Why Your Business Needs the Right Custom Walk-In Cooler

A custom walk in cooler is the perfect solution when standard refrigeration units simply don't fit your space, workflow, or temperature requirements. Unlike off-the-shelf models, custom units are built to your exact specifications - from precise dimensions to specialized features like humidity control, custom door configurations, and industry-specific certifications.

Key benefits of custom walk-in coolers: - Perfect fit - Built to exact dimensions (up to 16' wide x 65' long) - Temperature precision - Maintains 33°F to 38°F consistently - Energy efficient - R-29 insulation exceeds federal EISA standards - Durable construction - 4" thick panels with 12-25 year warranties - Industry compliance - UL, NSF, and application-specific certifications - Flexible placement - Indoor or outdoor installation options - Custom features - Specialized doors, shelving, lighting, and finishes

Whether you're running a funeral home, restaurant, brewery, or medical facility, the right custom solution eliminates the compromises that come with standard units. As one brewery owner noted in our research: "The combination of cooler with the A/C unit is amazing and keeps temperature extremely well... All of the material and components used are really first class."

We're American Mortuary Coolers, a Tennessee-based specialist in crafting custom mortuary coolers and related equipment for the funeral industry. Our unique approach provides durable, custom solutions with direct delivery across the contiguous 48 states. Over the years, we've seen how the right custom walk in cooler transforms workflow efficiency while ensuring reliable temperature control for sensitive applications.

Custom Walk-In Cooler 101: What Makes Them Different?

Think of a walk-in cooler as your business's cold storage workhorse. These large refrigerated units keep everything at that sweet spot between 33°F and 38°F - the temperature range that keeps food fresh and safe for commercial use.

But here's where things get interesting. A custom walk in cooler doesn't force you to squeeze your operations into a one-size-fits-all box. Instead, it adapts to your space, your workflow, and your specific needs.

Standard walk-in coolers are like buying clothes off the rack - they come in predetermined sizes and you make do with what's available. Custom units are more like having a tailor create something just for you. Every dimension, every feature, every detail gets designed around how you actually work.

