Why Walk Coolers Are Essential for Modern Cold Storage

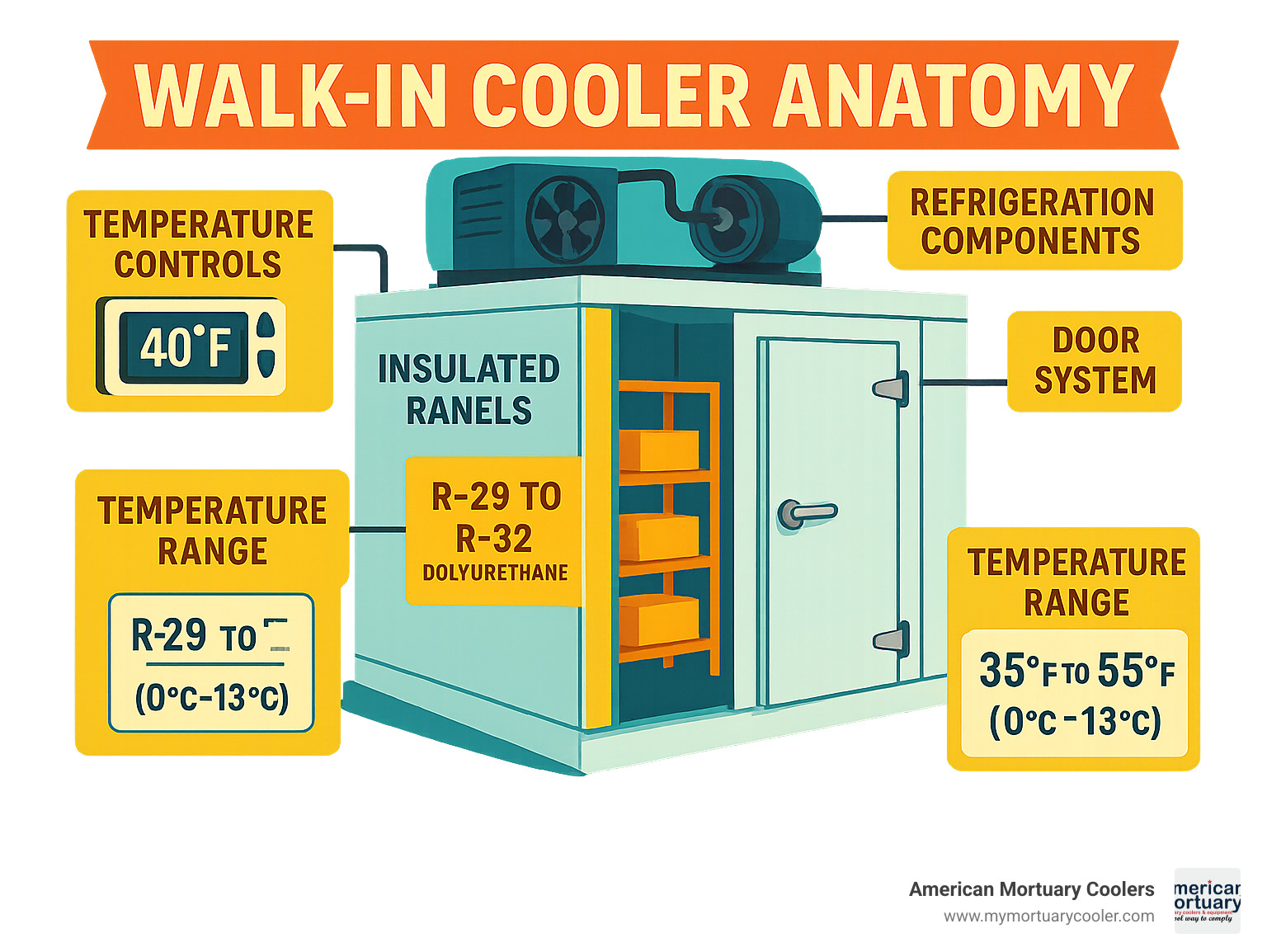

A walk cooler is a large, insulated refrigeration unit that allows people to walk inside for storing temperature-sensitive items. These commercial-grade cooling systems maintain temperatures between 35°F and 55°F, making them perfect for preserving perishable goods across various industries.

