, and Sklar Instruments offer their own versions of the ten blade scalpel, each with slight variations in manufacturing processes and materials.

Compatible Handles & Installation

Your ten blade scalpel works with several handle types: Handle 3 (standard flat profile), Handle 3L (longer reach), Handle 3 Graduated (with measurement markings), Handle 5B (heavier for stability), Handle 7 (longer/narrower for finesse), Handle 9 (specialized grip), and Handle B3 (ergonomic design).

When mounting, always use a needle holder or forceps rather than fingers. Align the blade's slot with the handle's groove, apply firm pressure until you hear a click, and test with a gentle wiggle to ensure secure attachment.

For more information on essential mortuary tools, check out our article on cutting-edge understanding mortuary tools.

Surgical & Non-Surgical Uses of a Ten Blade Scalpel

The ten blade scalpel serves as a trusted companion for medical professionals and morticians alike. Its graceful, broad cutting edge creates smooth, continuous cuts that few other instruments can match—like the difference between cutting fabric with scissors versus a quality rotary cutter.

In hospitals, surgeons reach for the No. 10 blade for reliable performance. General surgeons use it to open abdominal cavities, orthopedic specialists access joints and bones, and obstetricians rely on it for precise Cesarean section incisions. The blade particularly excels during radial artery harvesting for bypass surgeries. Veterinarians also appreciate it when working with larger animals.

A study on blade sharpness in dermatologic surgery confirmed that blade selection significantly impacts wound healing outcomes, with the clean cuts from a No. 10 blade often leading to better healing and reduced scarring.

While American Mortuary Coolers focuses on refrigeration solutions, companies like Mopec, Mortech Manufacturing, and Thermo Fisher Scientific offer comprehensive surgical instrument lines including various scalpel options for medical and mortuary applications.

Top Surgical Procedures Using a Ten Blade Scalpel

The ten blade scalpel truly earns its keep in several key procedures:

In abdominal surgery, this blade is often the first tool used, gliding through skin and fascia with minimal resistance during appendectomies, gallbladder removals, or exploratory procedures.

Orthopedic surgeons value how it creates clean separations in muscle tissue without unnecessary trauma. The curved profile allows for smooth cutting along natural tissue planes, reducing bleeding and speeding healing.

During Cesarean sections, obstetricians need to create a clean uterine incision while protecting the baby just millimeters away. The predictable cutting action provides the control needed for this delicate work.

Thoracic surgeons use the curved edge to create precise openings in the bronchus during lung procedures with minimal tissue damage.

What makes these applications successful is the blade's ability to create long, continuous incisions rather than a series of shorter cuts—like drawing a smooth line versus a dotted one—resulting in less tissue trauma and better outcomes.

Non-Clinical & Mortuary Applications

Beyond the operating room, the ten blade scalpel serves important purposes in other settings.

In mortuaries, morticians rely on it to create the standard Y-incision during autopsy procedures with clean, respectful precision. The curved design excels at raising skin flaps and accessing internal structures while preserving dignity. This matters tremendously for both forensic examination and preparation for family viewings.

In university laboratories, students learn anatomy through dissection with the No. 10 blade, which offers the control needed to explore the intricacies of the human body. Museum conservators use it for meticulous restoration work, and artists and craftspeople have adopted it for creative applications from model making to paper art.

At American Mortuary Coolers, we understand that quality tools complement quality refrigeration solutions. For more insights on selecting the right tools for your facility, check out our article on comparing scalpel blade options.

Comparing No. 10 to Other Blade Sizes

| Blade | Shape | Length | Primary Use | Compatible Handles |

|---|---|---|---|---|

| #10 | Curved with broad belly | 41.7 mm | Large skin/muscle incisions | 3, 3L, 3 Graduated, 5B, 7, 9, B3 |

| #11 | Triangular with sharp point | 39.3 mm | Stab incisions, precision cuts | 3, 3L, 3 Graduated, 5B, 7 |

| #12 | Hook-shaped with curved edge | 40.1 mm | Suture removal, tonsillectomy | 3, 3L, 3 Graduated, 5B, 7 |

| #15 | Small curved edge | 35.8 mm | Fine, precise incisions | 3, 3L, 3 Graduated, 5B, 7 |

| #22 | Larger curved edge | 53.8 mm | Deep, extensive incisions | 4, 4L, 6B |

The ten blade scalpel isn't randomly selected—it's carefully chosen based on specific procedural needs. Like kitchen knives serving different purposes, each scalpel blade has its own personality. The No. 10 excels at smooth, flowing cuts through skin and muscle tissue, with its curved design allowing for cleaner edges that heal better.