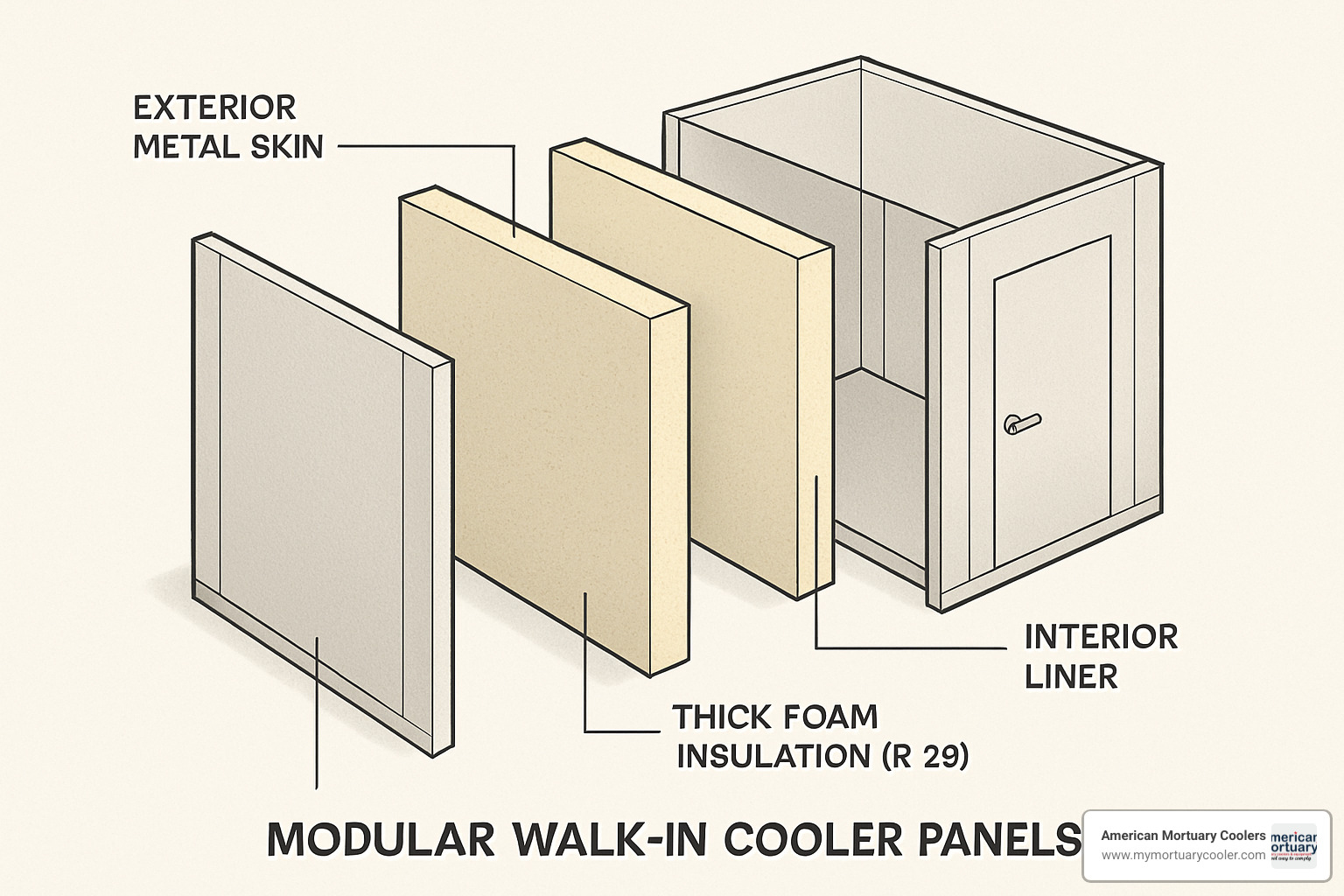

Most custom walk in coolers use 4-inch thick insulation panels with impressive R-29 values for coolers (and R-32 for freezers). This isn't just impressive on paper - it means they meet or exceed those strict US Federal EISA requirements for energy efficiency. Your electric bill will thank you.

The construction quality really shows in the details. We're talking seamless design with cam-action locking systems and heavy-duty gaskets that keep the cold air where it belongs - inside. This attention to craftsmanship translates into some pretty impressive warranty coverage, with quality manufacturers offering 12-year structural warranties and 25-year coverage on internal foam structures. That's confidence in their product.

These custom units serve a wide range of industries - from restaurants and breweries to floral shops, pharmaceutical companies, mortuary facilities, and specialized laboratories. Each has unique needs that standard boxes simply can't meet.

Why a Custom Walk-In Cooler Beats Standard Boxes

The biggest game-changer is space optimization. Custom-sized panels eliminate those frustrating layout inefficiencies that come with trying to fit standard dimensions into real-world spaces. If you've ever tried to squeeze a standard unit into an oddly shaped corner or existing kitchen layout, you know exactly what we mean.

Precise workflow integration is where custom units really shine. You get to decide where doors go, how big they are, and which way they swing. No more awkward reaches or blocked pathways because the door opens the wrong way. Everything flows naturally with how your team actually moves through the space.

Want your cooler to look like it belongs? Branding finishes and custom colors let you match your facility's design perfectly. Many manufacturers will even match specific paint codes, so your new cooler blends seamlessly with your existing setup.

The long-term ROI often surprises people. Yes, custom units cost more upfront than standard boxes. But the improved energy efficiency from proper sizing and better insulation, combined with fewer operational headaches, typically pays for itself within the first few years. It's like buying quality tools - they cost more initially but save you money and frustration over time.

Industries That Demand a Custom Walk-In Cooler

Restaurants face unique challenges fitting refrigeration into existing kitchen layouts without major (and expensive) renovations. Custom units solve this by adapting to whatever space you have available, with door configurations that work with your specific workflow.

Breweries need more than just cold storage - they need precise temperature control and often specialized features for keg storage or temperature cycling. Many require combination cooler-freezer units that standard manufacturers simply don't offer.

Floral businesses operate in a world where presentation matters as much as preservation. They need precise humidity control and often want display doors with specialized lighting so customers can see the beautiful arrangements inside.