Key Walk Cooler Facts:

- Temperature Range: 35°F to 55°F (0°C to 13°C)

- Common Sizes: 6×6, 8×8, 10×10, up to 16×60 feet

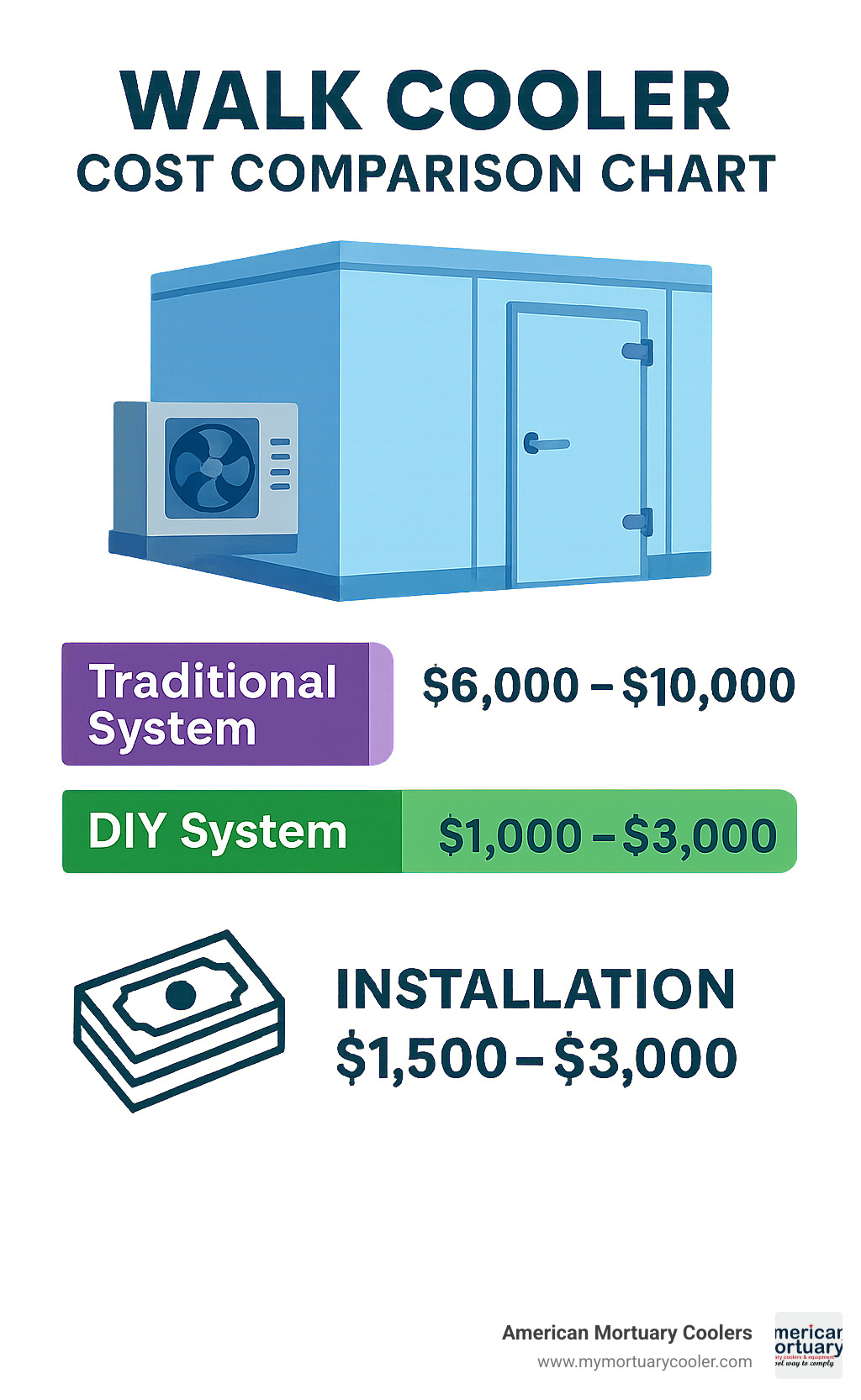

- Cost Range: $6,000-$10,000 traditional; $1,000-$3,000 DIY CoolBot systems

- Energy Use: 1.5-3 horsepower systems, 15-30 amps at 208-230 volts

- Lifespan: 15-20 years with proper maintenance

- Insulation: R-29 to R-32 polyurethane panels

Walk coolers serve critical roles in restaurants, hospitals, funeral homes, and distribution centers where reliable cold storage can mean the difference between operational success and costly product loss. As one industry expert noted, "For small farms, cold storage can mean the difference between profitability and not making ends meet."