However, it's not perfect for everything. For delicate work in tight spaces, the smaller No. 15 is more appropriate. For initial punctures or stab incisions, the pointed No. 11 serves better.

Professionals typically consider these factors when selecting a blade:

- What kind of cut is needed? (Long and smooth? Quick and precise?)

- What tissue is being worked with? (Thick skin? Delicate structures?)

- How much visibility is needed during the procedure?

- What feels most comfortable after years of experience?

Competitors like Integra Miltex, Fine Science Tools, and Sklar Instruments offer comprehensive blade sets with detailed selection guides to help professionals choose the right tool for each application.

Blade Shape & Cutting Action

The shape of a blade transforms its function. The ten blade scalpel's curved "belly" makes it perfect for slicing motions, creating smooth, controlled tissue separation—ideal for opening larger areas or creating Y-incisions in autopsy procedures.

In contrast, the No. 11 blade excels at precision piercing with its triangular shape and sharp point—perfect for creating drainage sites or accessing confined spaces. The No. 12 blade's hook shape smoothly slides under sutures for removal without damaging surrounding tissue.

For detail work, the No. 15 blade's smaller curved edge provides extra control around delicate structures like facial nerves or small blood vessels. For tough tissue like thick muscle or dense skin, the larger No. 22 blade provides extra cutting power without requiring more force.

When to Choose a Ten Blade Scalpel vs Alternatives

The ten blade scalpel shines when making longer skin incisions or working through multiple tissue layers. Its curved design creates smooth, continuous cuts that follow natural tissue planes—resulting in less trauma and cleaner healing. It's the go-to for general surgical procedures and Y-incisions during autopsy work.

However, for draining an abscess or inserting a chest tube, the pointed No. 11 blade provides the precise initial puncture that the No. 10 can't match. For removing sutures, the specialized hook of the No. 12 is unbeatable. In tight spaces or on delicate structures, the smaller No. 15 offers better control, while the larger No. 22 handles exceptionally thick tissue.

Your choice ultimately depends on four key factors:

- Incision Length: For longer cuts, the flowing curve of the ten blade scalpel maintains a smooth, continuous motion.

- Visibility: The No. 10's larger profile improves visibility during procedures.

- Control: The No. 10 excels for slicing motions but offers less precision for point work compared to the No. 11.

- Cost Efficiency: Understanding which procedures your facility performs most frequently helps optimize your blade inventory.

Safe Handling, Sterility & Disposal

Safety is essential when working with a ten blade scalpel. Always wear appropriate PPE, especially cut-resistant gloves when changing blades. If you fumble a scalpel, resist the instinct to catch it—step back, let it fall, and retrieve it safely using an instrument rather than your fingers.

When mounting a blade, use a needle-holder or forceps instead of your fingers to reduce injury risk. For removal, always use a purpose-designed blade remover. Several safety systems exist, including single-use blade removers and the KLEEN Blade Management System, which allow for hands-free blade removal and disposal.

In medical settings, most ten blade scalpels undergo Cobalt-60 irradiation sterilization, which thoroughly sterilizes without compromising cutting properties. Once a sterile package is opened, use it immediately or consider it contaminated.

For disposal, OSHA regulations require puncture-proof containers specifically designed for sharp medical waste, placed conveniently to encourage proper disposal. Unlike kitchen knives, surgical scalpels aren't meant to be resharpened—when a blade dulls, replace it.

Competitors like Mopec and Mortech Manufacturing offer specialized sharps disposal systems designed specifically for mortuary settings, while companies like Stericycle provide comprehensive medical waste management services that include sharps disposal.

Mounting & Removing No. 10 Blades Safely

A significant percentage of scalpel injuries occur during blade changes rather than during use. To safely mount a ten blade scalpel, use a needle holder or forceps to remove the blade from its packaging. Hold the handle with the fitting groove facing upward, align the blade's slot with the handle's post, and press down until you feel a snap as the blade locks into place. Always test the connection with a gentle tug.

Press the blade downward onto the handle rather than sliding it on from the side to prevent slippage. When removing a blade, use a purpose-designed blade remover. Insert the handle with the blade into the removal device following manufacturer guidance. The blade will safely detach and fall directly into the integrated sharps container.

Practice blade handling with simulation tools before working with actual blades, keep your eyes on the blade during handling, never rush, and position sharps containers where you're working to minimize carrying exposed blades.

Sterile vs Non-Sterile Packaging Options

The ten blade scalpel comes in various packaging options. For sterile applications, individual foil pouches provide complete isolation for each blade, maintaining sterility until needed. Peel packs offer a similar level of protection with a paper/plastic combination that peels open easily. Disposable sterile scalpels come as complete units with pre-mounted blades on plastic handles.

