Why Diamond Stainless Steel Delivers Superior Performance

Diamond stainless steel combines the corrosion resistance of stainless steel with a raised diamond pattern that provides improved grip, durability, and visual appeal. This textured metal solution addresses three critical needs: safety through slip resistance, hygiene through easy cleaning, and aesthetics through professional appearance.

Key Diamond Stainless Steel Applications:

- Industrial flooring - Diamond grip grating in 7", 9½", and 11¾" widths

- Architectural cladding - Quilted patterns from 3" x 3" up to 12" x 12" diamonds

- Food service equipment - Hygienic surfaces that resist bacteria buildup

- Safety walkways - Maximum traction in wet or oily conditions

- Jewelry - 316L surgical grade with diamond-textured finishes

The raised diamond texture is created through embossing rollers that press the pattern into flat stainless steel sheets. Common grades include 304 for general use and 316L for marine or medical applications. Pattern options range from fine-line designs for decorative use to deep-grip textures for heavy-duty flooring.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience specifying diamond stainless steel flooring and panels for funeral home equipment across all 48 states. Our direct manufacturing approach ensures proper grade selection and pattern sizing for each installation's specific safety and durability requirements.

Quick look at diamond stainless steel:

What Is Diamond Stainless Steel?

Diamond stainless steel is regular stainless steel with a raised diamond pattern pressed into its surface. The diamond pattern creates multiple contact points that help prevent slipping, even when the surface gets wet or oily.