The funeral industry faces unique challenges with cold storage requirements. Walk cooler systems must provide consistent temperatures, reliable operation, and often need custom sizing to fit existing facility layouts. Unlike standard commercial refrigeration, mortuary applications demand equipment that operates flawlessly around the clock with minimal maintenance disruptions.

Modern walk coolers come in two main configurations: modular panel systems that assemble on-site, and pre-fabricated units delivered ready to install. Indoor units work well for climate-controlled buildings, while outdoor models withstand weather extremes and free up valuable interior space.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in walk cooler solutions for funeral homes and related facilities. My experience includes sourcing and delivering reliable, American-made cold storage systems that meet the unique demands of mortuary operations nationwide.

Similar topics to walk cooler:

Inside the Machine: How a Walk Cooler Works & What It's Made Of

Ever wondered what makes your walk cooler tick? Understanding the inner workings helps you choose the right system and keep it running smoothly for years to come.

Think of your walk cooler like a giant refrigerator that works around the clock. The refrigeration cycle is the heart of the operation, constantly moving heat from inside your cooler to the outside world. Here's how it works: the compressor squeezes refrigerant gas, making it hot. This hot gas flows to the condenser outside, where it cools down and turns into liquid. The liquid then travels through an expansion valve and into the evaporator coils inside your cooler, where it absorbs heat and turns back into gas. The cycle repeats endlessly, keeping your storage space at that perfect 35°F to 41°F range.

The magic happens inside those thick walls too. Modern walk cooler panels use polyurethane insulation with impressive R-values of 29-32 - that's serious insulation power. These panels connect with cam-lock seams that create an airtight seal, keeping the cold in and the heat out. No gaps, no thermal bridges, just consistent temperature control.

Your thermostat acts like the brain of the operation, constantly monitoring temperature and telling the system when to kick in. Meanwhile, vapor-proof lighting keeps everything visible without creating heat or moisture problems. Those door gaskets might look simple, but they're crucial for maintaining the seal every time someone walks in and out.

Walk-in refrigeration systems must meet strict energy efficiency standards, so manufacturers design every component with performance in mind.

Core Components Explained

The compressor is your walk cooler's powerhouse, typically running 1.5 to 3 horsepower for most applications. Scroll compressors run quieter and last longer, while reciprocating compressors offer solid performance at a lower price point. Choose based on your noise tolerance and budget.

Unit coolers handle the actual cooling inside your space. These evaporator units come in different sizes and configurations, but they all do the same job - pull heat out of the air. Proper sizing prevents ice buildup and keeps temperatures consistent, even when you're loading and unloading frequently.

Dedicated condensing systems separate the hot components from the cold storage area, improving efficiency significantly. Instead of having everything in one unit, the condenser sits outside while the evaporator stays inside. This setup works especially well for larger installations or when you want to minimize heat inside your facility.

ECM fans represent the latest in energy-saving technology. These smart motors adjust their speed automatically, using less electricity while maintaining perfect airflow. They cost more upfront but save money every month on your electric bill.

Materials & Insulation Choices

Polyurethane remains the gold standard for walk cooler insulation. This material gets foamed-in-place during manufacturing, creating a seamless barrier that stops heat and moisture cold. No joints, no gaps, no thermal bridges - just solid insulation performance.

Polyisocyanurate takes insulation to the next level with even higher R-values and better moisture resistance. This rigid board material handles heavy loads and maintains its insulating properties longer than standard options. Perfect for high-demand applications where performance matters most.

Panel finishes come down to stainless steel versus galvanized options. Stainless steel costs more but offers superior corrosion resistance and easier cleaning - essential for food service applications. Galvanized finishes provide excellent durability at a lower cost and work well for most storage needs.