Pharmaceutical companies and medical facilities can't mess around with temperature fluctuations. According to the FDA's guidelines on temperature control, they need strict control and often require specialized certifications or documentation to meet regulatory requirements. Custom units can be engineered to meet these exact specifications.

In the mortuary industry - our specialty here at American Mortuary Coolers - funeral homes need units designed for specific dimensional requirements. They often need features like reinforced flooring or specialized access configurations that you simply won't find in standard models. Our experience shows that funeral homes benefit tremendously from units custom to their unique operational needs.

Laboratories round out this list, often requiring specialized temperature ranges, contamination control features, or specific certifications that standard units can't provide.

Design & Customization Checklist

When planning your custom walk in cooler, several key factors determine the final design and performance. Size and shape flexibility is one of the biggest advantages - custom units can be manufactured in sizes up to 16 feet wide and 65 feet long, allowing for significant flexibility in design and application.

The choice between indoor and outdoor placement significantly impacts design requirements. Outdoor units require additional features such as roofing, flooring, and weatherproofing, but they free up valuable indoor space and can simplify installation by avoiding interior refrigeration line work.

Panel thickness typically ranges from 4 to 5 inches, with thicker panels providing better insulation but at higher cost. The insulation material choice is crucial - options include polyurethane, expanded polystyrene (EPS), and polyisocyanurate (PIR), each with different R-values and characteristics.

Refrigeration system selection involves choosing between self-contained and remote systems. Self-contained units are easier to install but may be noisier, while remote systems offer quieter operation and better temperature control but require more complex installation.

Door, ramp, shelving, and lighting options should be specified based on your operational needs. Standard entrance doors are typically 35½" W x 78" H, but custom sizes are available. Replacement doors range from 30"x78" to 60"x84", with prices starting from $1,400.

Compliance requirements include EISA energy standards, NSF food safety certifications, UL electrical safety listings, and California Prop 65 requirements. Some applications may require additional certifications or engineering stamps for seismic, wind, or snow load compliance.

Humidity control systems are essential for applications like floral storage or pharmaceutical use, where precise environmental control is critical.

More info about walk-in cooler design

Selecting the Right Refrigeration Package for a Custom Walk-In Cooler

Proper horsepower sizing is critical for efficient operation. A typical mini walk-in cooler (70" x 30" x 74.5") uses 1/3 HP for cooling and 3/4 HP for freezing applications. Larger units may require 1½–3 HP systems requiring 15–30 amps at 208–230 volts, 3-phase power.

Ambient conditions significantly impact refrigeration requirements. Units operating in high-temperature environments or with frequent door openings need more robust systems. Outdoor installations require systems designed to handle seasonal temperature variations.

Modern systems increasingly use environmentally friendly R-290 refrigerant, which provides excellent performance while reducing environmental impact. Some manufacturers are moving away from older refrigerants to comply with environmental regulations.

Winter controls are essential for outdoor installations in cold climates. These systems include crankcase heaters and fan cycling controls for reliable cold-weather operation, ensuring consistent performance year-round.

Split systems, with evaporators inside and condensing units outside, offer precise temperature control and can extend equipment life by protecting the condensing unit from harsh indoor conditions.

Indoor vs Outdoor Custom Walk-In Cooler Placement

Outdoor installations require specialized roofing caps to protect against weather infiltration. These units often arrive fully assembled and only require simple electrical connections, which can save on installation labor and minimize business downtime.

Flooring insulation becomes more critical for outdoor units, especially in areas with ground freeze-thaw cycles. Proper foundation preparation and insulated flooring prevent thermal bridging and maintain energy efficiency.

Weatherproofing includes sealed electrical connections, corrosion-resistant finishes, and proper drainage systems. Some manufacturers offer quick-ship units that can be delivered fully assembled and ready to operate in as little as 10 days.

The choice between indoor and outdoor placement often comes down to available space, installation complexity, and operational preferences. Outdoor units can effectively expand usable indoor floor space without building additions, while indoor units may be easier to access and maintain.

Product Roundup & Buying Guide: Best Custom Walk-In Cooler Solutions

Finding the right custom walk in cooler manufacturer can make or break your investment. After years in the industry, we've seen which approaches consistently deliver quality solutions that stand the test of time.

