Why Diamond Plate Aluminum Sheets Are the Smart Choice for Durability and Safety

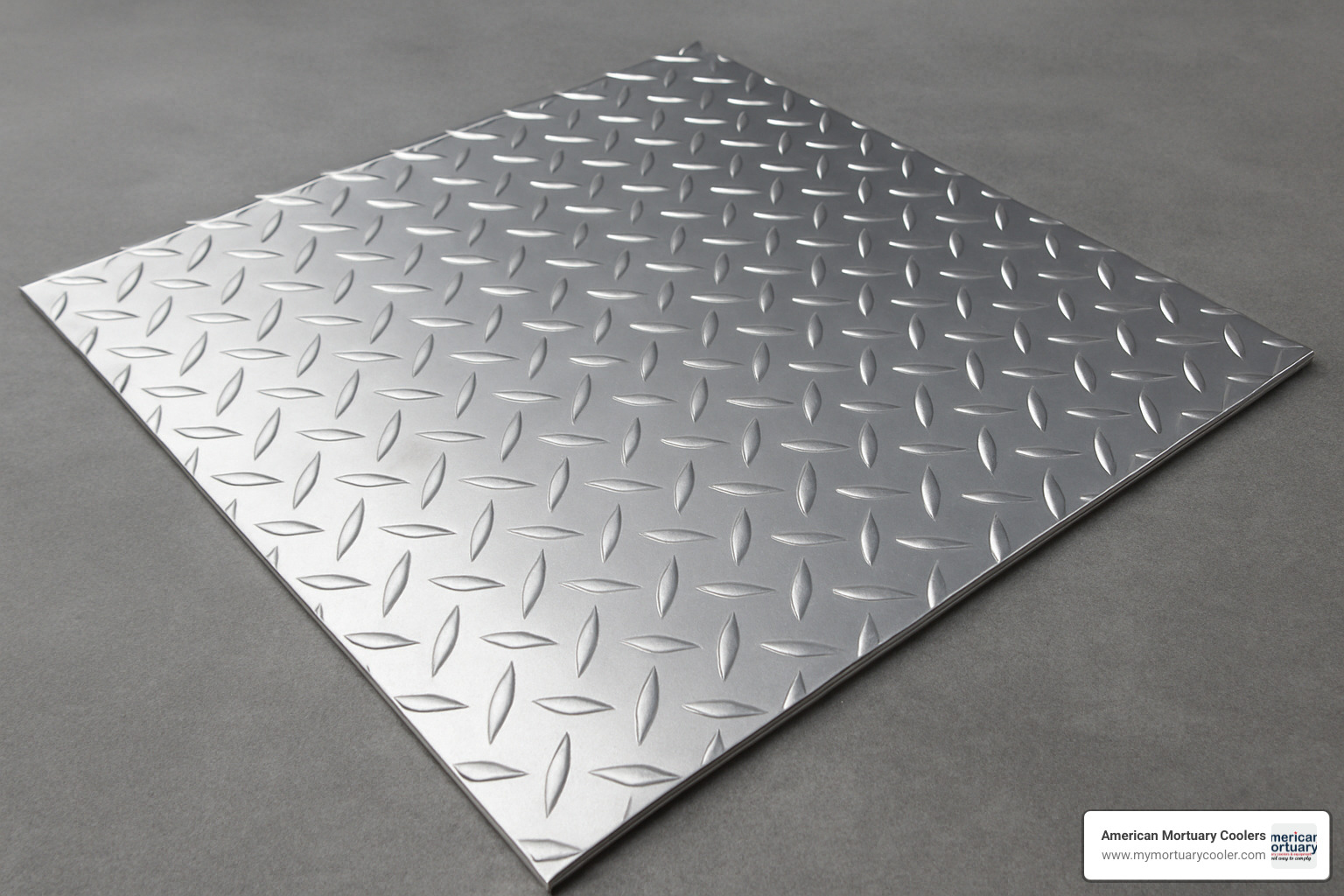

Diamond plate aluminum sheets are metal sheets with raised diamond patterns that provide slip resistance, corrosion protection, and lightweight strength for industrial and commercial applications.