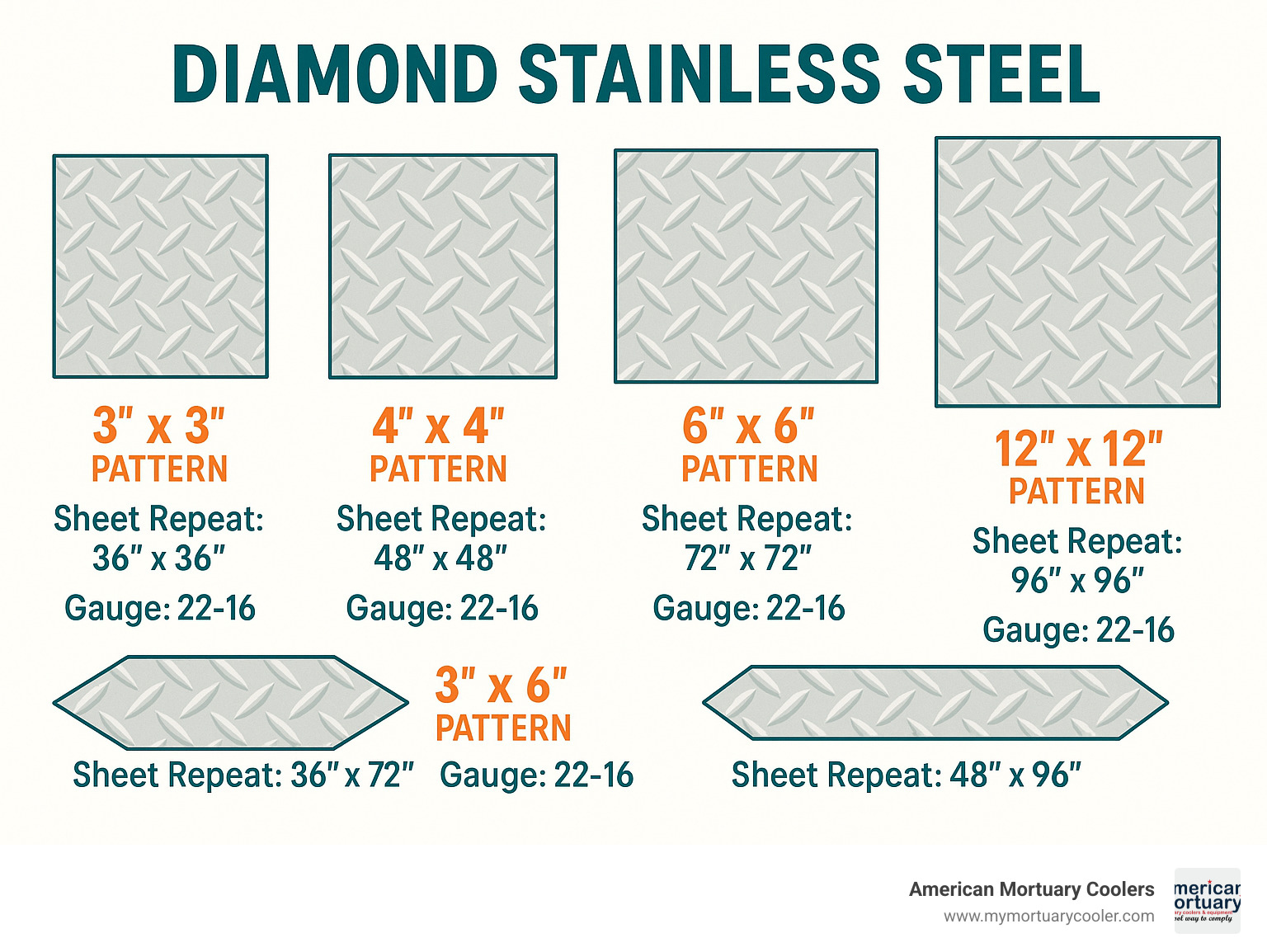

You'll find diamond patterns in two main shapes. Square diamonds range from 3" x 3" decorative patterns up to 12" x 12" architectural features. Elongated rectangles typically measure 3" x 6" or 4" x 8".

The diamond texture is created through an embossing process where powerful rollers press the pattern into flat stainless steel sheets. This embossing actually strengthens the metal by creating structural ridges.

Diamond stainless steel uses the same proven alloy formulas as regular stainless steel. The 304 grade contains 18% chromium and 8% nickel, perfect for indoor applications. For tougher environments, 316L stainless steel adds molybdenum for superior corrosion resistance.

| Property | Diamond Stainless Steel | Plain Stainless Steel |

|---|---|---|

| Slip Resistance | Excellent (multi-directional grip) | Poor (smooth surface) |

| Visual Appeal | Textured, professional appearance | Clean but plain |

| Structural Strength | Improved by embossed ridges | Standard sheet strength |

| Cleaning Ease | Good (self-draining pattern) | Excellent (completely smooth) |

| Cost | 15-25% premium | Base price |

How diamond stainless steel patterns are formed

The process starts with flat stainless steel sheets fed through specialized embossing rollers. These rollers have the inverse diamond pattern machined into their surface.

As the sheet passes through under tremendous pressure, the rollers press the diamond texture into the metal. Hot rolling is required for stainless steel because it's much harder than softer metals like aluminum.

Pattern dimensions are measured peak-to-peak. During manufacturing, protective film gets applied to prevent scratches during shipping and handling.

Grades used for diamond stainless steel

304 stainless steel is the workhorse grade for most indoor applications. With 18% chromium and 8% nickel, it offers excellent corrosion resistance for kitchen equipment and architectural use.

316 stainless steel adds 2-3% molybdenum for improved corrosion resistance. This grade handles chlorides and acids that would affect 304 grade. It's essential for coastal installations and chemical processing environments.

316L stainless steel represents the premium choice for demanding applications. This surgical-grade material offers maximum corrosion resistance and hypoallergenic properties for medical equipment and high-end jewelry.

For marine use, 316L is virtually mandatory due to salt water's aggressive nature. Food-grade applications typically use either 304 or 316L, depending on specific requirements.

Manufacturing Processes & Pattern Types

Creating diamond stainless steel involves embossing rollers - massive steel cylinders with the inverse diamond pattern machined into their surface. These rollers press the texture into stainless steel sheets under tremendous pressure.

Quilted patterns represent the standard diamond stainless steel applications. These uniform diamond shapes come in sizes like 3", 4", 6", and 12" squares. Smaller patterns work for decorative applications, while larger diamonds make bold architectural statements.

For maximum safety performance, grip grating features much deeper impressions engineered specifically for industrial flooring where slip resistance is critical.

For comprehensive information about choosing the right pattern, check out: More info about diamond plate options.

Fine-Line vs Beveled vs Two-Tone Diamond Stainless Steel

Fine-line diamond patterns create razor-sharp edges with maximum contrast between raised diamonds and recessed valleys, providing the best slip resistance and dramatic shadows under lighting.

Beveled diamond patterns soften sharp edges into gentle curves, reducing the chance of catching on clothing while creating beautiful light reflection patterns.

Two-tone diamond patterns use different finishes on the same sheet. Typically, raised diamond areas get a brushed finish while valleys stay polished, creating visual depth.

When installing multiple sheets, join alignment becomes critical. Modular sheets are designed with precise measurements ensuring perfect alignment every time.

Diamond stainless steel grip grating for safety

Industrial grip grating comes in three standard widths: 7", 9½", and 11¾", with two gauge options: .060" and .075" thickness. The heavier .075 gauge provides serious load capacity for heavy equipment or constant foot traffic.

The diamond pattern provides multi-directional slip resistance that works even when covered with snow, ice, oil, or other contaminants. The self-cleaning design prevents debris buildup, with normal rain or washing naturally clearing accumulation.

All quality grip grating meets ANSI compliance standards for industrial flooring applications. For specialized conveyor applications, find products built to ANSI B29.1 standards through resources like the Learn More Chain Configurator.

Applications & Performance Advantages

Diamond stainless steel delivers exactly what different industries need: safety, durability, and professional looks all in one material.