The foamed-in-place manufacturing process eliminates the weak spots that plague other insulation methods. When polyurethane foam expands inside the panel, it creates both insulation and a vapor barrier in one step. This process ensures consistent thickness and eliminates the air pockets that reduce efficiency.

Choosing the Perfect Walk Cooler: Types, Sizes & Installation Locations

Selecting the right walk cooler depends on your specific needs, available space, and budget constraints. Indoor units work well for climate-controlled facilities, while outdoor models free up valuable interior space and can effectively add square footage to your operation.

Modular panel systems offer maximum flexibility for custom sizing and future expansion. These cam-lock panels assemble on-site and can be reconfigured or relocated as needed. Panel systems typically ship in 2-10 days for standard sizes and accommodate virtually any dimension requirement.

Prefabricated fiberglass units provide seamless construction that eliminates thermal bridges and potential leak points. These one-piece designs offer superior energy efficiency and weather resistance for outdoor installations, though they limit customization options.

Combination cooler-freezer units serve dual purposes with separate temperature zones controlled by individual thermostats. These versatile systems work well for facilities needing both refrigerated and frozen storage in a compact footprint.

Quick-Ship programs deliver popular sizes like 8×8 and 8×10 units in as little as 2 days, while custom builds accommodate unique dimensional requirements with 10-day lead times for standard configurations.

Floor versus floorless installation depends on your site conditions. Floorless units leverage existing concrete slabs and simplify installation, while insulated floors provide complete thermal protection and easier cleaning.

Thru-wall installations combine outdoor refrigeration with indoor access, maximizing space efficiency while maintaining convenient product access. These configurations require careful planning for proper sealing and structural support.

CoolBot DIY systems convert standard air conditioners into walk cooler refrigeration for budget-conscious applications. These systems cost $1,000-$3,000 compared to $6,000-$10,000 for traditional refrigeration, though they require more hands-on installation and maintenance.

More info about custom solutions helps you understand specialized mortuary applications and sizing considerations.

Standard & Custom Dimensions

Standard walk cooler sizes include 6×6, 8×8, and 10×10 foot configurations with 8-foot ceiling heights. These popular dimensions offer good storage capacity while fitting through standard doorways during installation.

Custom sizing accommodates unique space constraints and specific storage requirements. Units can be built up to 16 feet wide and 60 feet long, with heights reaching 28 feet for specialized applications.

Rail systems improve storage capacity for hanging products, particularly useful in meat processing and mortuary applications. These systems integrate with 6×6, 6×8, 8×6, and 8×8 cooler dimensions for maximum versatility.

Interior dimensions matter more than nominal sizing - panels manufactured to actual rather than nominal dimensions maximize usable storage space. A nominal 8×8 unit provides approximately 7'8" × 7'8" of interior space.

Location Planning & Site Prep

Proper site preparation ensures optimal walk cooler performance and longevity. Concrete pads must be level, properly drained, and sized to support the unit's weight plus stored products - typically 1,200 pounds per square foot minimum.

Ventilation requirements vary by installation type. Indoor units need adequate airflow around condensing units, while outdoor installations require weather protection and access for service.

Electrical requirements typically include 208-230 volt, 3-phase power for commercial installations. Units drawing 15-30 amps require dedicated circuits and proper disconnect switches within sight of the equipment.

Drainage provisions prevent water accumulation from defrost cycles and condensation. Floor drains or external drainage systems must handle peak flow rates during defrost operations.

Seismic codes in earthquake-prone regions require engineered foundations and structural anchoring. California, Oregon, Washington, and other states mandate wet-stamped engineering documents for compliance.

Key Features & Accessories for Your Walk Cooler

Strip curtains reduce cold air loss during frequent door openings, improving energy efficiency and temperature stability. These vinyl barriers pay for themselves through reduced operating costs in high-traffic applications.

LED lighting provides energy-efficient illumination with longer service life than traditional fluorescent fixtures. Vapor-proof fixtures resist moisture and temperature extremes while providing excellent visibility.

Shelving systems maximize storage capacity and organization. Wire shelving promotes airflow, while solid shelving works better for smaller items. Adjustable systems accommodate changing storage needs.

Slip-resistant flooring improves safety in potentially wet conditions. Diamond-tread patterns and specialized coatings reduce slip hazards while maintaining easy cleaning.