Key Benefits:

- 60% lighter than steel diamond plate of same thickness

- Naturally corrosion resistant due to aluminum's oxide layer

- Available in multiple alloys (3003, 4017, 6061) for different strength needs

- Standard thicknesses from 0.063" to 0.500"

- Common sheet sizes include 4'×8', 4'×10', 5'×8', and 5'×10'

- Weight ranges from 1.20 lb/sqft (1/16" thick) to 7.30 lb/sqft (1/2" thick)

The brilliant shine and durability of diamond plate aluminum makes it perfect for everything from walk-in cooler floors to truck bed liners. Unlike steel alternatives, aluminum won't rust in wet environments and requires minimal maintenance.

I'm Mortuary Cooler, a national supplier of mortuary coolers and industrial refrigeration equipment with extensive experience specifying diamond plate aluminum sheets for walk-in coolers, freezer floors, and food service applications.

What Are Diamond Plate Aluminum Sheets?

Diamond plate aluminum sheets are specially manufactured metal sheets that feature a distinctive raised diamond pattern on one side while keeping the reverse surface perfectly smooth. You might also hear them called aluminum tread plate or checker plate.

Those raised diamonds serve a crucial safety purpose by creating an anti-slip surface that can literally save lives in wet or oily conditions. What really sets aluminum apart from steel alternatives is its natural corrosion resistance. Aluminum automatically forms a protective oxide layer that acts like an invisible shield against rust and corrosion.