In non-sterile settings, magazines containing 5-10 stacked blades in a protective case work well for educational or laboratory environments. Bulk packaging typically contains 100 blades bundled together, ideal for settings where post-purchase sterilization might occur. Guard-protected scalpels provide complete disposable units with protective covers for non-sterile applications.

All sterile ten blade scalpels include expiration dates, typically giving 3-5 years of shelf life when properly stored. Once sterile packaging is opened or damaged, the blade should be considered non-sterile regardless of the expiration date.

Sharps Disposal & Regulatory Compliance

Proper disposal of used ten blade scalpels is legally required. ANSI and OSHA regulations protect everyone from healthcare workers to waste handlers from accidental injuries and bloodborne pathogen exposure.

Requirements include: using puncture-resistant containers specifically designed for sharps disposal; ensuring containers can be securely closed, won't leak, and display the universal biohazard symbol; positioning them close to where sharps are used; and establishing regular collection and processing of filled containers.

The FDA classifies scalpel blades as Class I medical devices, subject to specific manufacturing and quality standards. Local biohazard laws may impose additional requirements beyond federal regulations.

For more information about other essential mortuary instruments, our guide on forceps types and uses provides valuable insights for mortuary professionals.

Buying Guide: Brands, Prices & Selection Tips

When shopping for ten blade scalpels, quality, reliability, and value are key considerations. Major manufacturers each offer distinct advantages.

Swann-Morton from the UK is often considered the premium option with their 200% inspection process and high-quality materials, priced at $0.80-$1.20 per blade. Many surgeons swear by their exceptional quality.

Cincinnati Surgical offers consistent quality at a more moderate price ($0.60-$0.90 per blade), making them popular in teaching hospitals and research labs where budgets matter but quality can't be compromised.

Lance from Pakistan provides budget-friendly options at $0.20-$0.50 per blade. While lacking the prestige of European brands, they perform well for many applications, especially training.

German-made Martor blades ($0.70-$1.00 each) focus on safety features and precision manufacturing.

Competing companies like Mopec, Mortech Manufacturing, and Thermo Fisher Scientific also offer scalpel blades as part of their mortuary and medical supply lines, often bundled with other instruments for complete procedural kits.

Price differences reflect material quality, manufacturing precision, and packaging. Carbon steel blades cost less than stainless but may corrode more easily. Sterile, individually-wrapped blades command premium prices over bulk-packed non-sterile options. Buying in larger quantities (typically 100-count boxes) reduces per-unit cost significantly.

Quality indicators include VCI paper in packaging (prevents corrosion), consistent grinding angles, smooth surface finish, proper CE marking, and GTIN numbers for traceability.

Leading Manufacturers & Price Snapshot

Premium manufacturers like Swann-Morton use specially formulated steel alloys and proprietary heat-treating processes. Their grinding techniques create more consistent edge geometry—visible under magnification.

Quality control varies dramatically between manufacturers. Budget brands might spot-check random samples, while premium makers inspect each blade multiple times, ensuring you won't find defective blades mid-procedure.

Some manufacturers offer specialty variants of the standard ten blade scalpel, including titanium nitride coatings for reduced friction, extra-hardened steel for prolonged sharpness, or colored handles for quick identification. These specialty products typically add 15-30% to the base price.

While all conform to general industry standards for the No. 10 shape, subtle differences in manufacturing tolerances affect performance. Some brands produce blades with more aggressive cutting angles that feel sharper initially but may dull faster, while others optimize for edge retention at a slight cost to initial sharpness.

Selection Checklist for Your Facility

Choosing the right ten blade scalpel for your facility requires considering your specific needs:

- Procedure demands: A high-volume autopsy service has different needs than a small funeral home doing occasional restorative work.

- Handle compatibility: Check your current inventory of scalpel handles to ensure compatibility.

- Sterility requirements: While hospitals need individually packaged sterile blades, many mortuary procedures can use high-quality non-sterile blades that cost significantly less.

- Budget considerations: A cheaper blade that dulls quickly might actually cost more in the long run than a premium blade that maintains its edge through multiple procedures.

- Vendor reliability: A supplier who consistently has stock available, delivers on time, and stands behind their products is invaluable.

At American Mortuary Coolers, we understand the importance of reliability in all aspects of mortuary operations. For more detailed guidance on selecting instruments for your facility, check out our guide to comparing scalpel blade options.

Frequently Asked Questions about Ten Blade Scalpels

What is the difference between a No. 10 and No. 15 blade?

The ten blade scalpel and the No. 15 blade have distinct characteristics that make each better suited for specific tasks.