Humidity control systems prevent excessive moisture that can damage products or promote mold growth. These systems maintain optimal 50-60% relative humidity for most applications.

Budget & Compliance: Costs, Energy Use, Regulations

Walk cooler pricing varies significantly based on size, features, and installation requirements. Traditional systems cost $6,000-$10,000 for standard sizes, while CoolBot-powered DIY systems range from $1,000-$3,000 with some farmers building for under $1,000 using repurposed materials.

Installation labor adds $1,500-$3,000 depending on complexity and local rates. Electrical connections, concrete work, and refrigerant charging require licensed professionals in most jurisdictions.

Warranty structures typically include 20-year panel coverage, 5-year door and compressor warranties, and 1-year parts and labor protection. Extended warranties provide additional peace of mind for critical applications.

Energy efficiency standards mandate minimum annual walk-in energy factors for different system types. Indoor cooler condensing systems must achieve ≥1.644 W-h/W-h (5.61 Btu/W-h), while outdoor systems require ≥2.227 W-h/W-h (7.60 Btu/W-h).

DOE and EISA compliance requires specific R-values and energy performance metrics. Panels must achieve minimum RSI-values of 4.40 m²·K/W for coolers and 5.64 m²·K/W for freezers.

Edaily formulas calculate maximum daily energy consumption for door assemblies based on surface area. Display doors follow the formula Edaily ≤ 0.4306 × Add + 0.41, while freight doors have different requirements.

Nameplate requirements mandate bilingual English and French labeling with brand, model, manufacture date, and indoor/outdoor designation clearly visible before assembly.

Financing & Warranty Structures

Lease options spread walk cooler costs over 3-7 year terms with buyout provisions. Monthly payments typically range from $150-$400 for standard units, making high-quality equipment accessible to smaller operations.

Rental programs serve temporary needs or allow trial periods before purchase. Short-term rentals cost $300-$800 monthly, while long-term arrangements offer better rates.

Panel warranties extend 20 years for structural integrity and insulation performance. This coverage reflects manufacturers' confidence in modern polyurethane insulation technology.

Compressor warranties typically provide 5-year coverage on parts and labor. Some manufacturers offer extended coverage up to 10 years for premium systems.

Meeting Federal & Provincial Standards

R-value targets ensure minimum insulation performance for energy efficiency. Cooler panels must achieve R-29 minimum, while freezer applications require R-32 or higher.

Bilingual labeling requirements apply in Canada, with English and French text mandatory on all regulated components. Labels must include brand, intended use, model number, and manufacture date.

CREED reporting requires manufacturers to submit energy efficiency reports through the Compliance Regulatory Energy Efficiency Database. Compliance database link provides access to approved product listings.

Testing standards follow 10 C.F.R. Appendices A, B, and C for energy consumption, R-values, and annual energy factors respectively. These standardized tests ensure consistent performance measurements across manufacturers.

Keeping Your Walk Cooler Efficient: Maintenance, Organization & Troubleshooting

Regular maintenance keeps energy bills low and helps your walk cooler last the full 15–20-year lifespan. Focus on a few high-impact tasks:

- Inspect door gaskets every month; replace anything torn, brittle, or loose so cold air stays in and humidity stays out.

- Clean condenser coils and fan blades monthly with a soft brush or vacuum. Dust buildup is the #1 cause of compressor failure.

- Verify interior temperature (35–41 °F) and humidity (50–60 %) with digital monitors; set text or email alerts for excursions.

- Maintain 1–2 inches of clearance around walls and shelves to ensure proper airflow.

- Schedule professional service twice a year to check refrigerant levels, electrical connections, and defrost controls.

Daily, Weekly & Seasonal Checklist

- Daily: Quick visual check for leaks, unusual noises, or rising temps.

- Weekly: Clean door tracks, confirm lights work, and test the safety latch.

- Monthly: Deep-clean coils, lubricate hinges, and inspect the defrost drain.

- Seasonal (before summer heat): Extra coil cleaning, verify refrigerant charge, and shade outdoor condensers if possible.