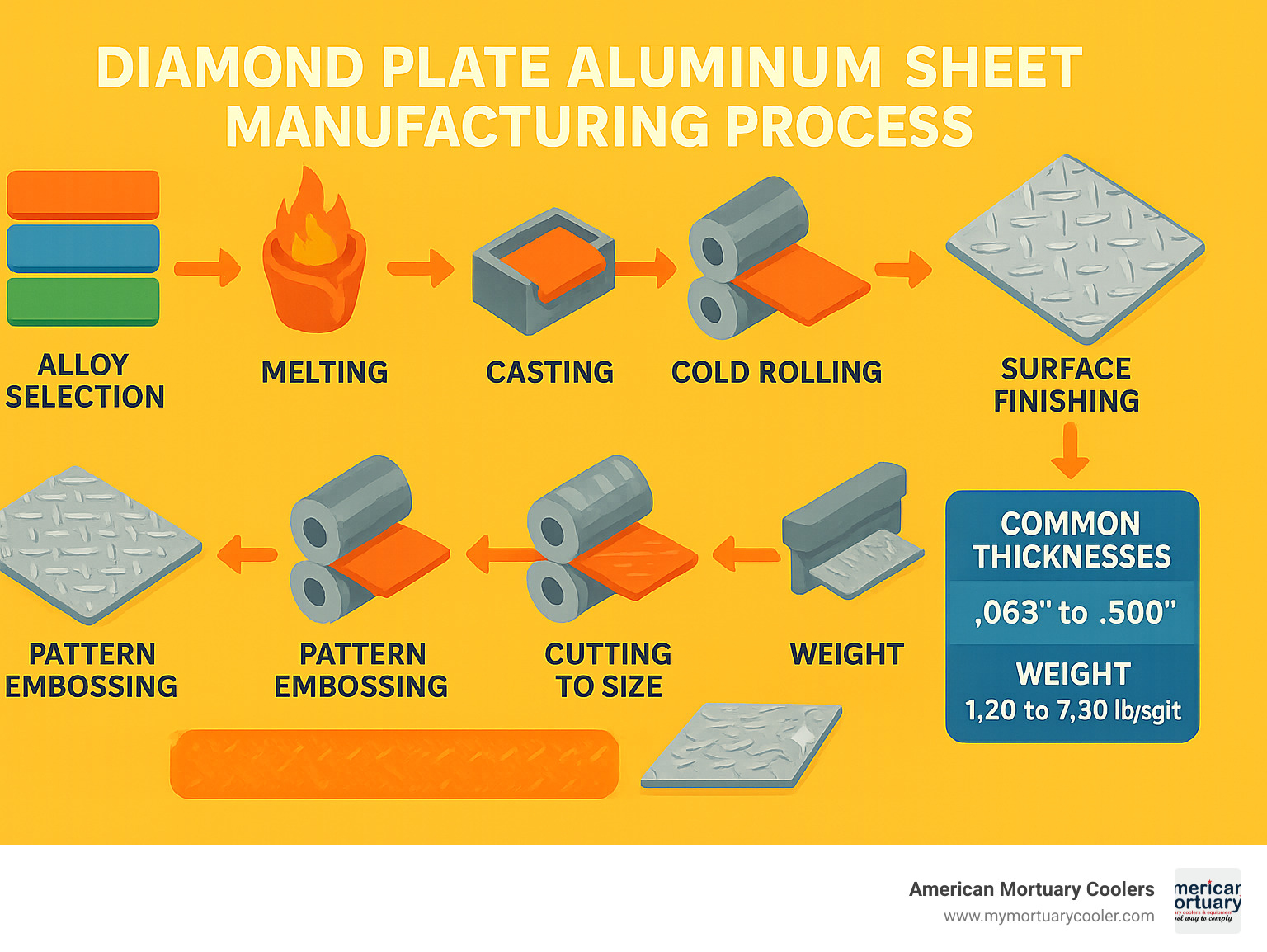

The manufacturing process starts with carefully selected aluminum alloy, which gets melted down and cast into thick slabs. These slabs go through hot-rolling at temperatures around 800-900°F to get the basic thickness, then cold-rolling to dial in exact dimensions and improve strength.

All quality diamond plate aluminum sheets meet strict ASTM specifications for dimensional tolerances and material properties, with standard tolerances typically within ±1/8" for stock sizes.

Anatomy of the Diamond Pattern

The most popular diamond pattern features a single-bar design with raised diamonds spaced about one inch apart from center to center. This spacing hits the sweet spot between maximum traction and professional appearance.

Some applications call for a five-bar pattern instead, which provides even more aggressive traction for extreme slip-resistance needs. When manufacturers list thickness measurements, they're talking about the base material only. The pattern depth adds another 0.020" to 0.030" on top of that base thickness.

Embossing rollers with precisely machined diamond patterns press the design into the aluminum under tremendous pressure, creating consistent pattern depth across the entire sheet without compromising structural integrity.