The ten blade scalpel is larger at about 41.7 mm long with a distinctive broad curved edge or "belly" that gives it excellent cutting power. In contrast, the No. 15 blade is more petite at around 35.8 mm with a smaller curved edge for more delicate work.

The No. 10 excels in general surgery, orthopedics, and autopsy procedures where longer incisions through skin and muscle are needed. The No. 15 is preferred for more precise work in plastic surgery, ophthalmology, and pediatric procedures where fine detail is essential.

The No. 10 provides excellent control for longer, sweeping cuts but might feel unwieldy in tight spaces. The No. 15 offers precision for detailed work but isn't ideal for longer incisions.

Both blades fit the same handles (No. 3, 3L, and others), making it convenient to switch between them during procedures.

Can I reuse or re-sharpen a No. 10 scalpel blade?

While it might seem economical to reuse or resharpen a ten blade scalpel, it's generally not recommended for several reasons:

Safety concerns: These instruments are designed for single use to prevent cross-contamination. Handling used blades during resharpening attempts increases risk of injuries and exposure to bloodborne pathogens.

Performance issues: Resharpened blades can't match the precision edge of fresh ones. Attempts often result in uneven cutting edges and compromised blade geometry, leading to reduced cutting efficiency and increased tissue trauma.

Regulatory compliance: Reusing single-use devices might violate facility protocols or conflict with accreditation requirements, potentially creating liability issues.

Material limitations: Modern scalpel blades are made from hardened steel with specific edge geometry that makes proper resharpening difficult without specialized equipment. Improper sharpening often creates micro-serrations that tear rather than cleanly cut tissue.

Purchasing ten blade scalpels in bulk quantities appropriate for your usage level is more cost-effective than attempting to extend the life of individual blades.

Which handle numbers fit a ten blade scalpel?

The ten blade scalpel fits several standard handle types, each offering different benefits:

- Handle No. 3: Flat, lightweight design for general use

- Handle No. 3L: Extended length for deeper cavities

- Handle No. 3 Graduated: Includes marking lines for controlling incision depth

- Handle No. 5B: Additional heft for more stability

- Handle No. 7: Longer, narrower design for delicate work

- Handle No. 9: Specialized grip

- Handle No. B3: Ergonomic design to reduce hand fatigue

These handles come in different materials: stainless steel (autoclavable and durable), lightweight aluminum (reduces hand fatigue), and plastic disposable options.

When selecting a handle, consider the types of procedures you'll be performing, their duration, your hand size and preferences, budget constraints, and whether you need reusable or disposable options.

The fitting mechanism is standardized across these handle types—the blade's slot fits over a raised post on the handle and locks firmly into place.

Conclusion

The ten blade scalpel has earned its place as a trusted companion in medical, mortuary, and laboratory settings worldwide. Its precisely engineered curved design with that characteristic broad belly makes smooth, continuous incisions through skin and underlying tissues feel almost effortless.

At just 41.7 mm long, 7.2 mm wide, and 0.4 mm thick, it strikes the perfect balance between strength and precision. Whether snapped onto a standard Handle 3 in a busy operating room or a longer 3L for procedures requiring extra reach, the ten blade scalpel adapts to various needs.

This blade shines in diverse scenarios—from the precision of general surgery to the substantial work of orthopedics, from C-sections to autopsy procedures—delivering reliable performance for those long, smooth cuts that other blades can't match. While the No. 10 excels at slicing motions, you might reach for a No. 11 for puncturing or a No. 12 for hooking motions, as each blade has its specific purpose.

Safety remains paramount when working with such sharp instruments. Proper mounting, careful removal, and responsible disposal prevent injuries and ensure compliance with important regulations.

For those managing inventory, manufacturers like Swann-Morton, Cincinnati Surgical, Lance, and Martor offer options ranging from $0.20 to $1.20 per blade in both carbon and stainless steel. Competing companies like Mopec, Mortech Manufacturing, and Thermo Fisher Scientific also provide quality options as part of their comprehensive mortuary supply offerings.

At American Mortuary Coolers, we understand that precision matters in every aspect of mortuary operations. Just as we custom-design our refrigeration solutions to fit each facility's unique requirements, we appreciate that having access to the right tools—including the versatile ten blade scalpel—is essential for maintaining the highest standards in mortuary services.

Our commitment extends beyond providing quality coolers to supporting mortuary professionals with knowledge and resources that help them excel in all aspects of their important work. Whether you're setting up a new facility in Tennessee, upgrading systems in Georgia, or expanding capabilities in Illinois, we're here to help create that perfect working environment where every detail matters.

For more information about refrigeration solutions that complement your precision work, check out our article on morgue coolers and funeral home refrigeration solutions.