Architects love how diamond stainless steel transforms building surfaces. Those facades and elevator interiors catch light beautifully while hiding fingerprints and minor scratches that plague smooth stainless steel.

Commercial kitchens have acceptd this material for backsplashes and wall panels that handle constant splashing, cleaning, and equipment bumps while maintaining that professional appearance health inspectors appreciate.

At American Mortuary Coolers, we regularly specify diamond stainless steel flooring for mortuary coolers throughout our service area. When staff work in potentially wet conditions, that slip-resistant surface is essential for safety while maintaining hygienic standards.

The transportation industry uses diamond pattern grip for trailer floors, truck beds, and loading ramps. Workers feel more confident, and cargo stays put during transport.

Architectural & interior design uses of diamond stainless steel

Interior designers appreciate how diamond stainless steel bridges industrial toughness with sophisticated beauty.

Kitchen backsplashes have become the star residential application. Whether you choose 3" x 3" diamond patterns for subtle texture or 12" x 12" diamonds for dramatic impact, the modular design ensures perfect alignment across 4' x 8' sheets.

Elevator interiors showcase durability benefits. These spaces endure constant use and fingerprints, but diamond stainless steel maintains that polished appearance.

Trim molding applications offer designers visual transitions between materials, with fine-line diamond patterns providing texture without overwhelming smaller spaces.

Industrial & safety uses

Catwalks and liftd walkways in industrial facilities depend on diamond grip grating to keep maintenance personnel safe. The open diamond pattern lets debris fall through while providing solid footing.

Stair treads represent critical safety applications. Diamond stainless steel maintains traction in all directions, even when wet.

Cold-storage floors present unique challenges that diamond stainless steel handles beautifully. Condensation, temperature swings, and constant moisture would destroy many materials, but the corrosion resistance combined with slip resistance makes this ideal for walk-in coolers.

Jewelry & consumer products

316L surgical-grade stainless steel leads jewelry applications. The superior corrosion resistance and hypoallergenic properties make it perfect for sensitive skin.

Micro-diamond finishes create subtle textures that catch light beautifully without aggressive industrial patterns. The contemporary styling appeals to consumers who appreciate the modern, high-tech aesthetic.

Selecting, Maintaining & Comparing Finishes

Choosing the right diamond stainless steel means matching the material to your specific application.

Pattern size makes a significant difference. Small 3" x 3" diamonds look refined, perfect for kitchen backsplashes. But industrial walkways need substantial 12" x 12" patterns that handle heavy boots and equipment.

Sheet gauge selection depends on abuse levels. Thin material works great on walls, but flooring needs heavier gauges that won't dent under pressure.

Diamond stainless steel costs about 15-25% more than plain stainless steel. You're getting better slip resistance, easier maintenance, and a surface that hides wear better than smooth steel.

For cleaning, diamond stainless steel is forgiving. Mild soap and warm water handle most situations. Use a soft cloth for regular cleaning and a soft-bristled brush for deeper cleaning in diamond valleys.

Avoid steel wool or harsh abrasives that scratch the surface and damage the protective oxide layer. Stick with gentle stainless steel cleaners.

How does diamond stainless steel compare? Aluminum diamond plate costs less but won't last as long. Plain stainless steel saves money but gives zero slip resistance. Galvanized steel seems cheap until you factor in ongoing maintenance and replacement.

Buyer checklist for diamond stainless steel projects

Start with your environment - that's the biggest specification factor. Indoor normal environments work fine with 304-grade stainless steel. Outdoor, salt water, or chemical exposure requires 316L grade.

Grade selection by exposure: Indoor kitchen equipment uses 304 stainless steel. Coastal restaurants need 316L. High-temperature work calls for 321 grade. Decorative interior panels can use 430 grade.

Sheet sizing affects budget and installation complexity. Standard 4' x 8' sheets work for most jobs, but larger 4' x 10' sheets reduce seams in bigger installations.

Check your fabricator's capabilities before committing. Not everyone has equipment for complex cuts or custom shapes in textured stainless steel.

Maintenance & care best practices

Regular maintenance is straightforward. Wipe down weekly with soft, lint-free cloth. High-traffic areas need more frequent attention.

Monthly deep cleaning keeps everything professional. Mix mild dish soap with warm water, use a soft-bristled brush for diamond recesses, rinse thoroughly and dry to avoid water spots.

Remove protective film promptly after installation to prevent adhesive buildup that's harder to clean later.

At American Mortuary Coolers, proper care extends diamond stainless steel flooring life in our mortuary equipment. Quality materials and regular maintenance provide years of reliable, safe service across all our installations.

Frequently Asked Questions about Diamond Stainless Steel

What makes diamond stainless steel more slip-resistant than plain stainless?