How Diamond Plate Aluminum Sheets Are Made

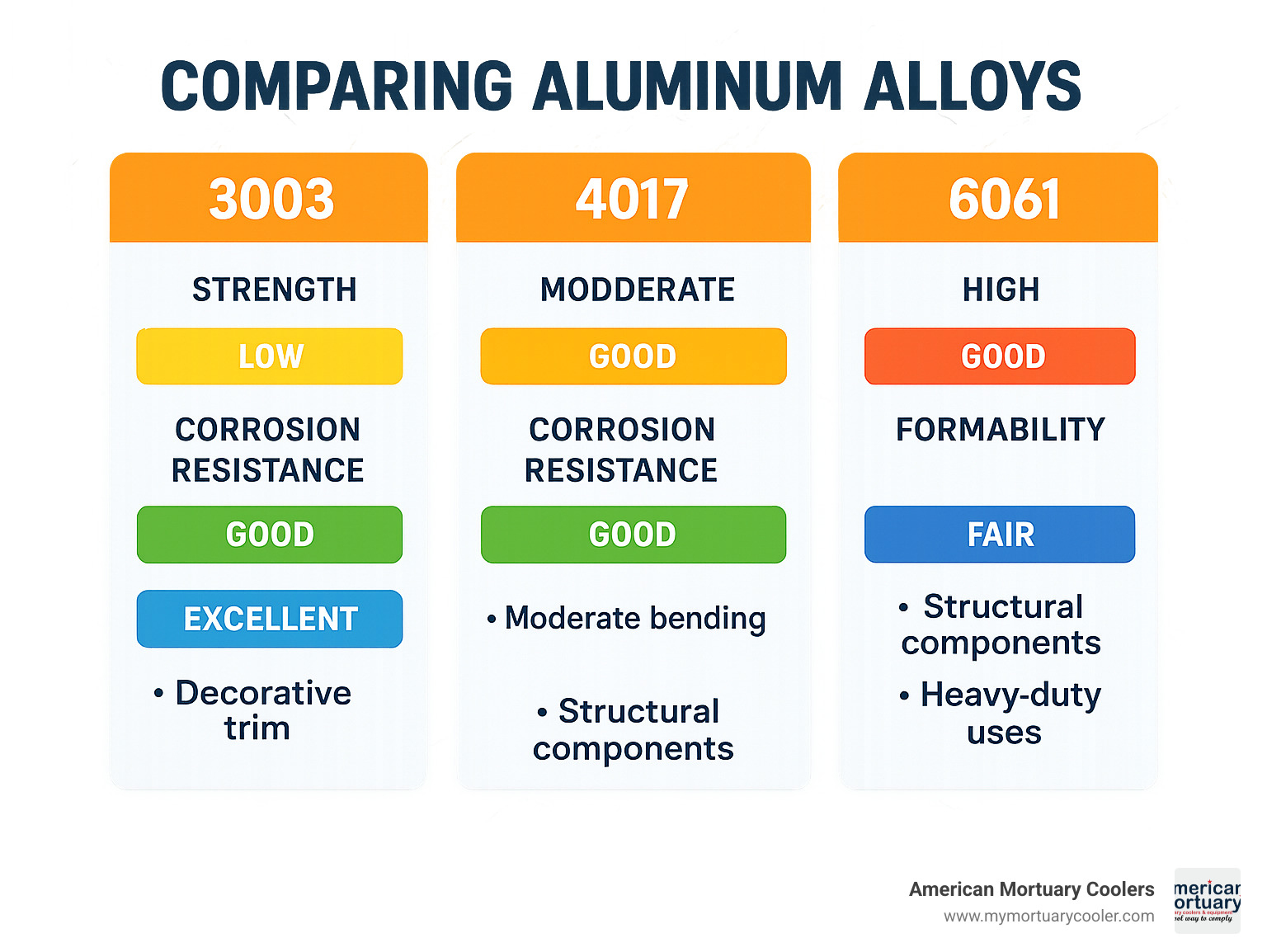

The journey from raw aluminum to finished diamond plate starts with alloy selection. Alloy 3003 works great for decorative applications, 4017 handles moderate strength requirements, and 6061 steps up for serious structural work.

After initial melting and casting, hot-rolling at extreme temperatures is followed by cold-rolling, which achieves precise dimensional control and makes the aluminum stronger through work hardening.

The high-pressure embossing happens at room temperature, making the process more energy-efficient than steel processing. Quality control checks thickness verification, pattern depth consistency, and surface finish quality. Some sheets undergo heat treatment after embossing - for example, 6061-T6 requires solution heat treatment and artificial aging to reach maximum strength properties.

Choosing the Right Diamond Plate Aluminum Sheets

Picking the perfect diamond plate aluminum sheets doesn't have to be overwhelming. Each aluminum alloy has its own strengths.

Alloy 3003-H22 is the friendly neighbor of aluminum alloys. It bends easily, looks great, and won't break the bank. This bendable champion offers solid corrosion resistance and excellent formability, making it perfect when you need to wrap corners or create curved surfaces.

Alloy 4017 sits right in the middle - the Goldilocks option. It's stronger than 3003 but not as rigid as 6061, giving you a sweet spot of strength and workability for projects that need moderate strength without being completely unbendable.

Alloy 6061-T6 is the heavyweight champion. Once heat-treated, this alloy becomes incredibly strong but loses its flexibility. The superior tensile strength and outstanding corrosion rating make it perfect for heavy-duty applications where you need serious load-bearing capacity.

Weight-saving is another huge advantage. Standard sizes like 4'×8' and 5'×10' sheets are surprisingly manageable compared to steel alternatives. Gauges range from 0.025" for decorative work up to 0.500" for industrial applications.

3003 vs 6061 Diamond Plate Aluminum Sheets

The battle between 3003 and 6061 diamond plate aluminum sheets comes down to whether you're going for looks or muscle.

3003-H22 shines for decorative beauty. Its formability means you can bend it around corners and create custom shapes using basic tools. Price points are friendlier too. It takes a polished finish beautifully, creating that mirror-like shine. For marine resistance, it holds up well in most environments.