Outdoor fiberglass units have earned solid reputations with their seamless construction that eliminates troublesome hot spots and moisture problems. Quality manufacturers offer impressive warranty coverage - 25 years on internal foam and 12 years on structural components. Some offer Quick Ship programs that can get units delivered in just 10 days, which is practically unheard of in the custom cooler world.

Modular panel systems take a different approach with cam-action locking devices and heavy-duty gaskets that create rock-solid seals for temperature consistency. These units not only meet EISA requirements but often exceed them, which translates to real energy savings over time. Quality manufacturers use thorough quote forms - sometimes almost intimidatingly detailed - but this attention to specification prevents costly surprises down the road.

For breweries and restaurants looking for versatility, combination cooler-freezer units offer the ability to switch between modes. This flexibility is perfect when your storage needs change seasonally or when you're expanding your operation but aren't sure exactly what you'll need.

Mini plug-and-play units (like 70" W x 30" D x 74½" H, 74 cu. ft. models) offer an interesting middle ground. These compact solutions require no professional installation and work both indoors and outdoors. They're perfect for smaller operations or as backup storage during peak seasons.

At American Mortuary Coolers, we focus specifically on mortuary-specific coolers designed for funeral home requirements. Our units feature reinforced flooring, custom access configurations, and compliance with industry-specific regulations that general-purpose manufacturers often overlook.

The price range typically spans from $7,000 for basic mini units to $40,000+ for large, fully-equipped custom installations. Don't let sticker shock scare you off - many manufacturers offer financing and leasing options that make these investments manageable. The key is finding a supplier who provides comprehensive after-sales support, including maintenance programs and reliable parts availability.