Smart Organization Hacks

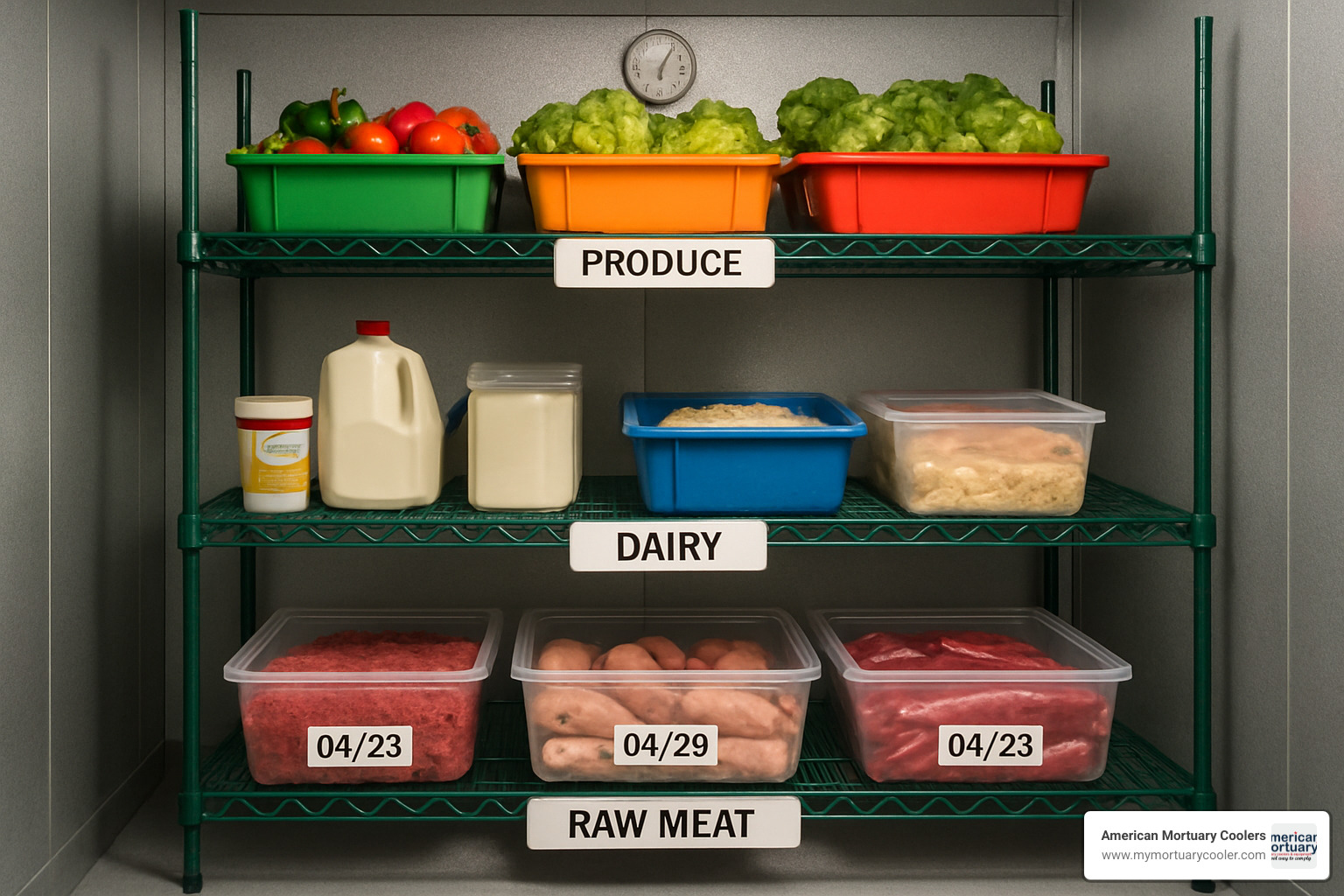

- Follow FIFO rotation and clear labeling to cut waste.

- Store raw meats on bottom shelves, prepared foods higher, and keep everything 6 inches off the floor.

- Use category shelving and color-coded containers to prevent cross-contamination.

Quick Fixes for Common Issues

- Ice buildup → check gaskets first, then defrost timer and drain line.

- High temperature alarms → clean coils; if temps stay high, call a technician to inspect for refrigerant leaks.

- Noisy fans → power down, clear debris, and tighten loose hardware.

More info about maintenance parts is always a click away for genuine components and tech support.