The secret lies in those raised diamond peaks that create dozens of tiny contact points under your feet. When you step on diamond stainless steel, you're not walking on a smooth, potentially slippery surface. Instead, your shoe grips the raised edges of each diamond, giving you traction in every direction.

Think of it like the difference between walking on ice versus walking on a textured sidewalk. The diamond pattern works the same way, creating grip points that hold firm even when conditions get challenging.

But here's the really clever part: those recessed areas between the diamonds aren't just for show. They act like tiny drainage channels, allowing water, oil, and other liquids to flow away from the walking surface. This means you're always stepping on the raised, drier parts of the pattern.

Testing proves this works remarkably well. Diamond stainless steel can provide up to 10 times better slip resistance than smooth stainless steel when wet. That's why we see it everywhere from industrial walkways to mortuary cooler floors where safety can't be compromised.

Which grade (304 or 316) should I choose for outdoor installations?

For outdoor projects, 316L stainless steel is your best friend. The "L" stands for low-carbon, and that molybdenum content (about 2-3%) makes all the difference when Mother Nature starts throwing her worst at your installation.

Here's why 316L wins outdoors: it laughs at salt spray, road salt, and industrial pollution that would gradually stain or pit 304 grade material. If you're anywhere near the coast, or in an area where they salt the roads in winter, 316L is absolutely worth the extra investment.

Now, 304 diamond stainless steel isn't completely out of the running for outdoor use. In dry climates with clean air, it can perform well. But most of us don't live in perfect conditions, and the cost difference between 304 and 316L is usually small compared to the headache of premature replacement.

At American Mortuary Coolers, we've learned this lesson from experience. The few extra dollars for 316L grade pays for itself many times over in reduced maintenance and longer service life, especially for equipment that needs to look professional for years to come.

Can diamond stainless steel be welded or bent without distorting the pattern?

Yes, but it takes a bit more finesse than working with flat sheets. Diamond stainless steel can definitely be welded using standard stainless steel procedures, though you'll want to use TIG welding for the cleanest results with minimal heat distortion.

The key is keeping your heat-affected zone as small as possible. Too much heat can flatten the diamond pattern near the weld, which isn't just an appearance issue - it also reduces the slip resistance in that area.

Bending is trickier but absolutely doable with the right approach. Sharp, tight bends will flatten or distort the diamond pattern, so gradual curves work much better. The good news is that the embossed pattern actually makes the sheet stronger and more resistant to oil-canning than flat stainless steel.

Here's something interesting: that raised diamond pattern acts like a series of tiny structural ribs, giving the sheet more rigidity. This can actually make fabrication easier in some ways, though it requires different techniques than smooth sheets.

For complex projects involving lots of welding or forming, it's worth finding a fabricator who has specific experience with textured stainless steel. They'll know the tricks for maintaining pattern integrity while achieving the shapes you need.

Conclusion

Diamond stainless steel stands out as one of those rare materials that truly delivers on multiple fronts. It's tough enough for industrial flooring, safe enough for commercial kitchens, and attractive enough for high-end architectural projects. That's a pretty impressive resume for any building material.

The beauty of this textured steel lies in how it solves real problems. Slippery floors become safe walkways. Plain walls transform into eye-catching features. Equipment surfaces that used to show every scratch now hide wear while staying easy to clean.

When you're choosing diamond stainless steel for your project, think about where it will live and what it needs to do. Indoor applications usually do fine with 304 grade, but don't skimp on 316L if you're dealing with outdoor weather or harsh chemicals. Your future self will thank you for making that investment upfront.

The pattern size matters more than you might think. Those small 3" diamonds work great for backsplashes and decorative touches. But if you need serious slip resistance for walkways or loading areas, go bigger with the 6" or 12" patterns. They'll give you the grip you need when safety is on the line.

Here at American Mortuary Coolers, we've seen how diamond stainless steel performs in demanding environments. Our mortuary coolers use this material for flooring because funeral professionals need surfaces they can trust. When you're working with sensitive equipment and maintaining strict hygiene standards, every detail matters.

We've been crafting custom solutions and delivering them across all 48 states for years now. That experience has taught us that the right material specification makes all the difference between a project that works okay and one that works perfectly for decades.

Whether you're planning safety grating for an industrial facility, stylish panels for a restaurant renovation, or specialized equipment surfaces that need to perform day after day, diamond stainless steel has probably solved similar challenges before. It's one of those materials that just keeps proving its worth across different industries and applications.

Taking care of your investment is straightforward too. Regular cleaning with mild soap keeps it looking professional, and the textured surface actually helps hide the minor scratches that would show up immediately on smooth stainless steel.

For more detailed specifications and application examples, check out our comprehensive resource: More info about stainless diamond plate. It covers everything from grade selection to installation tips that can save you time and headaches down the road.