More info about custom fridge guide

Cost Factors & Budgeting for Your Custom Walk-In Cooler

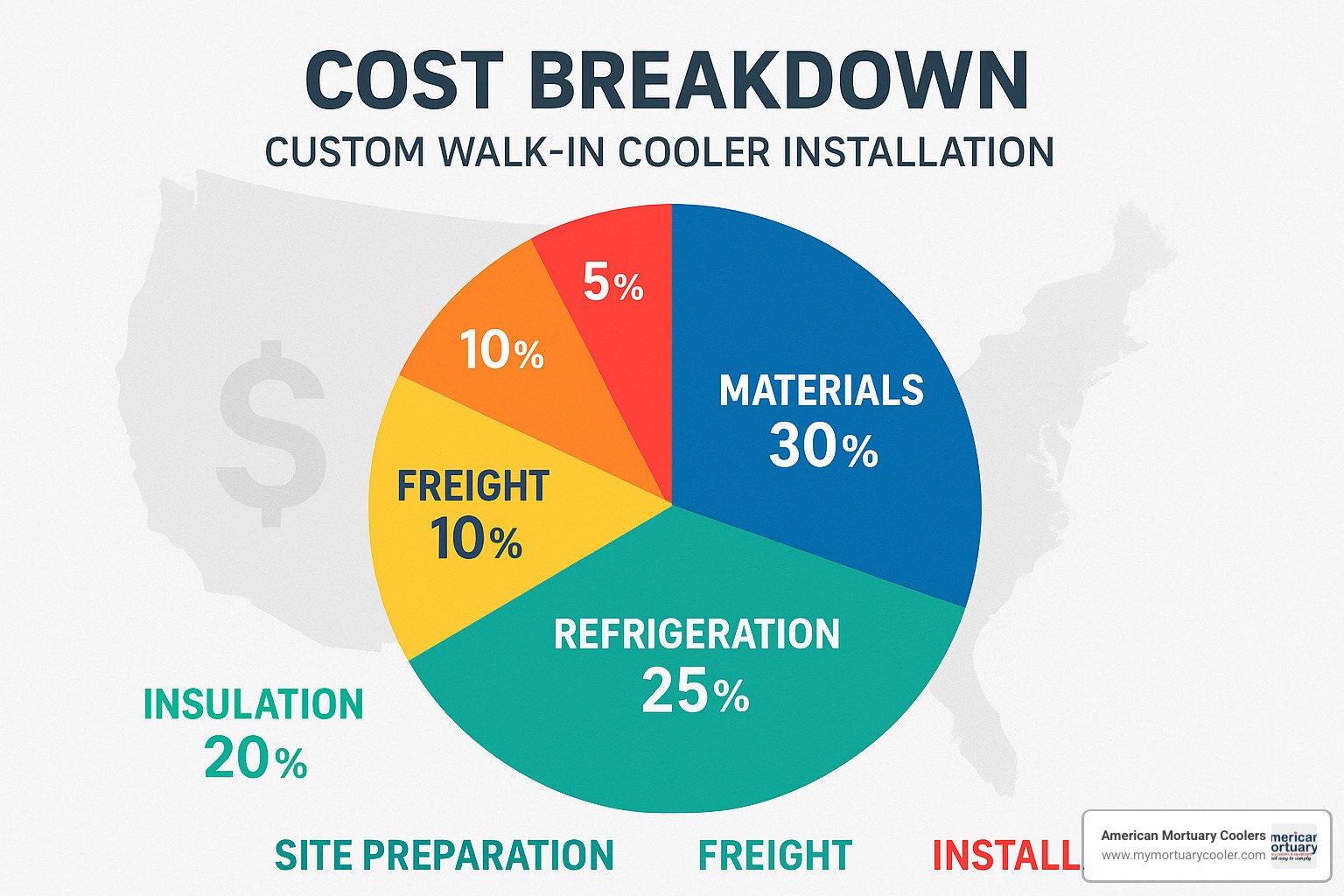

Understanding what drives the cost of your custom walk in cooler helps you make smart decisions about where to invest and where to save. Dimensions are the biggest cost driver - it's simple math that a 16x20 unit requires significantly more materials and a more powerful refrigeration system than an 8x8 installation.

Insulation choice creates an interesting cost-versus-savings equation. Higher R-value insulation costs more upfront but dramatically reduces energy consumption over the unit's lifetime. Those 4-inch thick insulation panels that exceed EISA energy standards aren't just regulatory compliance - they're money in your pocket every month through lower utility bills.

Refrigeration complexity varies dramatically based on your specific needs. Self-contained units typically cost less initially than split systems, but split systems often provide better performance and longer equipment life. It's one of those situations where spending more upfront often saves money in the long run.

Site preparation can blindside you with unexpected costs, especially for outdoor installations. Concrete pads, electrical service upgrades, and drainage systems add up quickly. Indoor installations might need floor reinforcement or structural modifications to accommodate the unit's weight and size.

Freight costs depend on distance and unit size, and policies vary widely between manufacturers. Some include delivery in their pricing, while others charge separately. Pre-assembled units cost more to ship but can save substantial installation labor costs.

Don't overlook energy rebates and incentives available for high-efficiency units. Local utilities and government programs often offer substantial rebates that can offset the premium for better insulation or advanced refrigeration systems. These programs change frequently, so it's worth checking before you finalize your specifications.