Frequently Asked Questions about Walk Coolers

Common questions about walk cooler systems cover temperature ranges, energy consumption, installation requirements, and maintenance needs. Understanding these basics helps you make informed decisions and operate your system efficiently.

Temperature ranges for walk coolers typically span 35°F to 55°F, with most food service applications maintaining 35-41°F for optimal preservation. Freezer applications operate at -10°F to 0°F for frozen storage.

Indoor versus outdoor placement depends on available space, climate conditions, and operational preferences. Outdoor units free up interior space but require weather protection, while indoor units offer easier access and climate protection.

Energy consumption varies by size, insulation quality, and usage patterns. Typical systems use 1.5-3 horsepower compressors drawing 15-30 amps at 208-230 volts, 3-phase power.

Lifespan expectations range from 15-20 years with proper maintenance. Quality components, regular service, and appropriate usage patterns maximize equipment life and return on investment.

DIY feasibility depends on local codes, available skills, and system complexity. CoolBot systems enable DIY installation using standard air conditioners, while traditional systems require professional installation and refrigerant handling.

What temperature should a walk cooler run at?

Walk cooler temperatures should maintain 35-41°F (1.7-3.3°C) for optimal food storage and energy efficiency. This range prevents freezing while providing adequate preservation for most perishable items.

Specific products may require different temperatures within this range. Dairy products prefer the lower end around 35-37°F, while produce often stores better at 38-41°F depending on the variety.

Temperature consistency matters more than absolute temperature in many applications. Fluctuations stress both products and refrigeration systems, leading to shortened life and increased energy consumption.

Digital controllers provide precise temperature management with adjustable deadbands and alarm functions. These systems maintain tighter control than mechanical thermostats while offering better monitoring capabilities.

How much electricity does a walk cooler use?

Walk cooler electricity consumption depends on size, insulation quality, ambient conditions, and usage patterns. A typical 8×8 unit uses approximately 3,000-5,000 kWh annually, costing $300-$600 in electricity at average commercial rates.

CoolBot-powered systems use up to 42% less energy compared to traditional refrigeration systems. This efficiency comes from optimized compressor cycling and improved temperature control algorithms.

Energy-efficient features like LED lighting, ECM fan motors, and high-R-value insulation reduce operating costs significantly. These upgrades often pay for themselves through reduced utility bills within 2-3 years.

Load factors affect energy consumption dramatically. Properly loaded units (75-90% capacity) operate more efficiently than empty or overloaded systems that experience excessive temperature swings.

Can I convert a room into a walk cooler myself?

Converting existing space into a walk cooler is possible with proper planning, skills, and local code compliance. CoolBot systems enable DIY conversion using standard air conditioners and insulation materials.

Insulation requirements include R-29 minimum for cooler applications, typically achieved with 4-6 inches of rigid foam or spray polyurethane. Vapor barriers prevent moisture infiltration that damages insulation and structure.

Electrical work often requires licensed electricians for code compliance and safety. Dedicated circuits, proper grounding, and appropriate disconnect switches ensure safe operation.

Refrigerant handling requires EPA certification for traditional systems. CoolBot systems avoid this requirement by using standard air conditioners that come pre-charged from the factory.

Building permits may be required depending on local codes and the scope of modifications. Check with local authorities before beginning any conversion project to ensure compliance.

Conclusion & Next Steps

Choosing the right walk cooler comes down to matching capacity, budget, and reliability to the realities of your funeral home. Whether you opt for a traditional refrigeration package or a budget-friendly CoolBot build, proper insulation, good airflow, and consistent maintenance will protect your investment year after year.

American Mortuary Coolers focuses exclusively on durable, American-made cold-storage solutions built for mortuary use. From our Tennessee headquarters we ship custom units to all 48 contiguous states—so no matter if you’re in Los Angeles, Pittsburgh, or the Rocky Mountain Region, we have a solution that fits.

If you’re ready to upgrade or expand, start by reviewing our Best Walk-In Cooler Options Available, then reach out to discuss dimensions, lead times, and delivery logistics. We’ll help you design a cooler that meets today’s needs and tomorrow’s growth without over-spending.

Reliable cold storage is non-negotiable in the funeral industry—let’s make sure yours is built to last.