6061-T6 flexes its structural muscles when you need serious strength. The marine resistance is outstanding - this stuff laughs at saltwater and harsh chemicals. While price points are higher, you're paying for engineering-grade performance that handles heavy loads and extreme conditions.

In our walk-in cooler business, we typically spec 6061-T6 for flooring because it handles constant moisture, temperature swings, and heavy equipment. For decorative trim work, 3003 gives us the workability we need.

Finish & Color Options

Mill finish gives you that classic industrial look with natural aluminum coloring. Bright polished finishes turn your aluminum into jewelry with mirror-like surfaces that catch light beautifully.

Anodized finishes thicken that natural oxide layer, boosting both corrosion resistance and durability while opening up color possibilities. Powder-coat colors let you match any design scheme while providing excellent scratch and weather resistance.

Vinyl-backed options are the clever solution for retrofitting existing surfaces with adhesive backing that makes installation a breeze. More info about flexible pickup bed panels shows how these innovative products transform ordinary surfaces.

Applications & Installation Tips

Diamond plate aluminum sheets solve real problems across countless industries. When you need slip resistance, corrosion protection, and good looks all in one package, aluminum diamond plate delivers. The bonus? It's 60% lighter than steel, making installation easier.

Cutting aluminum diamond plate requires the right tools. Carbide-tipped blades slice through cleanly, while water-jet and plasma cutting handle complex shapes with precision. For welding, both MIG and TIG welding work well. Clean the surface thoroughly first, and remember that aluminum doesn't change color when heated like steel does.

Flooring, Ramps & Walkways

Industrial flooring puts diamond plate aluminum sheets through their toughest test. Manufacturing facilities, warehouses, and food processing plants demand materials that handle constant foot traffic while staying slip-resistant and corrosion-free.

Freezer applications showcase aluminum's unique advantages. The material stays non-sparking even in sub-zero temperatures, eliminating static electricity risks. Whether it's a walk-in cooler at a restaurant or a massive cold storage facility, aluminum diamond plate maintains its grip and strength when temperatures plummet.

Load capacity depends on thickness and support. 1/8" thick sheets handle pedestrian traffic when supported every 12 inches. Step up to 1/4" thickness with proper framing for light vehicle loads.

American Mortuary Coolers improve safety and durability with diamond plate flooring shares our real-world experience installing specialized flooring in mortuary facilities.

Vehicles, Trailers & Toolboxes

The automotive world has acceptd aluminum diamond plate for good reason. Pickup truck bed liners get the slip-resistant surface truck owners need while shaving significant weight off the vehicle. Less weight means better fuel economy.

Trailer applications really highlight aluminum's advantages. Rock guards, fender protection, and flooring all benefit from the corrosion resistance, especially for long-haul truckers. That 60% weight savings over steel adds up to real fuel savings over thousands of miles.

Emergency vehicles rely on aluminum diamond plate for interior floors and step plates where failure isn't an option. The easy maintenance keeps these critical vehicles ready for action.

The ultimate guide to diamond plate trailer options covers transportation applications from utility trailers to commercial rigs.

Fabrication Essentials

Working with aluminum requires understanding its personality. Unlike steel, aluminum conducts heat rapidly and doesn't change color when heated, making temperature control trickier during welding.

For mechanical fastening, countersunk screws or rivets keep the walking surface smooth. Always use stainless steel fasteners to prevent galvanic corrosion. Pre-drill holes, especially near edges, to prevent stress cracks.

Protective trim and vinyl edge molding transform rough edges into finished, safe surfaces. Here's something many installers learn the hard way: aluminum expands about twice as much as steel with temperature changes. Large installations need proper expansion joints to prevent buckling.

Caring for Your Diamond Plate

Taking care of your diamond plate aluminum sheets is refreshingly simple. Unlike steel that fights a constant battle against rust, aluminum naturally protects itself and needs just basic maintenance to look great for decades.

The cleaning routine couldn't be easier. A simple wash with mild detergent and warm water does the trick. Use a nylon brush to work suds into those diamond grooves where dirt likes to hide. Stay away from chloride-based cleaners like bleach or harsh degreasers that can cause tiny pits in the aluminum surface.