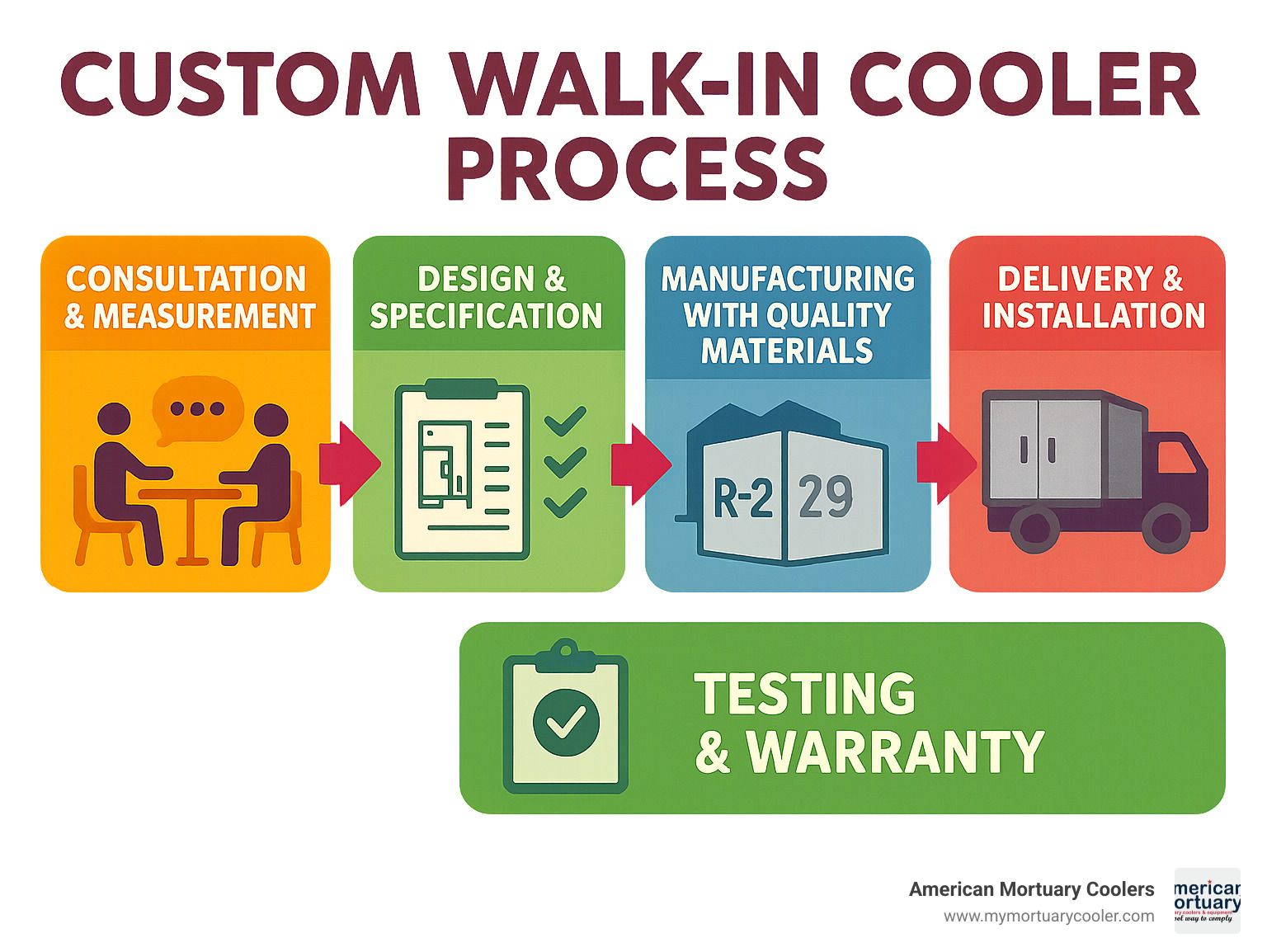

Ordering, Delivery & Installation Steps

The ordering process starts with a detailed quote form that captures every specification. Quality manufacturers have comprehensive forms that might seem overwhelming at first, but they're designed to prevent the costly miscommunications that can derail a project.

A site survey makes sense for complex installations, especially when you're dealing with tight spaces or unusual requirements. This step helps verify measurements, electrical capacity, and access routes before production begins. It's much cheaper to find problems during planning than during delivery.

Production timelines vary significantly based on customization complexity and manufacturer workload. Standard configurations might qualify for quick-ship programs with 10-day delivery, while fully custom units typically require 4-8 weeks for manufacturing. Plan accordingly, especially if you have seasonal deadlines.

Many custom units arrive pre-assembled, which initially seems expensive but often proves cost-effective. Factory assembly ensures quality control and dramatically reduces on-site installation time. Your crew can focus on connecting utilities rather than wrestling with panels and hardware.

Plug-in startup involves connecting electrical service, programming control systems, and verifying proper operation. Most manufacturers require licensed refrigeration contractors for this phase to maintain warranty coverage and ensure code compliance.

Maintenance schedules should be established immediately after installation. Regular cleaning, filter changes, and system inspections aren't just good practice - they're often required to maintain warranty coverage and ensure optimal performance.

Warranty registration protects your investment, but it's time-sensitive. Most manufacturers require registration within 30-90 days of installation to activate full warranty coverage. Don't let this administrative detail void your protection.