For polished finishes that have lost their sparkle, aluminum polishing compounds work wonders. The diamond pattern naturally camouflages everyday wear and tear, so your surfaces keep looking professional even with heavy use.

When deeper scratches happen, start with fine-grit sandpaper and work up to progressively finer grits before doing a final polish. It takes patience, but you can restore the surface to nearly new condition.

Aluminum is incredibly environmentally friendly. Aluminum recycling uses only 5% of the energy needed to make new aluminum from raw materials. Plus, your diamond plate will retain significant scrap value when it eventually needs replacement.

The www.P65Warnings.ca.gov WARNING provides information about aluminum exposure considerations, though normal use and handling present minimal risk.

Maintenance Checklist

Monthly cleaning with mild soap and nylon brush keeps everything looking sharp. Check for any loose fasteners or obvious damage.

Every three months, give high-traffic areas a good polish if you want to maintain that showroom look. Check expansion joints and trim pieces. In marine environments, a coat of anti-oxidation wax provides extra protection.

Annual inspections are smart for structural applications. Look for stress cracks, verify that your support structure is solid, and update any safety markings that might have worn off.

Eco & Budget Considerations

Think beyond that initial price tag. Diamond plate aluminum sheets cost more upfront than steel options, but the math often works in aluminum's favor over time. You'll never spend money on rust prevention treatments, and longer service life means fewer replacements.

The lightweight nature also cuts transportation costs and makes installation easier - which can mean lower labor costs. Current scrap aluminum prices typically run between $0.50 and $1.00 per pound.

From an environmental standpoint, aluminum's 95% energy savings during recycling makes it one of the most sustainable building materials available. These factors add up to make aluminum diamond plate a smart long-term investment.

Where to Buy & What It Costs

Shopping for diamond plate aluminum sheets has never been easier, thanks to online metal suppliers who offer everything from standard sizes to custom cuts delivered right to your door.

The cost varies quite a bit - you'll typically see prices ranging from $2 to $8 per square foot depending on what you're after. Thinner sheets in the 0.025" to 0.063" range cost less upfront but won't handle heavy loads. Thicker plates from 0.125" to 0.500" cost more but deliver the strength and durability you're paying for.

Finish choice makes a huge difference in your final bill. Mill finish keeps things economical, while bright polished surfaces add about 20-30% to the base cost. Anodizing or powder coating can add 50-100% more, but you'll get a finish that truly stands out.

Shipping weight adds up fast. A standard 4'×8' sheet of 1/8" aluminum diamond plate tips the scales at 122 pounds. Go with 1/4" thick, and you're looking at 237 pounds for the same size sheet.

Bulk discounts kick in around 10 sheets or more, with savings of 10-20% pretty common. Most online suppliers don't require minimums, though small orders sometimes carry handling fees.

Buy aluminum diamond plate online offers one solid option for direct purchasing with competitive pricing and professional cutting services.

Ordering Diamond Plate Aluminum Sheets Online

The internet has completely changed how we buy diamond plate aluminum sheets, putting competitive pricing and professional cutting services at your fingertips. Most suppliers stock standard 4'×8' and 5'×10' sheets in popular thicknesses from 1/16" to 1/2", ready to ship.

Online calculator tools take the guesswork out of ordering. Plug in your dimensions, and these tools estimate exactly how much material you need while accounting for normal waste. They'll even suggest the most efficient sheet sizes to minimize cutting costs.

Quote request systems let you shop around without spending all day on the phone. Send your specs - alloy grade, thickness, finish, and quantity - to multiple suppliers and compare responses.

The beauty of no-minimum order policies means even small projects are totally doable. Consider teaming up with friends or neighbors to reach those quantity discount levels.

Getting Custom Cuts & Trim

CNC routing and water-jet cutting open up possibilities beyond standard rectangular sheets. These precision cutting methods handle complex shapes and tight tolerances. Expect to pay $1-3 per linear foot of cutting.

Professional trim pieces make all the difference in how your finished project looks. Corner guards, J-trim, and H-seams are usually available in matching alloys and finishes.

DIY kits bundle everything together - pre-cut sheets, necessary trim, and all the fasteners you need for specific applications. These packages eliminate the guesswork and ensure all your components work together.

For complex installations, turnkey packages include design, cutting, and installation services. They cost more than doing it yourself, but you get professional results backed by warranties.

The ultimate guide to stainless diamond plate explores alternative materials when you need maximum corrosion resistance for the toughest environments.

Frequently Asked Questions about Diamond Plate Aluminum Sheets

When it comes to diamond plate aluminum sheets, we get the same questions over and over again. After years of helping customers choose the right materials for everything from walk-in cooler floors to truck bed liners, I've learned that most people worry about the same three things: strength, workability, and maintenance.

What thickness should I choose for load-bearing flooring?

The thickness you need depends entirely on what's walking across your floor and how well it's supported underneath.

For regular foot traffic like in walk-in coolers or warehouse walkways, 1/8" thick diamond plate aluminum handles the job beautifully when you support it every 12-16 inches.

Light vehicles like forklifts or small carts need more muscle. Step up to 3/16" thickness and tighten your support spacing to every 8-12 inches. This combination handles the concentrated loads without flexing.

Heavy-duty applications require 1/4" thickness or more with properly engineered support structures. We're talking about loading docks, vehicle ramps, or industrial equipment platforms. At this point, you really want a structural engineer to run the numbers.

It's always better to go slightly thicker than to find you went too thin after installation.

Can diamond plate aluminum sheets be welded or bent?

Absolutely, but the devil's in the details of which alloy you're working with.

3003-H22 alloy is your friend for bending and forming projects. This stuff bends like butter and welds beautifully, making it perfect for custom toolboxes, decorative trim, or anything requiring complex shapes.

6061-T6 alloy tells a different story. Once it's heat-treated to T6 condition, bending is off the table - it'll crack before it bends. However, it welds like a dream and provides incredible strength for structural applications.

When welding aluminum diamond plate, surface preparation is everything. Clean off any oils, dirt, or oxidation before striking an arc. The raised diamond pattern can make puddle control tricky, so practice on scrap pieces first.

How do I keep the polished finish from dulling over time?

Keeping that mirror shine on polished diamond plate aluminum sheets isn't rocket science, but it does take regular attention.

Regular cleaning makes the biggest difference. Use mild detergent and water with a soft nylon brush to get into those diamond grooves. Avoid anything with chlorides - no bleach-based cleaners that can cause pitting.

For maintaining that showroom shine, aluminum-specific polishing compounds work wonders. Apply them every few months or whenever the surface starts looking dull.

Minor scratches are fixable. Start with fine polishing compound and work in circular motions. For deeper scratches, you might need to start with 400-grit sandpaper, then work up through finer grits before final polishing.

The diamond pattern actually helps hide normal wear and tear, which is one reason why this material stays looking good for years with minimal maintenance.

Conclusion

When you're looking for the perfect balance of safety, durability, and good looks, diamond plate aluminum sheets really deliver. Whether you're installing slip-resistant flooring in a walk-in freezer or adding some sharp-looking trim to your truck, choosing the right material makes all the difference.

Here at American Mortuary Coolers, we've been working with diamond plate aluminum across Tennessee, Georgia, Illinois, and all over the country for years. We've seen how the right diamond plate aluminum sheets can transform a basic mortuary cooler floor into something that's both safe and professional-looking.

The beauty of aluminum diamond plate really shines when you think long-term. You might pay a bit more upfront compared to steel, but here's what you get: no rust worries, barely any maintenance headaches, 60% lighter weight for easier installation, and decent scrap value when you're finally done with it.

Understanding the differences between 3003 alloy for bendable decorative work, 4017 for middle-ground applications, and 6061-T6 for serious structural jobs helps you nail the right choice every time.

The online buying scene has made getting quality diamond plate aluminum sheets easier than ever. With custom cutting services, competitive pricing, and freight delivery right to your door, you can get exactly what you need without the old-school hassles.

Ready to see what professional-grade diamond plate can do for your project? Shop mortuary-grade diamond plate products and let our nationwide delivery network and years of technical know-how work for you. We've got the materials and the experience to help make your next project something you'll be proud of for years to come.