More info about choosing suppliers

Frequently Asked Questions about Custom Walk-In Coolers

When you're considering a custom walk in cooler for your business, you probably have questions about costs, timelines, and compliance. Let's tackle the three most common concerns we hear from clients every day.

What is the typical cost range for a custom walk-in cooler?

The honest answer? It depends on what you need, but we can give you some real numbers to work with. Basic mini units start around $7,040 - think of something like the compact 70" x 30" x 74½" Powers model that's perfect for smaller operations.

On the other end of the spectrum, fully-equipped large installations can reach $40,000 or more. These are the heavy-duty units with all the bells and whistles - specialized features, premium insulation, and complex refrigeration systems.

Most restaurants find their sweet spot in the $15,000 to $25,000 range for a typical 8x10 or 8x12 unit with standard features. But here's where it gets interesting for specialized applications like ours - mortuary coolers and pharmaceutical storage often cost more due to additional compliance requirements and specialized features that standard units simply can't provide.

The wide price range reflects real differences in size, insulation quality, refrigeration complexity, and customization features. When you're investing in a custom unit, you're paying for exactly what you need - no more, no less.

How long does it take to build and install one?

This is where custom really shines compared to trying to make a standard unit work. Quick-ship programs can get pre-configured units to you in as little as 10 days - perfect when you need a solution fast.

For fully custom units like the specialized mortuary coolers we build, plan on 4 to 8 weeks for manufacturing. This gives us time to get every detail right according to your specifications.

Installation time varies dramatically based on your choice. Pre-assembled units are the speed champions here - they often go from delivery truck to operational in just a few hours. You're mainly looking at electrical connections and startup procedures.

Modular systems requiring on-site assembly take longer, sometimes several days for complex custom installations. But don't worry - this extra time ensures everything fits perfectly and meets all your operational requirements.

How do I keep my unit energy-code compliant over time?

Staying compliant isn't complicated, but it does require some attention. The key areas to watch are pretty straightforward.

Door seals and self-closing mechanisms are your first line of defense. Regulations mandate self-closing doors for energy efficiency, so make sure these systems keep working properly. It's one of those simple things that makes a huge difference in both compliance and operating costs.

Insulation panel maintenance keeps your R-value performance where it should be. Address any damage promptly - even small issues can grow into big problems that hurt both efficiency and compliance.

Regular refrigeration system maintenance ensures optimal efficiency over time. This isn't just about compliance - it's about protecting your investment and keeping operating costs reasonable.

Here's something many people overlook: document everything. Keep records of maintenance activities and energy performance. During inspections, this documentation demonstrates your commitment to compliance and proper operation.

If you're working with an older unit, upgrading to meet current EISA standards might be necessary during major renovations. It's worth having a conversation with your supplier about whether upgrades make sense for your situation.

Conclusion

Choosing the right custom walk in cooler is one of those decisions that shapes your business operations for decades. After diving deep into the options, costs, and considerations, it's clear that custom units deliver something off-the-shelf models simply can't match - a perfect fit for your unique needs.

The numbers tell the story. With durable solutions backed by warranties up to 25 years and energy efficiency that meets or exceeds federal standards, a custom unit isn't just an expense - it's an investment in your business's future. The upfront cost difference between standard and custom units often pays for itself through improved workflow efficiency and lower operating costs.

What makes the difference is finding the right partner for your project. At American Mortuary Coolers, we've spent years perfecting the art of custom refrigeration for funeral homes across America. Our nationwide delivery service means whether you're running a family funeral home in rural Tennessee or a large facility in downtown Chicago, we can design and deliver exactly what you need.

Our expertise in the mortuary industry gives us unique insight into the specific challenges funeral directors face. We understand the importance of reliable temperature control, the need for specialized access configurations, and the regulatory requirements that come with this sensitive work. That's why funeral homes from coast to coast trust us with their most critical refrigeration needs.

The journey from initial consultation to final installation doesn't have to be complicated. With the right manufacturer partner, you'll have support every step of the way - from design and engineering through delivery and startup. That's the American Mortuary Coolers expertise difference.

Ready to stop compromising with standard units that don't quite fit? Let's design a custom walk in cooler that works exactly the way your business does. Our team is standing by to turn your specific requirements into a refrigeration solution that serves you reliably for decades to come.